-

Posts

902 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by giampieroricci

-

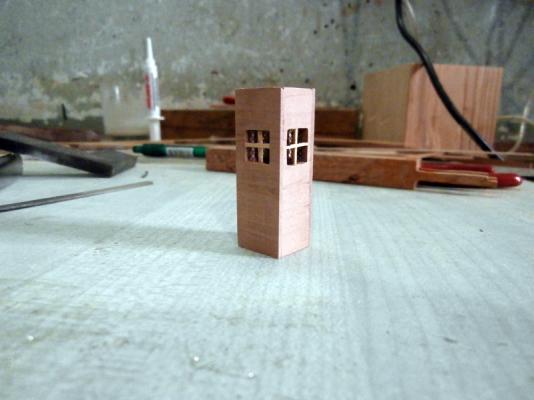

Thank you , friends! This is my first building of admirality model ship..... I'm trying to do my best! @Lee: where I find your log? Can you send me your link?

-

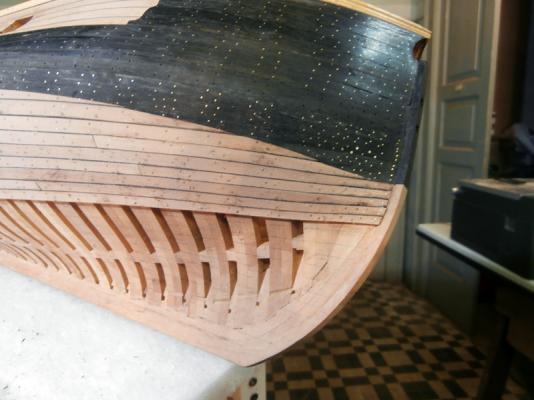

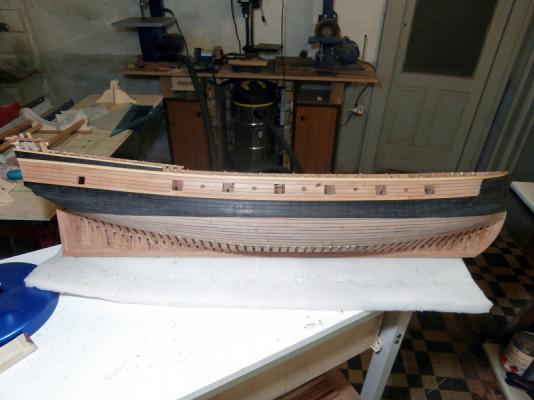

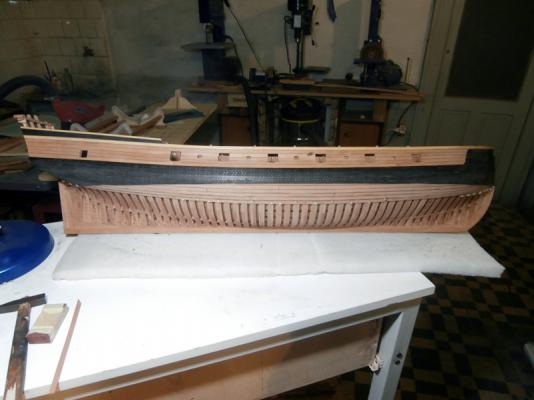

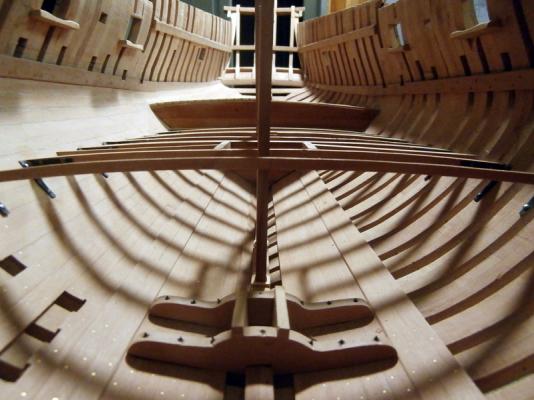

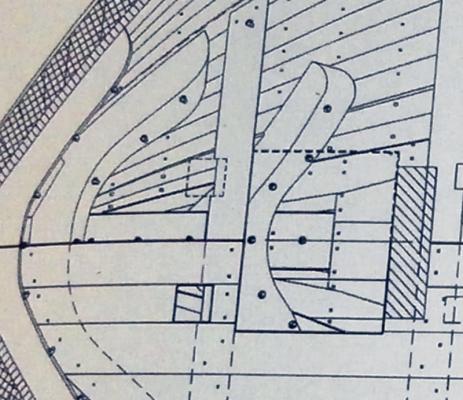

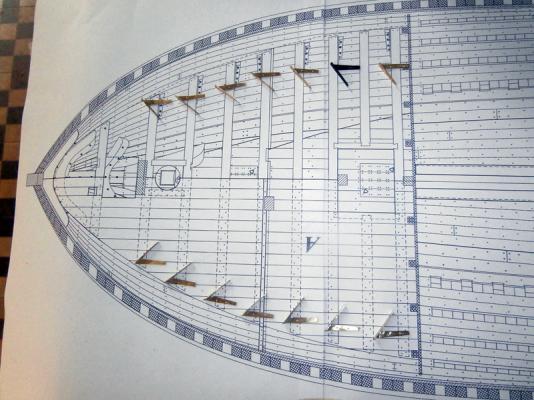

before continuing with the construction of the interior I thought it would be better to complete the planking of the hull of the starboard side: the side of the left will leave in carpentry. I drew with a pencil the locations of the strakes I started the laying of the first strips

-

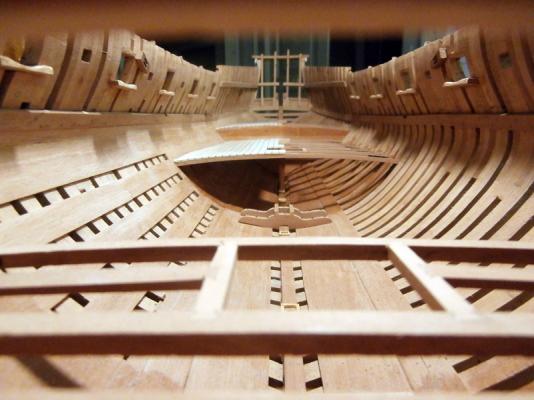

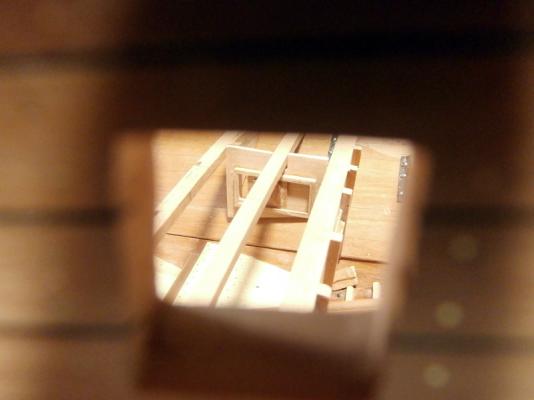

Thank you Giorgio!! But what you're doing is really wonderful!!!! I started laying the planks of the false bridge:

-

ancre La Salamandre by tadheus - 1:24

giampieroricci replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

wonderful work!!! -

ancre La Salamandre by tadheus - 1:24

giampieroricci replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Beautiful work!!!!! Why you used the iron nails? The iron oxidizes over time....... -

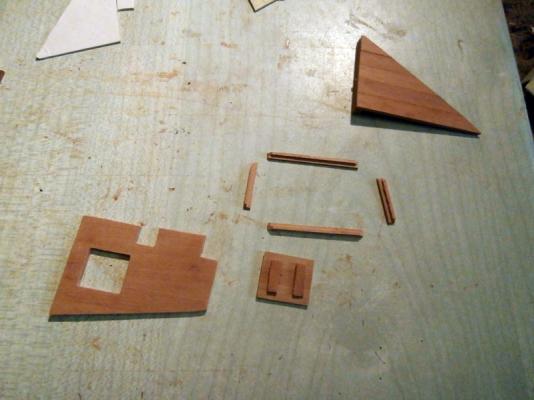

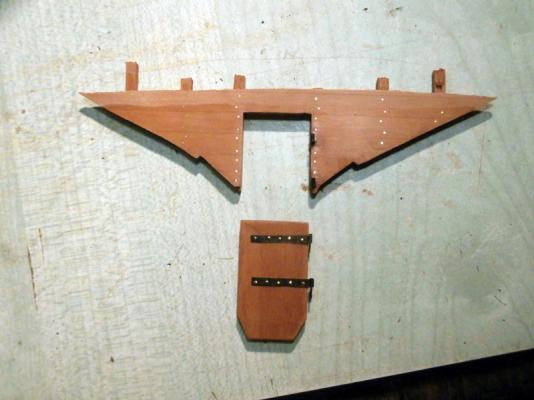

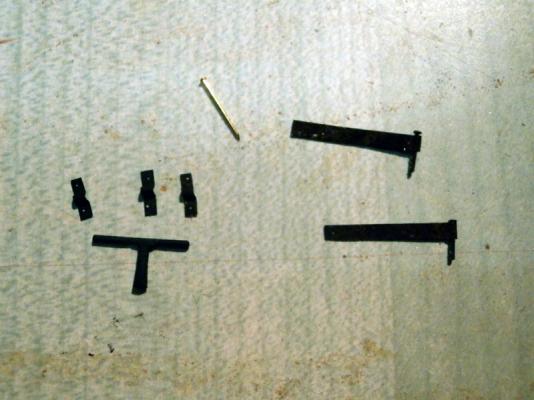

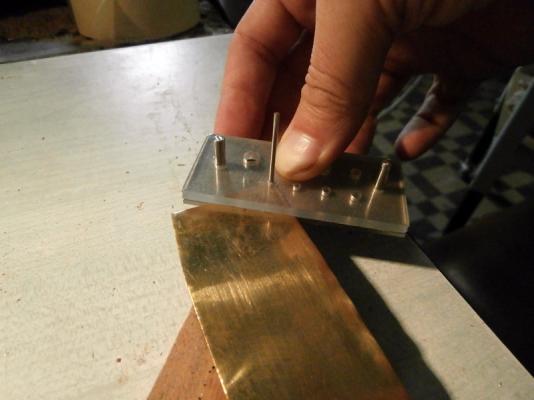

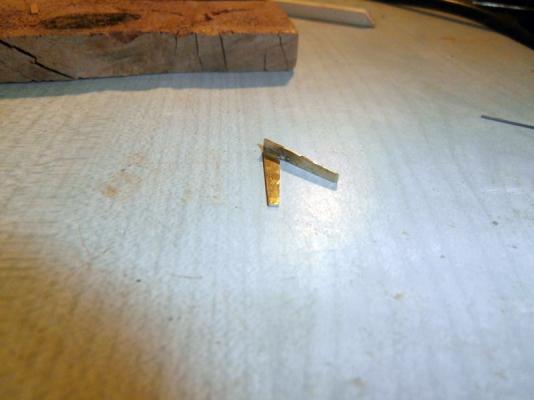

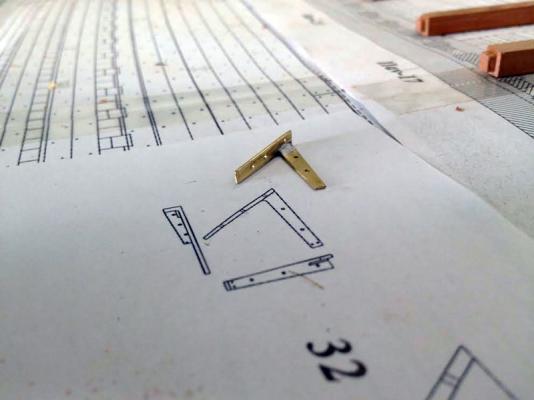

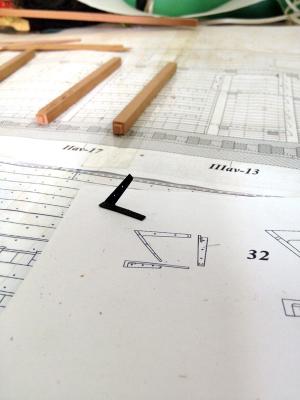

I tried an idea to remedy the problem of nailing garlands that does not conform to the drawings of the monograph, which some friends I have pointed out: Then I had a strange idea that in the end I think it has given the desired results: I tried to build the pins with washer using brass wire of 0.6 mm and thin brass sheet from which I got the tiny washers

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.