-

Posts

1,641 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SJSoane

-

Thanks so much, everyone. This was a major hurdle for me, thinking about it for many years, and now able to move forward. A couple more thoughts, for those working on paintings like this. 1. Using frisk to lay down the base yellow ochre actually accomplished a couple of things. Not only did it allow a smooth application of airbrush paint, but it also solved part of the problem of getting the design transferred to the hull. Because the frisk is based on an accurate drawing, there is no need to worry about sketching in the design on the model itself, trying to keep faithful to proportions and sizes. It is as accurate as the drawing used to cut the frisk. 2. To get an accurate underlying drawing, I scanned photos of the painting on the original Bellona model, and imported them into my CAD software (HighDesign 9 for Mac). I then resized them to approximately the correct sizes and printed them. When I cut out each print and laid it onto the hull, I could see where the shape needed to be adjusted for more or less curve, a little wider or narrower. I would then make these adjustments to the CAD drawing, print again, adjust and so on until the CAD drawing was an accurate fit. Then I knew the frisk would fit well in its assigned space. 3. Regarding airbrush paint, I also started with Vallejo, which is highly regarded by many modelers online. But I also had problems with these clogging my airbrush (Harder and Steenbeck Evolution). Although I tried a number of suggestions for thinners seen on YouTube videos, nothing seemed to work reliably for me. It may be that I did not work out a good way of mixing the paint and thinner, or it may be that spraying on wood rather than plastic makes a difference. Golden High Flow paints worked without thinning, which does allow for a greater consistency in what is going to happen when you pull the trigger. And they match the Golden Fluid acrylics for hand painting. 4. As David Antscherl pointed out in his section on painting in the Fully Framed Model, the base layer of yellow ochre is a translucent paint, not opaque. So when spraying or hand brushing yellow over Prussian blue, the resulting color goes green. David's advice of mixing some white into the yellow ochre for hand brushing helps, while a number of layers of airbrushed yellow ochre eventually goes opaque. They dry so quickly that it is possible to get an opaque finish in one session of airbrushing. I look back and wonder why it took me so long to work out this painting business; and now I remember the many experiments, dead ends, different products.... Mark

-

HI everyone, A long time since my last post. I realized that I was getting to far ahead of myself, building up the stern with everything just pinned. I needed first to paint the lower and upper counters before I could actually start assembling things. And learning how to paint the friezes was a major learning curve! I greatly followed David Antscherl's advice on painting in the Fully Frame Model, vol. II section 7.26. It was exceptionally helpful for everything from paint and brushes to technique. Alas, I discovered after a great deal of experimentation that hand painting alone did not work well for me. Particularly for the background Prussian blue and the letters "Bellona" on the stern, I needed a way to get things sharper and more even in tone. So, I turned to my airbrush. I masked everything but the counter and sprayed away. I glued artist's frisk onto a print of the upper counter letters and frieze elements (a woman riding a sea monster, a man riding a galloping horse). I could then turn the frisk/print every which way on my light table, and very carefully cut the frisk with a scalpel. I then attached the frisk and sprayed everything that would be the yellow ochre base for all of the frieze work: I then used white graphite transfer paper to trace the rest of the pattern onto the surfaces: Then following David's advice of painting highlights and shadows on the basic forms, I eventually got to an imperfect copy of the original Bellona model: I learned to admire those original model builders for their painting skill. Try as I might, I just could not get to the same level of skill. But as good as I can do! So, moving on to actually gluing together the stern! I did learn a few good things that I will pass on for anyone else attempting these kinds of friezes. First, after trying a number of airbrush and hand paint brands, I settled on Golden. They have the same colors in different densities, for airbrushing and hand painting; the colors match the historic colors I was looking for; they come in plastic bottles with ball bearing inside, for mixing. They spray without problems through my airbrush. And they are highly regarded in the artist community. Second, I struggled with the acrylic paint drying too quickly on the palette when I was trying to mix colors. My son introduced me to the model gamers' favorite tool, the Army Painter Wet Palette. This tray holds a water saturated pad, upon which is placed a parchment sheet. Paint mixed on top of the parchment can stay wet and mixable for as long as 48 hours. A huge help! A glass of wine tonight in celebration, and on to assembling the stern! Mark

-

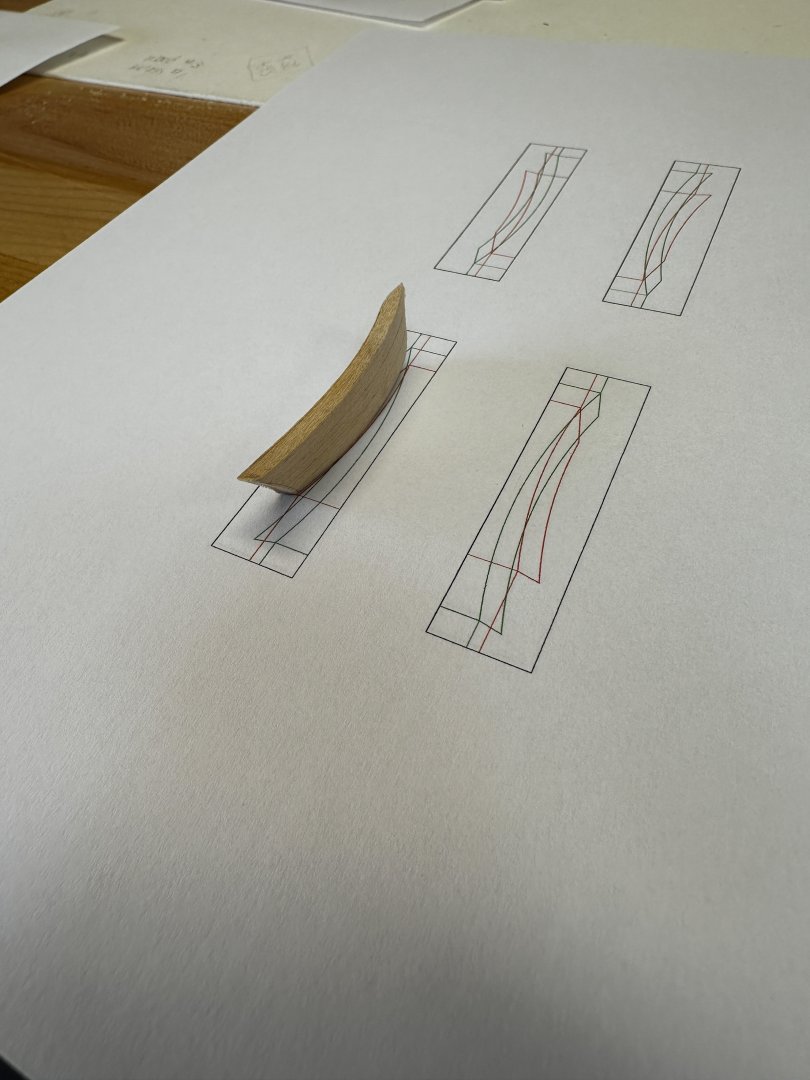

Hi everyone, Sorry for the long silence; other things going on! To catch up. First, Der Boss, thank you for your kind comments. Slow and careful keeps me moving along! Trevor, thanks for the reference to Roberts. I haven't seen that, but I do have the facsimile book and set of plates for Steel's Naval Architecture. I have used that to help with several questions of drafting, but could find nothing on the curved surface between the upper deck and quarter deck windows on the quarter galleries. And Gary, good to hear from you! We old timers go back a long way on our 74s! And druxey, thank you for your list of tools and materials you used. I did a little test fret-sawing boxwood, and if I find myself going down the route of fret sawing, I have determined that wood is too crude for the very thin cross grain pieces (see below). I can see plastic would be a much better material, no grain to deal with. And once I saw that plastic might be the right material, I mocked up the curved surface in basswood to see just how sharp the compound curves would be. This would be to test whether glue would be enough to hold flat plastic against the curved surface. And the surface turned out to be less curved than I thought. The front edge sweeps back at a good angle, but at any line drawn between the upper and lower moldings, the surface curve is gentle. So for now, I will explore having these laser cut. I first need to reinstall everything with the final windows (coming from Chuck, thanks so much!), and then carve the final curved surface to measure and expand for a true elevation of the fretwork. Mark

-

Thanks, everyone, for your comments. Kevin, intriguing idea about 3-D printing, but I don't think I have the skill to work up a 3-D drawing of the double curved quarter gallery surface. It is no known regular geometrical shape, and would have to be built up in sections and faired like a hull. I may come back to this if I can't figure anything else out. And thanks for reminding me of Marc's fabrication techniques. Marc, thanks for thinking about this. Your techniques could well provide a way to build these forms up, rather than attempting to pierce saw them out as a whole. My first experiments showed me some problems with attempting to cut these out of boxwood--grain runs across some of the thin pieces, doesn't have any flexibility--and so I may have to explore other materials if I go down this route. Or, maybe I just make up individual strands with the grain running the length of the piece, and then glue them together at the intersections. This would be more like a mesh that could settle onto the curved form behind, because it could slightly bend at each joint. druxey, I greatly admire your fretwork on the Polyphemus. That is exactly the same kind of fine delicacy of inter-weaving lines that I need to produce. And your's is flawless! Did you fret saw those out of boxwood as individual strands, or pierce-sawed some of them as panels? Sailor, thank you for your kind thoughts. I admit that this challenge slammed on the brakes for a bit, but I remind myself that I have always found a way forward when this happened in the past, particularly with help from this forum. And Greg, like you, I sometimes reflect on the astonishing skill of the 17th and 18th century model builders, especially given their technological limitations relative to our age. Like the old saying about Ginger Rogers--that she did everything Fred Astair did, but backwards and in high heels--the original model builders often did more with less than we have. One can hardly believe humans are capable of such fine work. I also find myself sometimes channeling the original shipwrights, when I am fashioning a piece and realize that a number of people did exactly this same thing two to three centuries ago. What a great hobby. Mark

-

Hi Alan, Feel free to use the expanded sketch of the stern works. Amazing that it would fit both the Bellona and Bellerophon, but then they were sister ships. And I guess you and I are building pretty close to accurate.... So maybe instead of pierce sawing, I temporarily glue a thin layer of wood to a curved backing, and carve down like a bas-relief all the way through. When it is released from the backing, it will look pierce sawn and pre-fit to the needed curve. I will try to think this through.... Mark

-

HI everyone, I have hit one of the most challenging parts of my Bellona build, the fretwork on the quarter galleries and balcony rail. Here is photo I took of the first Bellona model a number of years ago, showing the serpentine curve of the balcony I am intending to reproduce: And here is a photo I took a few years ago of the second model, showing how the balcony railing is actually pierced, not solid. and this shows the fretwork on the quarter galleries, which is not shown in the first model. I had been planning to have these laser cut from plastic, based on my drawings of the correct shape and proportions of each frame (thanks to Chuck!). But when I mocked up the double curved surface on the quarter gallery, I discovered that these fretwork panels will have to conform to some very warped surfaces. I am not sure plastic with very little gluing surface can be reliably fastened down by glue alone. I toyed with capturing them in rabbets behind the horizontal mouldings, then I realized that this would not exert enough pressure at the extreme edges to press them against the warped surface. This led me to thinking about maybe pierce sawing them out of a more pliable material, or maybe pierce sawing them out of blanks that are already curved to the correct shape. Or, maybe having them laser cut out of a more pliable material. I tried an experiment of pierce cutting these out of thin boxwood, but the grain was too course for these thin filaments, and the piece broke when I tried to curve it. It looks to me like the second model pierce cut these out of probably ivory, which would solve the problem of a fine enough grain. Maybe Tagua nuts since ivory is not an option? I even thought about pierce sawing them out of thin metal that could bend to the warped surface, then painting them a tan color. Any thoughts about any of this? Best wishes, Mark

-

Hi Vossiewulf, Yes, the Knew Concepts saw was a game changer for me as well. I was hesitant to try the Knew Concepts metal bench pin, fearing dulling my blades when accidentally cutting into the pin. But I tried it and will never go back to a wood bench pin. This pin gives exceptional stability when sawing very small parts. I periodically slide the piece and the saw back and forth sideways until I find the center of the slot, and then line up the cutting line with the slot. I rarely hit the metal any more. I also finally figured out, after too many years of struggling, that the size of the blade really matters for smooth and accurate sawing. Relative to the thickness of the wood, I read a rule of thumb that at least 3 teeth should be in the wood for smoothness, and at the other end, not too many teeth because it goes very slowly. I tended to use whatever blade was last in the saw, no matter what the thickness of the wood, and the results were not great. Once I decided to size the blade to each piece of wood to be cut, I drew up some charts and glued them to my saw blade storage containers. These show the thickness of wood along the top, and the details of the various blades down the left side. The blue squares show the range of blades suitable for that thickness of wood. I may redraw these soon, because I have found after using these for some time that I am always choosing a finer blade than my chart would suggest. Maybe that is a consequence of the wood I use. I stick a bent piece of wire into the hole of the blade I am currently using, so I can easily put the blade back in its proper place when I switch blades. That means I am mixing up new and used blades in each hole, and I randomly choose one each time. If the blade I choose seems dull, I toss it and grab another. This hasn't happened often. These blades really hold up. There is only one blade that overlaps in size between the Otto Frei jewelry saw blades on the left, and the Pegas fretsaw blades on the right. Together they accommodate wood from .016 to 1 inch. Up at the greater thicknesses, I tend to use my bandsaw. Mark

-

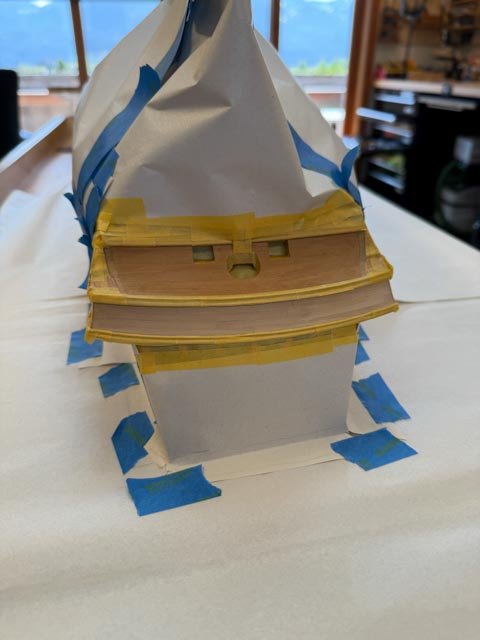

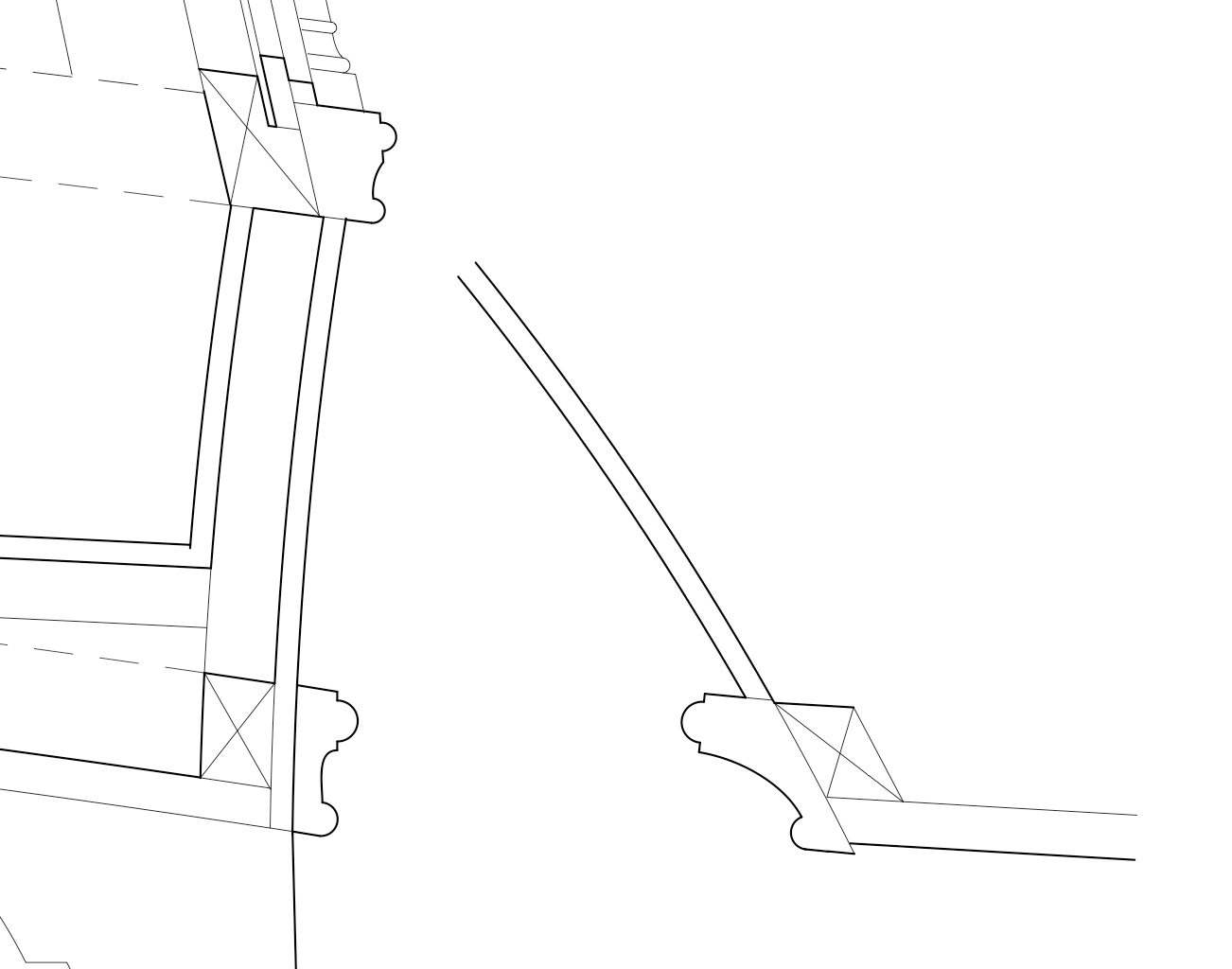

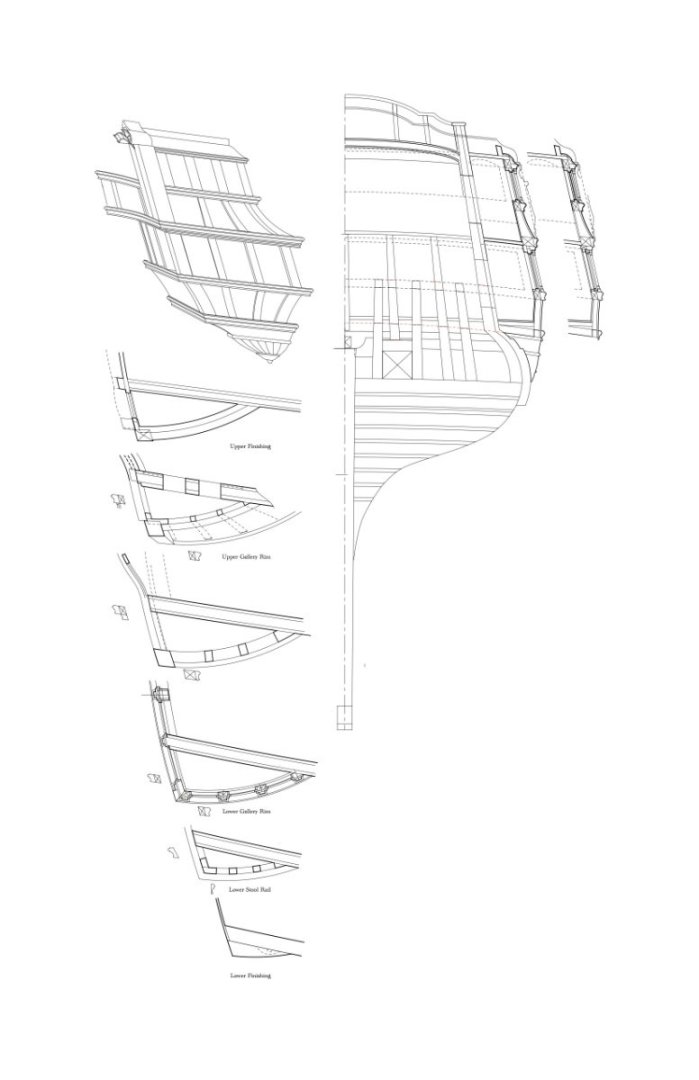

hi everyone, Druxey, those 18th century shipwrights sure enjoyed playing with fluid shapes; the shipwrights must have groaned when they saw the latest shape to manufacture! Greg, Kevin and Cisco, thanks for your thoughtful comments about the complexities of these constructions. I continue to be amazed when the underlying logic or geometry finally reveals itself, as I struggle to fit all the parts together in three dimensions. I am in awe of the original shipwrights who could visualize and then construct such complex forms. And how the complexity all adds up to something exceedingly beautiful, and simple in its overall visual effect. Hakan, yes, that is a Tormek in the background. I bought it many years ago, struggled to make it work for me, and then put it away. I pulled it back out more recently, to see if I would have better luck now I have had more years of experience with tools. It doesn't help with the small chisels, but some success with the larger ones. Steady progress, but slow going as I work out the intricate geometries of the stern and quarter galleries. I redrew the stern, expanding the geometry in the x and y directions to get a true projection of the sizes and angles. I taped some card to the stern and marked various key points including the important diminishing of the verticals. I then scanned this and put it into CAD, where I could extend the verticals to a common point on the centerline, allowing me then to find the correct angles for the outer edges of the quarter galleries. Here is the flattened drawing: This then allowed me to fabricate the false window walls on the aft side of the quarter galleries, which provides all of the important locations for everything in this area: and then I used spacers to locate the middle railing and top surface of the captain's head. (The horizontal plate one down from the top is a temporary form to help me locate the railing at the base of the windows at this location; it will go away once the railing is in place). I discovered that in this recreation of the original Bellona design of 1760, the captain's space here is pretty tiny. He has about 14" of clearance between his forward door and the curved side of the quarter gallery. It gets a little wider towards the seat at the stern, but even there he has only 2'-9" of clearance. It looks great on the outside, diminishing the entire quarter gallery as it ascends to the top; but the captain could not have been very happy with this. Indeed, in the 1780ish rebuild shown in the second Bellona model, the captain's head is much expanded to match a little closer the size of the officers' head below. Today is the 254th anniversary of Thomas Slade's death, the famous shipwright for the Bellona and Victory. He must have been annoyed when asked to expand the captain's quarter gallery; it looks so much better the way he originally drew it! To help with cutting and shaping these increasingly small and awkward pieces, I bought the Veritas miniature workbench clamping devices. I made up a surface with regular holes, which can attach to the front of my workbench with the GRS mounting plate: Here is the GRS plate holding a Knew Concepts bench pin and saw. I am turning to these increasingly to shape these small parts. This turned out to be such a handy surface for fine work, I added a bench hook for cutting small pieces with the razor saw. It has dowels on the bottom that drop right into the flat surface holes: All for now, Mark

-

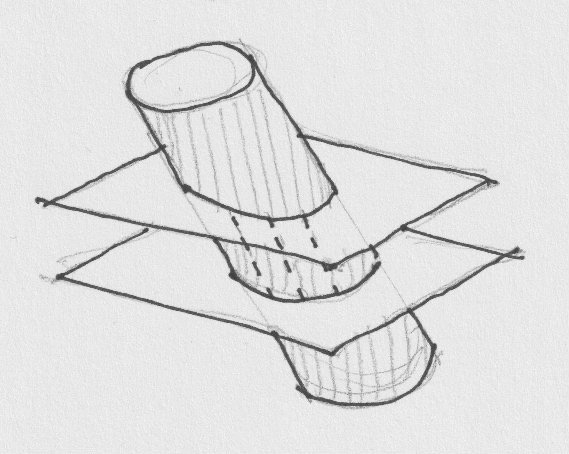

Hi everyone, Thank you, Kevin, for your kind words. It is definitely turning into my life's work after all these years, and many more to go at my current pace. I might as well make it as good as I can! druxey, I agree with your "gazunder" conclusion. Given the geometry of the quarter galleries, the only direct drop from the upper--captain's--seat of ease would discharge directly onto or out of the face of the false window in the quarter gallery below. Not likely. I am sticking with a chamber pot and proceeding accordingly! The stern construction is undoubtedly the most difficult thing I have ever attempted to make. Even planking the upper counter seemed straightforward at first, but the wood is so thin here that I struggled to keep the surface fair while rounding up and aft, and on a curved frame in the vertical direction. I had to redo in order to remove some initial hollow low spots. All is well now, ready for paint. It also strikes me the ridiculous fragility of this entire stern. No wonder captains dreamed of raking their opponents through the stern. Moving to the side lower windows of the quarter gallery, I had read long ago that the upper and lower boundaries of these windows had to be exactly the same radius, held in the same orientation when the top one is offset to the stern. This is to ensure that the vertical mullions between the three windows are parallel to each other in the x and y axis. If they are twisted, the windows would be twisted and could not be paneled with flat sheets of glass. I thought of it as a cylinder sloped back at the angle of the windows across the stern, and then parallel planes aligned with the sheer of the hull cutting through to define the tops and bottoms. Hopefully this diagram makes this clear. The dotted lines are the lines of the window mullions: I arranged this by making panels top and bottom to the same template, then ensuring that the curves coming forward made the same angle with the stern moldings top and bottom: And these resulted in window surfaces that are flat and untwisted. However, the three windows are not geometrically the same, which initially surprised me. Although the length of the sides are the same--since the two planes forming the top and bottom are paralleI--the angles these form with the top and bottom edges of the window are not the same. The sternmost window has a sharper angle, the middle one somehat less but still sharper than the foremost window. I eventually realized that this would have to be. The aft most is most parallel to the side of the sloping cylinder, while the foremost is coming around to the fore face of the cylinder, which is less angled relative to the cutting planes. The sides of a window on the front surface would be at right angles to the tops and bottoms. I also noticed that the changing geometry created an optical illusion. I initially made the three windows the same width fore and aft, then saw that the aft most window looked too skinny relative to the other two. I made a number of paper templates installed in the openings, varying the widths until they "looked" the same width. It turned out that the aft most had to be made wider, then the middle a little less but still wider than the foremost window. Here is the result with the final paper templates: I also discovered the reason for the little scroll work carving at the fore end of the windows, which shows up in every 74 gun ship of this era. It hides the fact that the fore edge of the foremost mullion is not parallel to its aft edge; the upper edge has to be longer than the lower edge in order to fair to the side of the hull. This would have been visually clunky, so they disguised it with a little carving to cover it up. Looking forward, here are paper templates of the upper works: Still a lot to do! Mark

-

Interesting, interesting! Thanks everyone! So here is a first thought about how the pipes would run to a discharge in the lower counter, under the quarter galleries. Some assumptions: 1. The pipe from above has to run down the outer face of the hull--along the inner wall of the lower quarter gallery, in other words--because there is no place to bury the pipe in the hull itself. Presumably there would be a paneled chase to disguise it. 2. Offsetting the seats doesn't appear possible, or helpful. The Bellona admiralty drawing show the lower one centered in the bench. The upper bench is so short that there is not much room to offset. And given number 1 above, there is no advantage gained in an offset a few inches one way or the other since the pipe has to bend inboard to run down the outer face of the hull anyway. 3. The two discharges could be aligned athwartships, with the upper pipe closer to the hull and the lower pipe further out. maybe closely paired like twin exhausts in a sports car! 4. I don't see these both bending sharply forward another three feet--and outward to clear the tumblehome-- in a two foot drop to discharge through the lower finishing. It is just asking for clogs. 4. I have provided a chamber pot for the upper toilet, just in case those long runs of pipe with bends doesn't always do the job!🙄 Mark

-

Thanks so much, Alan and Marc. I don't know if I am slowing down because I am getting older or the work is getting more complicated, or both. But it is a good push to keep going when I am able to share progress. Interesting question about the plumbing arrangements in the quarter galleries in the mid eighteenth century. I have only found Brian Lavery's account in the Arming and Fitting of English Ships of War, pages 202-204. He says that "presumably there was some form of piping...especially from the upper galleries." And he refers to some pipes on models. I have not seen this. Can anyone send me a photo of a model with this piping showing? I am looking at the path piping would have to take, particularly from the upper quarter gallery, and there are some serious bends and long horizontal runs to get to a discharge in the lower finishing. One wonders how this was efficiently flushed out. Lavery notes that a flushing cistern and water closet was first ordered in 1779, 20 years after the Bellona was completed, and even then few ships were fitted with such. Without such a device, it would have been jugs of water poured down, and maybe a long loo brush or sewer snake? The alternative idea, of a chamber pot, would have replicated the same toilet arrangements many of the officers would have experienced in their land based homes at the time, I presume. I also noticed that in the HMS Victory quarter gallery open to public viewing, the hole is in a hinged hatch on the bench, which I interpreted to be the access to the chamber pot beneath. But that is pure speculation on my part. Small point that I probably won't address further in my model, but it is an interesting question about 18th century technology. Any further information on this would be greatly appreciated!

-

It has been a long time since I last posted. This stern structure is undoubtedly the most complex and difficult thing I have ever attempted to build. But I am making progress. I had to use the horizontal moulding between the lower and upper counters, and also between the upper counter and the window sills, as templates for determining the curve and width of the quarter galleries. So these were left unmoulded for a time--and therefore a little stiffer--in order to keep everyone in alignment. Here I am confirming the window layout. the window frames will obviously require some leveling when they are finally installed: And here is a template to see how it is all going to line up: Next, the officer toilets are constructed. Working from a cryptic plan drawing in the original admiralty draughts, and a photo of Victory's quarter gallery, I decided that these were likely just holes in a bench with a chamber pot underneath, retrieved by a hinged top to the bench. Fun work for the officer servants to clean up every day. I wonder where they dumped these overboard--at the head, perhaps? And then the mouldings are given their profile, and glued in place at last! Next to come, planking the upper counter and the veneer of planking on the quarter galleries, druxey's great suggestion. I don't know how I would ever have formed these pieces without carving them from a whole piece. Curves in too many directions!

-

druxey, great idea, planking over the blank rather than scratching in the plank lines. That way, I can get tight joins to the mouldings, and also cope with how the planking on the counter intersects the planking on the quarter gallery. I am thinking that the planking on the quarter galleries runs past the planking on the counter, so the planking ends are seen from the stern and not from the side. that was going to be very hard to do, if I had to rabbet the quarter gallery blanks to receive the ends of the planking on the counter. And thanks, Marc, for reminding me of Siggi's work. There is always much to learn from him. His post was like a road map for me, what is coming next and how to deal with it. It also reminded me that I have some challenging painting to do on the lower counter! Mark

-

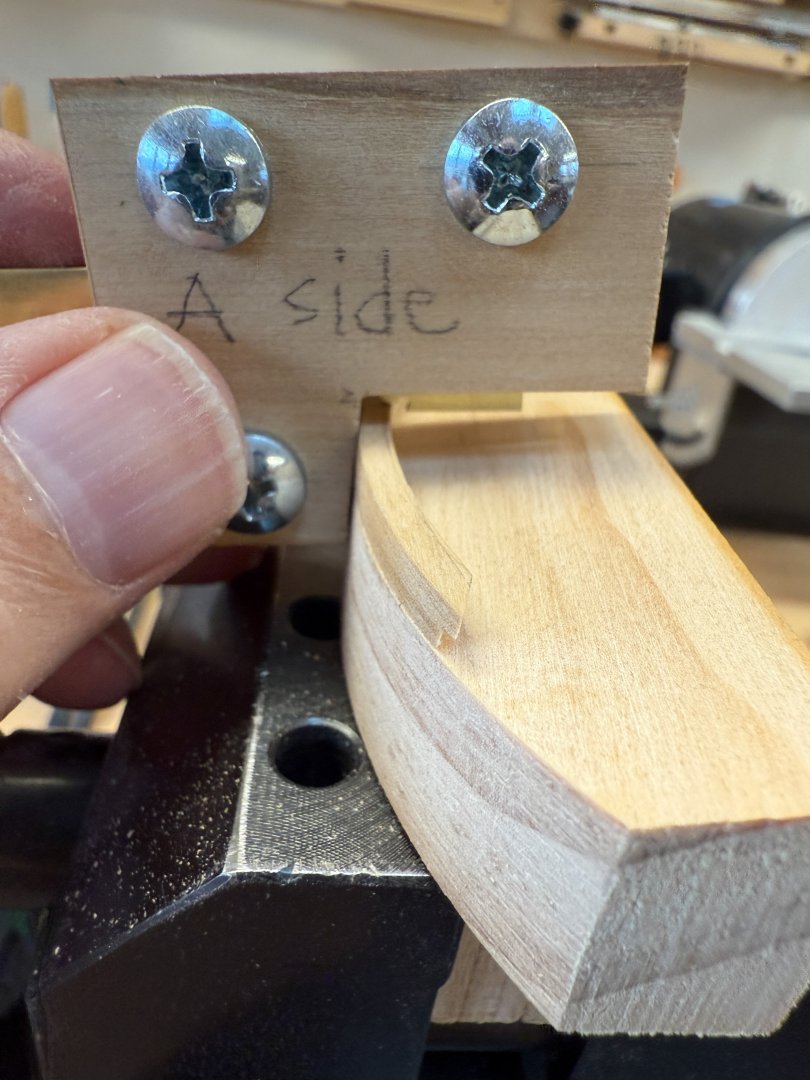

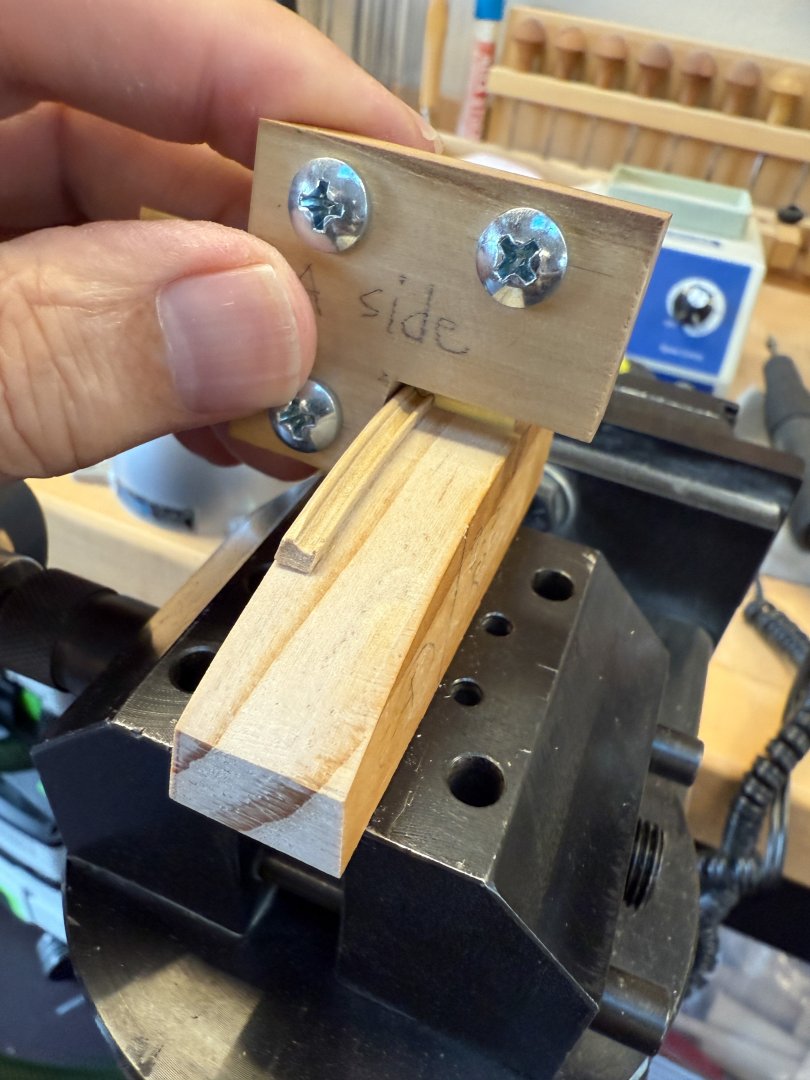

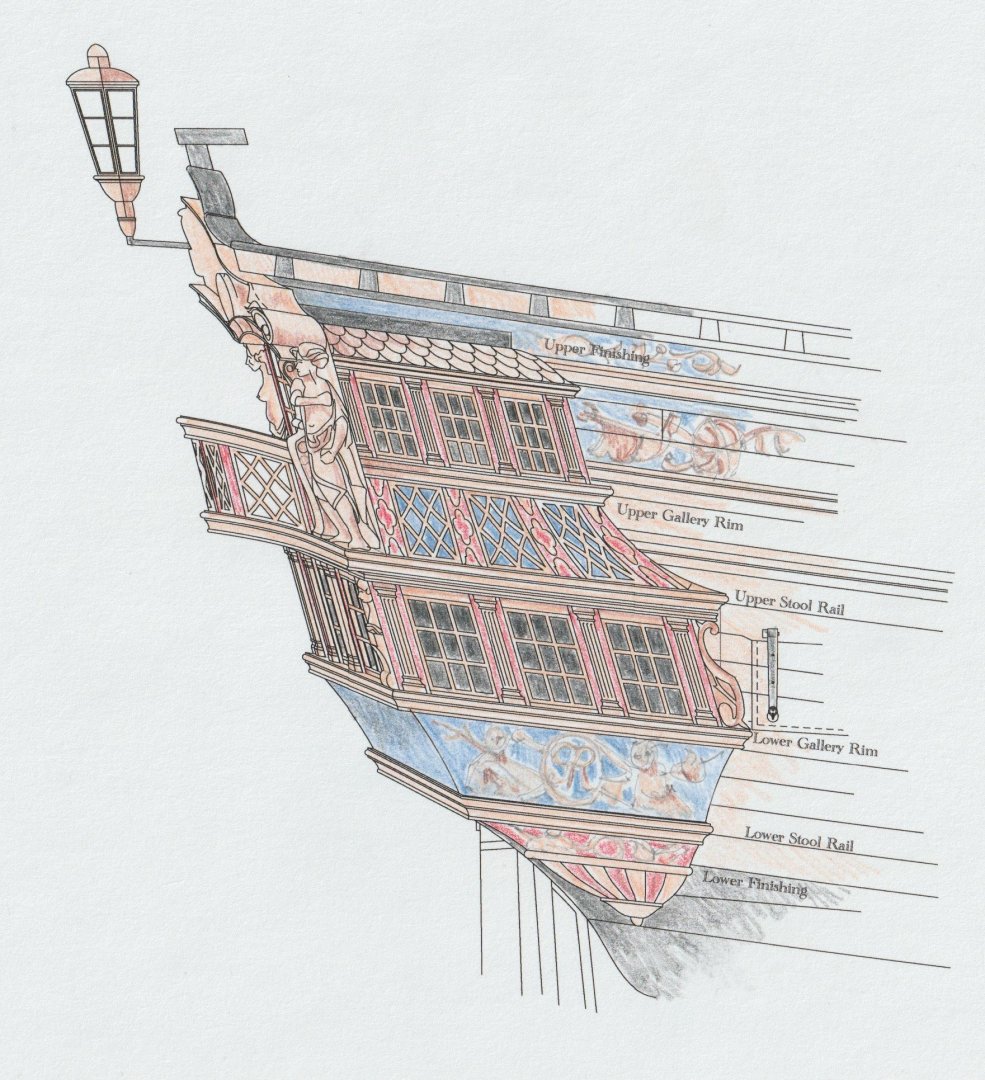

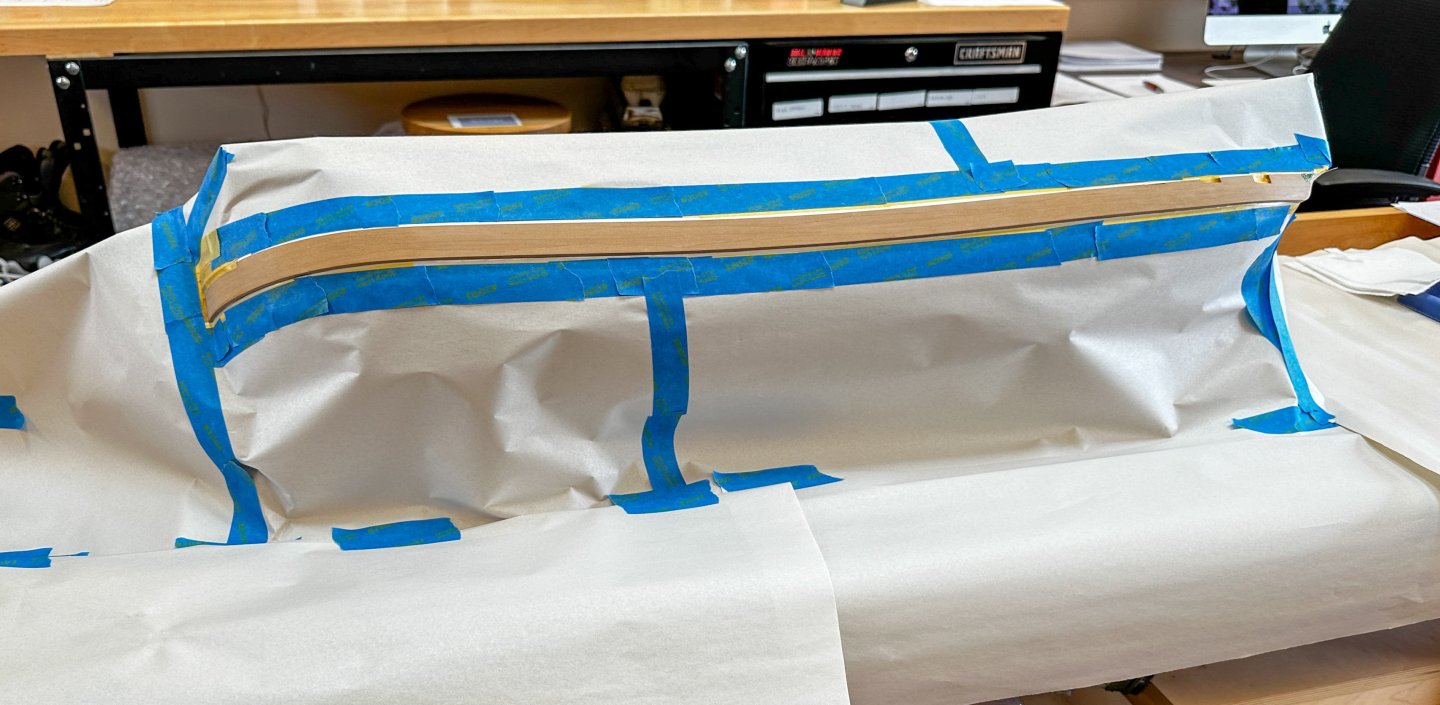

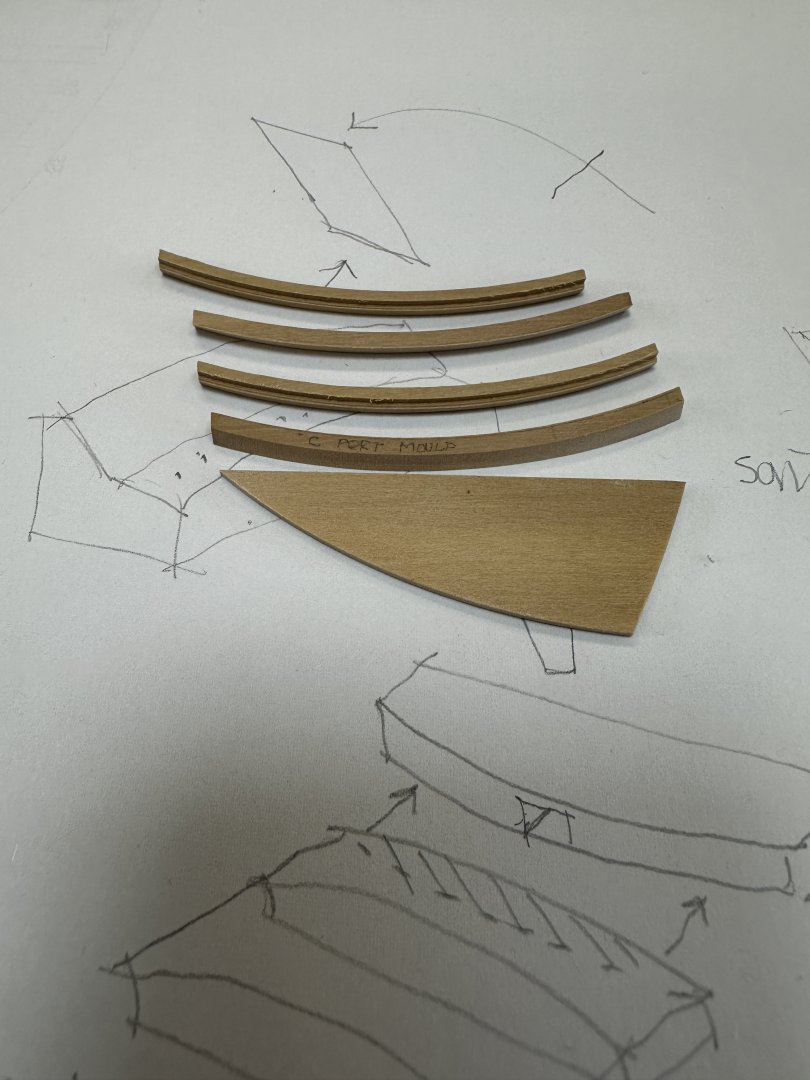

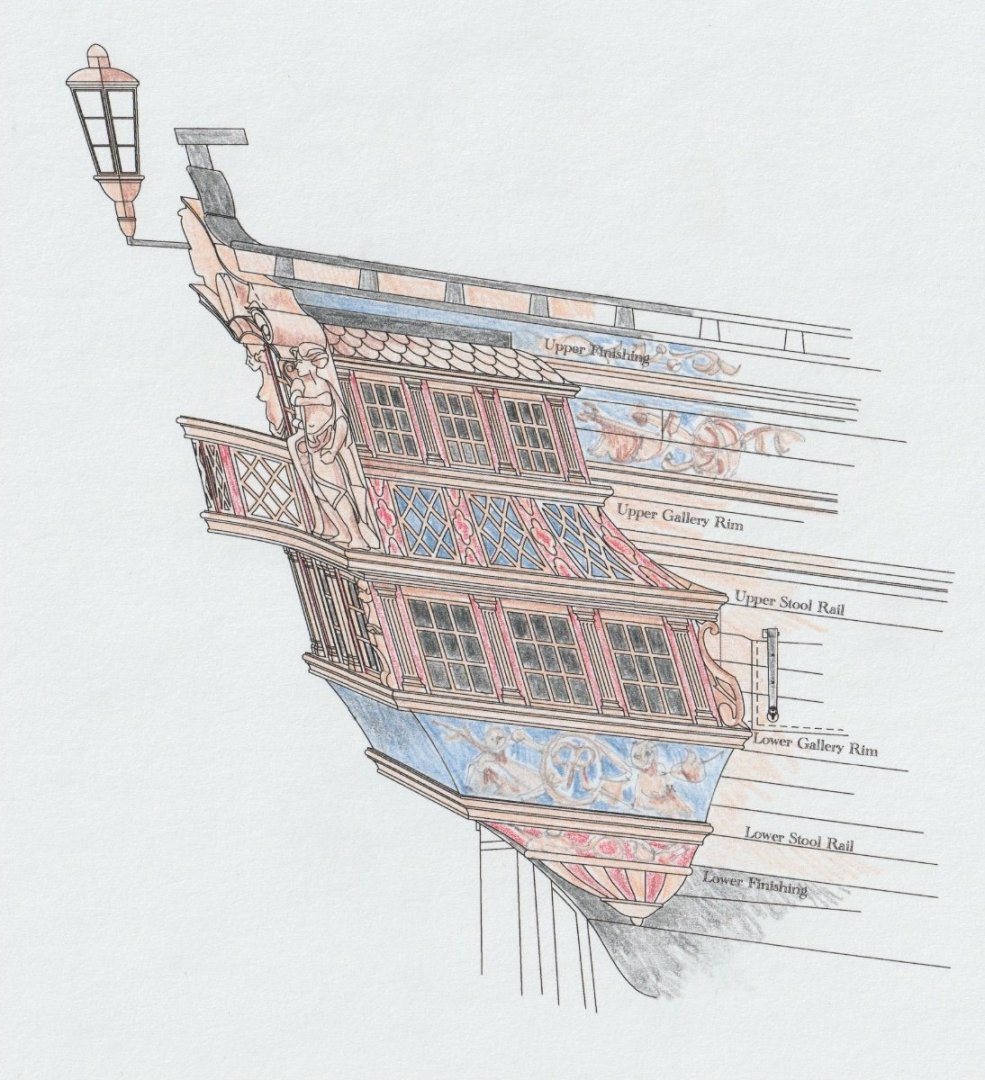

Thanks so much, Yves, Scrubby and Mike, for your kind comments. I have not posted in a while, because I was having to work out a few new challenges as I begin to work my way up from the lower finishing. First challenge: how to frame and plank the quarter gallery surface above the lower finishing? This is the blue band between the lower stool rail and the lower gallery rim, below: It curves, twists, and fays to the side of the hull with a shape I could not determine in advance. Also, how would I plank the inner surface once the framing was in place? I remember seeing a model of the Superb, with its stern in pieces. With the quarter gallery lying on its side, it is possible to see that this piece appeared to be cut out of a single block. So I decided to do that. This way, I could fair each edge to a known surface, and thereby discover the actual form. Then I could scribe the planking on the outer surface later. First, I drew the top and bottom profiles as best I could determine from my drawings. I pasted one on top and bottom of a blank, then shaped the outer surface to match each edge. After refining while checking against the actual model, I came up with the shape and how it fit against the hull: Here you can see the wicked twist in the shape. And here you can see it pinned temporarily in place (this is a trial blank I made out of basswood, to quickly see if this would work): Next, I had to work out the shapes of the mouldings on its lower edge, which is the knuckle between the lower and upper counters. It took a long time to realize that the moulding here is the not the same profile along the counter as it is along the side of the quarter gallery. These have to miter cleanly at the corner, but they are very different profiles. Looking carefully at the sections below (cut through the quarter gallery on the left, and through the knuckle of the lower and upper counters on the right), you can see that the face of the quarter gallery is almost vertical, whereas the face of the upper counter slopes back quite substantially. I finally realized that in order for these to miter together, the important thing is the thickness of the moulding in both locations has to be the same at the top and the bottom. Also, the top edge of the moulding on the quarter gallery has to align with the roundup of the moulding along the counter, whereas the top edge of the moulding on the counter has to align with the sheer of the external hull planking. A little geometry worked out the profile for each, so they would fair to their own surfaces while mitering cleanly at the corner. Next challenge: how to cut the profiles with a scraper? All of my earlier mouldings were just straight blanks cut on a flat surface and later gently bent to the sheer of the hull. But these mouldings are on sharply curved surfaces. I decided for reasons of accuracy in the overall construction to shape the blanks of the mouldings to their final curves, rather than making flat mouldings and bending them to the shape later. I saw too many places for things to get out of alignment if I did not make accurate blanks to start with. So how to scrape a shape on a curved blank, which also has top and bottom edges not at right angles to the face of the moulding? I decided to make formers, to which I could temporarily glue the blank, and use the former to guide a fence on my cutter holder. Here you can see the cutter for the moulding on the quarter gallery. The face of the fence is at an angle to the cutter, corresponding to the angle of the top of the moulding. You can see the necessity of the angle, because if the fence were at right angles, the cutter would tear up the shape as it progressively works its way down. Here is the scraper at work: And here is the moulding temporarily spot glued in place, to check its fit and final size. This is also the final faux planked piece, cut out of boxwood after the basswood trial worked: The flat piece faintly labeled STAR BD eventually goes away. This was a temporary former for getting all of the railings in their proper location and shape. The rabbeted rail is the base of the window frames still to come. I have frankly struggled with making scraper profiles, until Chuck suggested I just make them out of brass rather than fussing with tool steel, softening to file and hardening to use. Each profile here is only going to be used for one or two parts, and then can be thrown away. So I worked out profiles based on the two semi-circles, and accurately drilled these in the brass blank on a mill: Then I carefully filed the remainder of the profile using a needle barrette file and a jewelers clamp to ensure right angles to each side. This is important for the cutter to work the same in both directions. At last, I got accurate profiles with no heat treating challenges. Thanks, Chuck! Now on the port side, and the big moulding along the knuckle here. Best wishes, Mark

-

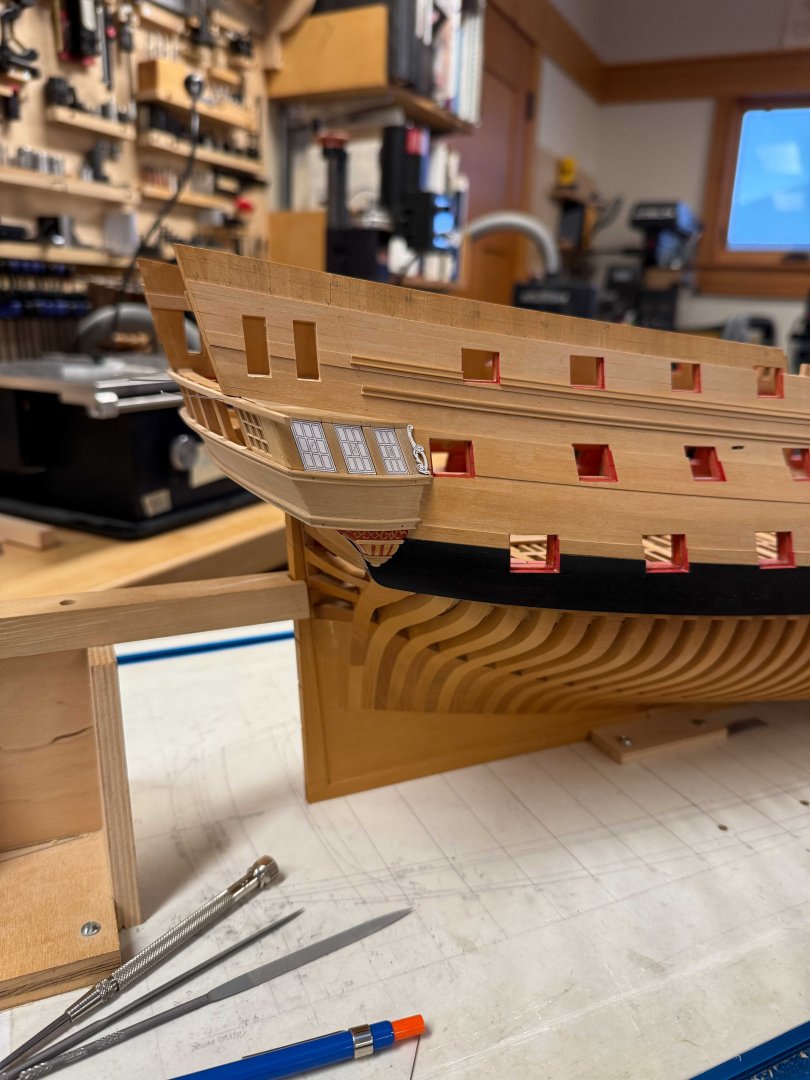

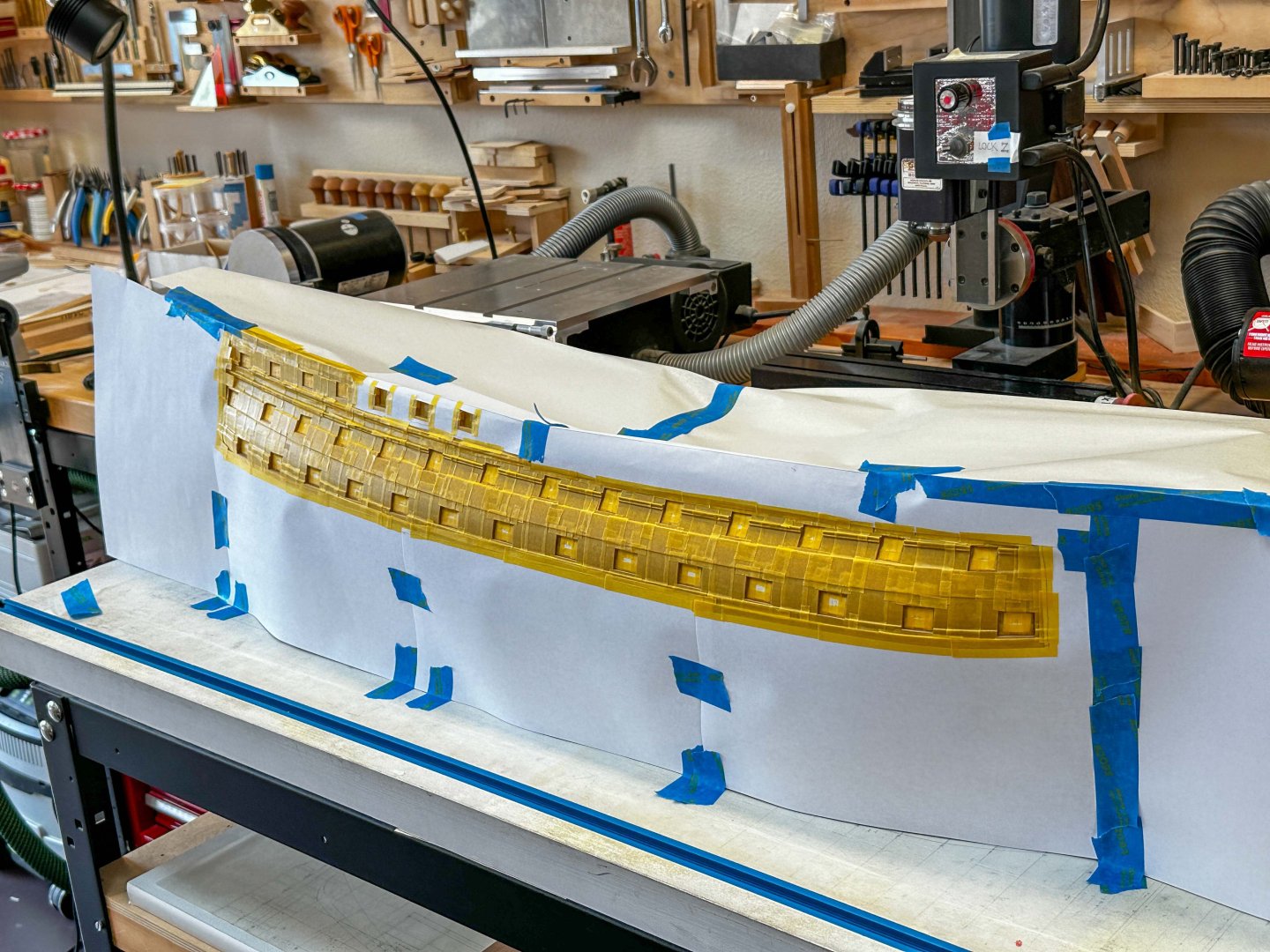

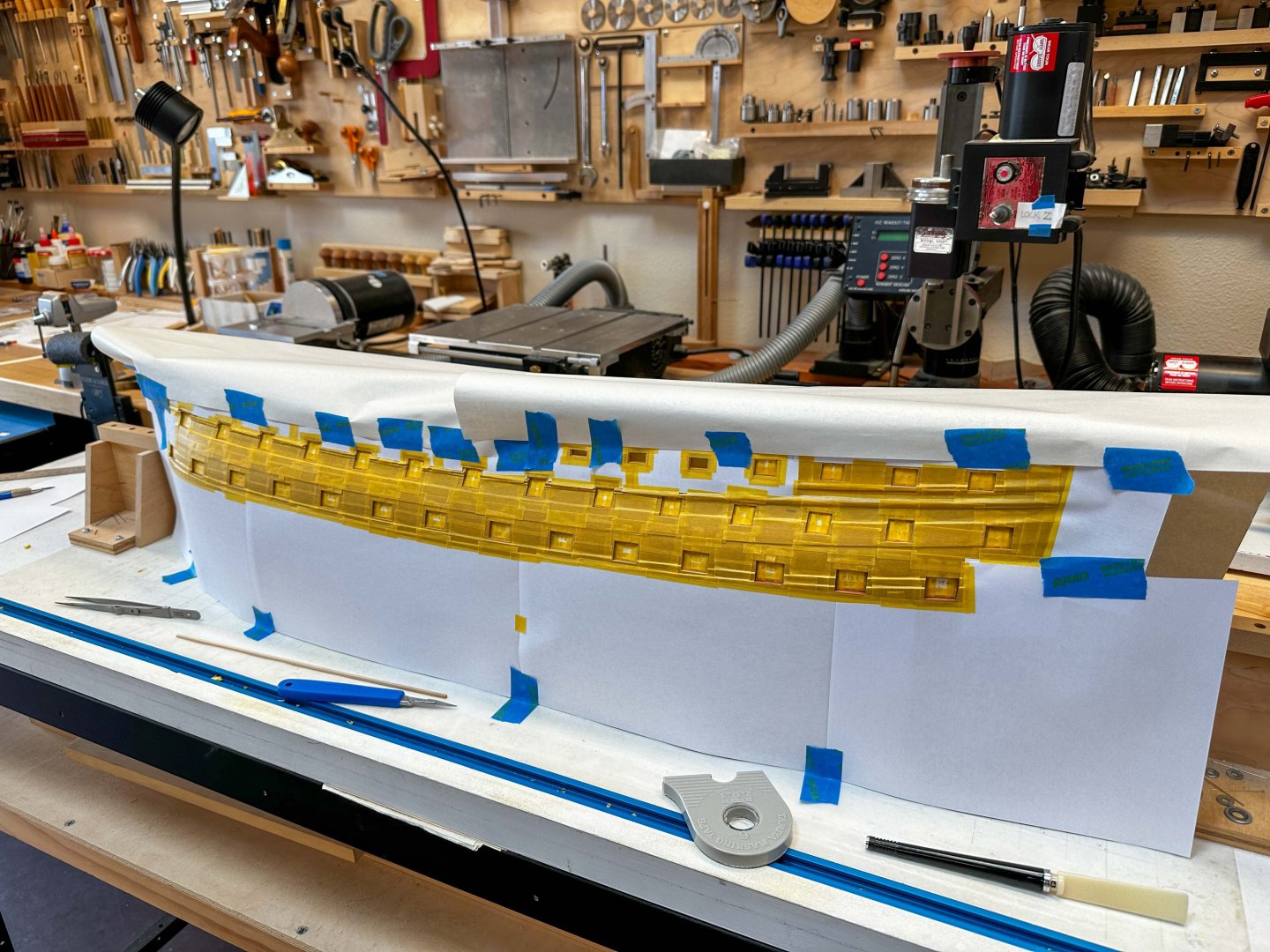

And in just one more day, the port side is painted. Much faster second time through. I got more efficient with the masking: The port side. I am glad I took the time to paint the edges of the planking at the ports with red, giving a very clean junction where they cut into the wale at the stern. And very satisfying to see both black wales from the bow: And now back to the quarter galleries! Mark

-

Hi JD and Mike, I use General Finishes Gel Topcoat, Wipe On Urethane in Satin (cleans up with mineral spirits). It is a rub in, rub off finish. On the raw boxwood, it darkens it up and gives the slightest sheen. You can see it on the exposed futtocks below the wale, compared to the raw wood above the wale. It is a little challenging to apply to all of the ledges and carlings on the exposed deck frames; I haven't quite figured out an efficient way to apply it between the spaces, and then rub off well into the corners. I used Vallejo Model Air acrylic for the black. Thanks, Chuck, for the kind comment. I am trying some Vallejo colors for spraying the plastic window frames to look like boxwood. I'll let you know what works best! Mark

-

Thanks, Greg, for the kind comment on the project. And druxey, thanks for clarifying why the quarter galleries shape to a point at their fore end. While "ensconced", the Captain could keep an eye on the trim of the sails from a different perspective! After a great deal of fussing with airbrush and compressor, I finally got the starboard wale painted. It is currently flat black, but will have a coat of the transparent poly gel over it, the same finish as for the rest of the hull. it will give a little sheen and lighten the color, according to my test pieces. It looks nice with those mean black cannon poking through the ports... Another fun masking process before the paint. I had to turn the hull on its side so I could spray the under edge of the wale, avoiding using an airbrush pointed upwards.... Next, the port wale, and then back to constructing the quarter galleries! Mark

-

The starboard masking for the gunport edges went much faster, only 3 days of masking..... So now I am ready for the black Wales at last. Just one more round of final sanding for the sides (some masking tape ghosts to clean up). As I was preparing to paint this last round of red, my airbrush compressor suddenly stopped pushing air. I looked around for the cause and noticed that the hose connecting the compressor to the filter had completely severed at the fitting pressed onto its end, either rotted away or twist stressed. I did my best to cut a clean edge on the hose and reattach it to the screw fitting, only to discover that there were slow leaks at several other cramped points in the hose. I taped those up, completed the painting, and then the other end of the hose severed from its pressed on fitting. I had to order a new hose, and the black wales will have to wait for delivery. The compressor was probably 15 years old, maybe the shelf life for hoses.... Mark

-

Druxey, I have been pondering the same question; how did these stern structures come about? I am no nautical historian, but just looking at ships from the previous century the structures were significantly different. So someone decided they needed updating! Although we are so used to seeing the mid eighteenth century sterns that they seem natural and inevitable, the most curious part for me is the quarter gallery curving to the hull at the fore edge, leaving a thin and useless wedge of room inside as one moves forward within it. Who thought that was a good idea?🤨 Thank you Mark and Marc, I always appreciate your kind thoughts--they keep me going when I don't always feel like working! I have been very slow in progress lately, although now working every day for a good part of each day. I ran into one of those: "ok, I will do X; wait, before I can do X I need to do Y; and before I can do Y I have to do Z..... The next step in the quarter gallery construction is to glue the lower finishings in place, so I can begin to built up the structure from that foundation. But before I can glue the lower finishing in place, I need to paint the black main wale, which the lower finishing sits upon. And just when I was taping out the black wale, I realized that the gun ports at the stern cut deep into the wale, revealing a thick edge of wale around the port. What color is that, I wondered? After looking at the Bellona second model, I realized that the edges of all the ports are painted red, right out to the face of the planking. I had left the edges natural. So, wanting authenticity, I had to paint the edges of all the ports red before I could proceed. And then the fun began. Almost 20 years ago, I had decided to create the red color by putting Transtint dye into my poly gel natural finish. It makes a great, somewhat weathered, red. But when this is applied on wood it is difficult to keep a clean edge; the dye tends to run into the pores of the wood, under the mask, leaving unsightly streaks. After some failed experiments with the red dye idea, and also with a paint brush, I decided that I would be better off spray painting the edges of the gun ports. I found an old bottle of Floquil Caboose Red that best matched my dyed wood, and then masked the entire hull leaving only the edges of the exposed planking at each port. This took me way more time than I would ever have expected--maybe five days of masking. Then it was a quick business with an airbrush, giving really clean lines. Now the starboard side, and then the black wales, and then the lower finishings, and then the quarter gallery structures.... Good thing I am not in a hurry... Mark

-

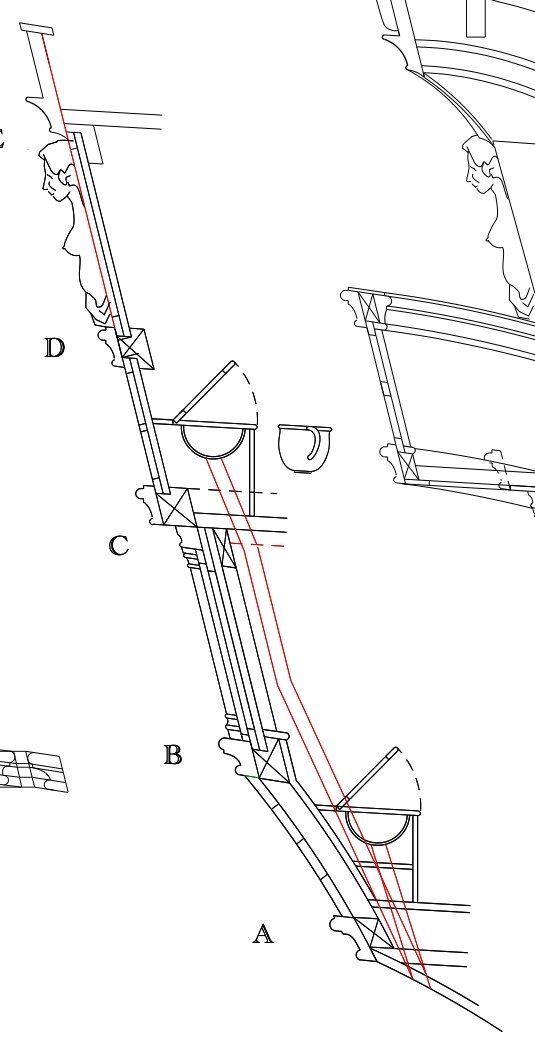

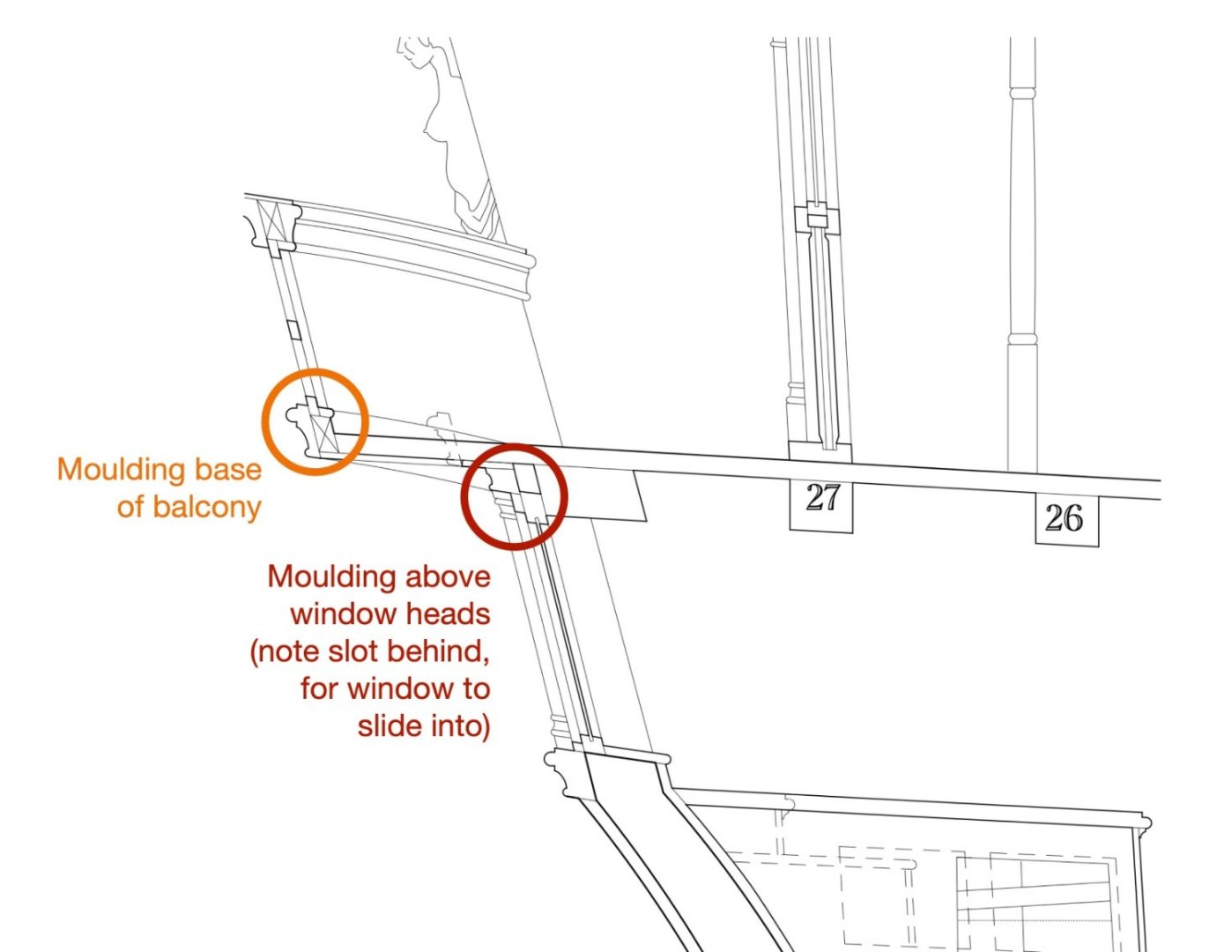

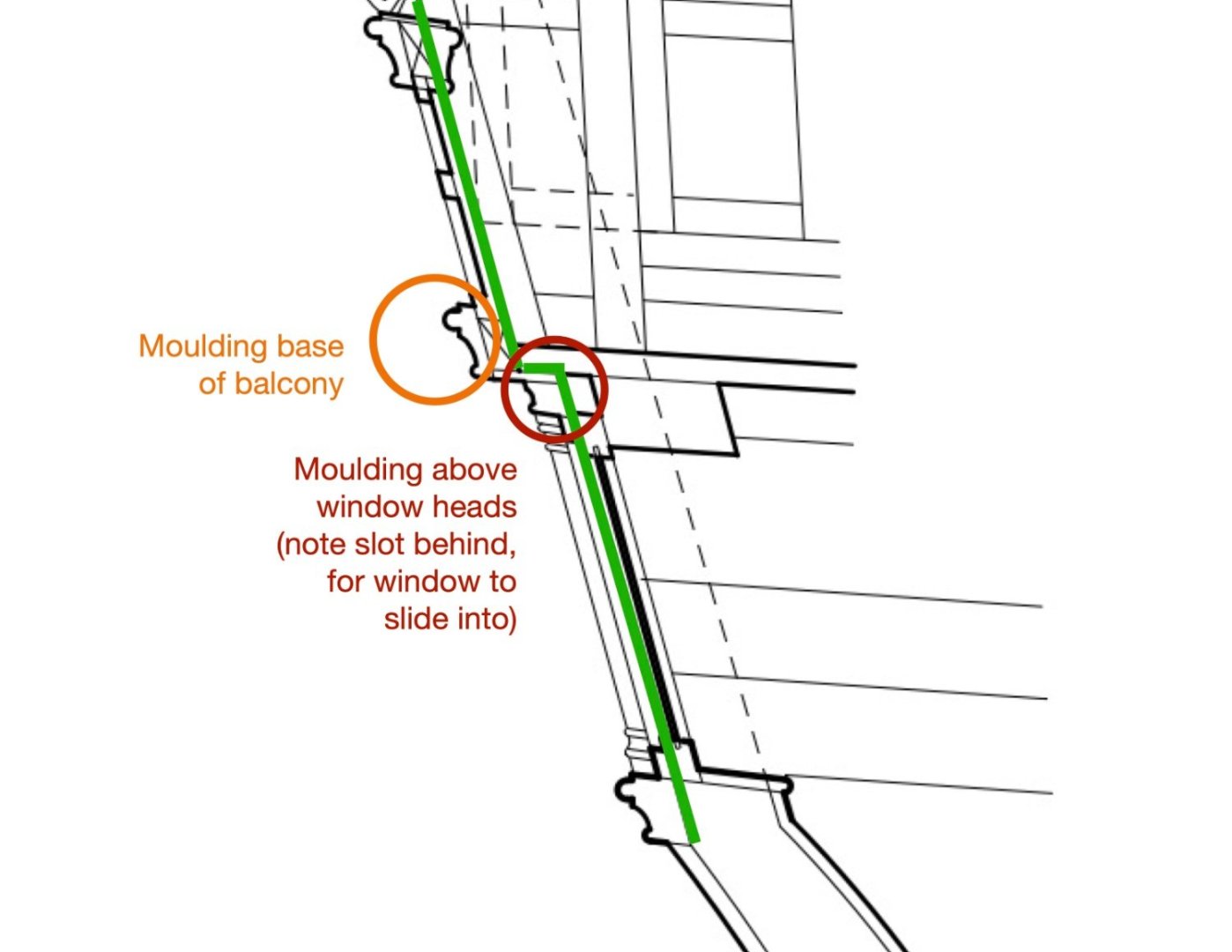

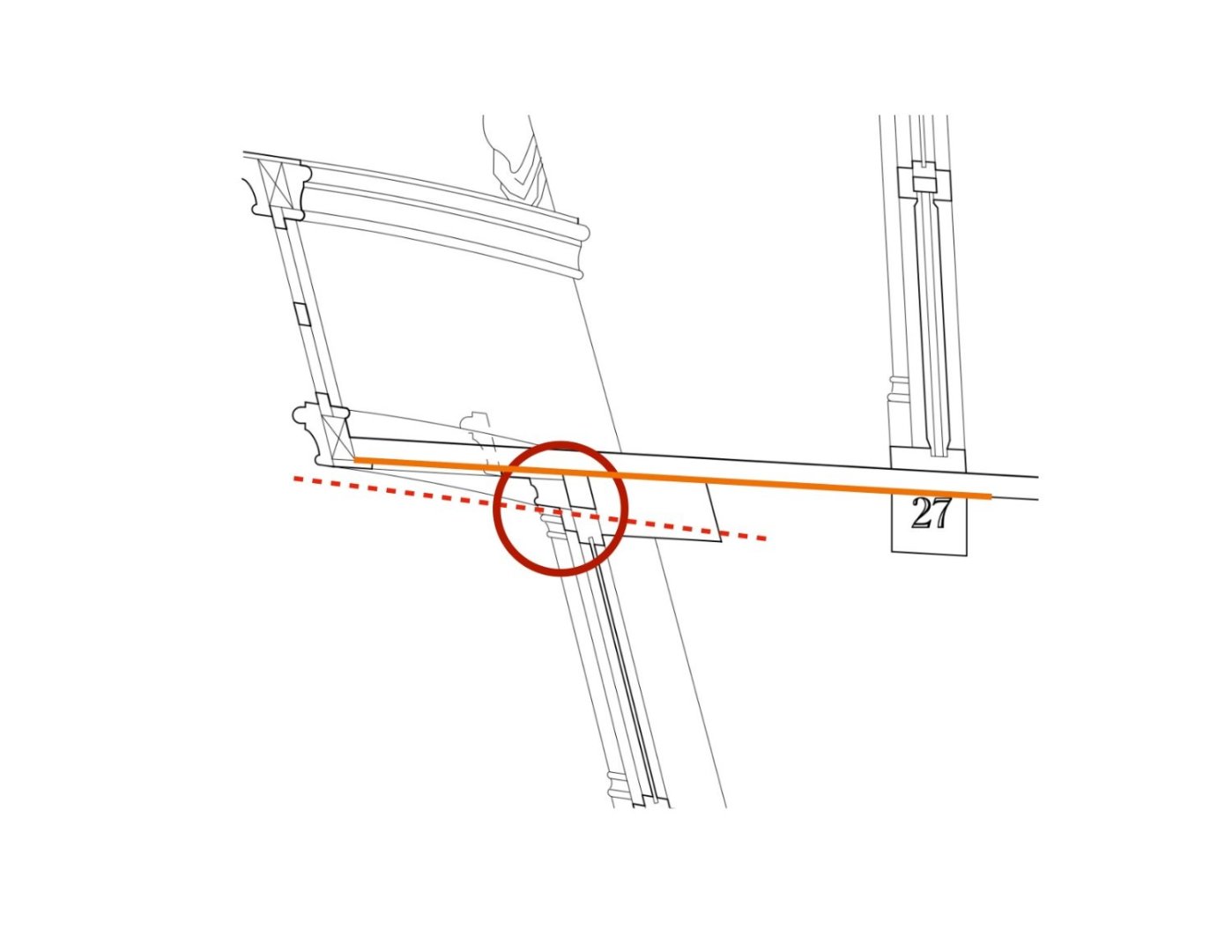

Sorry for the long delays in posting. Lots going on in the summer outside the shop, and progress is very slow when I am in the shop! Thanks so much, druxey, Albert, Marc and Michael for your kind thoughts. These keep my spirits up as I plod through the slow business of building the quarter galleries. I have found it most effective to treat each level of the quarter galleries--at levels of both decks and railings--as a little platform with the structural rails temporarily glued to the outside edges. This allows me to keep the correct curve and location where the rail hits the side of the hull. I used the mouldings at the stern as guides for the angle at which the platforms are temporarily glued in their locations, and carefully measure from the channel wale to find the correct sheer fore and aft. I check with a height gauge to ensure the platforms are symmetrical port and starboard. I recalled reading many years ago that the fore and aft curves of the quarter galleries must be parallel to each other, although offset fore and aft by the amount of the slope of the aft windows. This is to ensure that the vertical mullions are parallel to each other and not in different planes which would create a twist in the plane of the windows themselves. Not good for flat sheets of glass! So I was very careful in maintaining the angle at the aft, outboard, intersection of the two structural rails. This ensures that the platforms above and below the window will remain parallel to each other even as the sides of the hull at different heights vary in their angles due to the tumblehome. This should become clearer in later posts, when I start to lay out the mullions themselves. Here are more images of the platforms slowly coming together. The first one below also shows how the structural beam at level C had to be notched for the window frame to slide up behind the stern moulding. It is actually a blind window, but I needed to do this so my windows would remain constant in their heights across the full width, for ease of construction. Best wishes, Mark

-

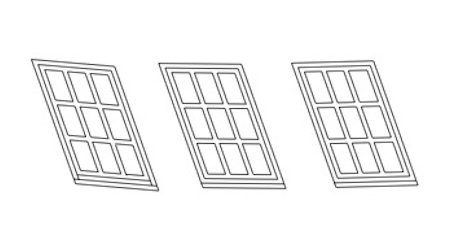

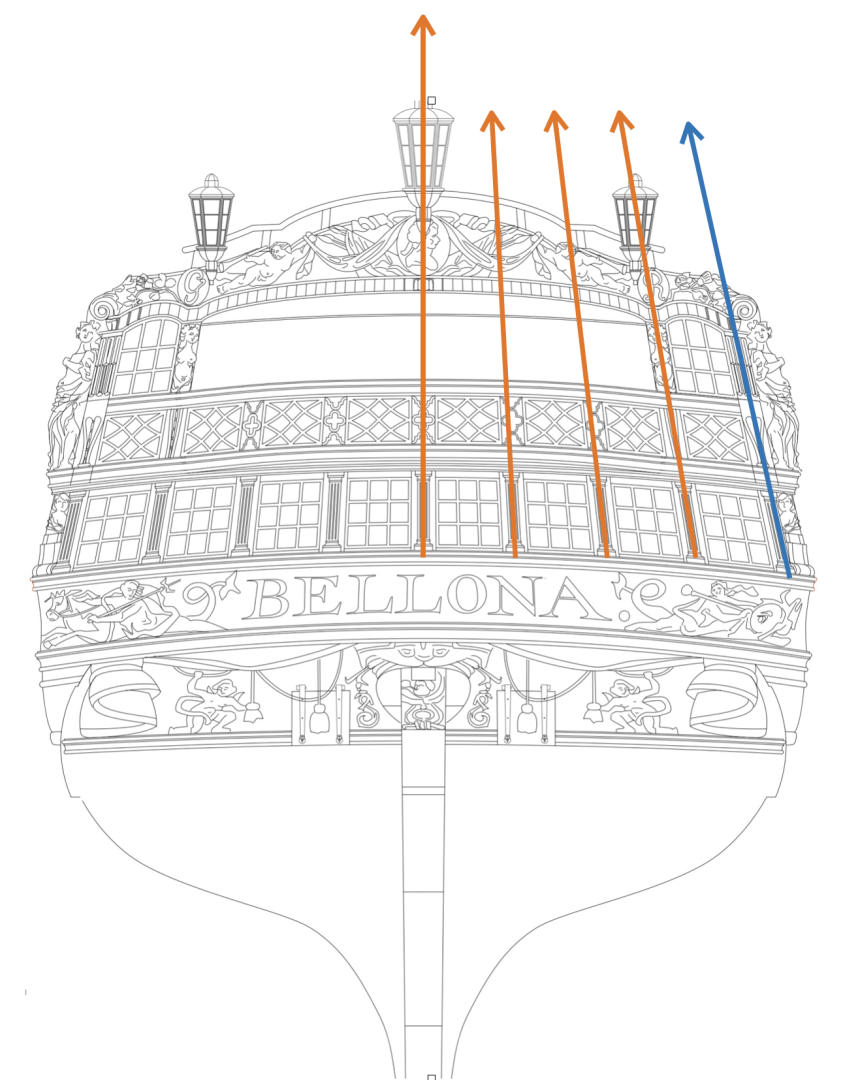

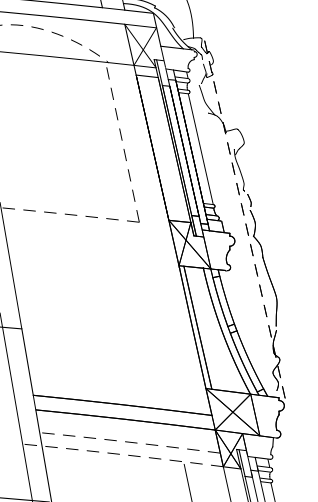

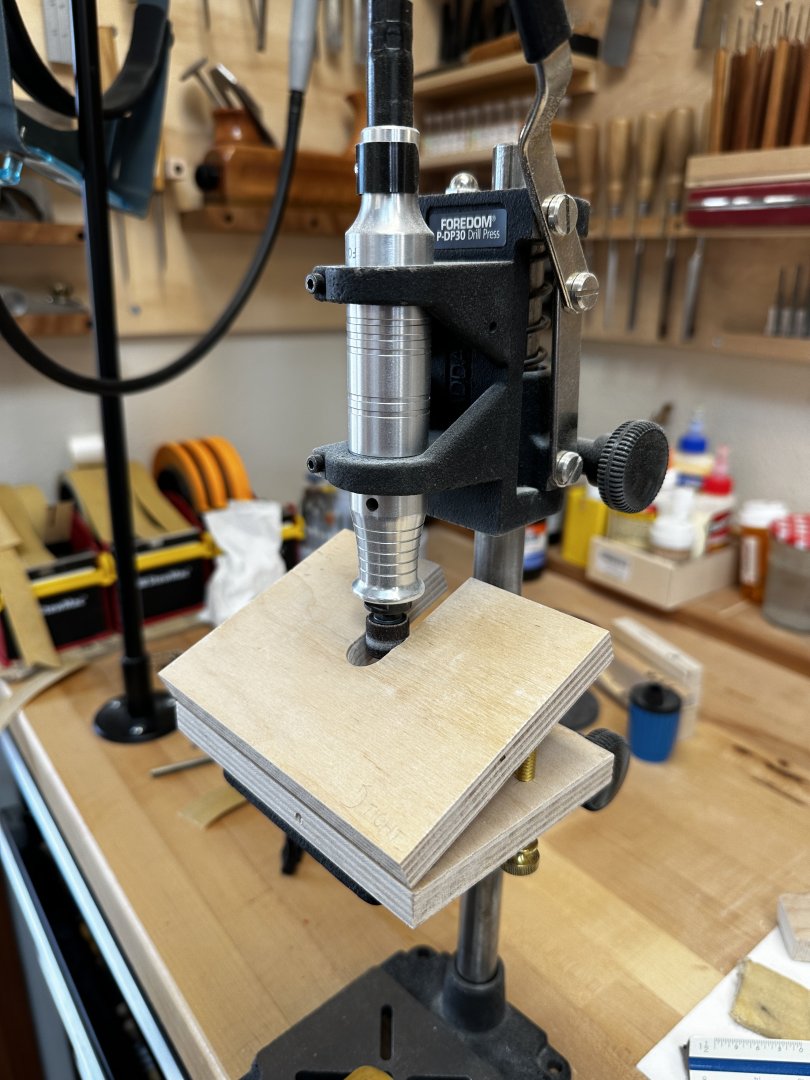

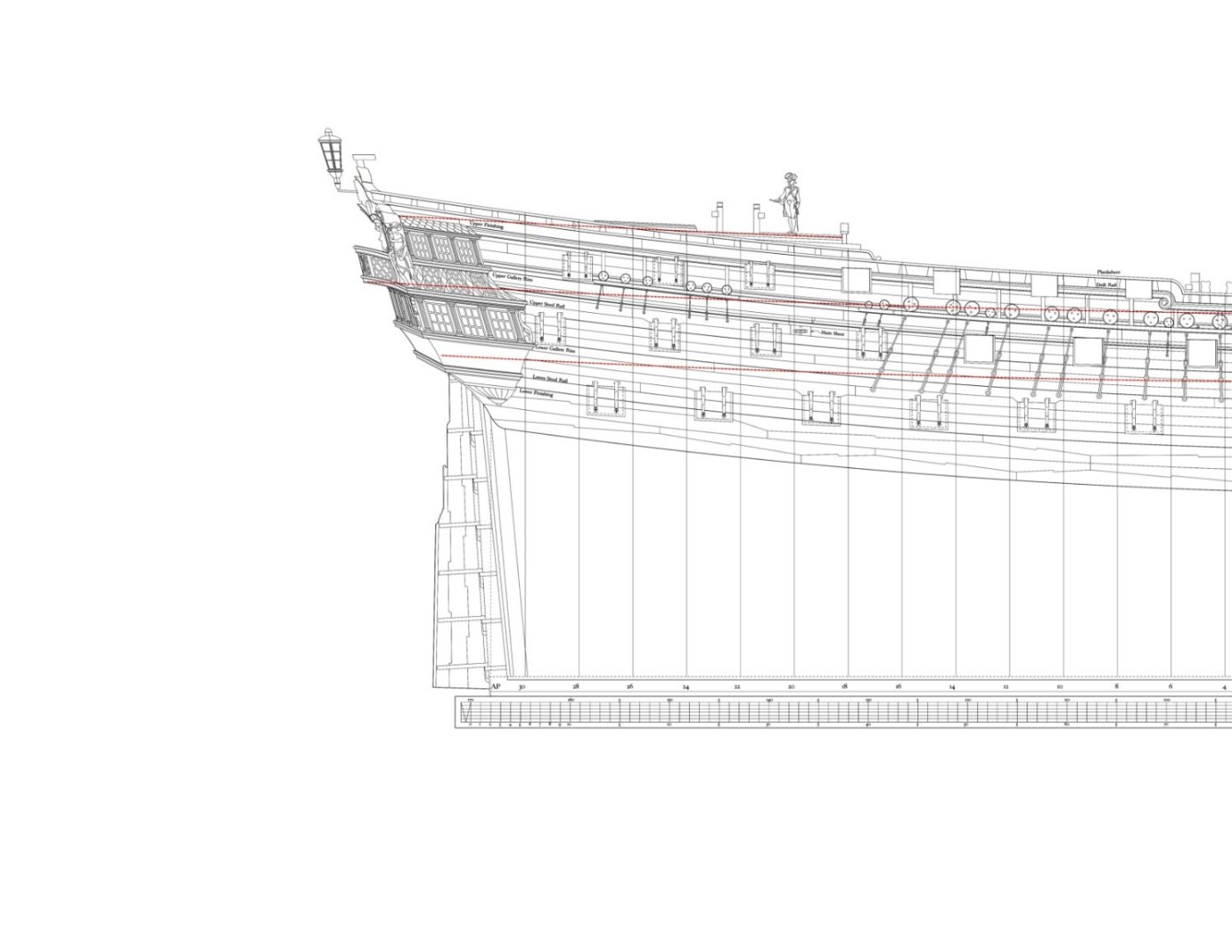

Hi Dan and druxey, Your recent kind comments made me realize that I have not posted in a long time, and you inspired me to catch up a little. I am still a little slow after my health issues, although things are definitely on the mend. What has slowed me the most is that this stern is exceedingly complicated to construct, I have discovered. I have had to do more drawings to figure out how everyone will go together, and then fabricate a number of structural members that will eventually form the framing for the quarter galleries. This has involved cutting parts with a roundup like the decks, with a curve fore and aft, some with a slope matching the aft face of the quarter gallery and some others with a slope matching the outboard face of the quarter gallery, and then rabbets on these multi-curving surfaces for windows top and bottom. I have made many mistakes so far, keeping it all straight.... First, determining the location and widths of the quarter galleries relative to the hull. There are no original drawings of the Bellona stern, and only the most basic hint of the quarter gallery plan, showing the curvature of its outboard edge. So I had to reconstruct from photos of the models, and some geometry. The key to reconstruction is that the stern windows to the upper deck are evenly spaced, and they all converge at a point some distance above the hull. In the drawing below, the 4th orange line to the right is the end of the hull itself, while the blue line is the outer edge of the quarter gallery window. Keeping the spacing of the windows the same, and on the correct angle, this then tells me the width of the quarter gallery at various levels: Here are windows mocked up to determine the lengths of the stern mouldings forming the various levels of the stern:' The following drawing shows some of the geometry involved in the structural parts. Nothing is true size in these, since they are bending and sloping. Everything will have to be measured on the hull itself, and parts fitted to previous parts. Then I had to determine how to make the windows, and therefore how to frame for them. I mentioned before that Chuck has laser cut some beautiful prototypes for me, using my drawings. I have decided on .029" plastic, painted to match the boxwood of the hull. Using mica for the glass (.005" thick) means that I can build windows thin enough to bend to fit their curving surfaces. But to do that, I had to devise a way to trap the window frames and mica between the outer moulding and a rabbet in the structural frame behind. You can see below how the structural frame behind the windows has a rabbet, and once the mica and window frame are put in, the moulding then presses the two tightly together. That is the plan, anyway! You can see in the drawing below how the structural frame (with the crossed lines) slants inward, and also of course bends from the outer edge of the quarter gallery at the stern, to hitting the hull further forward. The frames on the aft side of the quarter galleries also have to round up like the decks. To make these curved and sloped parts, I made an adjustable angle table for my Foredom. I pre-cut each curve with a jeweler's saw, then sanded to the line making a sloped, curved, edge. I then refined these edges on an appropriately curved sanding stick. I then set up a fence on the Foredom with the handle and bit turned upside down, to act as a router table with the bit coming up from underneath. Below you can see the rabbet marked on the end of the structural piece (temporarily glued to the edge of a plywood handle, to keep my fingers away from the bit). The tops of the windows required an acute angle--made with a dovetail bit as below-- and the bottoms required an obtuse angle made with a straight bit. And here is one set of frames (port and starboard) and moulding blanks for the sides of one level of the quarter gallery. All of the sides are now complete. I am now working on the structural frames on the aft end of the quarter galleries. Maybe someday I will be able to start putting some of this together! Best wishes, Mark

-

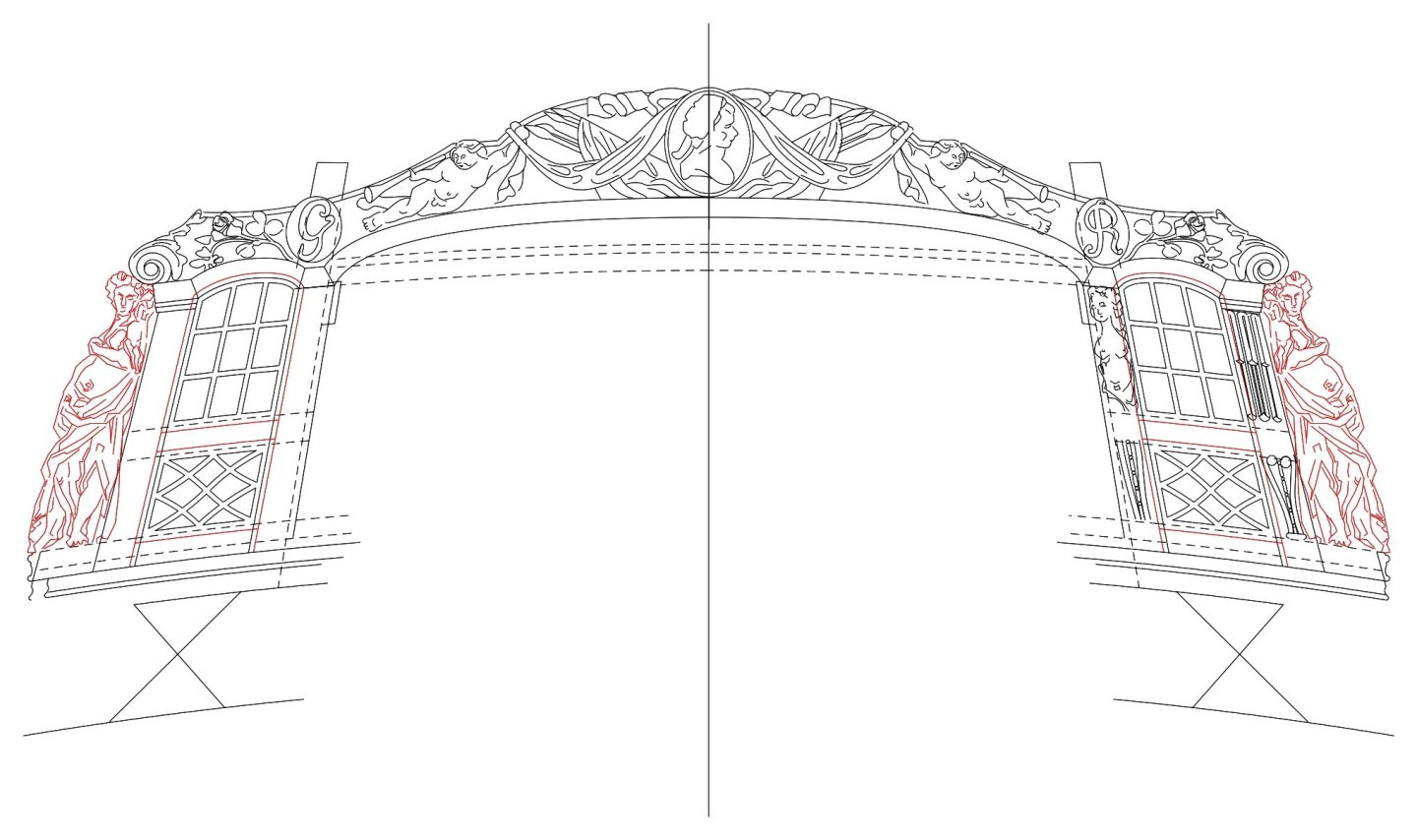

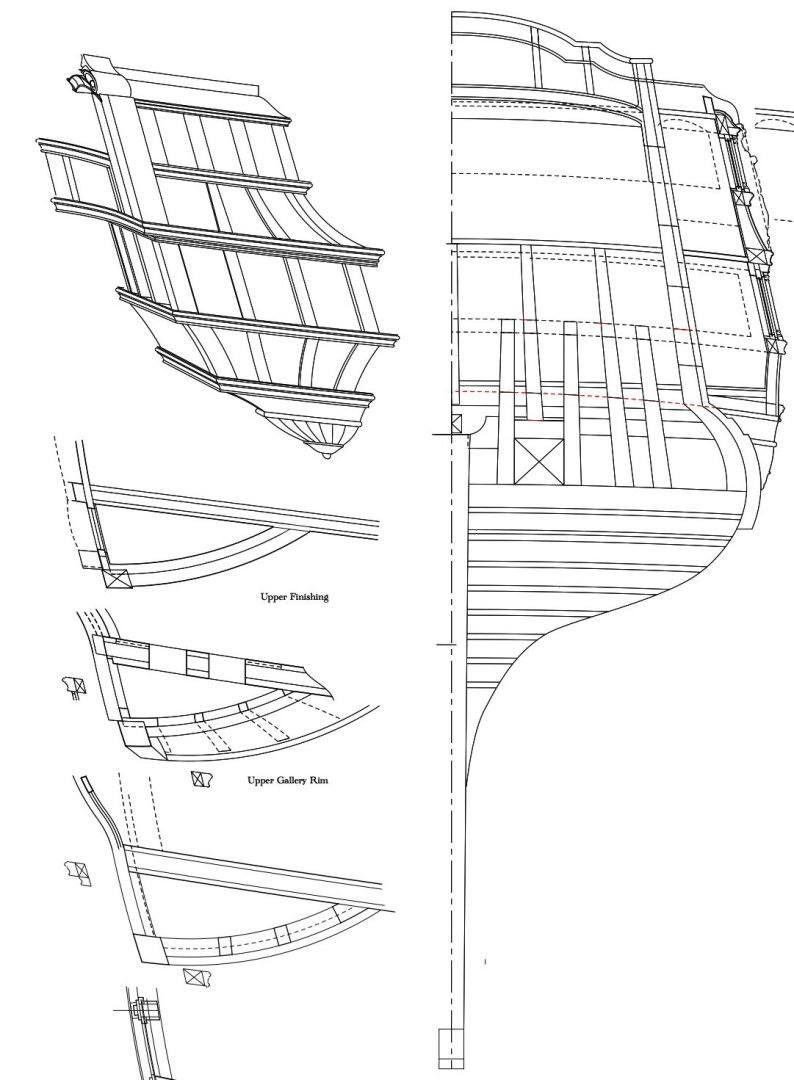

Now for some analysis of geometry and construction. Fifteen years ago, I built the stern frame based on my observation of the first Bellona model, and the Admiralty drawings. I did not understand what I was building at the time, I just followed what I saw. And now I understand as I get into the details. In the model, you can see a couple of strange things. first, the tops of counter timbers with the dovetail joints stand proud of the horizontal transom tying them together. This leaves a gap of about 2". I now realize that these gaps provide a space for the bank of sash windows to slide up into. It means that the windows can be opened at the bottom by about 9"; not a lot, but better than no opening! Second, the side counter timbers, effectively the end of the hull frame, project out from the bottom of the balcony upwards. that is, the bank of windows are recessed back relative to the balcony, creating a shadow line between the upper and lower parts of the stern. There is no functional reason I can see here; it is a visual trick to emphasize the sweeping serpentine curve of the balcony from one side of the composition to the other. That creates some complication in how this is constructed. The green line shows the aft most edge of the side counter timbers, or hull. There is one moulding along the tops of the window bank, just under the balcony, in red below. Another moulding runs along the base of the balcony, in orange below. when the balcony swings out from the stern, the two mouldings split from each other: The next item I did not fully appreciate until I started constructing the stern is how its design needs to reconcile two geometries working against each other; the upper sweep of the sheer, and the flatter sweep up of the decks (red lines below). The conflict shows a little where the gun ports cut into the sheer in odd places. But at the stern they really need to be resolved. One of the most important, I discovered, is that the moulding at the tops of the windows must align with the sheer of the deck at its upper edge (orange line below), since it sits flush under the deck itself; but its lower edge must conform to the sheer of the hull (dotted red line below), since it turns the corner and runs along the side of the quarter galleries that align with the hull's sheer. And then one more thing about the stern. In 2014, ten years ago, I posted a question about the stern geometry (posting #173). I noticed a discrepancy in the drawings relative to the roundup of the quarterdeck. If I continued the deck aft with its normal roundup, it was a couple of inches lower than the deck as it was shown coming out into the balcony. There was a lot of discussion around posting 173 as to whether this was a mistake in the drawing, or something else. I finally found in Steel that the quarterdeck does indeed increase its roundup as it approaches the stern balcony, to give a lighter, more springy feeling to the visual lines of the stern. So the drawing is correct, and this needs to be accounted for: So, construction next! Mark

-

Yves, thanks for sharing your model. I was aware of a kit, but I have never seen it! It looks like you did a very nice job of it. scrubbyj, the history of the Bellona in Brian Lavery's Anatomy of a Ship has the ship paid off in 1762 after her initial service, turned into a guardship, briefly recommissioned, and laid up in ordinary in 1771. Then she was given a major repair in 1778, completed in 1780. this was now 20 years after her original launch. I can only assume that the first model represents her before the major repair, and the second one represents her afterwards. Adding that railing on the roundhouse bulwarks was very typical of designs of this later period, as best I can tell. Visiting my son in London last year, we visited the National Maritime Museum and toured around endlessly disappointed that they had removed most of the models. Then we walked into the room devoted to the Napoleonic Wars, and there were two representative models, the first and second Bellona models side by side! At last two decent models, and they were the Bellona! In this photo you can see that the second model is larger than the first, which I never realized until seeing them side by side. Busy day outside the shop, not as much done on the Bellona as I had wished... But I did get a chance to color the stern quarter galleries based on my reconstruction:

-

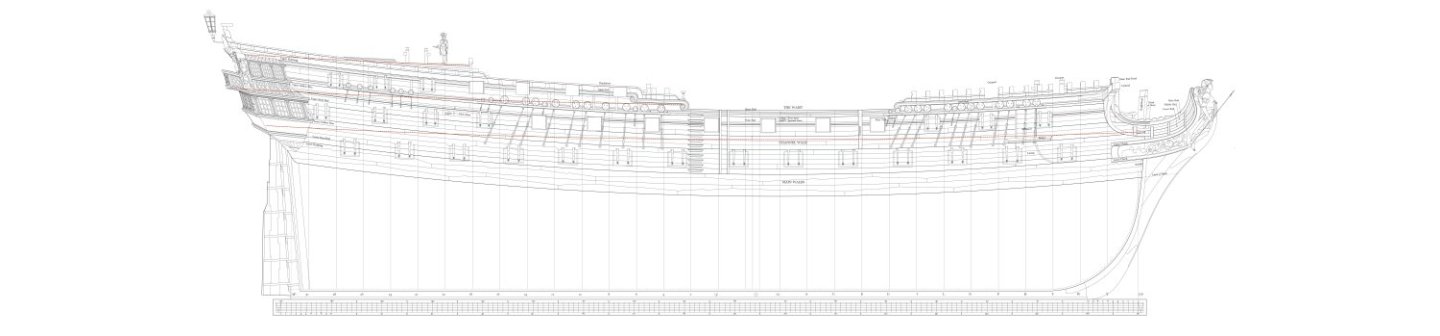

Thanks so much, Marc, Hakan, Allan, Mark and Dan. It really means a great deal to me to hear from all of you. I have a meeting with a pain specialist on Friday, and hopefully I will be able to get past this soon! In the meantime, I have been working away on what has been the biggest challenge for me so far, the stern. I plan to make a number of posts on this, starting today with an overview of the end goal; what will it look like? I have always aimed to base my model on the original design and the first model, shown here: Although this model shows mainly the framing system, it does have a hint of what the original design intended on the stern at least down to the bottom of the captain's balcony. Everything past this is speculation for a reconstruction! The second model, made twenty years later after a major refit of the ship itself, shows much more detail (see below). At first glance, this provides information on all of the detail not shown in the first model. But the second model changed the original design in ways I did not find pleasing. It added an ugly railing above the roundhouse (nice for the sailors, bad for the aesthetics). The balcony railing makes a sharp turn into the stern one bay inboard on each side, whereas the original model has a nice sweeping serpentine curve across the entire stern. The original model has nicely proportioned vertical supports (painted red) with nicely detailed fretwork, whereas the second model skinnies those down and punches crude holes for detail. The first model carries additional carving down to the bottom of the railing adjacent to the large corner post carvings of women, linking things together visually. The second model unsatisfyingly smashes the balcony into the corner sculpture. And in terms of color, the second model uses white for the balcony fretwork and the pilasters on the band of windows, which I find visually jarring relative to the rest of the ship. There are a few other examples of white windows, pilasters and fretwork on other roughly contemporary ships, most notably the Princess Royal in the Annapolis museum; but not many either in models or paintings of the period. This is not typical, in other words. I suspect this was the modeler's effort to give visual "punch" to his model, not a reflection of common practice in the actual ships. I suspect the Princess Royal model has white details like the Bellona second model because it was built by the same modeler; the friezes on both ships are identical in painting style and technique, and the models were likely built at the same time. It may be two different modelers used the same frieze painter, but given the rarity of this look in most other ships, I think we are seeing the personal signature of a modeler here. I would be very interested to hear if others have another view of this. So, how can I reconstruct the original model, from the incomplete information in the original model? Here, for better or worse, is my first shot at a reconstruction (see below). I reproduced the balcony geometry, the carvings, and the wider balcony vertical supports with the more elaborate fretwork. I picked up the little bust carvings below the balcony from another contemporary ship. I accepted the pilaster design from the second Bellona model, although in the spirit of visual harmony I continued the red down from the balcony into the boards behind the pilasters. In the same spirit of visual harmony, I propose to keep the pilasters and the window frames natural wood, along with the carvings and mouldings. The second model friezes and paintwork on the upper and lower counters are really quite delightful (just like on the Princess Royal). So why not use them, with no other sources to draw upon for this? I propose to reproduce those paintings in my model, including the tone and hue of the background blue paint. I would be very interested to hear any opinions as to whether I am on the right track on this reconstruction. Next posting will discuss the very complex geometry in this stern, and my efforts to bring it under control for construction. While I am working on that, I am also working with Chuck of Syren models, who is going to laser cut the window frames and balcony fretwork for me, using my drawing templates. I had long wanted to make everything on this model myself, but I finally had to face the reality that I did not have the skill to make window frames just .023" thick, or even worse, the pierced fretwork. And after a long and fascinating chat with Chuck at the Admiralty Models workshop on carving in Annapolis in October, I came to see that this is just using another tool to achieve my modeling needs, still based on my drawing. Thank you Chuck! By the way, Chuck also pointed out to me that the very fine details like window frames were made of ivory in original models, because it could hold the detail better than even boxwood. Most models seem to have colored this; the second Bellona model builder maybe put up the freshly cut window or fretwork and thought, "looks good as is!" Best wishes, Mark

-

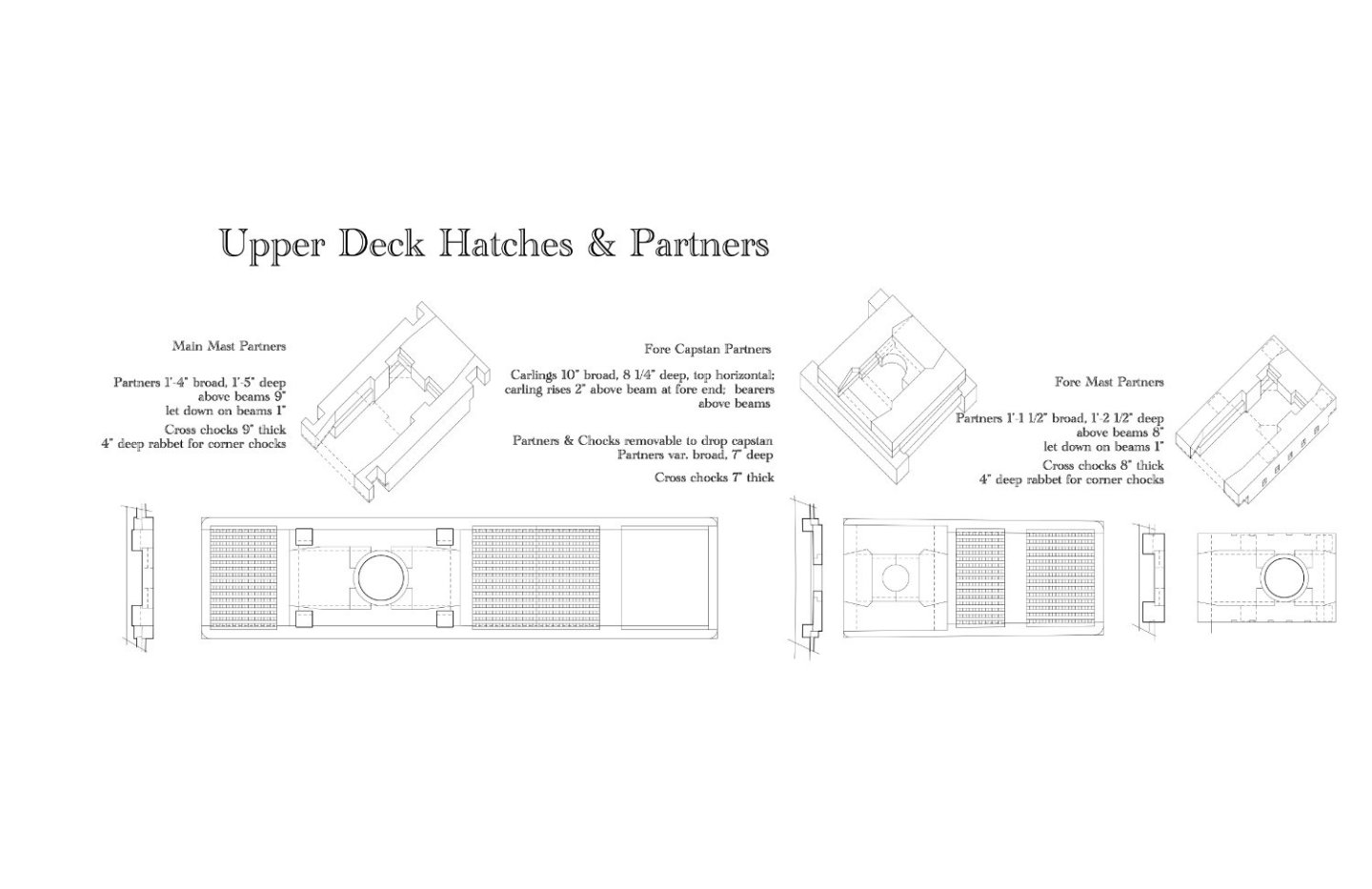

Pirate Adam, Dave, Druxey, JD and Amalio, thanks so much for your kind welcoming back comments. This really is a genuine community. JD, I did work for several months at my computer with it propped up on a stool on my desk. Unfortunately, my shop work surfaces are not moveable, and so I work for a bit, lie down a bit, then work again. More doctor visits coming up, hopefully we can get this finally resolved. Amalio, I have so far drawn the Bellona for my own modeling purposes, and also because I like to draw. I am not sure they are in a state where I could reliably say they are complete and consistent. I am also not sure what copyright issues would be involved in selling these, since they are derived from prints of the original Admiralty draughts I obtained from the National Maritime Museum many years ago. And I don't want to get into running a business now I am retired. But I do want to share, where appropriate, back to this community that has helped me so much over the years to develop many of the details I have now incorporated. Here are a few more examples, first, the stern framing I am now working on in the actual model. A note of interest is that I found it necessary to suggest a false floor in the quarter gallery of the upper deck (the lower of the two). If the floor of the gallery were down on top of the lower finishing, it would be a long step down from the door cut in the bulwarks, as measured on the original plans. I imagine it would be a continuation of the upper deck in height and roundup. This is an interesting case of where they needed to resolve the different sheers of the outer bulwarks and the inner decks at this point. Further below, I am showing some of the hatches and partners on the upper deck I will be building at some time in the future. Interesting construction issues in these! Best wishes, Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.