Bob Cleek

Members-

Posts

3,342 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bob Cleek

-

Use canned clear shellac (about a 2 pound cut - Zinsser Bullseye brand or equivalent) to cause the line to stiffen. Shellac is dissolved in alcohol. As the alcohol evaporates, the shellac soaked into the line will begin to harden and the line can be formed into any shape. Once the shellac has dried (within minutes) the line will be stiff and hold whatever shape you have given it. If more working time is needed, simply apply additional alcohol and the shellac will soften again. Results example below. Coils made on a form consisting of map pins placed into a wooden base around which the coils were wound. Coils were installed on the model, softened with alcohol, and formed in place to depict normal hanging behavior of full-size line.

-

QuadHands are "finestkind." You'll love them. Nobody should waste their money on those near useless ball-jointed "helping hands" that you have to adjust by tightening wing-nuts. They are really junk. (And, like so many others years ago, I bought one, too! ) One thing to be careful about, though, is to make sure you buy the real QuadHands fixtures. There are "carbon copy" Chinese knockoffs all over the internet, but they aren't the same quality at all. The QuadHands uses high quality alligator clips for one thing. Cheap alligator clips are a dime a dozen, and they don't hold well at all. Don't subsidize intellectual property theft. Buy the real McCoy!

-

Sorry about that. I got interrupted writing the above post. In the meantime, it looks like you "pulled the pin" and ordered a vise from Micro-Mark when you could have ordered it from Walmart for ten bucks less. I won't rub it in, but only to say that it always pays to shop around before buying anything from Micro-Mark.

-

An excellent tool that everybody should have. However, you should shop around on the internet to find the lowest price. As usual, Micro=Mark has more tools for modeling than most any catalog, but nearly always at a considerably higher price. For example, see: Universal Work Holder Peg Clamp Jewelers Engraving Hand Tool for Jewelry Making - Walmart.com This tool has a handle that can be screwed off and the base neck is hexagonally shaped so it can be placed in a bench vise. That's often a more convenient way to use it than holding it in one hand and some tool or paintbrush in the other. Fancy articulated bench top holders are made for it, or sold with this vise, but all are of questionable utility (often too weak) and overpriced. The best option is to buy a decent small 2.5" or 3" bench vise with a clamping attachment for $30 or less. E.g.; $23.50 Clamp-On Swivel Vise - Lee Valley Tools Another option that is very handy to have is one of the extremely versatile QuadHands holding platforms. These are heavy iron plates with flexible arms holding heavy duty alligator clips that attach to the base plate with rare earth magnets. Sold on Amazon and elsewhere. They are really useful for lots of applications, particularly holding parts for painting, gluing, and soldering. This is a commercial grade tool made for and marketed to the electronics assembly industry. Beware of identical-appearing Chinese knock-offs. The quality is not the same. "QuadHands" is the brand you want. See: QuadHands® - Helping Hands Tool They come in several sizes and additional "arms" and attachments are available, starting at around $40. Also sold on Amazon.

-

You might want to reconsider the above. In practice, it appears that reef points on any given sail would all be of the same length in any event. The "rule of thumb" from Falconer's above sounds right, but here again the maxim, "Different ships, different long splices." applies. The reef points need to be long enough to conveniently encircle the mass of gathered canvas in the sail to be secured. Therefore, the size of the sail is the determining factor. In different periods, the common square sail sizes varied. In later times, particularly with merchant vessels, the size of the sails was reduced to permit easier handling and, thus, smaller crews, which meant more profit in the operation of the vessel. Obviously, a longer square sail will require longer reef points than a sail that's half as long. Naval vessels would furl sails very tightly such that the sail gathered and tied on the spar would not exceed the diameter of the spar. On the other hand, a merchant vessel would characteristically be less fastidiously maintained, and sails might be furled less tightly, if not just making a sloppy job of it sufficient only to get the canvas under control and out of the way and so might have longer reef points. Not to make you crazy or anything, but depending upon the scale you're working in and the level of detail you are depicting, note also that reef "points" were so called because they were "pointed" by working a taper into their ends. There were general standards for the length of the reef points. (Note the term "reef points" references the pointed shape of these lines. It does not have anything to do with the gromets worked into the sail through which reef points are passed, as is modernly a commonly heard misuse of the term.) A bit of research in the appropriate sources for the period of your model will answer your questions much more specifically. For example, see "Steele's" for both the Admiralty and merchant marine practice circa 1794: https://maritime.org/doc/steel/large/pg148.php There you will also see the number of gaskets that are required for each rate of ship (by the number of guns) to tie the completely furled sail to the yard. Illustrations are also provided. For example, excerpts from Steele's: GASKETS. Braided cordage used to confine the sail to the yard, when furled, &c. ARM-GASKETS; those gaskets used at the extremities of yards. BUNT-GASKETS are those used in the middle of yards. QUARTER-GASKETS; those used between the middle and extremities of the yards. GASKETS are made with three-yarn foxes. Those for large ships consist of nine foxes, and those for smaller of seven. Place four foxes together, but lay them of unequal lengths; mark the middle of the whole length, and plait four foxes together, for eight or nine inches; then double it and plait the eight parts together for five inches, and work in the odd fox. The whole is then plaited together for eighteen inches in length; then leave out one fox, and so keep lessening, one fox at a time, till you come to five. If the foxes work out too fast, others must supply their places, till the whole length is worked, which is from five to seven fathoms long. To secure the ends, make a bight, by turning upwards one of the foxes, and plait the others through the bight, then haul tight upon that laid up. (Obviously, few modelers will actually plait their reef points as described by Steele, but an understanding of the full-scale practice better enables the modeler to depict such detail as they may wish secure in the knowledge of what it's supposed to look like.) POINTS, short pieces of braided cordage, plaited together as gaskets are; beginning in the middle with nine foxes, and tapering to five at the ends, and from one fathom and a half to one fathom in length. They are used to reef the courses and topsails. ROPEBANDS differ from gaskets only in their length, being from seven to nine feet long. POINTING. Tapering the end of a rope, or splice, and working over the reduced part a small close netting, with an even number of knittles twisted from the same, to prevent the end untwisting, and to go more easily through a block or hole. REEF. That portion of a sail contained between the head or foot, and a row of eyelet-holes parallel thereto, which portion is taken up to reduce the surface of the sail when the wind increases. Sails, according to their sizes, have from one to four reefs. A BAG-REEF is the fourth, or lower, reef of a topsail. A BALANCE-REEF crosses boom-mainsails diagonally, from the nock to the end of the upper reef-band on the after-leech. When modeling, the best approach is to experiment with a sample of the sail material you'll be using and simply measure how much line it takes to tie the reef lines and let that be your guide for the length of reef lines and gaskets. Many will reduce the model's sail size in order to more easily depict a tightly secured sail on the spar, in which case a similarly sized sail sample will yield the proper length of reef line or gasket needed.

-

Bending hard brass.

Bob Cleek replied to navarcus's topic in Metal Work, Soldering and Metal Fittings

Probably. For a good example of brass skeg fabrication see: -

Bending hard brass.

Bob Cleek replied to navarcus's topic in Metal Work, Soldering and Metal Fittings

It's not about the type of vessel or style of hull. He has as 10" x 1/2" x 1/8" piece of "hard" brass to use as a skeg which he wants to bend in order to make it "3/4" lower at the middle to clear the prop." If the stock is to be a skeg, given it's dimensions, I'd expect he wants to know how to bend it 3/4" across the 1/2" wide vertical face of the skeg. "Hard" brass can easily be annealed with a torch, but there are limits to "bending across the flat" which would seemingly be exceeded in this scenario. -

Bending hard brass.

Bob Cleek replied to navarcus's topic in Metal Work, Soldering and Metal Fittings

I'm sorry. Maybe it's me, but I can't figure out the bend you are contemplating. A picture is worth a thousand words sometimes. I'm not sure how you want to bend it. If you're trying to do what I think you are trying to do, I'd have to answer "No can do." -

It's nice to hear of another who remembers Ray Aker, a man who certainly deserved greater fame than he realized during his lifetime. He was a very good maritime historian and one of the better draftsmen around. I still have the copy of his beautiful technical drawing of the remains of the 1840 whaling bark Lydia uncovered during excavations for the 1978 construction of the San Francisco Peripheral Sewer project which he gave us when I knew the archaeological impact report consultants on that project. http://library.mysticseaport.org/ere/odetail.cfm?id_number=1961.72 Without passing any judgment pro or con regarding your posting your research records on the Drake Navigator's Guild's website, as a fellow member of our generation, I would urge you to strongly consider making provision for the donation of your research files to the J. Porter Shaw Library at the San Francisco National Maritime Museum at Fort Mason, San Francisco. As you probably know, the J. Porter Shaw is the best recognized repository for such subject matter these days.

-

Sorry for the confusion. I was in the middle of an edit, so you caught only the beginning of the post. Check out the link I provided above to the U.S. Amazon and eBay websites and you'll see they are both offering new and used copies. Beyond that, I expect the cost of shipping is prohibitive. We keep hearing that in recent times on all sorts of modeling essentials. The cost of an item on the opposite side of the Pond seems to almost double when the shipping is added. We have U.K. books listed on U.S. eBay, so I'm not sure why it doesn't work the same the other way around. Is it possible the "not available" status is a result of some sort of E.U. customs issue?

-

It was an expensive book when first published and seems to have remained so. Apparently, it was until rather recently only available directly from the publisher, Ancre, in Nice, France. The Art of Shipmodeling - Bernard Frolich - Ancre There are now new and used copies available on U.S. Amazon (The Art of Ship modeling: Bernard Frolich: 9782903179847: Amazon.com: Books) and U.S. eBay: (https://www.ebay.com/sch/i.html?_from=R40&_trksid=p2334524.m570.l1313&_nkw=The+Art+of+Shipmodeling+by+Bernard+Frolich&_sacat=0&_odkw=The+Art+of+Shipmodeling&_osacat=0) Believe me, we feel your pain over here, as well. We have to pay the same exorbitant shipping costs from the U.K. to the U.S. that you apparently must in the opposite direction. I believe this increase in shipping costs was attributable to the fact that all shippers seem now to be sending everything air freight. Time was, you could order something from Europe and it might take three or four weeks to get here, but the shipping didn't break the bank unless you wanted to opt for air freight. Now it's all air freight whether you need it or not. On top of that, you may also be paying the price for "Brexit," but I'm not really all that familiar with that issue, of course. Perhaps you might consider having a friend who is making a run to the South of France "smuggle" a copy back for you from Ancre. It's really a valuable resource.

-

I believe that The Art of Shipmodeling has reached that pinnacle of universal reference work that it is simply referred to by its author's last name: "Frolich." I see where, inexplicably, Amazon has it for sale new for $70.00. That's a steal at less than half the price most of us paid over the last 22 years since it was first published. I'd grab a copy in a hot minute if I were you. There's a wealth of information in it. But beware! Do not confuse The Art of Shipmodeling by Bernard Frolich with The Art of Ship Modeling by Richard Mansir, which is an entirely different book. It's "Frolich" that you want to make sure you are buying. If it's classic books on modeling technique and "tricks of the trade," I'd strongly recommend: The Techniques of Ship Modeling, by the late Gerald Wingrove: The Techniques of Ship Modelling by Wingrove, Gerald A. Hardback Book The Fast 9780852423660 | eBay There are always a few used copies on eBay (both hardcover and quality paperback) so shop for the lowest price, usually less than ten bucks used. Ship Modeler's Shop Notes, Volumes 1 and 2 from the NRG. There are always used copies of these on eBay and Amazon. New copies are available from the NRG store through this forum. As for Volume 1, I'd advise you get a newer printing with the spiral binding which permits the books to be laid flat on a workbench or tabletop when working from them. The original binding was a glued spine paperback and the glue dried out and the pages come loose. My copy of Volume 1 is held together with a bulldog clip. I should bring it to Staples or one of those places and have them spiral bind it for me. William Frederick's (1874) Scale Journey: A Scratchbuilder's Evolutionary Development, by Antonio Mendez C. This book was "remaindered" on eBay a couple of years ago for seven bucks a copy and I grabbed one. It's focus is radio controlled sailing scale models, but its content is a survey of technique, and it is full of subjects not found elsewhere, especially regarding tools and shop practices. It would take you years of following build logs on MSW to pick up but a fraction of the how-to-do-its in this book. Unfortunately, it appears to have become something of a collectable at this point and Amazon is now selling them for $47.00. If you watch out for a copy on eBay, you may get lucky and snag one for closer to the price when they were selling off the remainders new. William Frederick's (1874) Scale Journey: A Scratchbuilder's Evolutionary Development: mendez, antonio: 9780975577202: Amazon.com: Books I checked eBay just now and see where they have three between $50.00 and $169.00! (Let this be a lesson to modeling library builders everywhere!) Plank-On-Frame Models and Scale Masting and Rigging, Vol. 1: Scale Hull Construction and Plank-On-Frame Models and Scale Masting and Rigging, Vol. 2: Scale Hull Construction by Harold A. Underhill. This two-volume set is a classic and there are lots of used copies on eBay for surprisingly reasonable prices. (Still in print, new copies run around $90 per volume!) plank on frame models underhill for sale | eBay Masting and Rigging: The Clipper Ship and Ocean Carrier by Harold Underhill. This is what I'd call the Bible of the last days of commercial sail. If you are interested in clippers and windjammers, as well as general rigging practice at the highest level of its evolution, this book is it. Used copies are available very reasonably priced on eBay. Masting and Rigging: The Clipper Ship and Ocean Carrier for sale | eBay These titles are recommended for their treatment of general modeling practices and techniques more than for specific research data on specific types and periods. When your interest becomes focused on a particular type of vessel in a particular period, there are specific reference works that become "must haves," but they tend to be expensive (some running more than a hundred dollars and up) and sometimes very difficult to find. If you continue to pursue your interest in ship modeling, you will find yourself acquiring a library of some value and doing that easily becomes a related hobby in and of itself.

-

Yes, I don't see any reason why the Byrnes drawplate can't be sharpened. All it takes is a flat surface, some fine abrasive sheet that will cut metal decently, and the patience to do the bit of handwork required (which I expect could actually be substantial if the drawplate is hardened steel as I expect the Byrnes model is. I've also used razor blades as well as hacksaw and drywall knife blades as stock to grind my own scraper shapes which works fine once you master the shaping. I use a rotary tool with a diamond burr or a metal cutting ceramic disk. It takes a careful touch, of course. l've never tried to sharpen the Artesania Latina molding scrapers. While I haven't found the need to do so as yet, I expect it would be possible, but how effective, I'm not sure. Further experimentation is in oder! The Artesania Latina scrapers are a bit pricy and not essential for ship modeling until you run into a more complex molding shape that's required. Simple 1/8" half rounds and larger probably just as easily made with DIY scraper. Artesania Latina scrapers come into their own when the more detailed and complex trim and molding shapes that are much more difficult to grind yourself are required.

-

Ah ha! I know the name of that tune. Back in the days before the Dictionary of American Naval Fighting Ships ("DANFS") ( https://en.wikipedia.org/wiki/Dictionary_of_American_Naval_Fighting_Ships ) was posted, in part at least, on the internet (https://www.hazegray.org/danfs/) I had acquired for free in a "junk books pile" a set of the nine-volume "Encyclopedia Britannica" of U.S. Navy ship histories and photographs going back to "day one" of the U.S. Navy less one volume. Published by the Naval Historical Center, the large and expensive, somewhat limited edition series had been out of print since 1991 and there was little chance of my ever obtaining the missing volume. Then, one day when I had some time to kill, I was perusing the stacks of the county main library which I rarely visited and I spotted a DANFS volume! Unbelievably, it was the one volume that I didn't have! I checked the card catalog and there was no listing for any DANFS volumes in the library's collection. I took the book to the head librarian and explained my situation, the fact that it appeared this volume was an "orphan," and that there was no sign of it or the rest of the set in the card catalog. Explaining my interest in maritime history, I asked her as nicely as I could if it were possible for me to buy this rather esoteric research book from the library so they could use the money to buy another book more likely to be read by the library's patrons. She looked at the volume and noted it had a library stamp and all that in it, but nobody had ever checked it out. She looked at me and said, "I have no idea where this book came from. It should have been culled from the stacks long ago. If we kept every book that came into our possession, we'd quickly run out of shelf space. Just take it. We're glad to get rid of it and I'm happy to see it go to somebody who wants it." Thanking her profusely, I walked out with a free book which, considering its value as the "missing link" to a now complete DANFS set, I would have gladly paid a fair price for! I'm not so sure whether you'd be so lucky with a set that's worth close to a thousand bucks, though! You can always try. Stranger things have happened! BTW, I just ran a search on the DANFS set and there's a complete nine volume set for sale on eBay right now for a rather excellent price of $101.19 with free shipping! I'm not sure why, but there it was: https://www.ebay.com/itm/325989377449?chn=ps&_trkparms=ispr%3D1&amdata=enc%3A1qIDhXgXvR8eXOOj6-pkOmQ61&norover=1&mkevt=1&mkrid=711-213727-13078-0&mkcid=2&itemid=325989377449&targetid=4580771614098651&device=c&mktype=&googleloc=&poi=&campaignid=603247547&mkgroupid=1234752552191001&rlsatarget=pla-4580771614098651&abcId=9316119&merchantid=51291&msclkid=4c8398c3d71f1a7cd709fedb7e6913fd Note that "complete" eight volume sets were the original set. The ninth volume was an additional supplement updating additional vessels. Prices for complete sets appear to be running closer to $200 to $300, plus shipping. Anybody who's interested in U.S. Navy fighting ships really shouldn't miss this opportunity.

-

Well, I learn something new everyday! Thanks for the clarification, guys! It makes sense that a metalworking drawplate might have a slight chamfer on the "exit" side of the plate to allow for a bit of 'wiggle room" as the wire exits the plate. I guess I've just been lucky in obtaining woodworking drawplates without knowing the difference. My Byrnes drawplate is marketed as useful for making trunnels nails, but doesn't mention any further distinction regarding its use for wood or metal one way or the other. It has "(T)hirty precision holes cover the range from .016" through .059" - at 1:48 (1/4" scale) that represents full-size trunnels of 3/4" diameter through almost 2" in diameter!" The smallest holes on the Byrnes drawplate are so small as to be nearly invisible when viewed from the back ("exit") side and I had to hold it up to the light to see them without a magnifying glass. The back of the Byrnes drawplate is perfectly flat and the "exit" side of the holes aren't chamfered. Like all things "Byrnes," this drawplate is an elegantly finished tool, although I can't imagine ever needing a .016" diameter dowel, nor finding a species of wood that would draw down to such a size without breaking! (Some species of long-grained bamboo, perhaps?) The cheesy drawplate I got first from Micro-Mark has 24 holes, which are not numbered as to size. The smallest hole looks to be about the same diameter as the smallest hole on the Byrnes drawplate, but the largest hole is around .125", a bit more than twice the diameter of the largest hole in the Byrnes drawplate. Thus, the Micro-Mark drawplate provides a wider range of sizes in a fewer number of holes and therefore a much less gradual progression of hole sizes. This fact makes it a lot more difficult to use with the narrower holes because each successively sized hole takes a much larger "bite" out of the material at each step in the shaving process than a greater number of holes over the same size range which tends to encourage breakage, . The "exit" side of its holes aren't chamfered. The second drawplate which I acquired, (if memory serves, on eBay,) has 83 holes running from about .125" to what looks like a couple of steps smaller than the smallest hole on the Byrnes drawplate at .016, a rather wide range of sizes with three and a half times as many holes over the same range of sizes on the Micro-Mark drawplate. This fact greatly reduces the problem of breakage characteristic of the Micro-Mark with its greater a progression between sizes. While the Byrnes drawplate is marked with wire gauge sizes for each hole, neither of my other two are. The larger drawplate I got off of eBay is better finished than the Micro-Mark drawplate and, of course, the Byrnes drawplate is impeccably machined. (I have no idea where any of their manufacturers get the bits that drill the smallest holes!) My largest drawplate is about .225" thick. The Byrnes drawplate is about .125" thick, and the Micro-Mark drawplate is about .096" thick. The Micro-Mark drawplate decidedly lacks the "heft" of the other two. Given the example of the Byrnes drawplate, I "lapped" the other two on their back ("exit") sides to "sharpen" their wood-cutting edges by taping a few abrasive sheets to the machined cast iron table of my Unisaw and took them down to a uniform surface finish of about 600 grit. This markedly improved their cutting smoothness. I have on a few occasions drawn annealed fine copper wire through these plates with acceptable results, but never having done so with a "real" metal-working drawplate I can't offer any comparisons between the two types of plates for drawing wire. I would expect that a goldsmith or silversmith would be far more demanding of the results than my limited experience permits! As much of a conclusion as I can offer from my limited experience is that a woodworking drawplate can be made to draw metal wire, albeit perhaps crudely by professional jewelers' standards, but a metalworking drawplate cannot be used to "shave" wood at all, at least not without taking the back ("exit") side of the plate down below the chamfer to the level of the sized hole alone as noted in the comments above. That said, while I've found this to be so only with round-sectioned material, I doubt the same can be said for many, if not all, of the many other drawplate section shapes available for drawing wire. It certainly would be convenient to be able to get out half- and quarter-round wood trim on a drawplate, wouldn't it? I currently produce half- and quarter-round trim stock with an Artesania Latina scraper applied to the edge of a suitably-thicknessed strip of wood and then cut the shaped edge from the strip on my Byrnes table saw and have no complaints beyond the tedium of the scraping. For those unfamiliar with these handy tools, they come in three separate sets ("Set A" through "Set C") of three scrapers each. Every shape is different. Available in the U.S. from all the "usual suspects" and sometimes on eBay. Priced between USD$10.00 and USD$17.00 per set of three scrapers. Pictured below approximately "life-sized." (Note below: Not my hairy thumb!) Note: I find it more effective to hold the scraper in a jeweler's hand vise with the vise jaws close to the working edge of the scraper. This further stiffens the scraper and gives better control of the scraper, not to mention saving wear and tear on fingertips! SET "A": https://artesanialatina.net/en/micro-tools/1295-micro-moulding-scrapers-a-shapers-for-wooden-plastic-models-miniatures-8421426273007.html SET"B": https://artesanialatina.net/en/micro-tools/1296-micro-moulding-scrapers-B-shapers-for-wooden-plastic-models-miniatures-8421426273014.html SET "C": https://artesanialatina.net/en/micro-tools/62355-micro-moulding-scrapers-c-shapers-for-wooden-plastic-models-miniatures-8437021128222.html

-

I have no experience with "blue mold" holly, but I've dealt quite successfully with mold on other wood species by bleaching it with a solution of oxalic or citric acid and water. Oxalic acid is sold in crystal form in paint stores as "wood bleach." (Don't buy "teak bleach" or other such products. Just get plain oxalic acid crystals marketed as "wood bleach" 'and follow the instructions on the container.) As I said, I haven't ever bleached moldy holly, but, to one degree or another, I've had success with bleaching other wood species. Oxalic acid wood bleach is relatively inexpensive, so you won't be out much if it doesn't work and you'll always have it to try on other species that you want to bleach back to "just cut" color. Do wear nitrile gloves or the equivalent when working with oxalic acid solutions. It's not particularly dangerous, but prolonged exposure to skin can cause acid burns and soaking your fingers in the stuff, which will first attack the soft flesh beneath your fingernails, but only start hurting several hours after exposure, is one of those things you'll probably only ever do once in your life. (Don't ask me how I know this! )

-

The Micro-Mark drawplate you've mentioned is insanely overpriced. If it is anything like the same item I once naively purchased from Micro-Mark ages ago, it's junk, probably made in India or Pakistan. Drawplates are not inexpensive. The decent ones are made to high tolerances of accuracy from high-quality steel, or even tungsten, but they run in the same price range, if not lower, than the crummy low-quality one Micro-Mark offers. The fact that Micro-Mark claims its "regular price" is $75.00 is ludicrous! Rule one on tool buying (which in this instance I broke, to my dismay) is to only buy a tool when you need it and then buy the best tool of that type you can possibly afford. Quality compromises will allow you to get a lesser quality tool, but in this instance, the Micro-Mark drawplate is at the bottom of the barrel in terms of quality and priced equivalent to, if not more than, professional level jeweler's drawplates sold by the top jewelers' tool supply companies. Drawplates come in various size ranges as well as a wide variety of extrusion "shapes.' You can get drawplates that will produce wire sizes with "star" shaped cross-sections, as well as squares, half-moons, diamonds, half-rounds, and so on. Obviously, a simple round shape drawplate is the easiest to make and will therefore be less expensive that the more difficult to fabricate shapes. While Micro-Mark is always an entertaining catalog and their sales are sometimes quite worthwhile if you know what you are buying, the best source of quality ship modeling tools will often be found in the catalogs of professional supply houses that cater to jewelers, and in dental and medical instrument supply houses. Check out what Otto Frei, one of the largest jewelers' supply houses, has to offer: Drawplates & Drawbenches — Otto Frei Otto Frei's least expensive offerings are priced about the same as Micro-Mark's offering, and up, but you should be able to expect that you will be getting a better quality tools from them. (Rather commonly, retailers that focus on the "hobby" market, will sell lower cost, lower quality products than retailers that focus on professional customers.) There is also a plethora of jeweler's drawplates listed for sale on eBay. Of course, eBay is definitely "buyer beware country," but if you examine the listings closely and avoid buying from an Asian distributor of knock-off tools, you may find some good bargains: jeweler's drawplates for sale | eBay

-

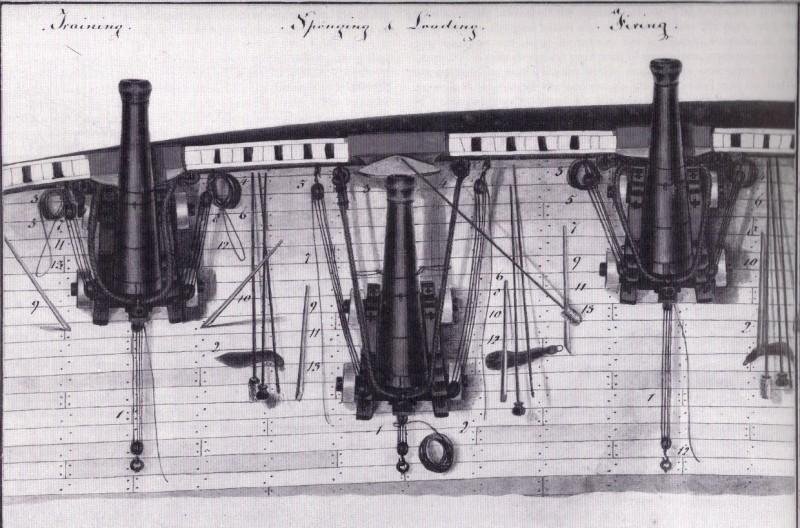

It wasn't until I posted the below comments that I saw Allan's post from Caruana. Fortuitously, it seems my deductions were correct. It appears that The History of British Sea Ordinance, volumes I and II need to be acquired! I was not familiar with the work. Thanks, Allan! On second thought, having just looked up The History of British Sea Ordinance, volumes I and II, I'm afraid I'll just have to pass at $450 each used on eBay! Thanks again, Allan! *********************************************************************************************************************************** I believe it had to be a little bit of both, depending upon the size of the gun, first and foremost. As the saying goes, "Different ships, different long splices." Heavier guns had larger breaching ropes and larger rope tied through rings doesn't lend itself well to the mechanics of tying knots, so bends are the more common means of attachment. Then again, three well-done seizings will hold as well as a knot and be easier to remove that a knot that's been pulled tight by repeated jerks from a bucking cannon. For lighter guns, which will have smaller breaching ropes, they might dispense with bends entirely and just employ seizings, particularly where the rope is turned about a thimble on the ring or, as in one instance illustrated below, a thimble on a clevis pin. For the purposes of modeling, the modeler may well decide that in the case of a smaller scale model, that a bend around the ring isn't a sufficiently noticeable detail to merit the work to tie them, while on the other hand, in the case of larger scales (and especially "gun station models") a proper commitment to accuracy at the finest level of detail possible will mandate that a proper bend and seizings are done. The below contemporary drawing of heavy guns shows what appears, albeit unclearly, to be breaching ropes that have been bent around the ring, much as a cable was bent around an anchor stock ring with an anchor bend finished with the bitter end whipped. In the below drawing the use of some sort of bend (an "anchor bend" it might appear) is used to secure the breaching rope to the ring in the same fashion as would a cable be fastened to an anchor stock ring with a bend and three whippings, the first being a throat seizing. Here again in the below photo of a gun station on an unknown museum ship, apparently perhaps of later construction than your late 18th Century, a purpose-built toggle and clevis fitting with the clevis passing through a thimble about which the breaching rope is simply seized with a throat seizing and two common seizings. Here, the thimble precludes the bend about a ring and provides a neater, more elegant connection. Detail of above arrangement, albeit without a throat seizing: Below are photos of guns rigged "for sea," rather than "for action." (Modelers always seem to depict all their models' armament rigged for action, even to the point of all guns run out port and starboard, which would only occur on a rare occasion when the ship would be "breaking the line" and firing as her guns bore simultaneously on the enemy ships of the line to port and starboard (and to devastating effect as Nelson demonstrated at Trafalgar.) When the guns were not manned and rigged for action, they would be rigged for sea, meaning that all extraneous tackles and implements would be stowed (likely below), the barrel would be secured, more likely in the fashion shown in the first picture, than in the second, which isn't clear as to what is being used to secure the barrel, although it is not the breaching rope), and then the gun would be secured to prevent its movement on the deck in a seaway perhaps with its tackles set fast. (If the ship were sailing in any fashion which would cause her to heel when the guns were in action, the leeward guns would have to be restrained from rolling "downhill" towards the rail by their inhaul tackle, while the windward guns would have to be restrained from running backwards inboard by their outhaul or "training" tackles.) In the first picture below, however, the positioning of the gun is incorrect. In a seaway, the guns would not be stowed run out through the bulwark or through open gunports. Not only would open gunports be hazardous in a seaway (the lower deck ports often being only mere feet above the waterline) but the stability of the ship would be enhanced by bringing the weight of the guns as far inboard as possible. The above "stowed" options may warrant more research as to the exact practice common in a given navy at a given period. I included these for the sake of completeness. Although cannon depicted as rigged for sea are rarely seen on models today, they can be a lot less work to model than gun stations rigged for action and, if one must, there's always the option to combine the two conditions, with a couple of chase guns run out and perhaps two, four, or six stations rigged for action as if the larger modeled vessel were running down a much smaller quarry.

-

Probably a receipt for the purchase of the bone or synthetic material would be a good first step. If a real problem was anticipated, I expect you could get a certificate from some sort of testing laboratory that confirmed, through DNA testing, perhaps, that the bone was not from a protected species. Bone, of course, is readily distinguishable from ivory, but I expect your concern is well-founded that it would be difficult to distinguish a piece of cow bone from a piece of bone from a whale or an elephant short of some sort of scientific analysis.

-

Not side-tracked at all. Interesting thoughts. Ivory is, of course, out of the question and I suppose elephant bone would also be similarly unavailable and illegal to trade in most everywhere in the civilized world. The laws are labyrinthine, though. Sometimes ivory is still released on the world market from various legitimate sources, such as national "treasuries" of confiscated poached elephant ivory. Some nations permit antique (over 100 years old) ivory items to be imported and/or sold, while others do not. Some permit exceptions for possession of musical instruments containing ivory, such as antique piano keys. Reportedly, the acquisition of "legal" ivory is not recommended because, due to changing national and international law, products made from protected endangered animals change so fast that one can't rely on any one law remaining in effect for any great length of time. As you probably know, the same is true for protected woods, e.g., African ebony and Brazilian rosewood, etc. These international trade restrictions commonly adversely affect musical instruments (with stories of famous musicians finding their prized antique instruments confiscated by the customs authorities when they travel internationally to perform, but they certainly threaten the same sort of nightmare for any "traveling" ship model which may contain now-prohibited endangered materials. My dentist is a very accomplished miniature carver, producing very fine human figurines of about an inch tall out of various materials used for dental prosthetics and the like. Not that I otherwise ever look forward to going to the dentist, but I'll have to ask her when I see her next what synthetic ivory-like materials are best for carving small details. Plastics pose the problem of possibly melting from the heat of a rotary carving burr, but there must be stuff dental technology has developed to get around that. As for bovine bone, one source I've found that's quite convenient is our pet stores here in the U.S. I don't know if the same is true in Germany, but all U.S. pet stores sell sterilized, fully dried cow bones in various shapes and sizes which are for the enjoyment of people's pet dogs. (They also sell "smoked" flavor cow bones, but these are stained brown and don't appear as the boiled, dry white bones used in the French prisoner-of-war bone models.) While I haven't gotten around to it as yet, I expect that when the occasion arises next, I will try cutting up some of these bones and epoxy-laminating them where necessary to obtain the size and shape of stock I require. Straight leg bones of eight to ten inches are available, as are knee and hip joint bones. The joint "balls" have a finer-grained texture and polish up better than the non-joint bone and can be as large as around three inches in diameter and solid throughout. Animal bones do have one minor drawback, however. If a rotary dental burr is used to carve them and the burr gets hot enough from friction to burn the bone material, it has a rather disagreeable aroma. I expect, though, that using a modern air turbine dental handpiece with a water-jet cooling feature should negate that. I think, though, that most carvers using dental burrs prefer to use the old belt-driven laboratory "dental engines" which are much easier to control in a "high(er) torque - low(er) speed" mode than the newer turbine and micro-motor handpieces that operate on a "low(er) torque - high(er) speed" basis and the slower speed should keep the heat down if one takes care not to overdo it.

-

Use of “other power tools”

Bob Cleek replied to kgstakes's topic in Modeling tools and Workshop Equipment

Yes, I've considered the Cricut as well. My daughter has one. The manufacturer's specifications indicate that grown wood or veneer up to 2.4 mm thick or plywood up to 1/8" thick (why they mix the measurement systems, I have no idea) can be cut on the machine. I suppose, theoretically at least, that computer data for an entire ship model, in some cases, at least, could be sold for use on the machine to cut out all the parts for a decent model. In theory, at least. It would have to employ some card stock modeling techniques. The machine surely has many applications for modeling, although most all of which I'm aware are already well-covered by existing technology. They seem to be a lot of fun to play with. Whether you need one or not, is up to you. -

This thread seems to have reached the level of sophistication where this short video of how N.G. Herreshoff measured the offsets from the carved half-hull models he initially created as the basis of each of his designs. It works great for a half-hull model-sized subject. Obviously, it would be rather cumbersome to build the instrument he used for the scale models he carved! While he used a geared dial measuring device, I expect a similar device with a scale on the measuring bars would work as well, albeit with less speed. All in all, it's a great illustration of how a table of offsets works. (The speaker is using a laser pointer and you have to look closely to see it on the screen in the video.)

-

That might be worth a shot. I'm sure there are contractual restrictions between German Frers and HR concerning disclosure of design details, but German Frers may be the one who held onto control of that distribution. I'd suggest approaching them as a ship modeler wishing to build a model of the design and ask if there is a way they can provide you with information sufficient to base a model on without compromising any intellectual property interests they may have. I don't know exactly how they do it, but most naval architects do produce what they call "study plans" of their designs which, while appearing to provide details of hull shapes, are not exactly accurate in ways that preserve the confidentiality of their actual work. Often, these "study plans" are sufficient to produce adequately accurate details for modeling use. You may get lucky and be able to obtain a "study plan" of this vessel from the actual design firm that drew it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.