-

Posts

117 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kayakerlarry

-

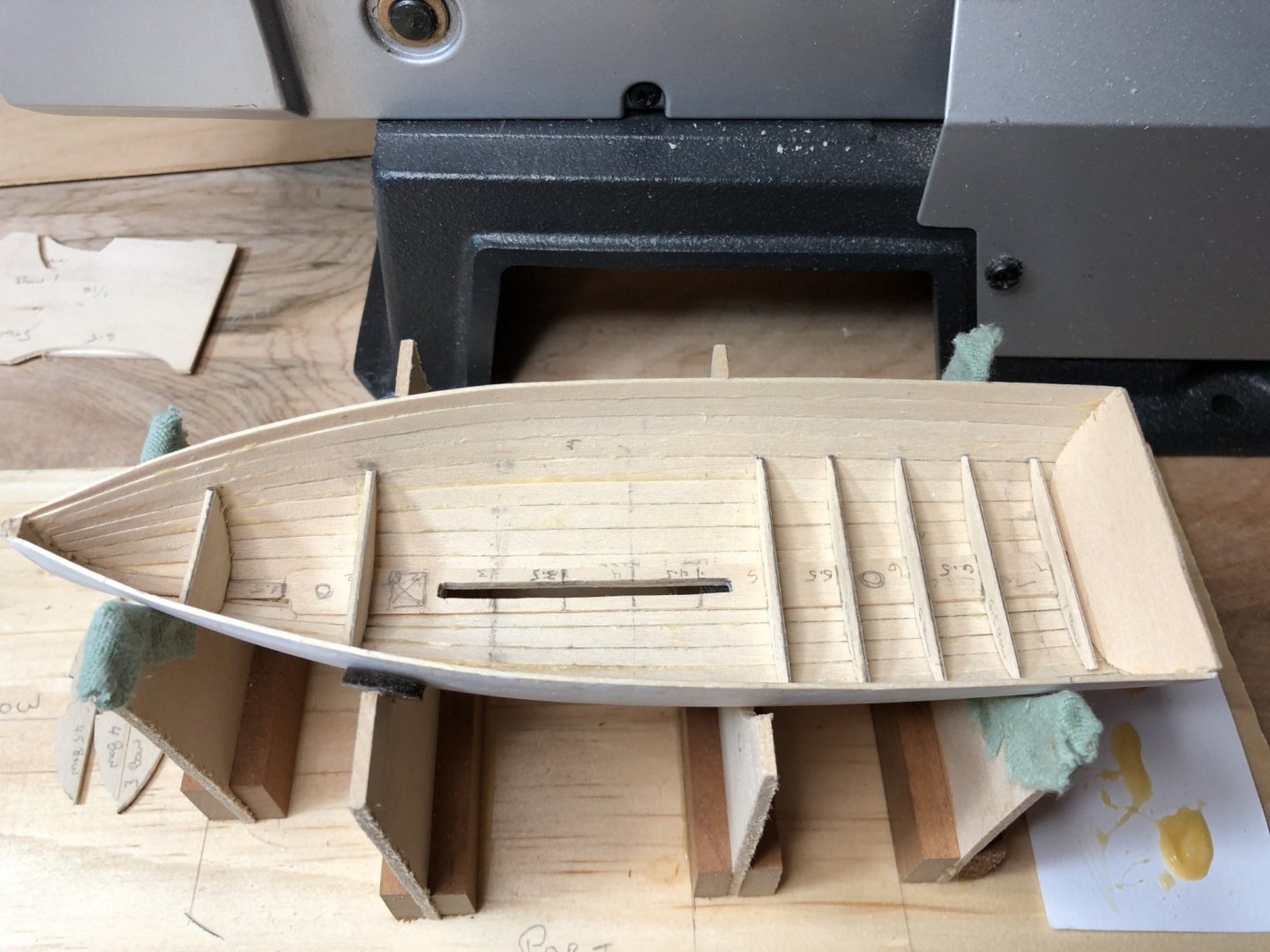

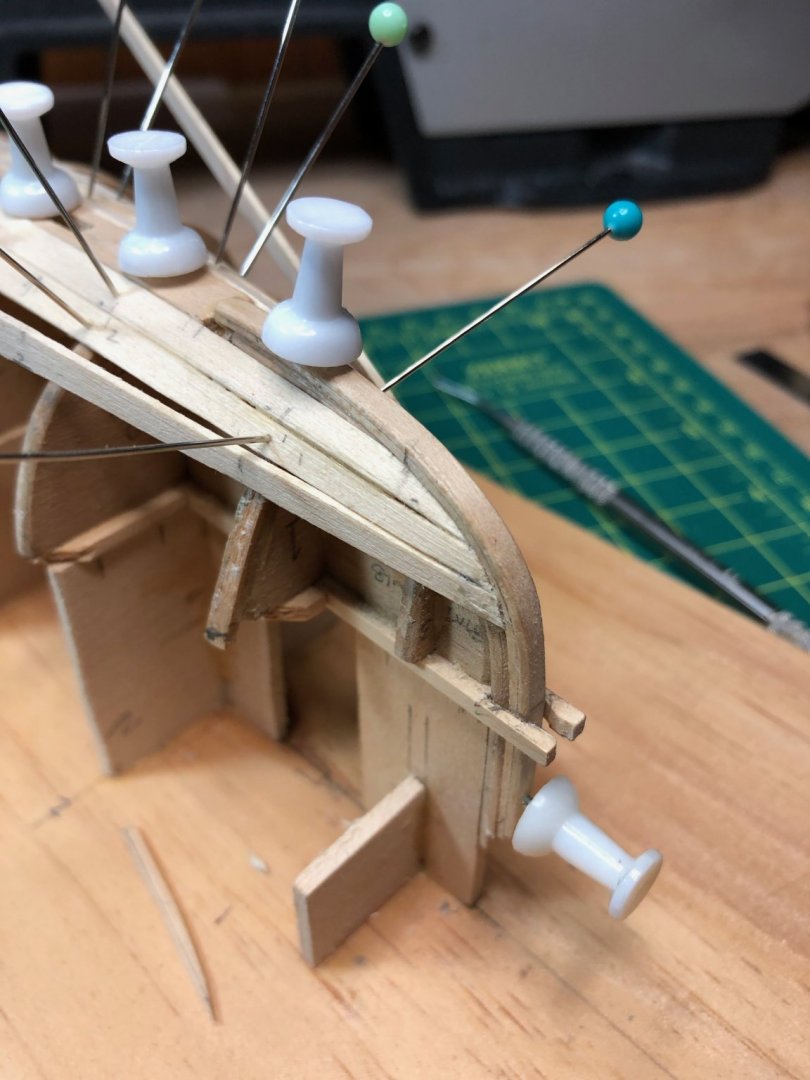

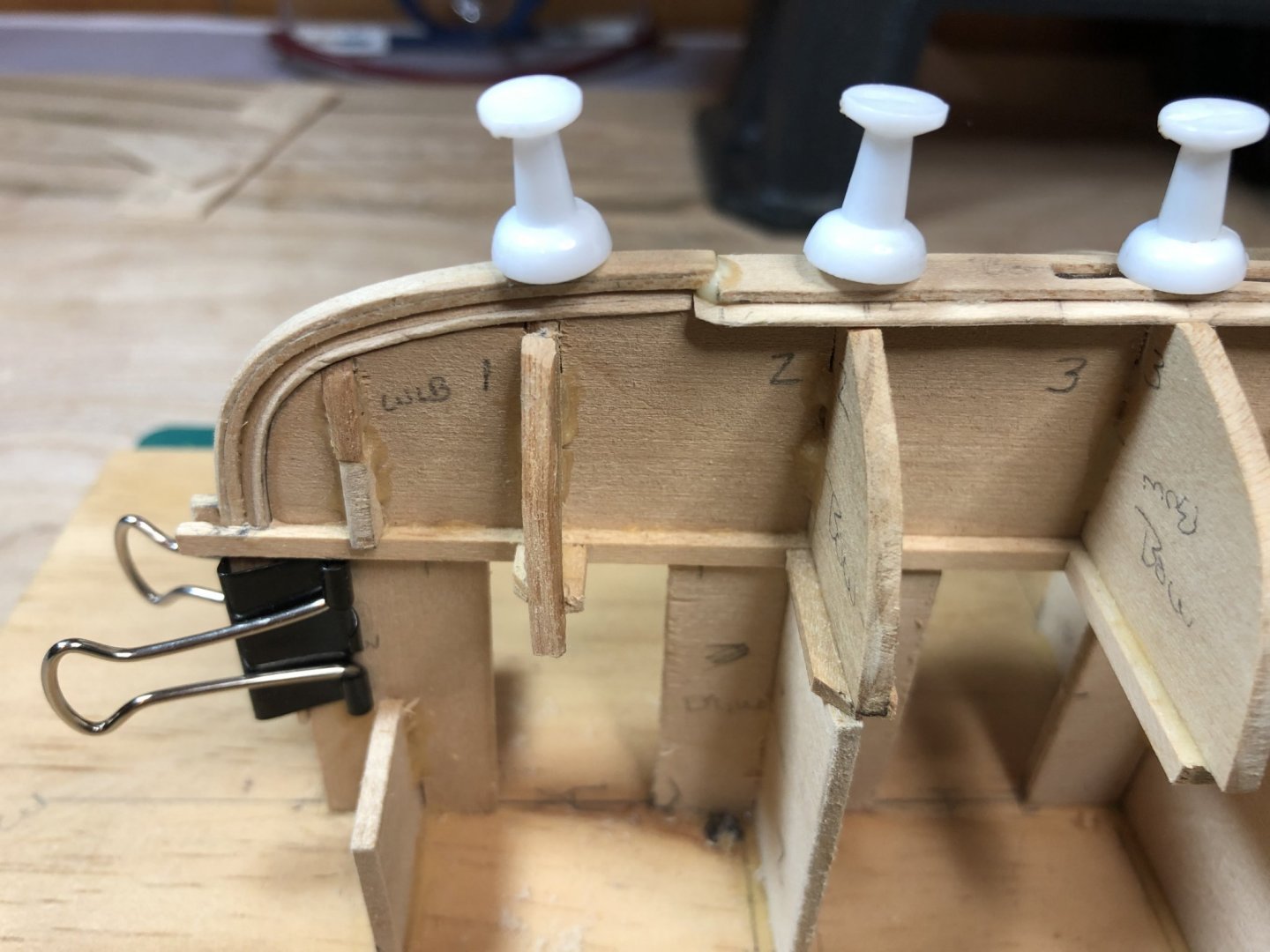

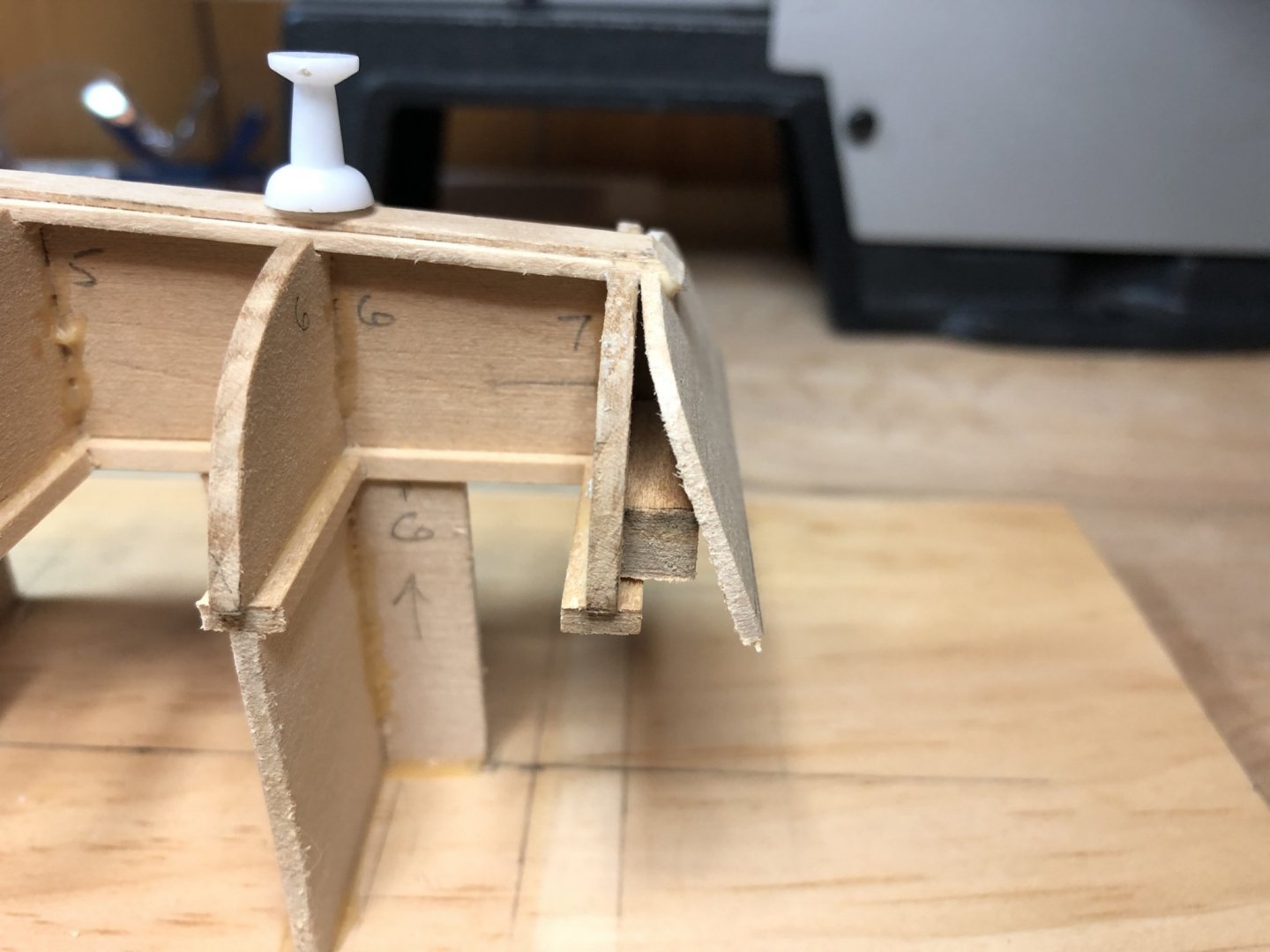

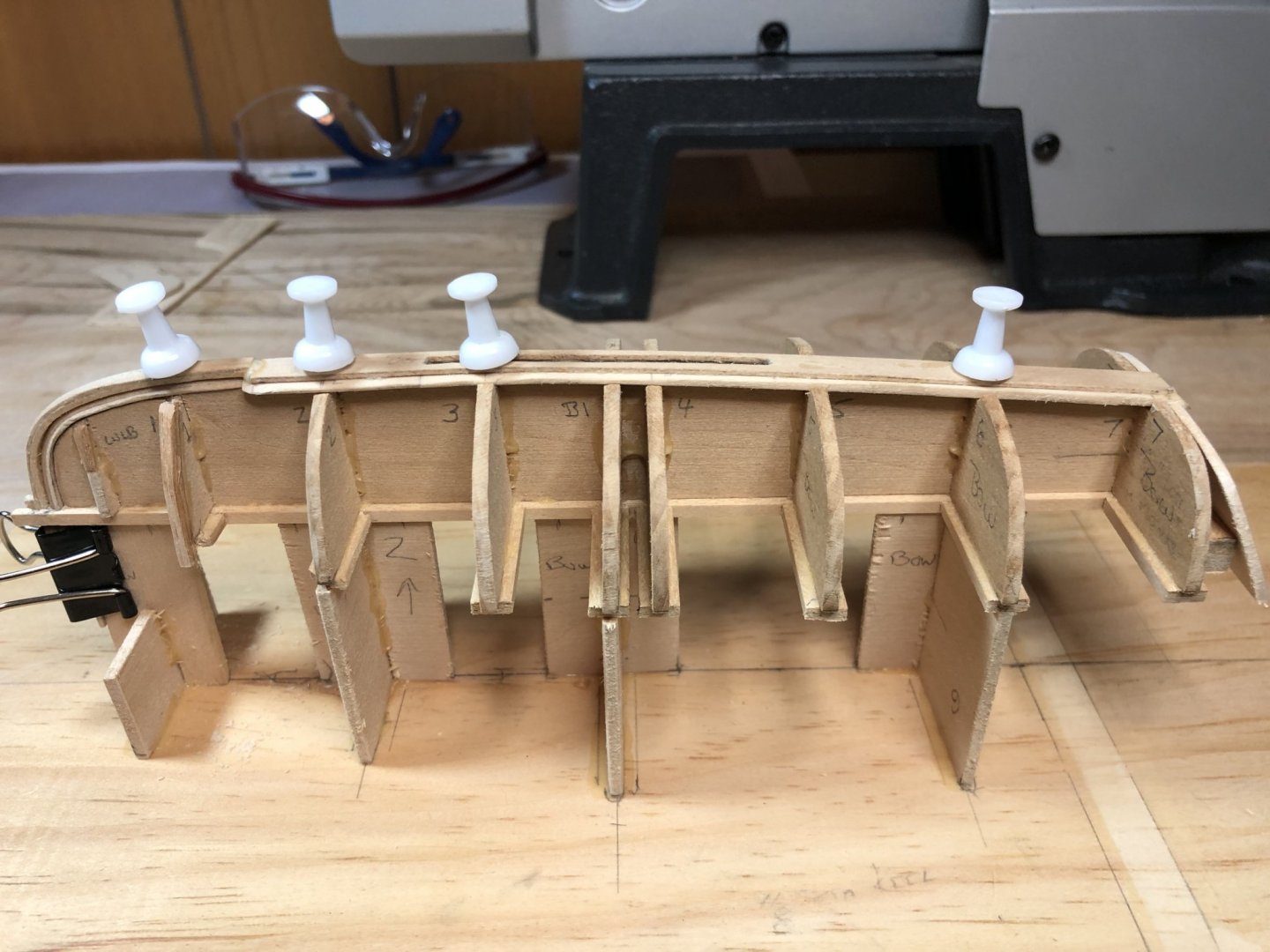

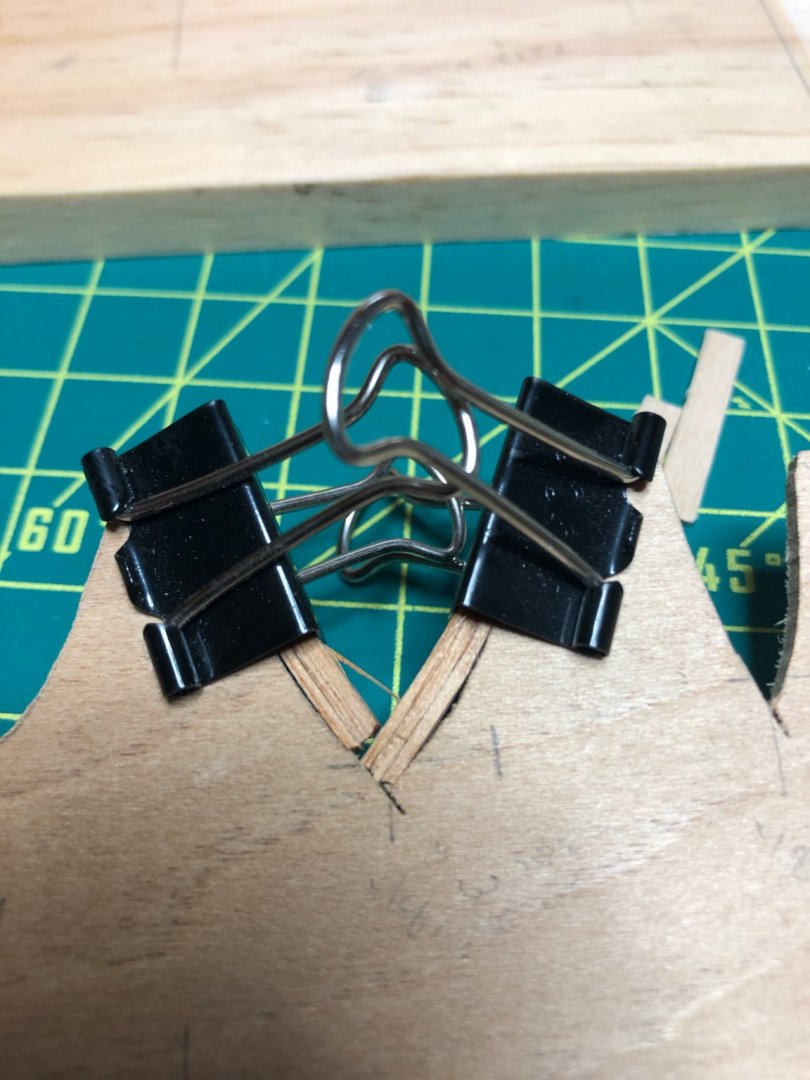

Frames for floorboards installed in stern. Next up build centerboard trunk and then install remaining frames on either side of centerboard. Remaining frames all cut (actually have outlined 3 remaining sets of frames on 1/16" sheet so there won't be any design work involved on next 3 boats). Then will install frames up from floorboard frames to top edge of planks on both sides - that should provide good stability so I can address the weak seams in the mid-ship planks. This time I remembered to deal with mounting blocks before it's too late so I have something to drill and insert brass rods (see circles). Mast is marked to go right in front of centerboard trunk. Thinking ahead I think one of my biggest challenges will be how to build the metal sail track sliders on the mast and boom and then the slides attached to the sails - if anyone has any ideas would be much appreciated.

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

Ready to rock and roll...good thing I only have to build one mold and one stand for the four boats! Frames are up next. Measured the beam width and it comes up short but I think I can expand the flexible midsection when I build the frames so they push out the sides.

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

Removed from mold without much problem. Had to put a bit of carpenters glue "caulking" between a few seams to strengthen the thin sections from the inside. Thank goodness for my dental tool plaque remover to scrape off a few protruding glue burrs. Light sanding and now building the stand to work on inside - frames next.

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

Thanks, all. Moab - I just hope I can complete all four boats by next August! My current plan is to donate the first two I build (Loon and Hawk) to camp (Loons and Hawks are around Maine lakes), the third (Gull) I keep as that bird is certainly common on the Maine coast where I live and the fourth (Falcon) will either go to my cabin counselor who introduced me to sailing when I was 10 or to son of the camp director who was a year ahead of me and as trumpet players we both played taps on the lake. Hopefully my next four months working at H&R Block don't interfere with my modeling...could be some long days after April 15th!

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

Planking finished... and sanded...but was a little too aggressive in midsection where marked trying to get smooth but a 1/32" plank can't be sanded too much! so tried my first attempt at using wood filler which seemed to work pretty well. Used Exacto for "putty knife". Will sand next and then remove from mold and work on internal frames to give some stability.

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

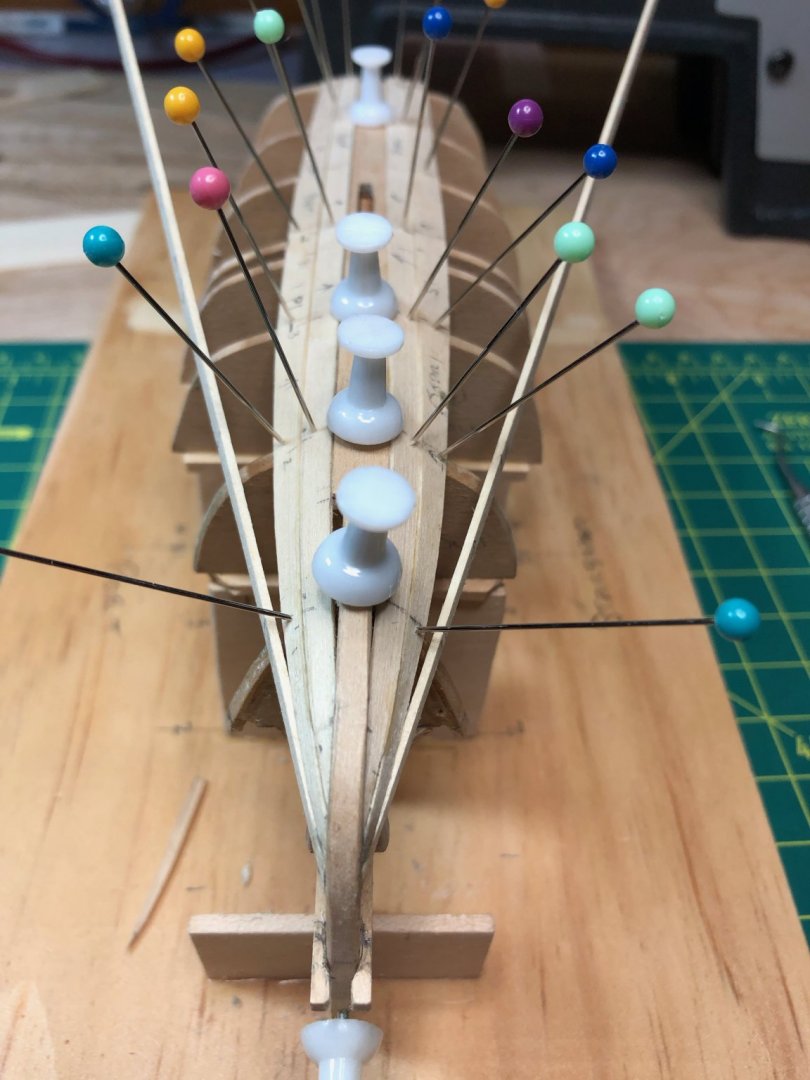

Wasn't happy with the lay of planking at frame #1. Obviously my hand drawn lines were not quite right. Will add a few pieces of planking wood to build up the extra space and sand to achieve more realistic lines. Soaked planking and shaped by putting into cut out for frame #1. Let's hope this works.

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

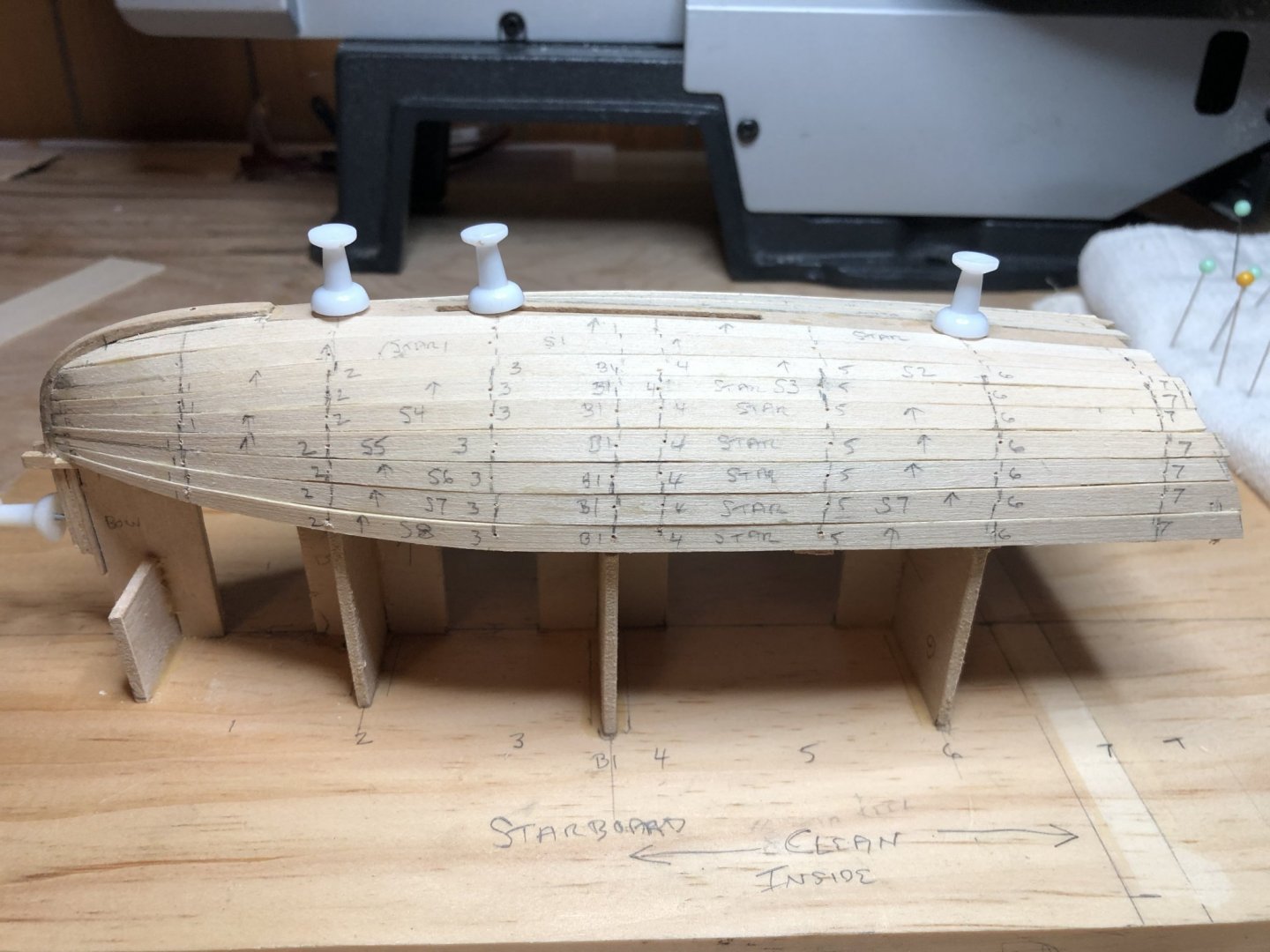

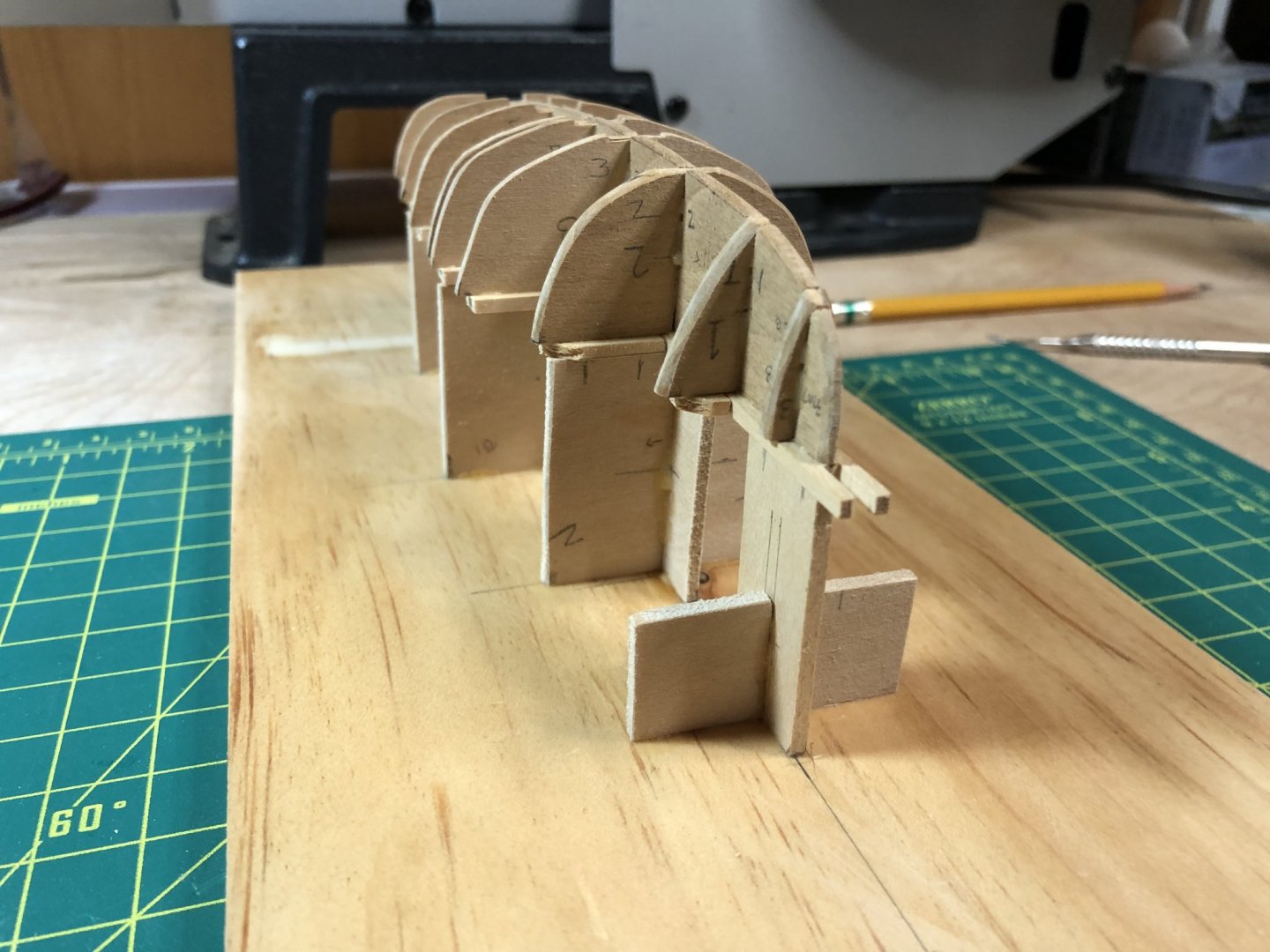

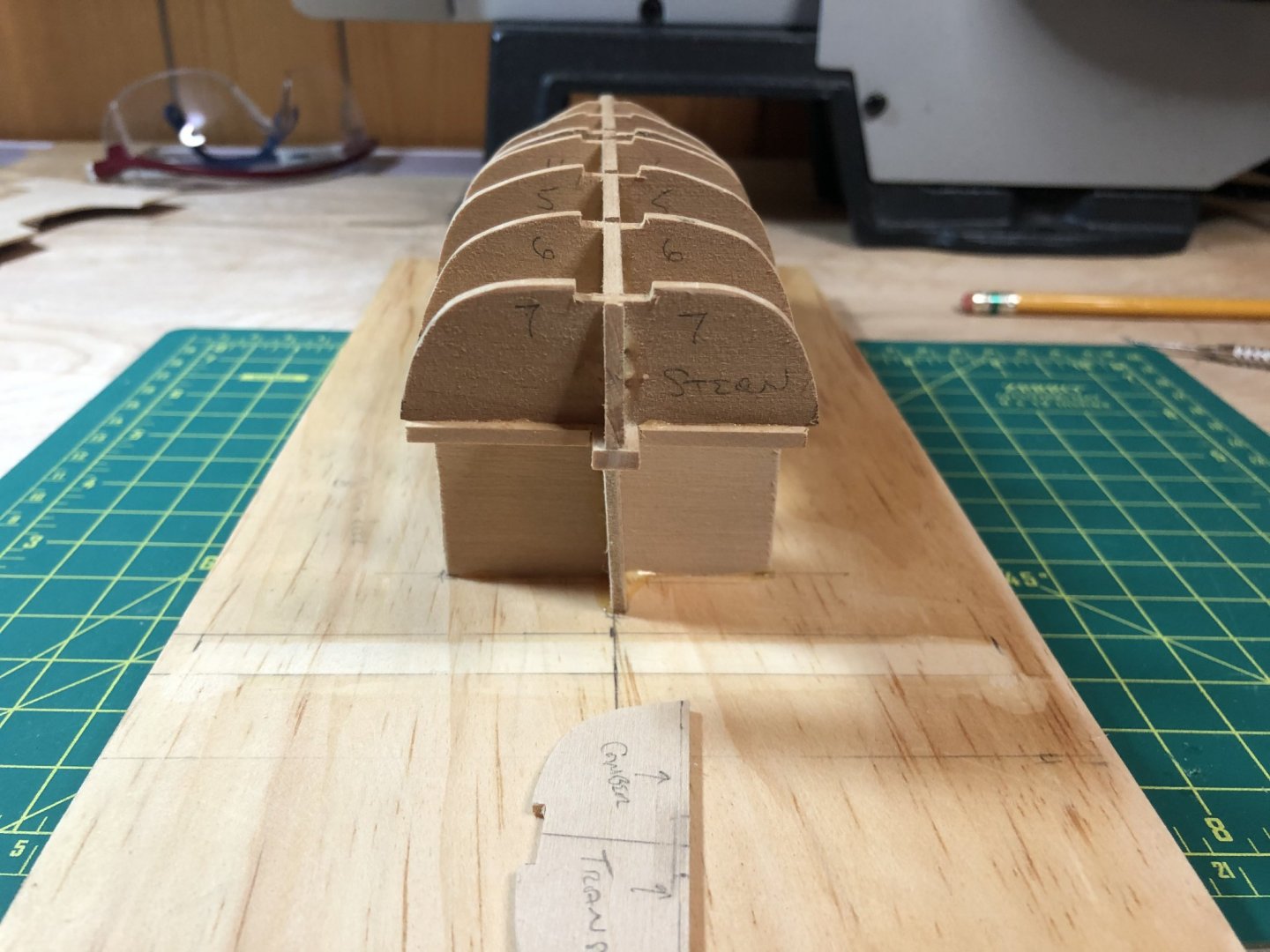

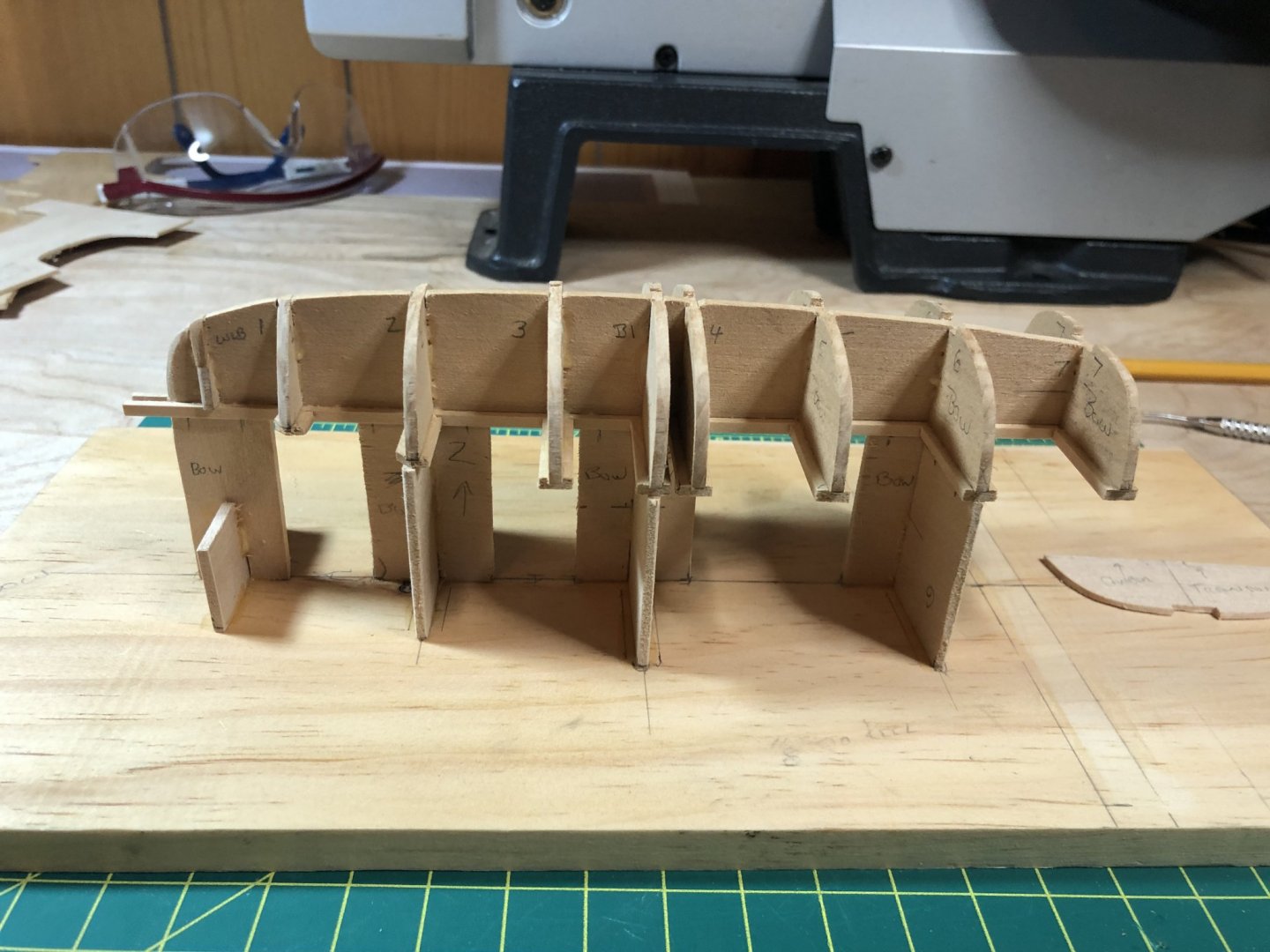

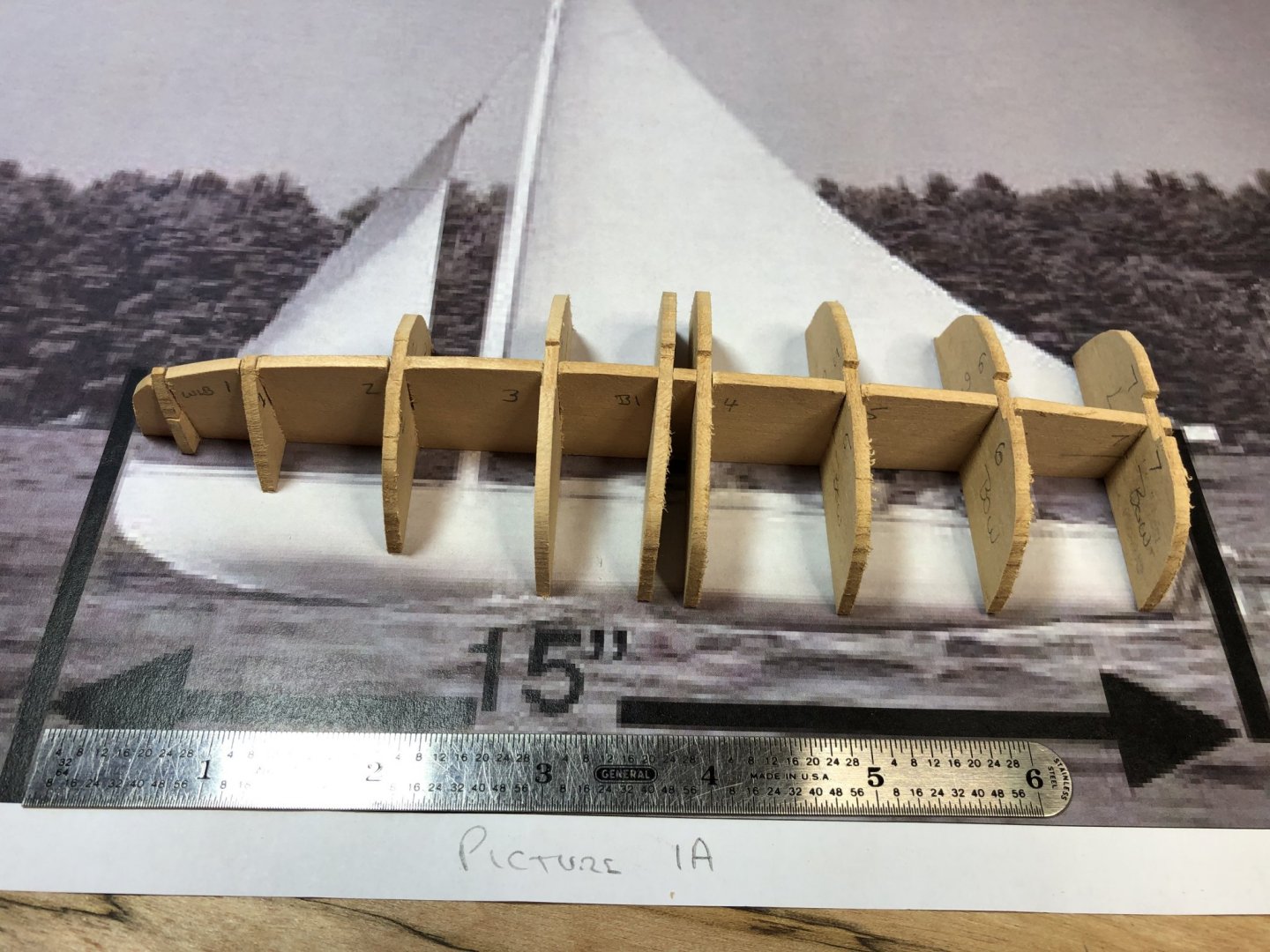

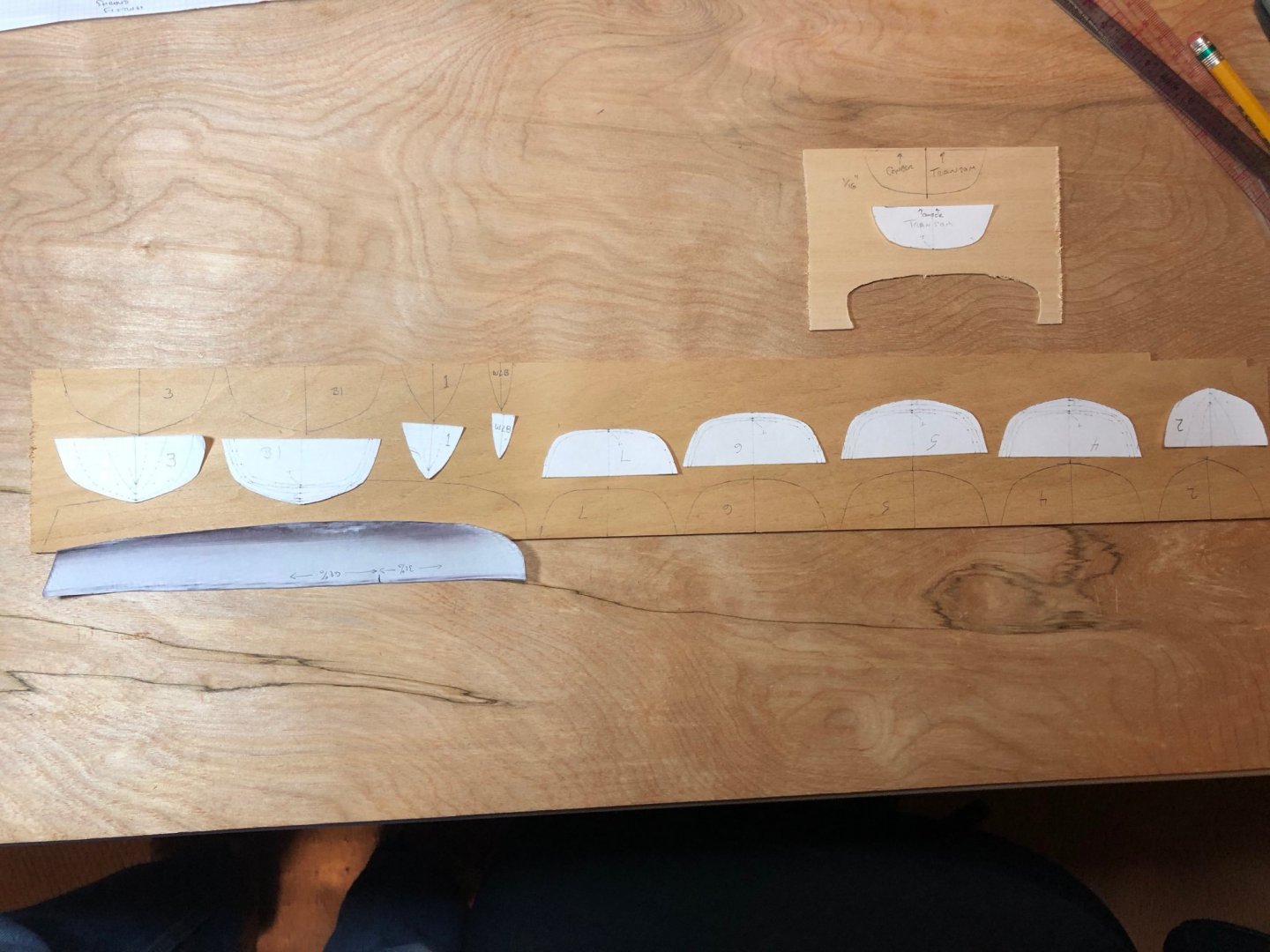

Mold cut, camphered and glued. Reasonability happy with how the frame molds came out as they seem to be a decent representation of the actual hull shape in the pictures. Next step will build the horses and mount mold to horses, cut and laminate bow keel pieces, cut and install 2 keel pieces with centerboard slot (note the slots for the flat keel pieces so I can keep the rounded hull bottom when planking)

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

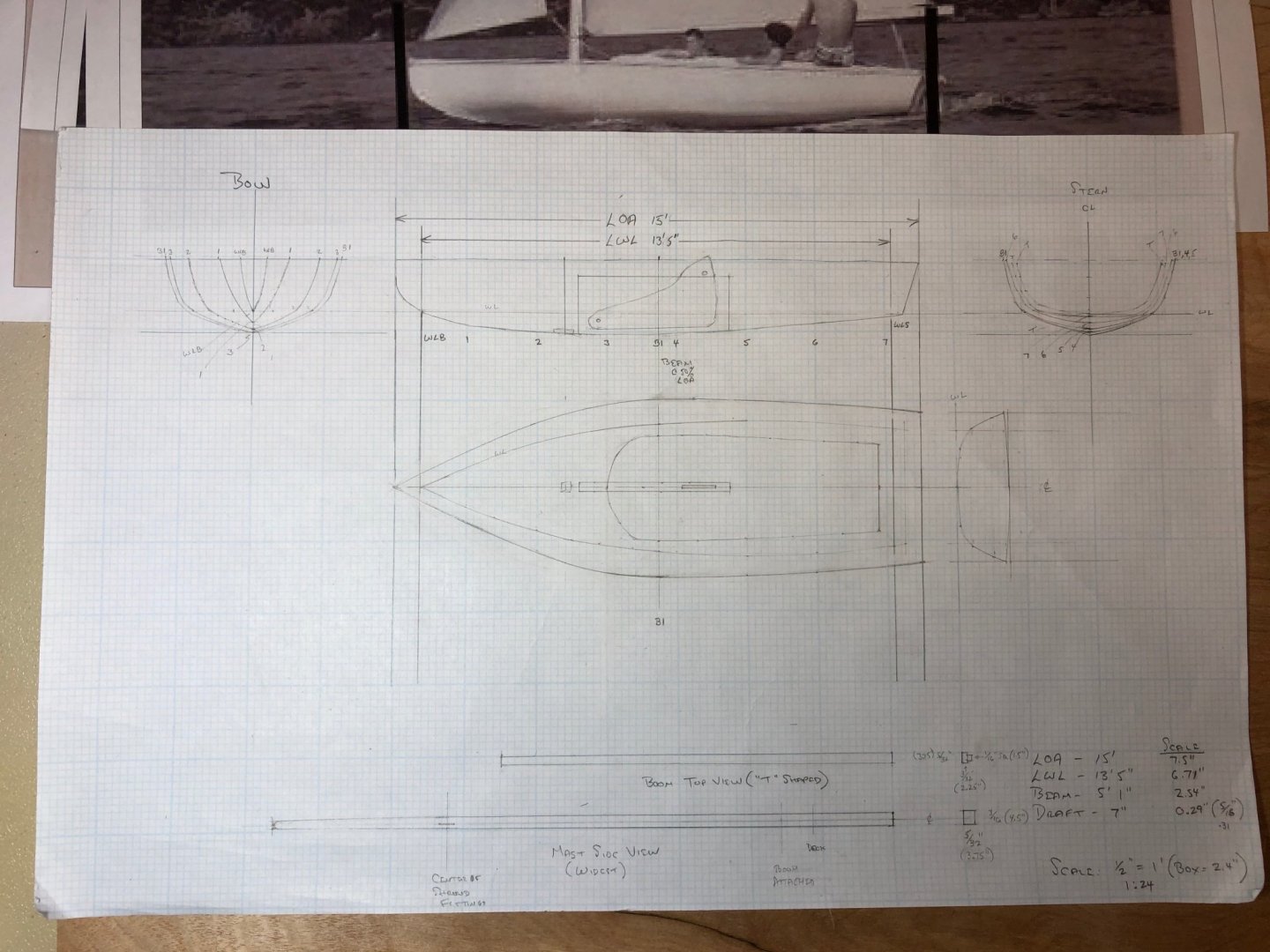

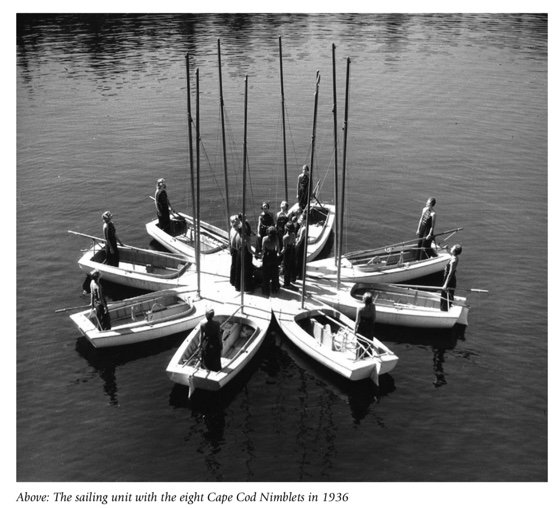

Plans are mostly complete and ready to cut the bulkhead frames for the mold. Based on my correspondence with the current president of the original manufacturer (Cape Cod Shipbuilding Company) they "built wooden boats upside down, which assured better quality". Therefore I will use the same mold methodology as I started (and put on hold for this project) for the New Bedford Whaleboat. As a rounded bottom with no protruding keel I will need to modify the process from the Whaleboat but I'll determine that as I proceed. To get a lot of my dimensions I have used the two boats in the 7 and 8 o'clock positions in the 1936 sailing unit picture above using ratios between known measurements and photo measurements (as best I could) - obviously the angles hamper a "true" measurement but unless someone has a better suggestion this will be the "answer"...

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

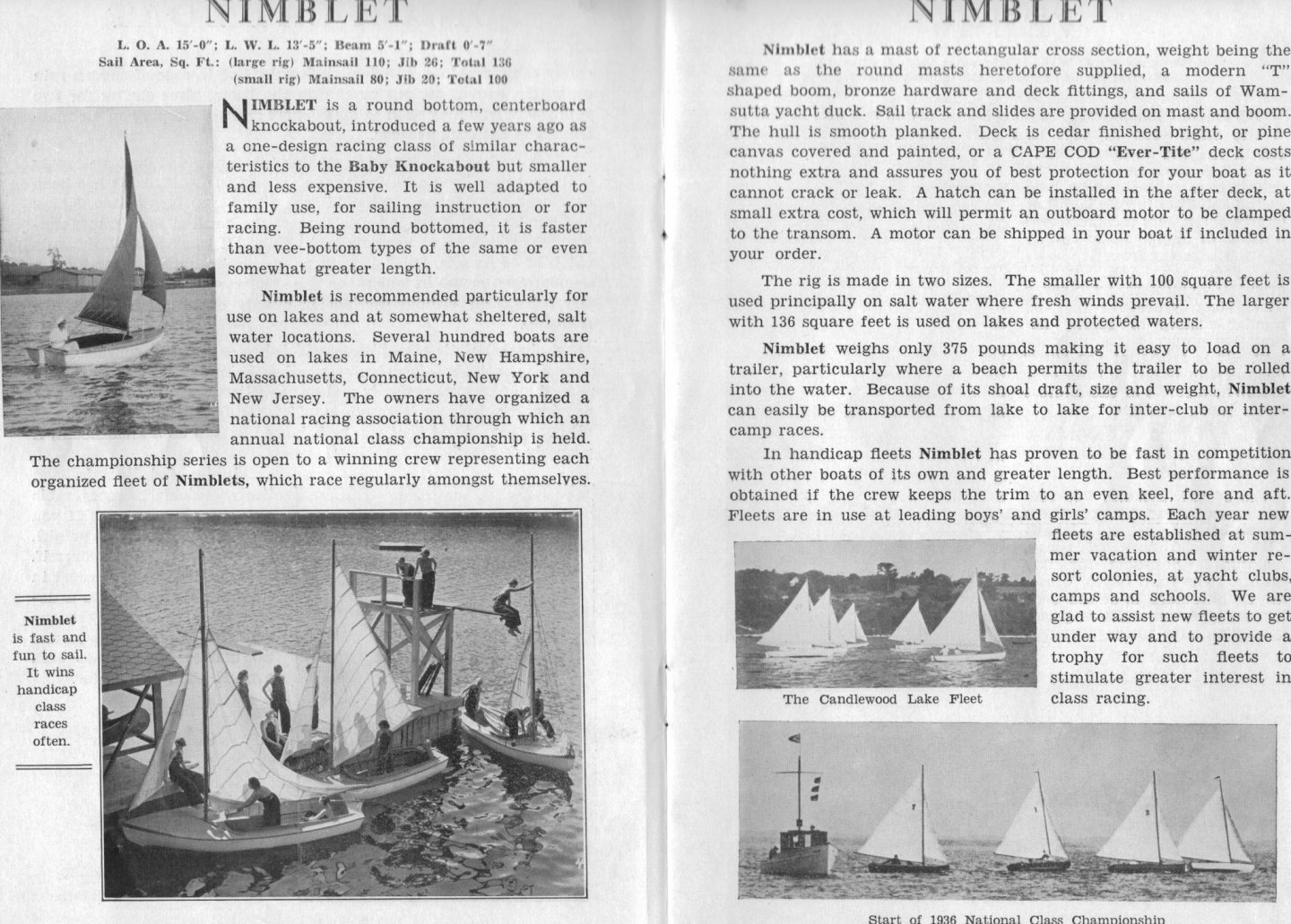

Hi John, Not a Gunter rig - it's a simple sloop rig with metal sail track and slides on both the mast and boom - see specs in the 1936 brochure that was provided to me by the boats original builder, Cape Cod Shipbuilding Company. The problem I'm going to have is that I still "vaguely" remember all the parts and will now have to properly model them to scale. Larry

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

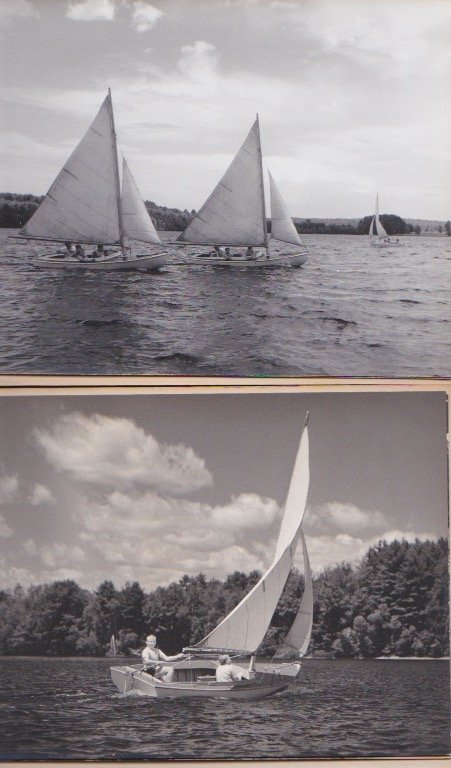

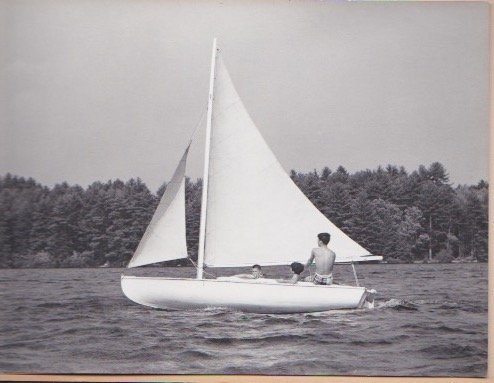

I previously posted a topic on how to take lines/plans off photos for a very basic sailboat that I learned how to sail in way back when...the camp in Maine where I went had four of these boats and I would like to build scale models of the four boats (named the Loon, Gull, Hawk and Falcon) for the 100th anniversary of the camp next August and donate them at the event. Obtained this brochure page from the president of the company that manufactured this boat (Cape Cod Shipbuilding Company) but no other records exist. I do have several pictures of the boats under sail from old camp pictures and a memory of how they worked but if anyone can provide any additional pointers that would be very helpful. Didn't have any responses so I decided to just dive in to the project. Four of these boats that were purchased by Camp Wohelo were eventually purchased by Camp Hawthorne Here are the boats on Panther Pond, Camp Hawthorne, Raymond, Maine. BTW, the skipper in the first picture is yours truly during my stint as Sailing Counselor in 1967... Current progress to follow...

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

- 43 replies

-

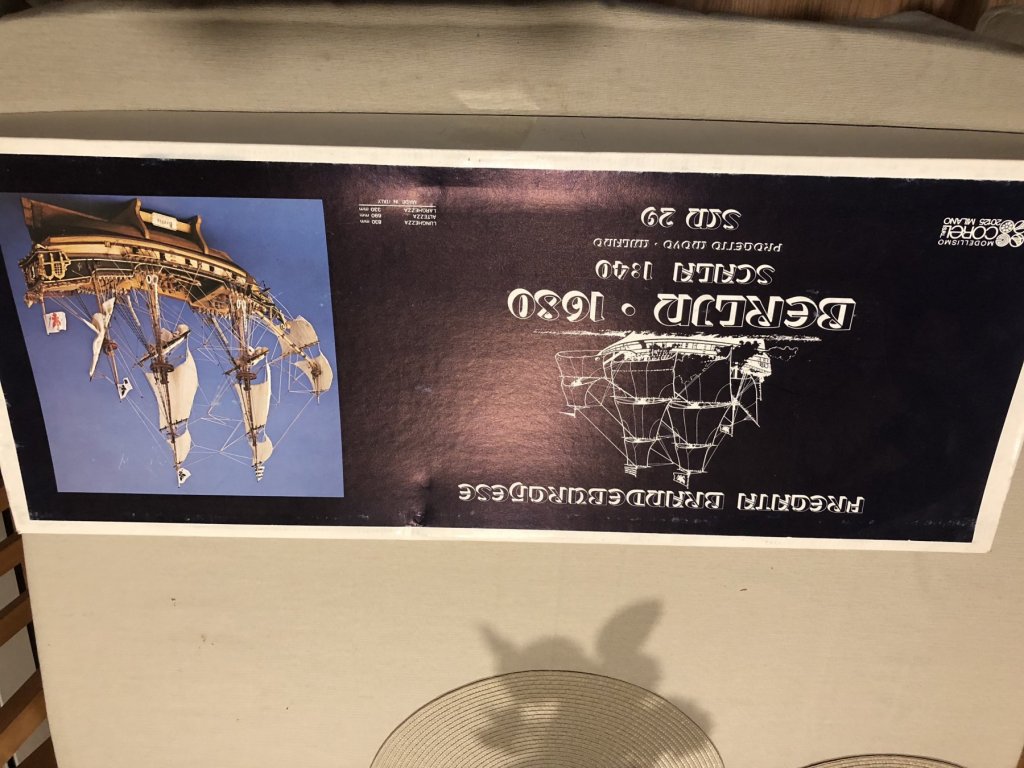

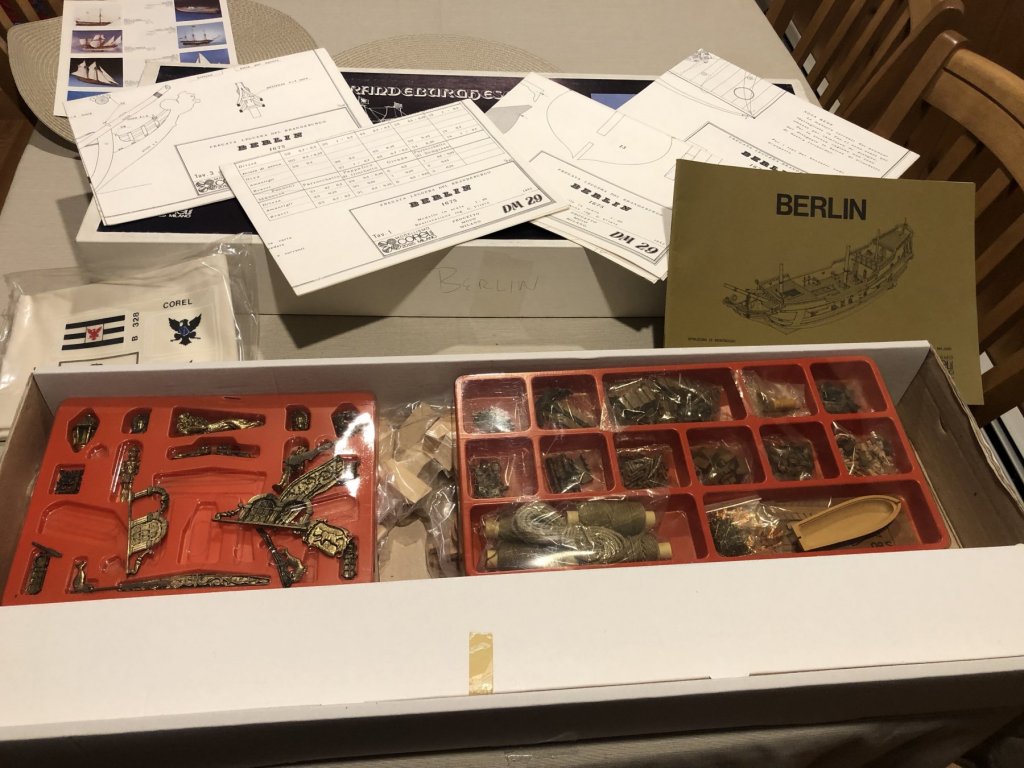

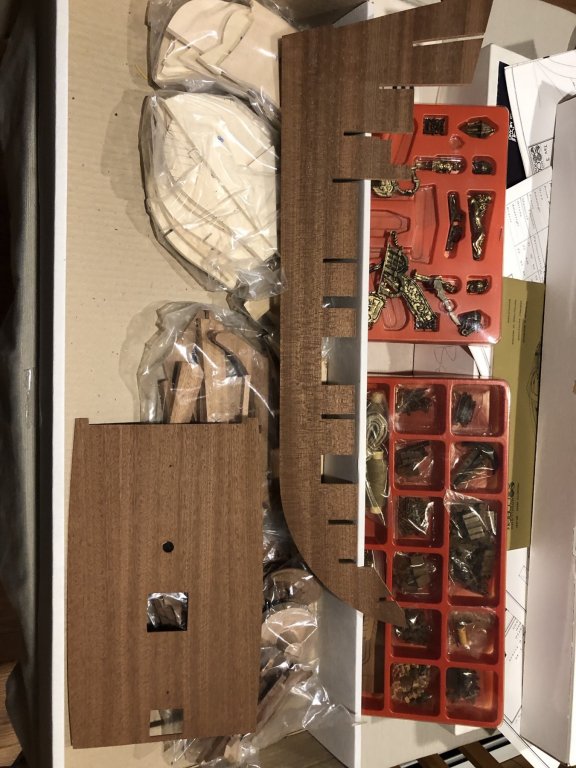

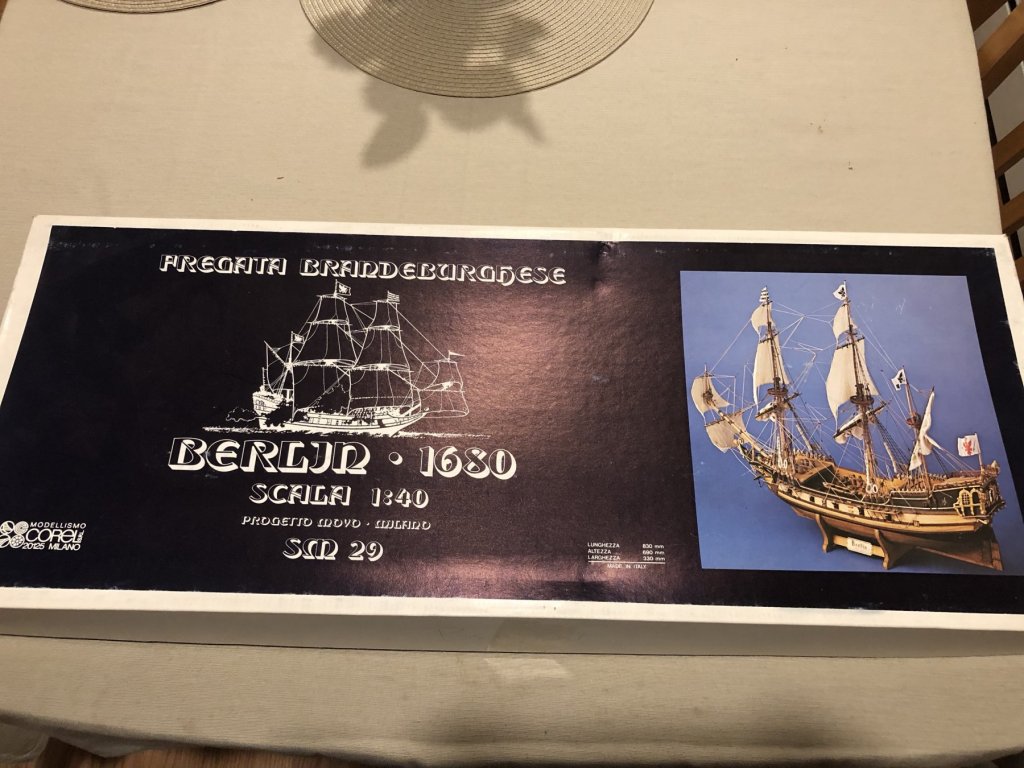

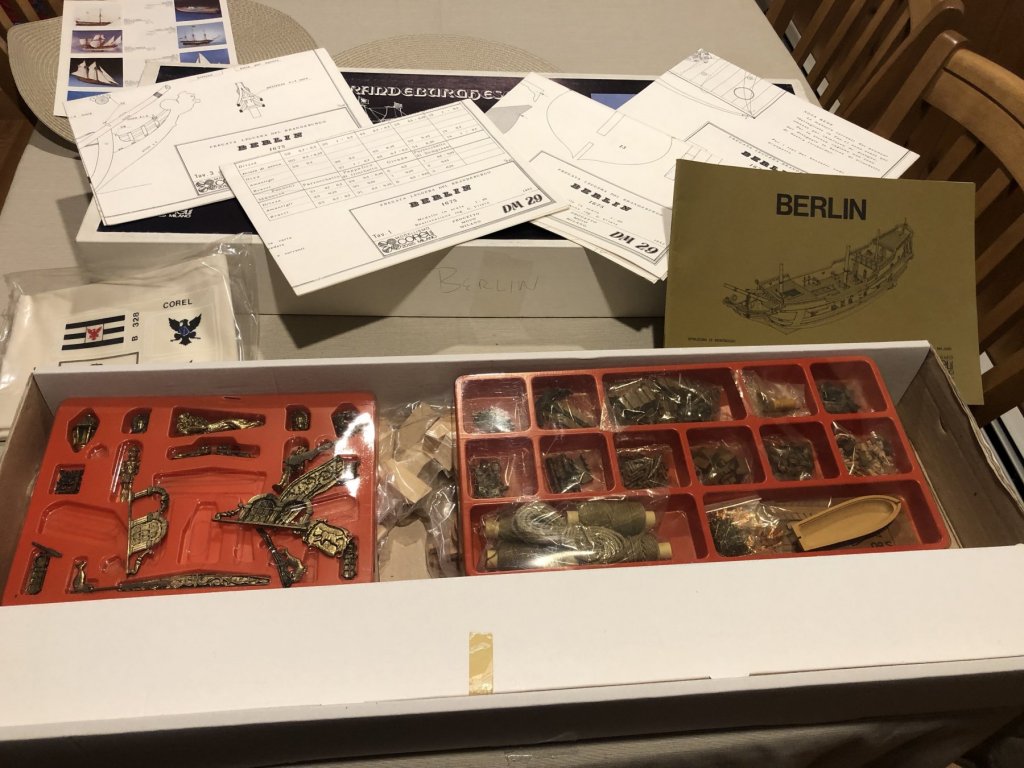

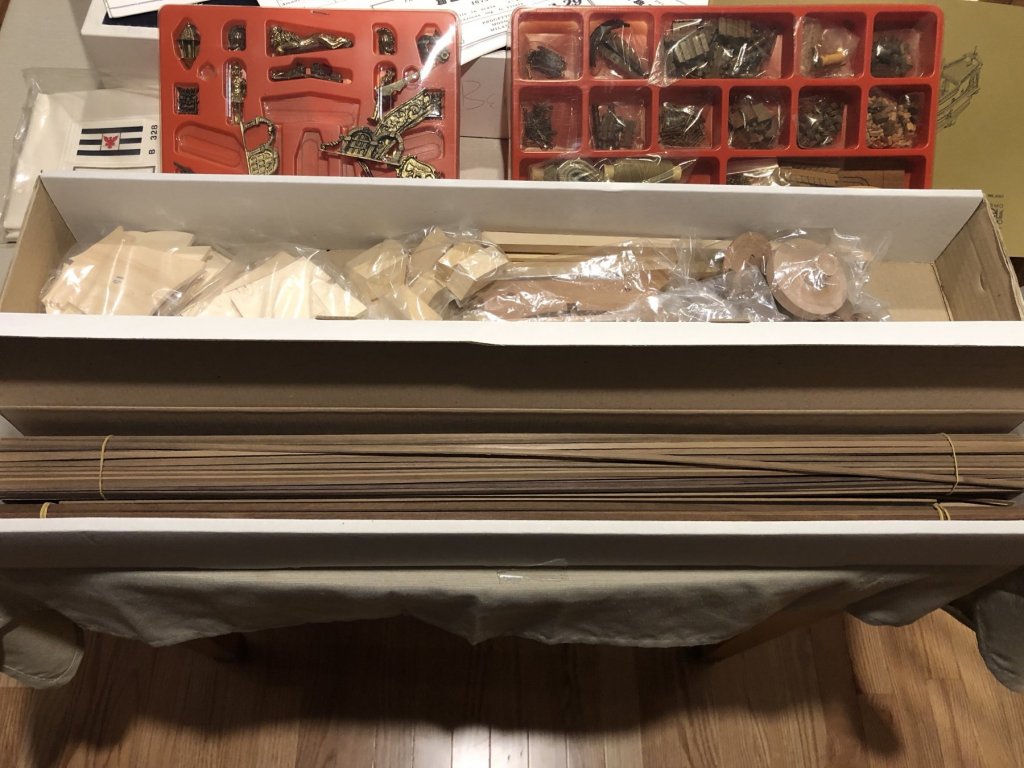

Complete Berlin kit for sale - $350. Trying to clean out models I will never build (working on New Bedford Whaleboat and have Puritan and La Toulonnaise in storage). If any interest will set up PayPal account. Located in Scarborough, ME. Did Google search on model and cheapest I could find was $479 with most coming in at $600+. Will pay postage up to $50.

-

Thanks, Mark. Here is her final resting place on stair landing - we are going to do a kitchen/living room reno and perhaps she will get the place of honor in the living room built in... Model Shipways New Bedford Whaleboat just arrived today so hopefully this one won't take me 5 years! Thanks for everyone's support and guidance. Larry

- 43 replies

-

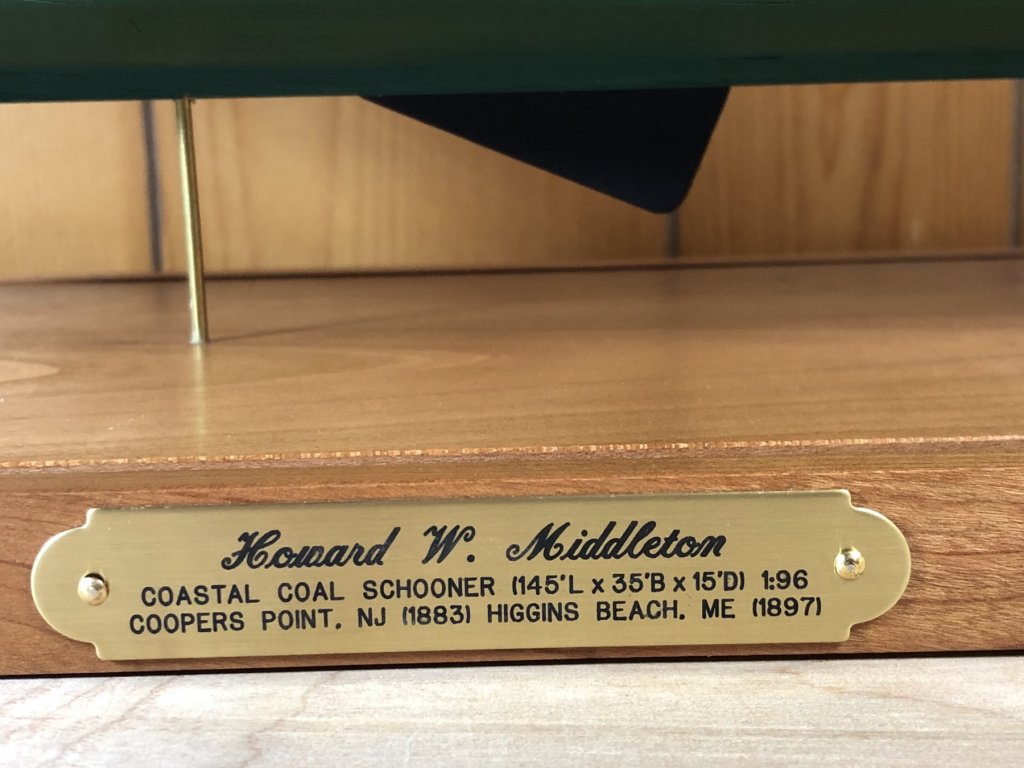

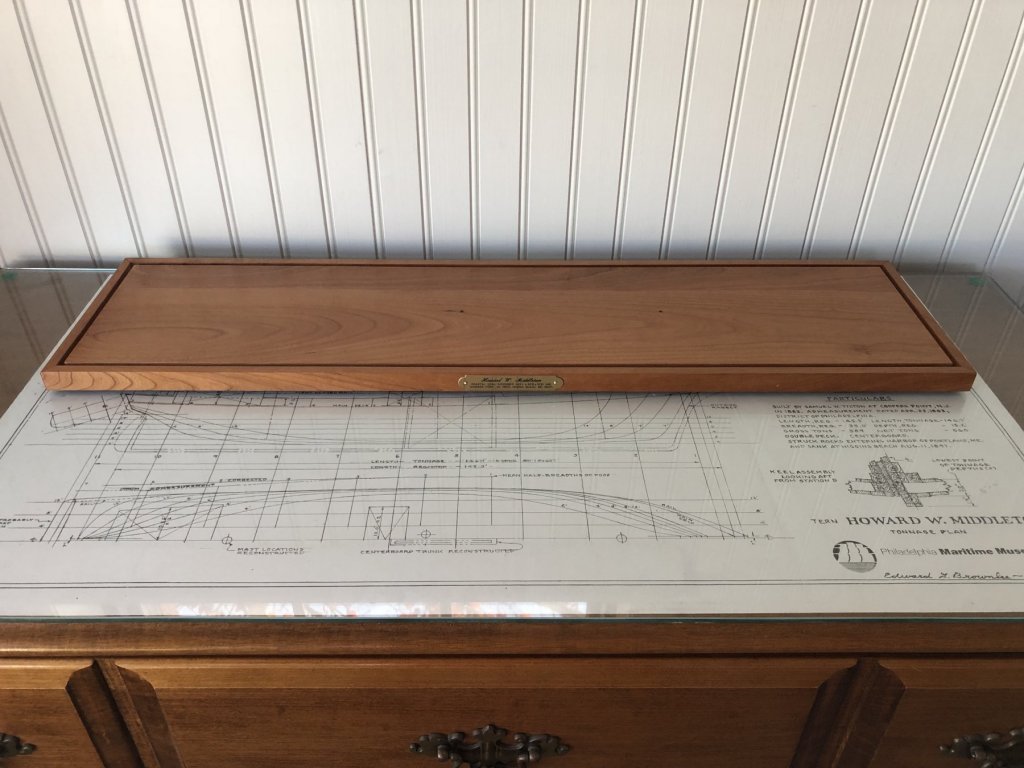

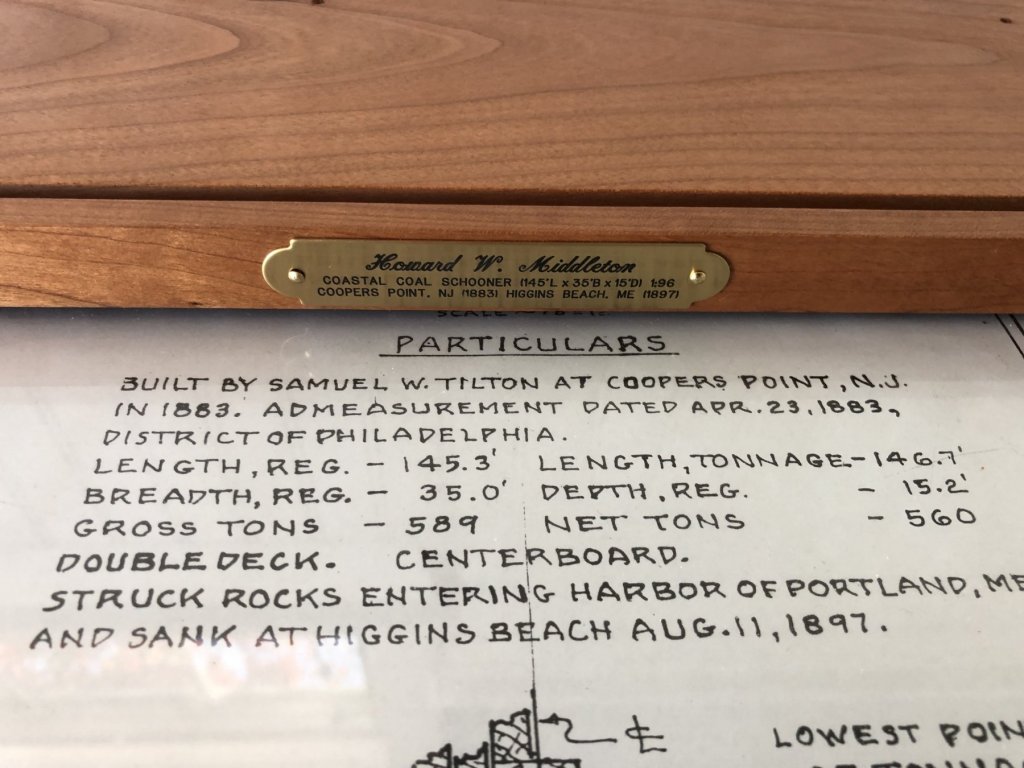

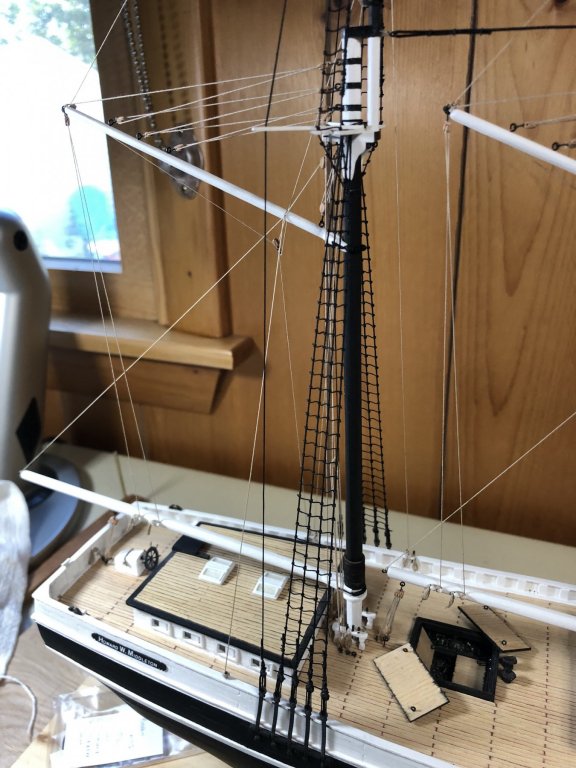

FINISHED!!!!!! Only took me 26 years since measurements were taken of actual wreck on beach and 5 years from first purchase of wood for model - now what am I going to do for the next 26 years???? A few final pics before I put on glass case top and move to final resting place...

- 43 replies

-

Great work so far! After 5 years working on a scratch built coastal coal schooner (Howard W. Middleton) I am literally hours away from placing the glass case over the model - sometime next week. Time to think about my next build and this model has caught my eye as I need something that may take a bit less time but holds some interest and challenge. I never had a chance to go to the New Bedford Whaling Museum but I am sure it would be a great way to get some background on this boat. However, I did meet Erik Ronnberg years ago and have followed much of his work so I am sure this model is as good as it gets. Good luck with your ongoing project and I look forward to following the build. Regards Larry

- 21 replies

-

- whaleboat

- model shipways

-

(and 1 more)

Tagged with:

-

- 43 replies

-

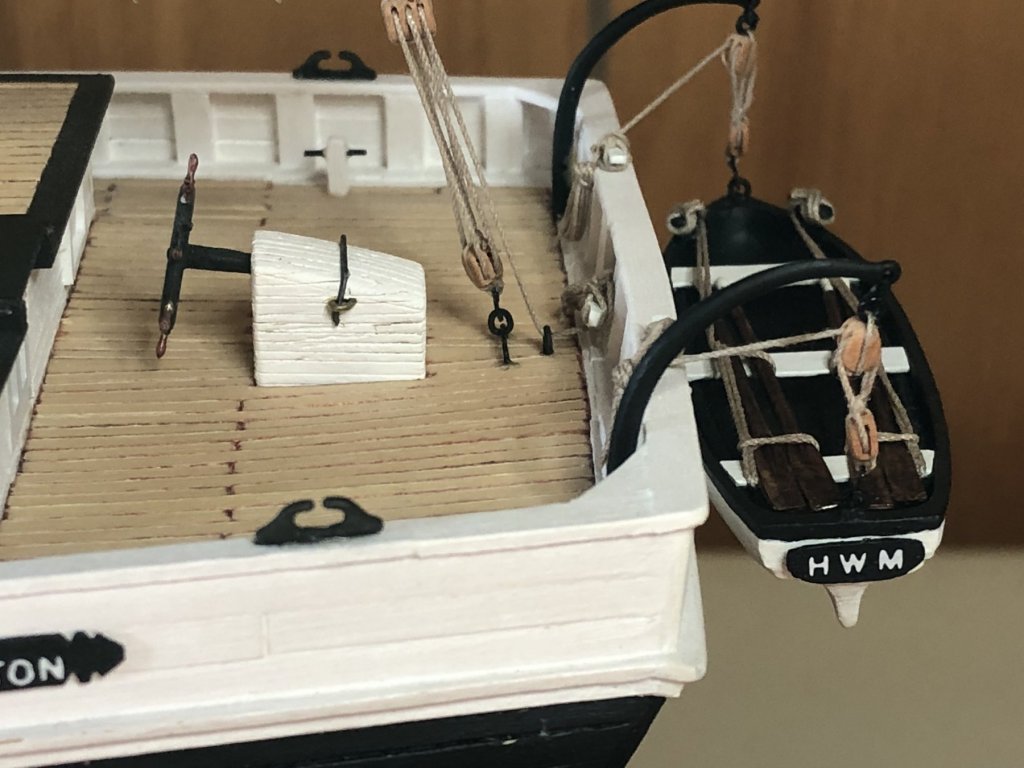

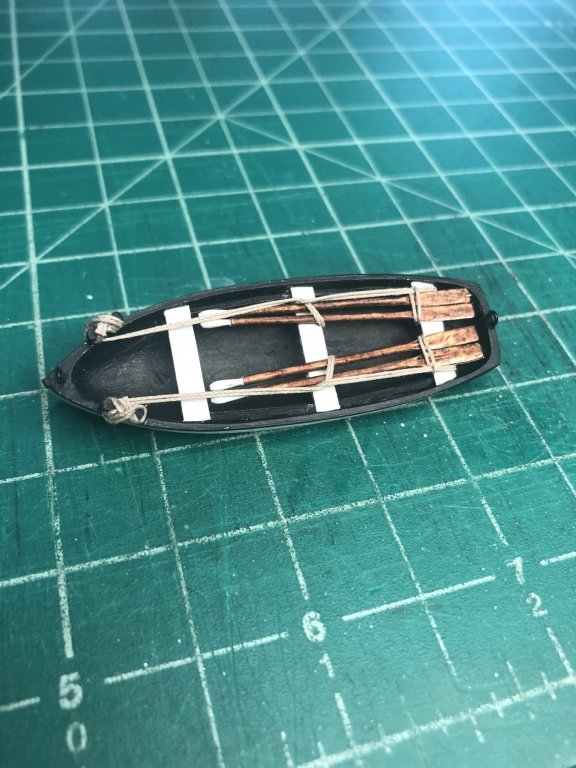

Here's a view from the opposite direction where you can see the "deadly" rock just exposed at a very low tide. And here is current progress - almost done. Installed mizzen backstay and working on main/fore mast backstays. Cherry base has final coat of finishing oil and final work to be done on installing centerboard, rudder and dinghy - all ready to go once model is placed onto 3/32" brass rods on base. Will post final pictures once complete.

- 43 replies

-

Cherry base delivered and incredibly it fits the glass case perfectly (good to have good helpers...)! My original idea of 1/16" brass rods to support model that was planned to sit 1 1/2" above base to show 3/4" of lowered centerboard will not work unless I want to see entire model shake anytime someone walks by. Have ordered 1 3/8" high brass pedestals that I think should properly support model and still leave enough room to display partially lowered centerboard. Now working on rope coils for all the belaying pins - lots of good suggestions here. Have also attached a picture from a kayak trip this week out to Richmond Island just off Higgins Beach. The Middleton rounded this point in dense fog and heading into what they thought was a protected cove - it was if they headed to starboard but by heading a bit more to port they hit a rock and ended up on our beach. For those football (American) fans in the crowd, if you look really carefully you can see Roger Godell's summer "cottage" in the distance out on Prouts Neck - and no, the local lobstermen don't care for him...

- 43 replies

-

Being that tonight is the 121st anniversary of the demise of the Howard W. Middleton just a short distance from where I now sit it is fitting that I spend a few minutes and update folks on my progress. Move from Mass to Maine is complete and modeling area is set up with LOTS of boxes still to be unpacked (priorities...). Mizzen rigging complete and now working on anchor and associated fittings (was researching anchor chain and seemed like I should build two anchor boxes). Final list of to dos complete with probably another month of work ahead of me. Unfortunately one of the victims of the move was "misplacing" all the 1/4" brass angle I purchased so had to reorder from K&S Metals. Spent past two days (probably total of 5 hours) building glass case. Had the expert help of a good friend who is a retired 777 pilot for Air Canada so we had lots of time to debate how to best measure all the pieces using either centimeters or inches - inches won. All in cost for the case (30"L x 20"H x 7"W) is approximately $100 for brass and 1/8" glass (let's not worry about having to reorder all that brass angle...). Cherry base will be built by a good friend who loves to build furniture so there will be some donation for that! Attached are the final pictures of the case - we didn't have the equipment to do nice mitered edges but snips and files did the job pretty well.

- 43 replies

-

Mizzen mast rigging almost complete, dinghy ready and all glass and brass angles ready for case construction. However, it's time to move the Middleton back to her final resting place at Higgins Beach, Maine for completion. Moving truck arrives July 1st and we close on our condo in MA on July 10th and move into our house at Higgins Beach. So signing off for a while until I can figure out where my modeling work area is going to go in a smaller house with limited storage. And then there is the age old problem of where I am going to "display" my four completed models and make way for the one that gets top billing - the Howard W. Middleton...I guess there are bigger problems we all face!

- 43 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.