-

Posts

911 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by giampieroricci

-

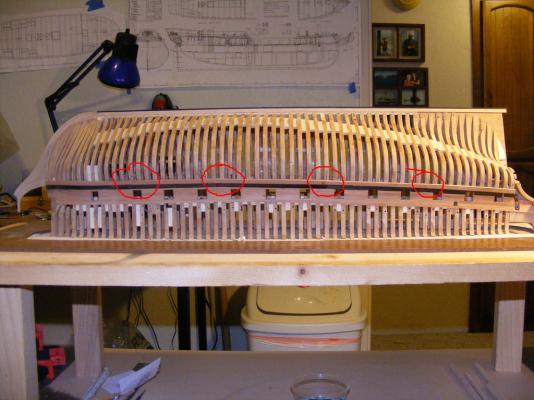

I started the construction of the gunwale, starting from the bow where must engage in the oarlocks. Everything is only hinted at plenty fat: it will be finished later

-

Oh! Sorry!!! With this: Synthaglass http://www.drtoffano.com/toffano_prodotti/pg_prodotti.htm

-

After several attempts came bad, I managed to make a window more acceptable; I do not know if I can, but I want to try to fix the two hinges to be able to open; will be very difficult to fix the hinges to the threshold ......... In the photos the window is stuck

-

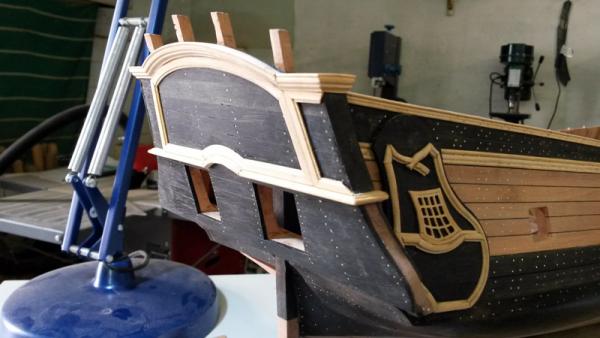

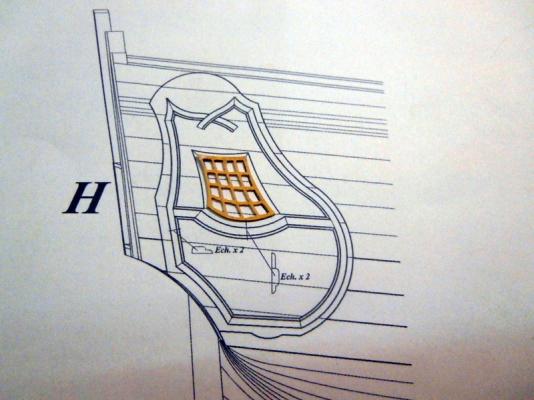

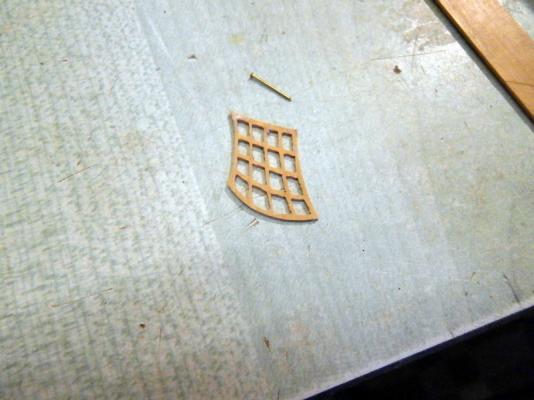

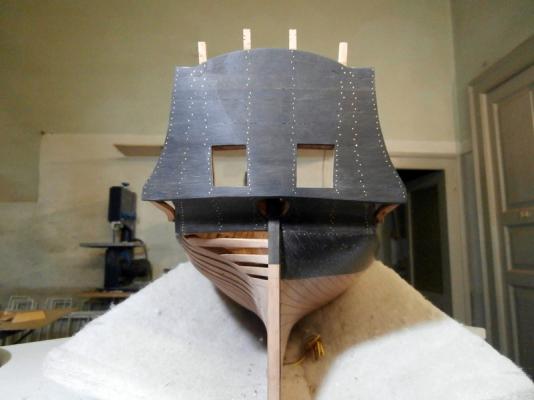

I started working on the transom, probably the less successful because of some asymmetry that I hope, completing the work, it is not too obvious. Meanwhile, I trimmed the excesses of strakes: I built the two stretchers of the transom: And the crowning that supports these stretchers: From this picture I get the impression that the courses tend to rise slightly to the left, although it seems not live; mah!

-

Exscuse me, Mark.... From the first picture I see that the plank of ebony has not a curvature harmonious but has edges a bit 'too accentuated. This could affect the lines and the beauty of the model! You still have time to correct this error!

-

I cut the excess The final result; I'll probably still reduce thickness because it seems a bit 'too much, but I'll do it later, when I finish the walled inside starboard and adjusted the length of the lead lining.

-

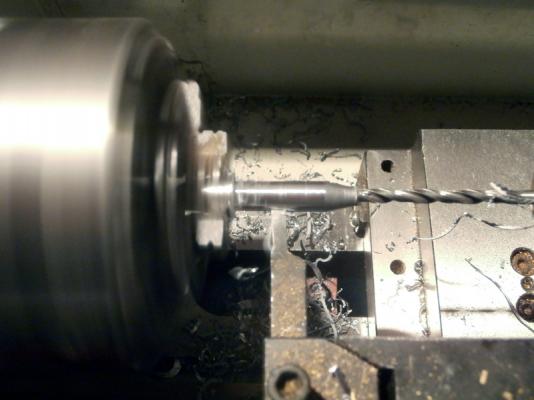

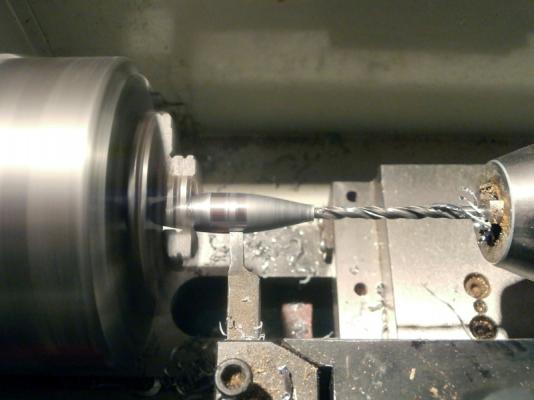

Before fixing the dolphins I believe I must cover the hawse pipes with lead foil. For this, I thought of using the commonest fishing sinkers, long enough and suitably machined on a lathe to obtain a kind of tube: Reached the diameter must have stuck in power, tapping it with a hammer. the tube in hawses

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.