-

Posts

1,655 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SJSoane

-

Michael, Those blocks rival the ones on the 18th century models in the National Maritime Museum. Mark

- 2,215 replies

-

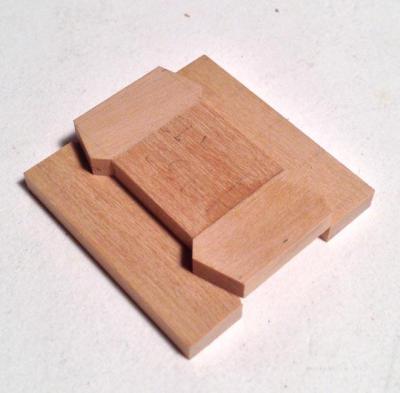

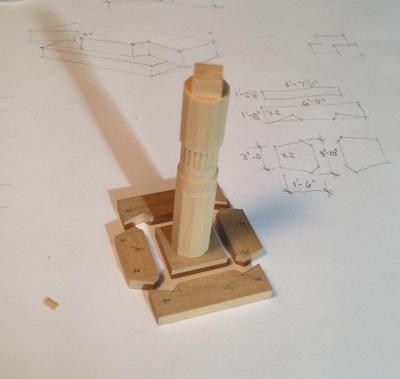

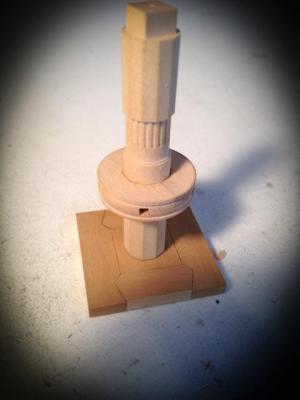

Thank you Michael, Bob and Toni. Your comments help keep me going. I was feeling less skilled this weekend, still struggling with the whelps and chocks on the capstan. After trying several ways to cut the rabbets for the chocks, without success, I had another idea that I will try this afternoon. But while I was pondering this, I took some time to clear my head by moving from little to large. I re-leveled the top of my workbench (I haven't done that since I built it 20 years ago), using a hand plane. Very satisfying physical work after so much close precision. Lefties will note that I built this bench backwards, with the shoulder vise at the right end, since I am also left-handed. Back to whelps and chocks.... Mark

-

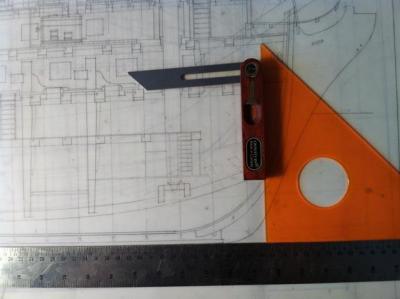

I use a 9H lead in a mechanical pencil, sharpened every other time I use it. The finer the line the more precise the work. The best is to scribe lines with an exacto knife, or a marking knife used to mark out dovetails in full size construction. A scribed line lets you register a chisel precisely on the line for really precise work. Mark

-

Foredom or Dremel Fortiflex ?

SJSoane replied to Mcdood's topic in Modeling tools and Workshop Equipment

Martin, I don't know about the Dremel, but the Foredom is a high quality, well built tool and a pleasure to use. Mark -

Gaetan, I really enjoy your collage of photos. I wish you could publish a book of these photos. Spectacular! Mark

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

ancre Le Fleuron 1729 by rekon54 - 1:24

SJSoane replied to rekon54's topic in - Build logs for subjects built 1501 - 1750

Giorgio, nice to see your build in fast forward. What great craftsmanship! Did you carve your captain/shipwright? Mark -

Chuck, very nice project, and instructions. I will definitely follow this when I get around to building a longboat for the Bellona (maybe in 10-12 years, at the rate I am going....) Mark

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

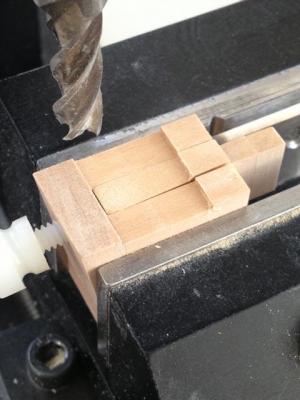

Thank you Colin, my skills have definitely improved as I get further into the project. Gaetan gave me great advice, which is to think of potentially boring tasks like cutting hundreds of mortises for the deck carlings and ledges as a way of honing skills. It makes the time pass more tolerably, and skills definitely increase! I still return to mechanical devices like mills and custom jigs to control cuts where precision is important and I don't trust my hand, but I am slowly learning more hand skills with chisels and planes. It is all part of the fun of the project. One of these days, I might try writing down what I have learned about craftsmanship so far through this project, from some great tutors on this site. Mark

-

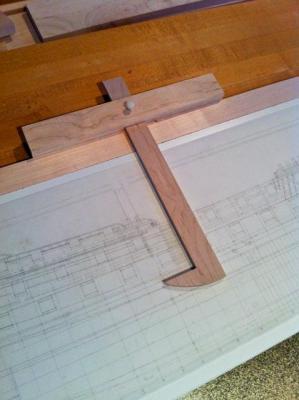

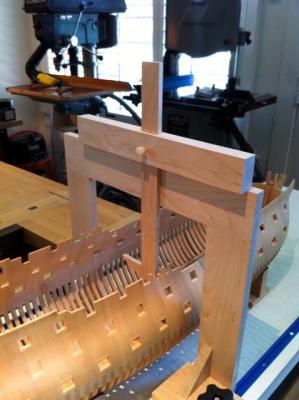

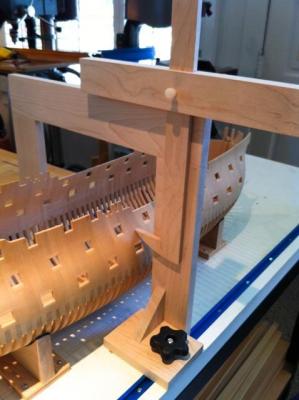

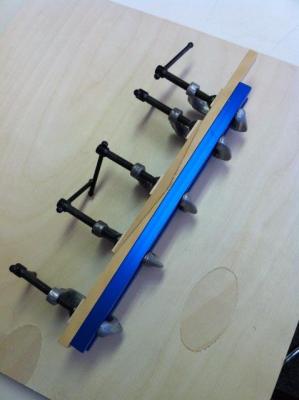

Thank you, druxey, Christian and Ed. All of this re-posting is allowing us to see all of the builds afresh! Ed, I will be particularly happy when we have your index again. I used that fairly regularly. Daniel, the blue track idea comes from Ed, and it is made from components purchased at Rockler Woodworking. All of the parts for the track and the tightening bolts and knobs are already made. The link to the site is: http://woodworking.rockler.com/c/jigs-jig-its-t-tracks I recall that I used a router with a bit exactly the width of the track, using a fence on the router to keep it parallel to the sides of the building board. Once the grooves are cut, the tracks are very easy to screw in. The bridge was a little trickier, because it wants to be exactly right angles to the building board, and have some way of lining up with the station lines of the plan on the board. Ed developed one idea, and I tried a slight variation that I showed in the previous pictures. Ed, are you able yet in your re-posting to link to your bridge design? I recall Ed has an way of fixing his camera to the bridge, which I want to try someday. The final complexity was to get the top of the bridge to the building board surface to be exactly the same distance as the top of my board with the section drawing pasted on, to the bottom of the keel. That is so measurements taken off the board with the drawing will exactly match the same height on the actual model measured from the bridge. I hope the photos explain this well. If not, I'll do a little drawing of the arrangement. Best wishes, Mark

-

Remco, That mast still stands as the ultimate of craftsmanship, and an inspiration to us all. Mark

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

HI Gary, Looking forward to the rebuild of your log. It is quite fun to simplify years of work into a shortened story. I have always enjoyed your project, with its close attention to detail, beautiful construction and exceptional research. Also, you have always been a number of steps ahead of me on a 74, and I see your work as an invaluable road map for what I will need to do next, with very helpful instruction. Can't wait to see the Alfred again! Best wishes, Mark

-

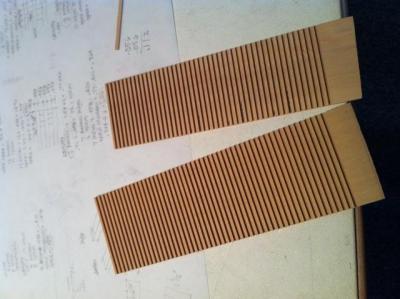

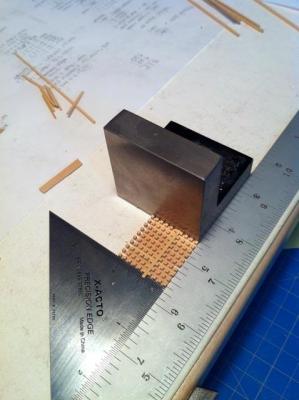

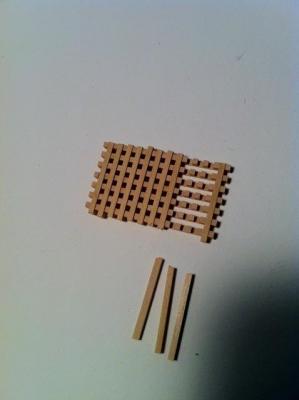

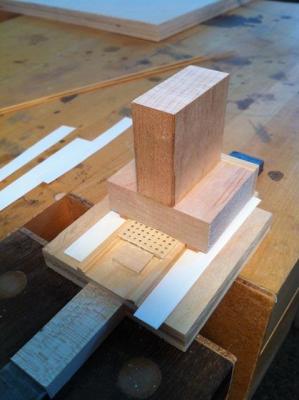

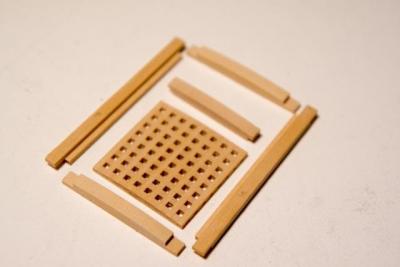

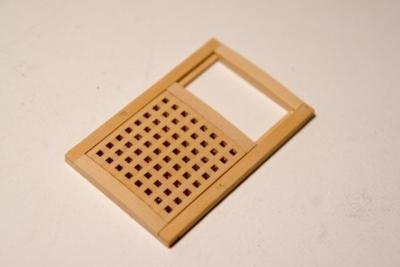

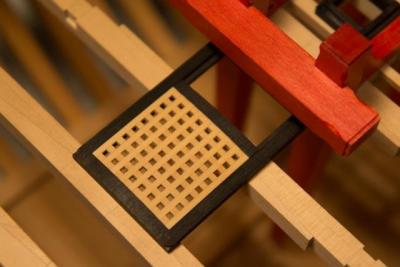

Thank you, Michael, John, and Elia for your encouragement. It really helps keep me motivated. Greg, I looked for a photo of how I made the grating sanding jig, but can't seem to find it. I'll keep looking. Yes, there is sandpaper underneath, but only exactly to the edge of the grate. There are little runners on each side that bottom out on the lower part of the jig once the right depth is reached. I made the profile of the sanding surface by gluing the profile on the end of some maple, which I then ran across the routing table with a piloting bit. It shaped the entire surface of the maple block with the right profile. In image #17 in the background you can see the calculations I made for each grating, where I attempted to calculate the exact size of the parts for each grating so it would be a perfect fit within the coaming. But I more recently put the other gratings in place on the deck, and something isn't lining up yet. I may have to do those over. It wouldn't be the first time for me that very careful calculation nonetheless got it wrong... I have attached an image of the Bellona model looking through the quarterdeck onto the upper deck, which shows a couple of gratings that were imperfectly fitted to the coamings. Maybe they took those from an earlier model and made do, or maybe that is how they really worked. Most of the rest seem to fit better. Harvey, I am not sure which jig you would like to see. I have attached some photos of the bridge for measuring, and how I used it for transferring heights inboard and outboard from my drawing. I took the idea of the track and the bridge directly from Ed. The little blocks in the blue track I used for help in cutting beams so that the center of the made-up beams always aligned with the center of the hull, using the proportional dividers. But right now, I can't remember why I needed the blocks when I could just use the dividers. I'll remind myself when I start making the beams for the upper deck. If you let me know which jig you are interested in, I would be very happy to make a sketch! Best wishes, Mark

-

HI Ed, What a relief you have your posts as Word pages. I was going to have serious withdrawal symptoms thinking about not having access to all of the tips in your posts that I regularly scrolled back through. I still intend to buy volume 2 when it comes out, but it was handy looking things up with your index. Best wishes, Mark

-

Thanks, Mark, Remco, Grant and Greg. It has been fun going through the photos to tell the story in sequence, without extraneous stuff. Greg, I arranged with the curator a private showing of the Bellona when I was last in England. It was in January when the exhibits were closed at Chatham, which helped. I understand the Bellona model has pride of place in one of their exhibit halls. The "breadboard" style after the old Admiralty models has caused significant movement in the hull with the season changes, because of the cross grain construction. Colorado can go from 12% to 70% or more. I used to live in house with a humidifier which kept things constant. But the new shop has no humidifier, and the hull regularly opens up a joint here or there in the winter. It used to cause me some distress, but everything stays in place when summer comes around again. I guess this worked better in England, when the humidity was uniformly high. If I had life to do over--or maybe for the next model--I would frame like your's and David Antscherl's system. The space between frames allows expansion and contraction longitudinally, without stressing the longitudinal members like the keel. Best wishes, Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.