-

Posts

411 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alross2

-

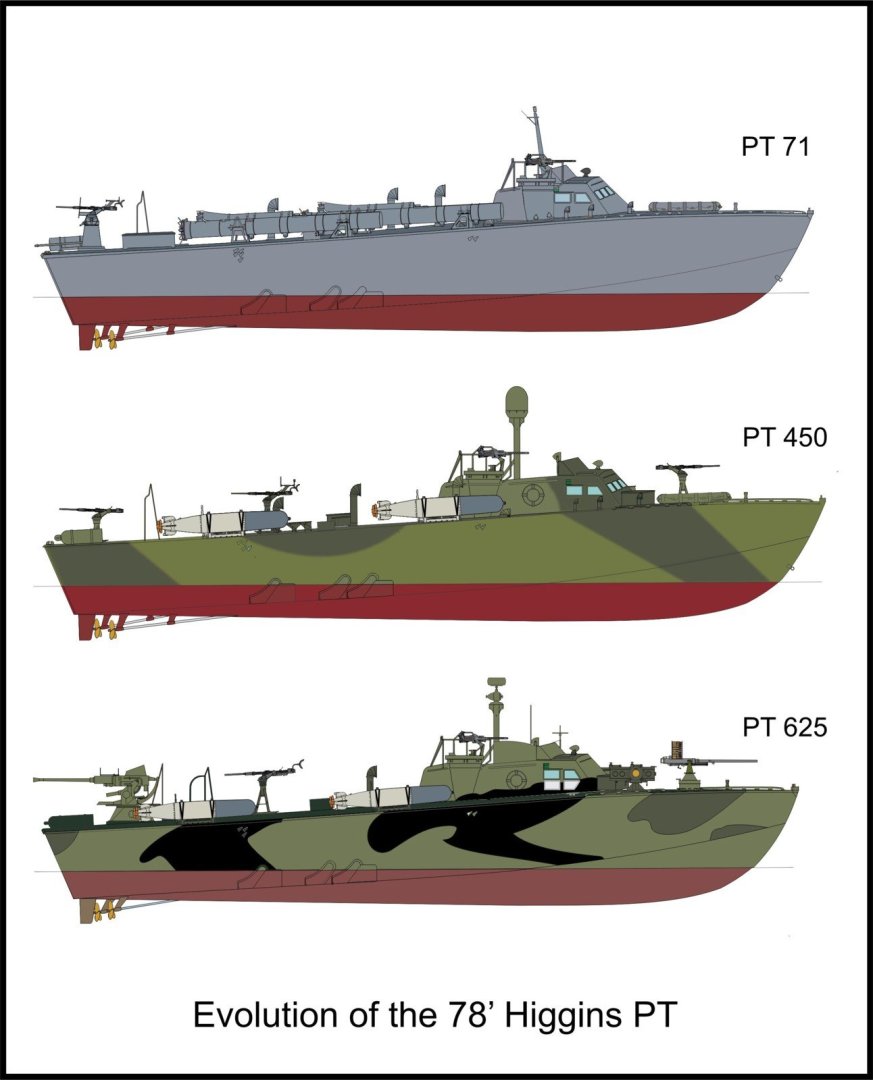

A bit further along. The main deck is now on and has the locations of the major deck furniture lasered on it. This saves the modeler from having to measure from the plans. This arrangement is for the initial series boats, so I haven't added the locations for the torpedo tubes or the roll-off racks. Still not sure which version/versions I'll end up doing. Profiles for the three as built are shown below but there were many reconfigurations of all three groups over time.

-

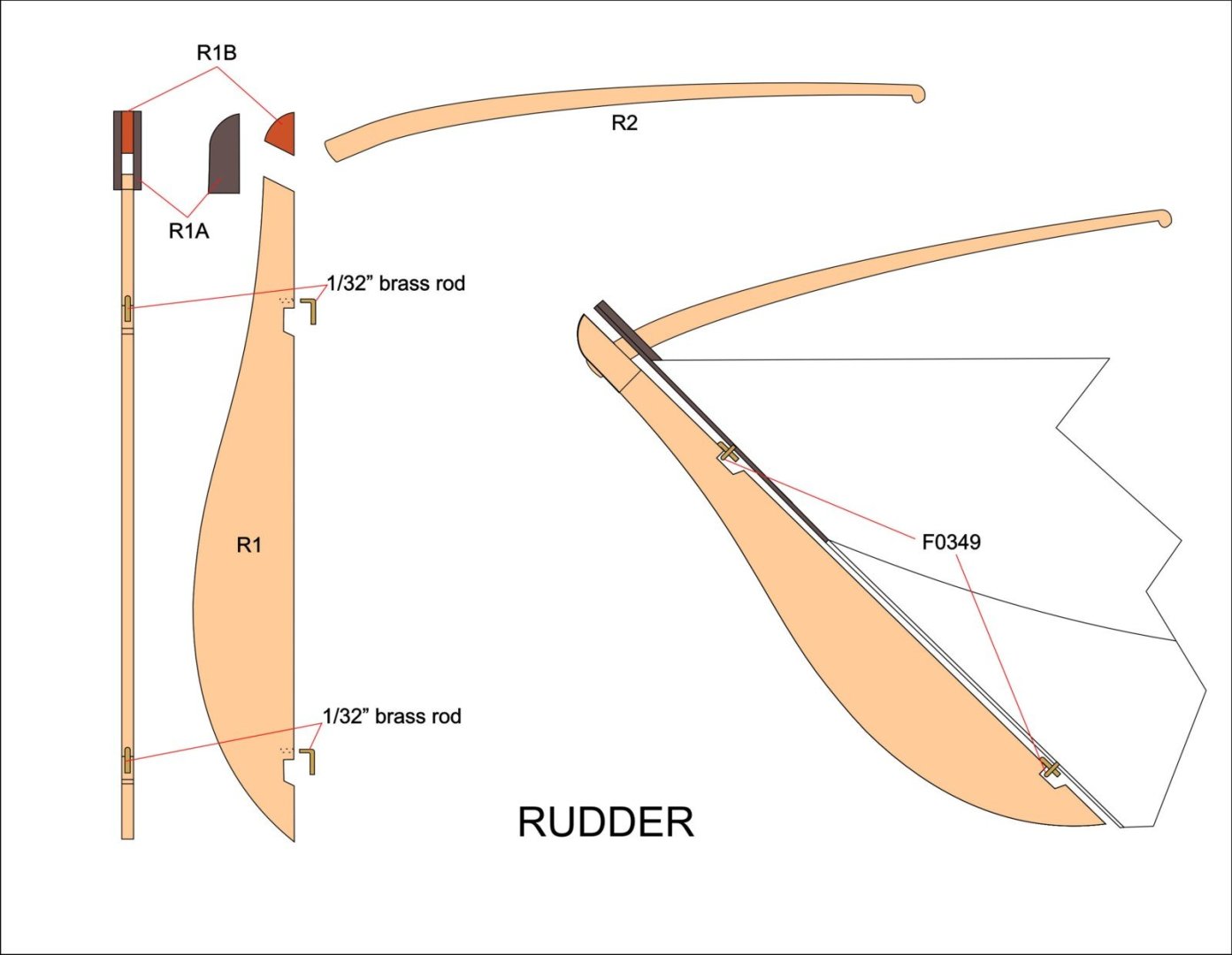

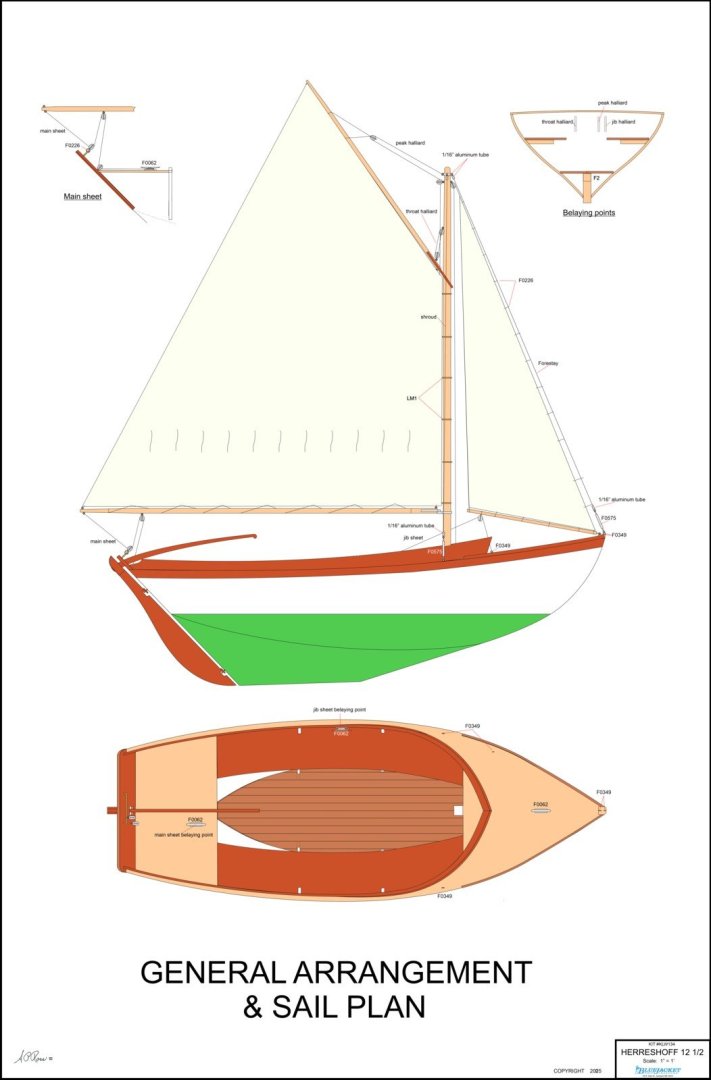

At the moment, along with developing new kits I'm also revising some of the older kits. One thing that computer drawing has let me do is add color to the traditionally black and white plans. This makes it easier to differentiate among the various laser-cut components and saves having to describe the color scheme for the model. I'm just finishing up revising the Herreshoff 12 1/2 kit and here are a couple of the new drawings. The GA/Sail Plan drawing is 24" x 36", so some of the details may be hard to see in this reduction.

-

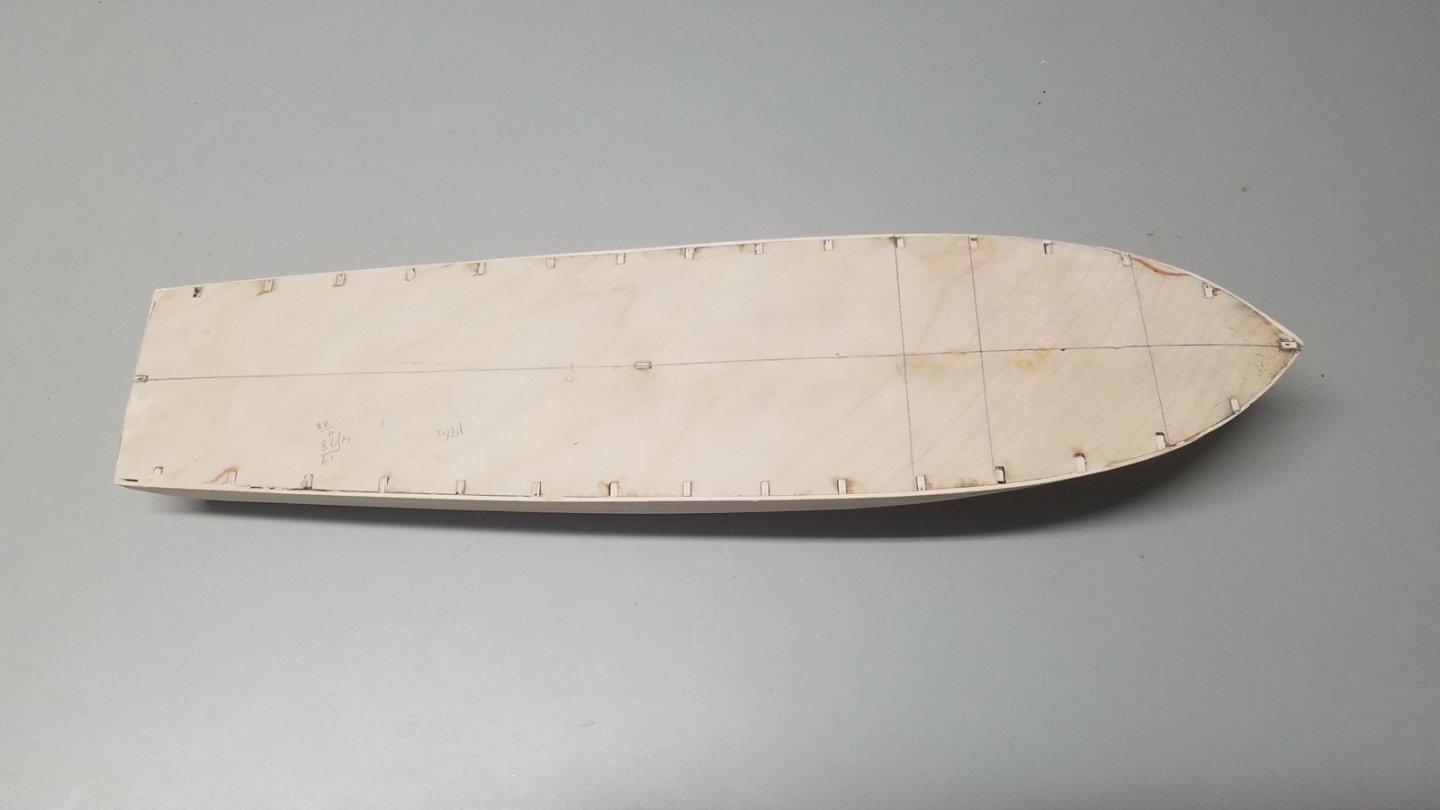

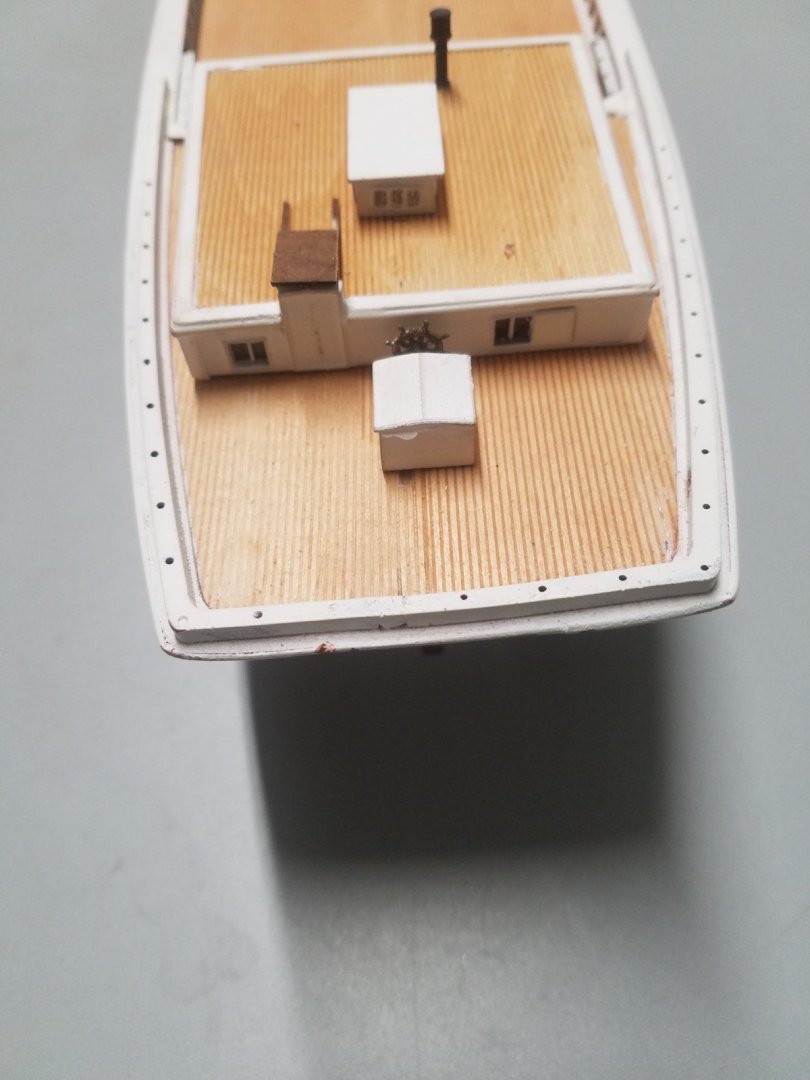

A bit further along on the potential 1/48 scale Higgins kit. The hull is planked and filled and I've adjusted the laser drawings a bit. The deck you are seeing is the subdeck. It will be covered with a 1/32" ply deck that has the positions of the primary components (deck house, engine room hatch, etc.) lasered onto it. I'm toying with the idea of including enough materials to do any of the three different classes. There were two slightly different hulls. The initial hull form was slightly tunneled aft while the later hull was flat aft as they discovered the tunnel caused drag. There were three different pilot houses as well. We'll see what happens as I play around with this one.

-

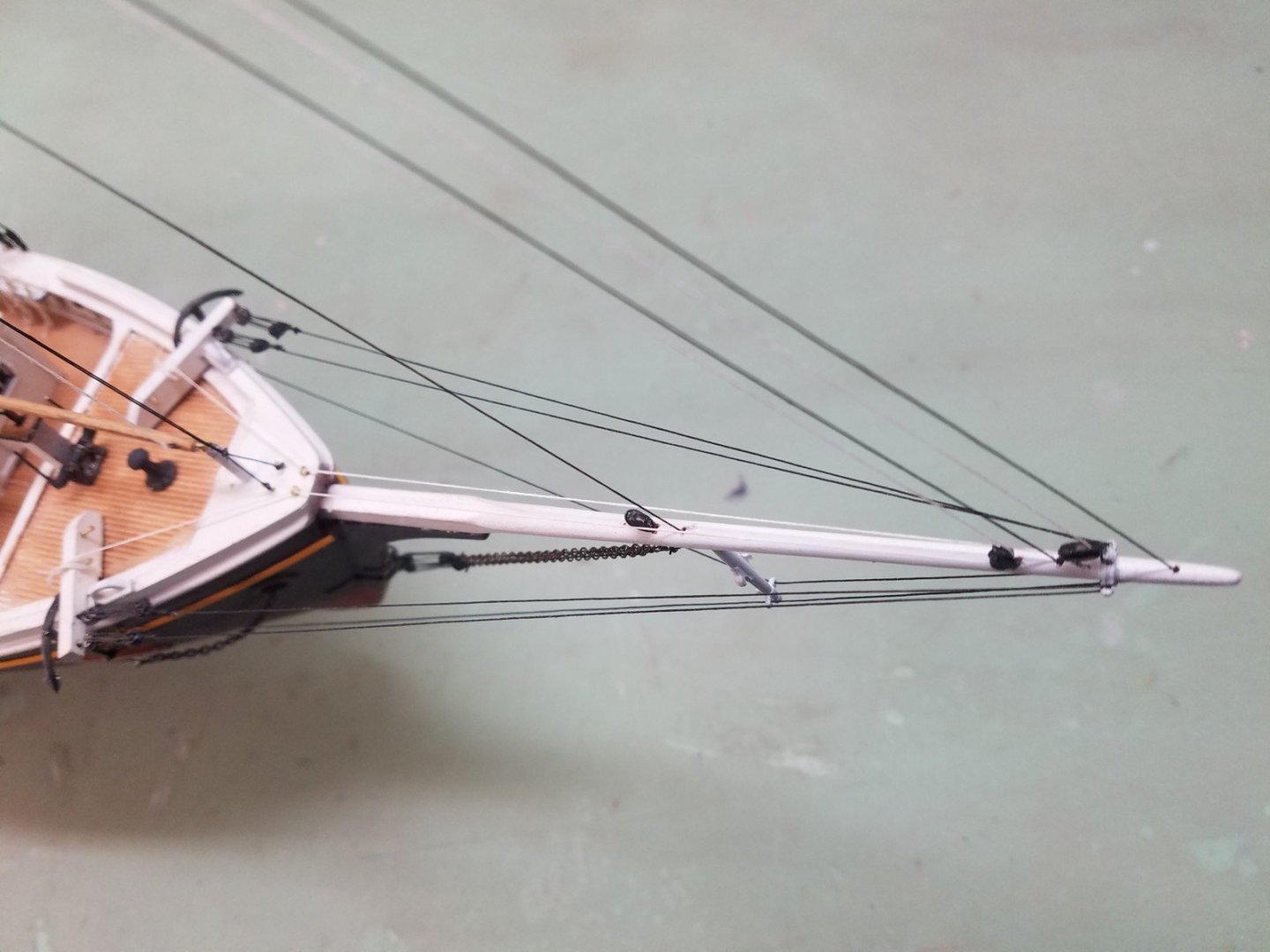

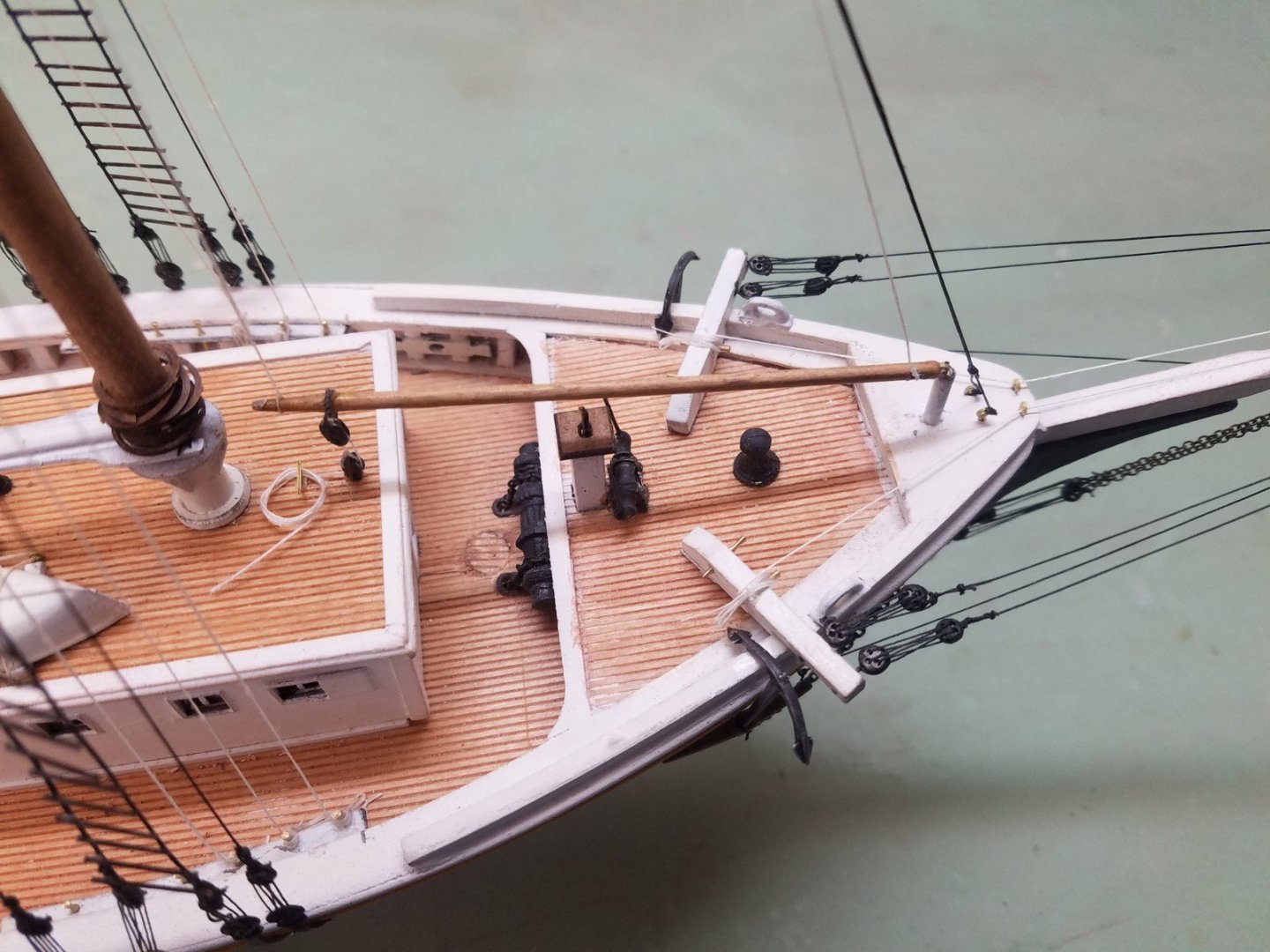

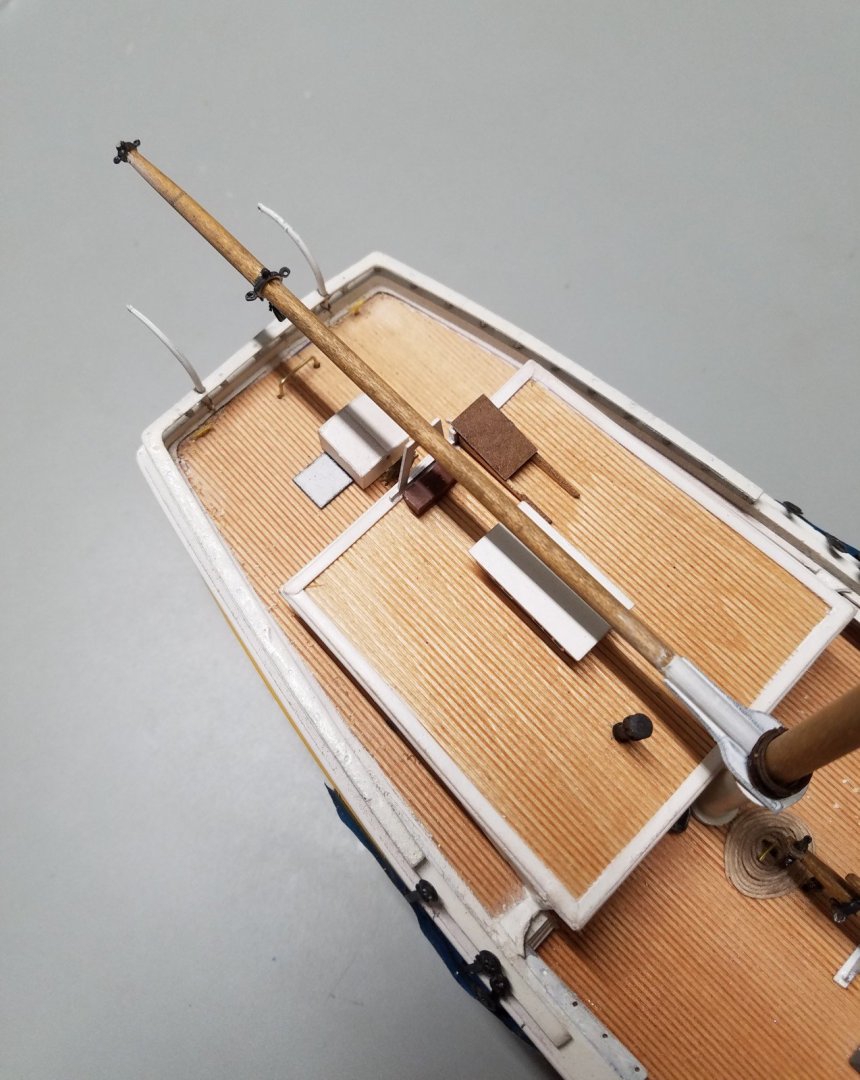

Now that Nic has finished rigging it (looks great up close!). I'll finish up adding a couple details and she's done. After that, I have to adjust the plans a bit, finalize the instructions, do a cost analysis, get Josh to set a retail price, and she'll be ready for release. The kit will probably be available early Spring. Here are a few detail shots.

-

I recently reworked what had been an old Laughing Whale kit, the Square Toed Frigate. This was a 30' version of a typical 19th Century scow sloop, so the kit is in 1/24 scale. It's plank on bulkhead with lots of laser work including a deck with simulated trunnels and butt joints. Planking mimics the original - longitudinal side and transverse bottom. It's available now @ $199 plus shipping. Kit #K1119.

-

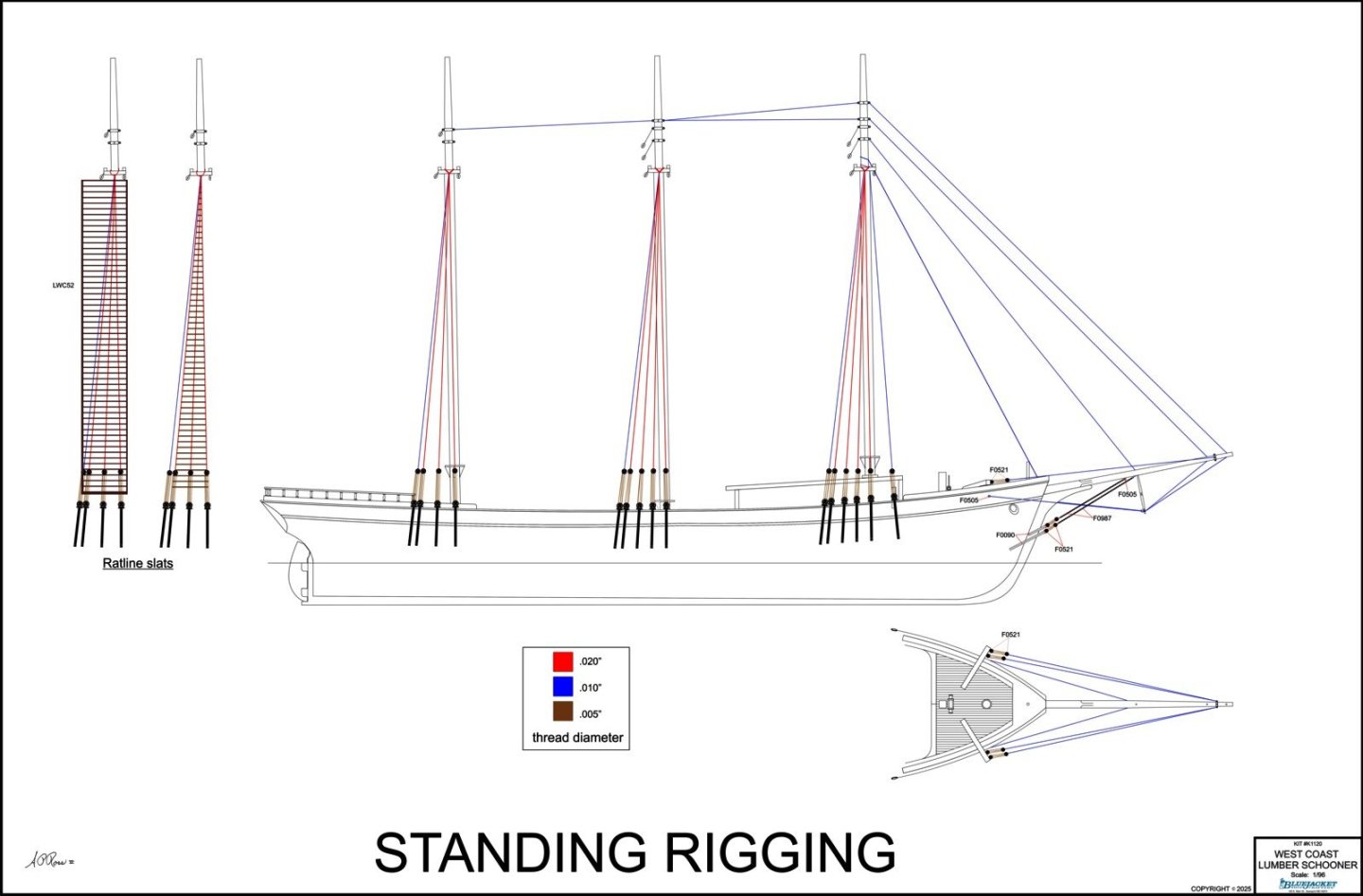

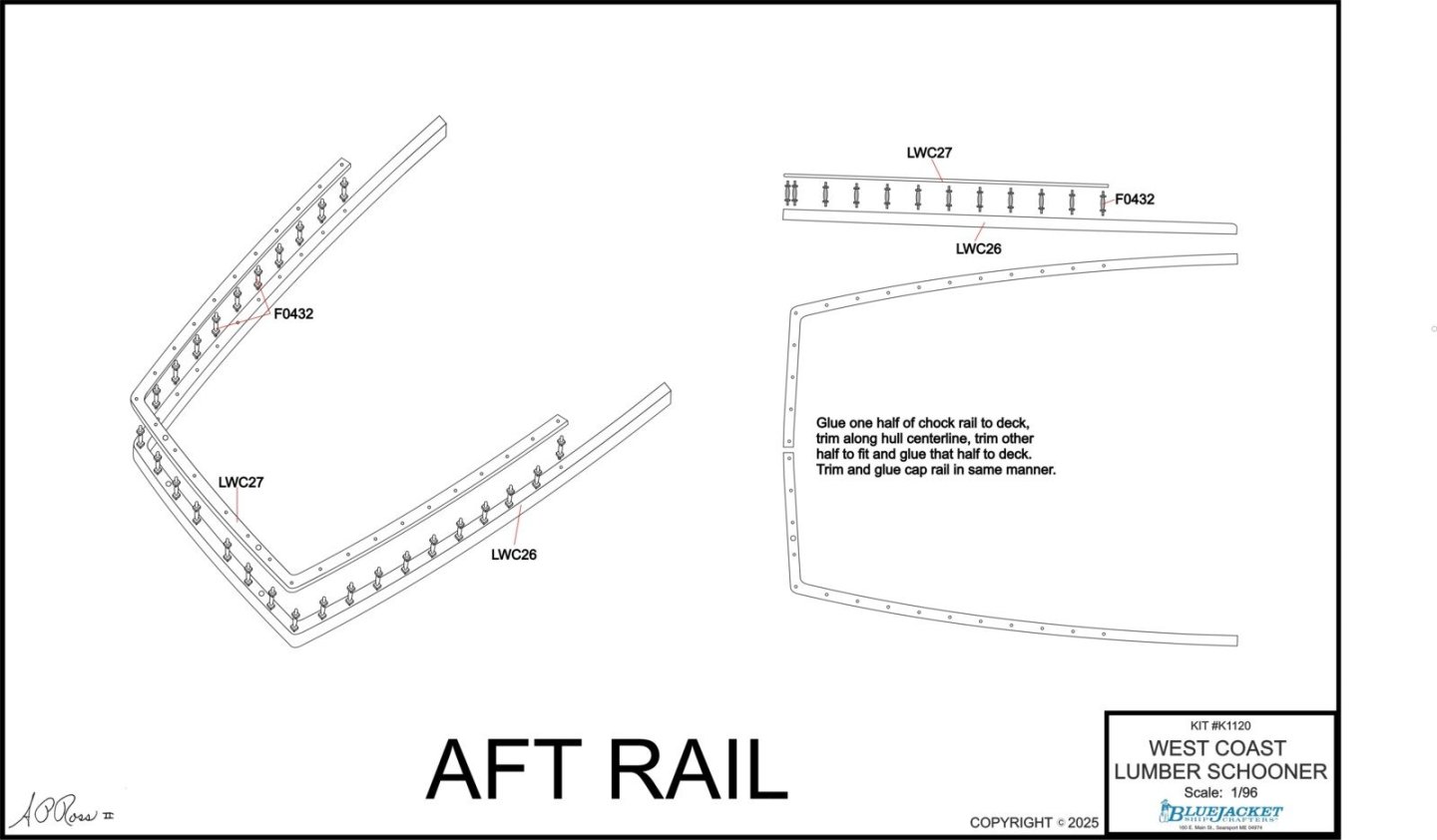

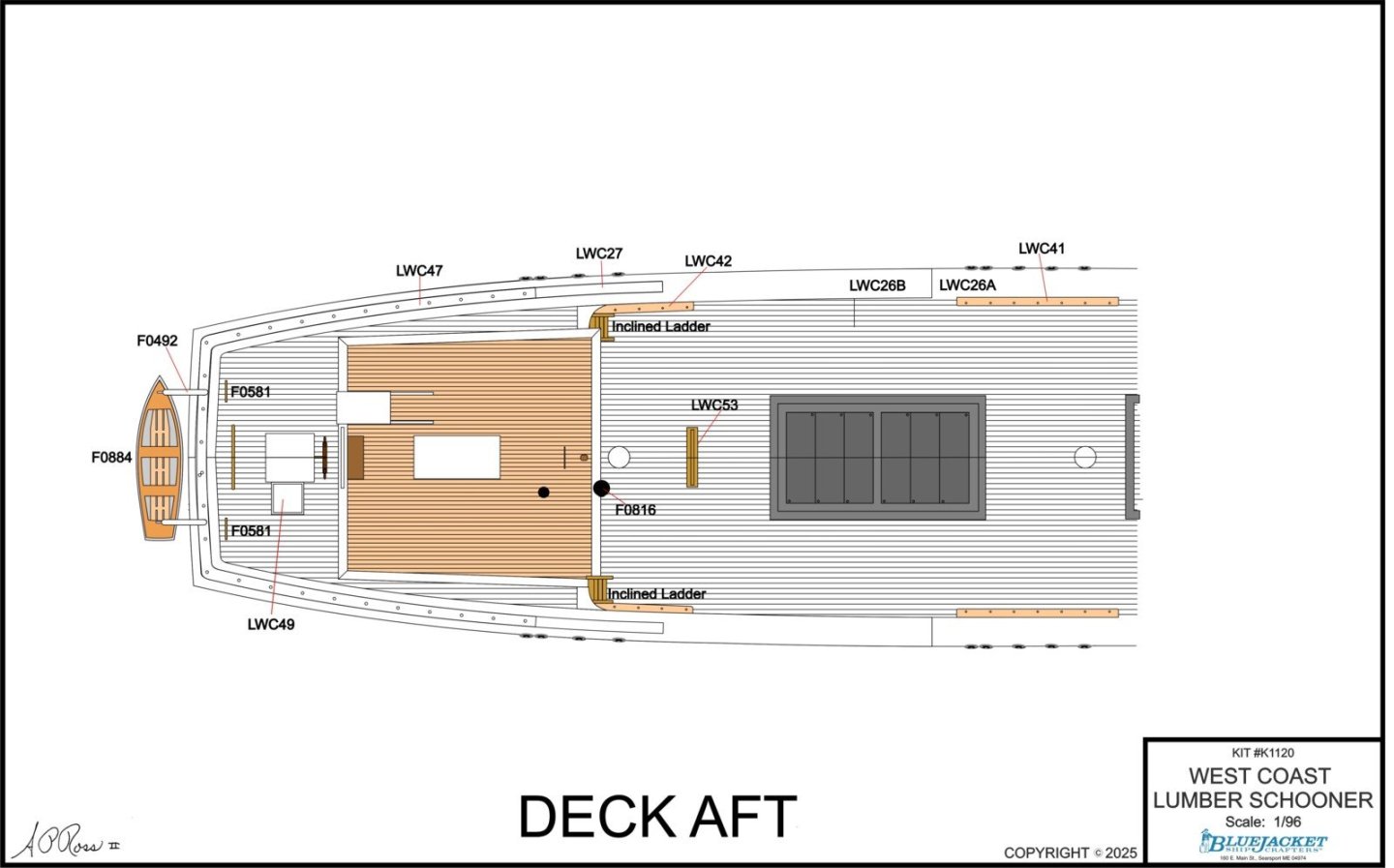

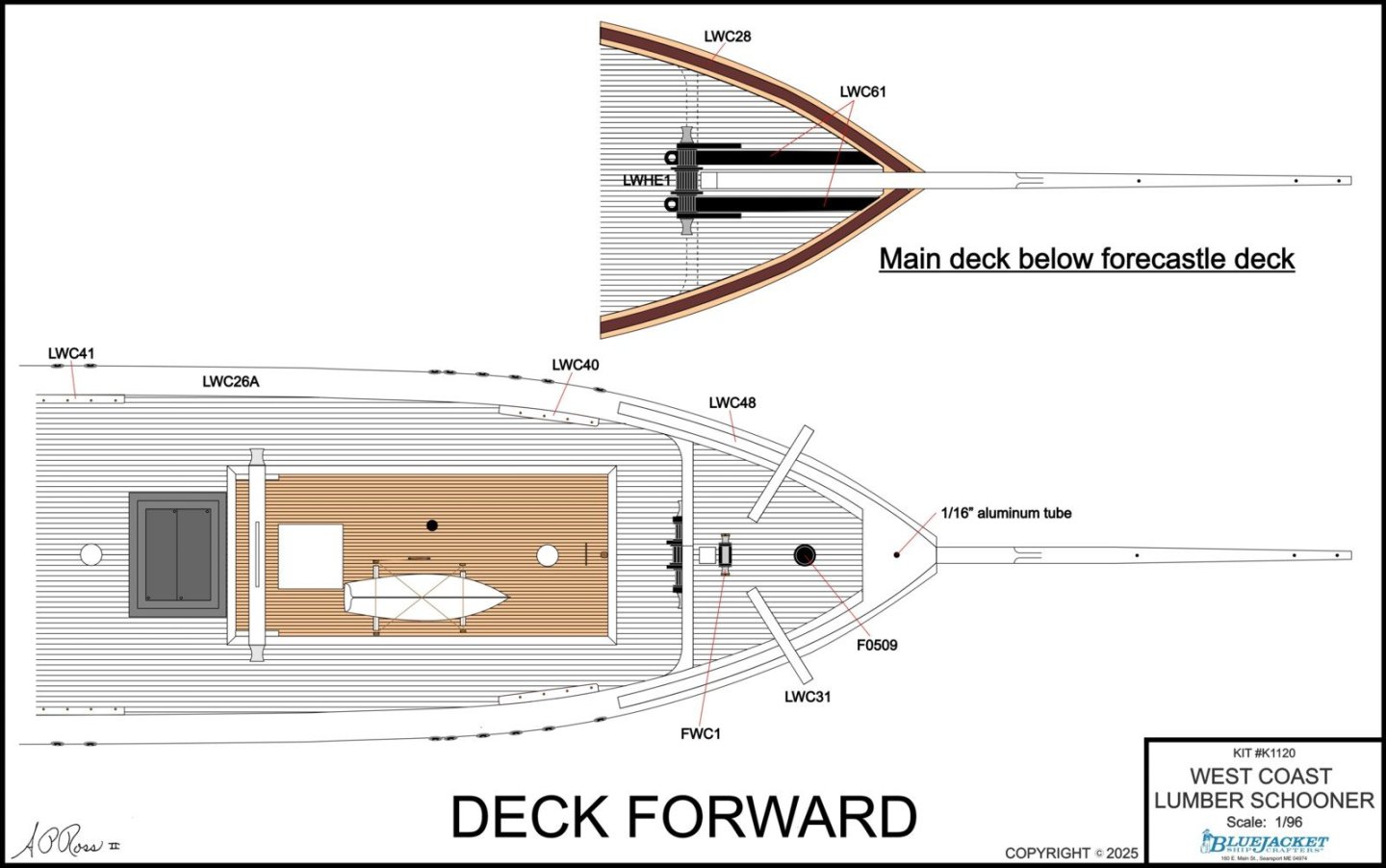

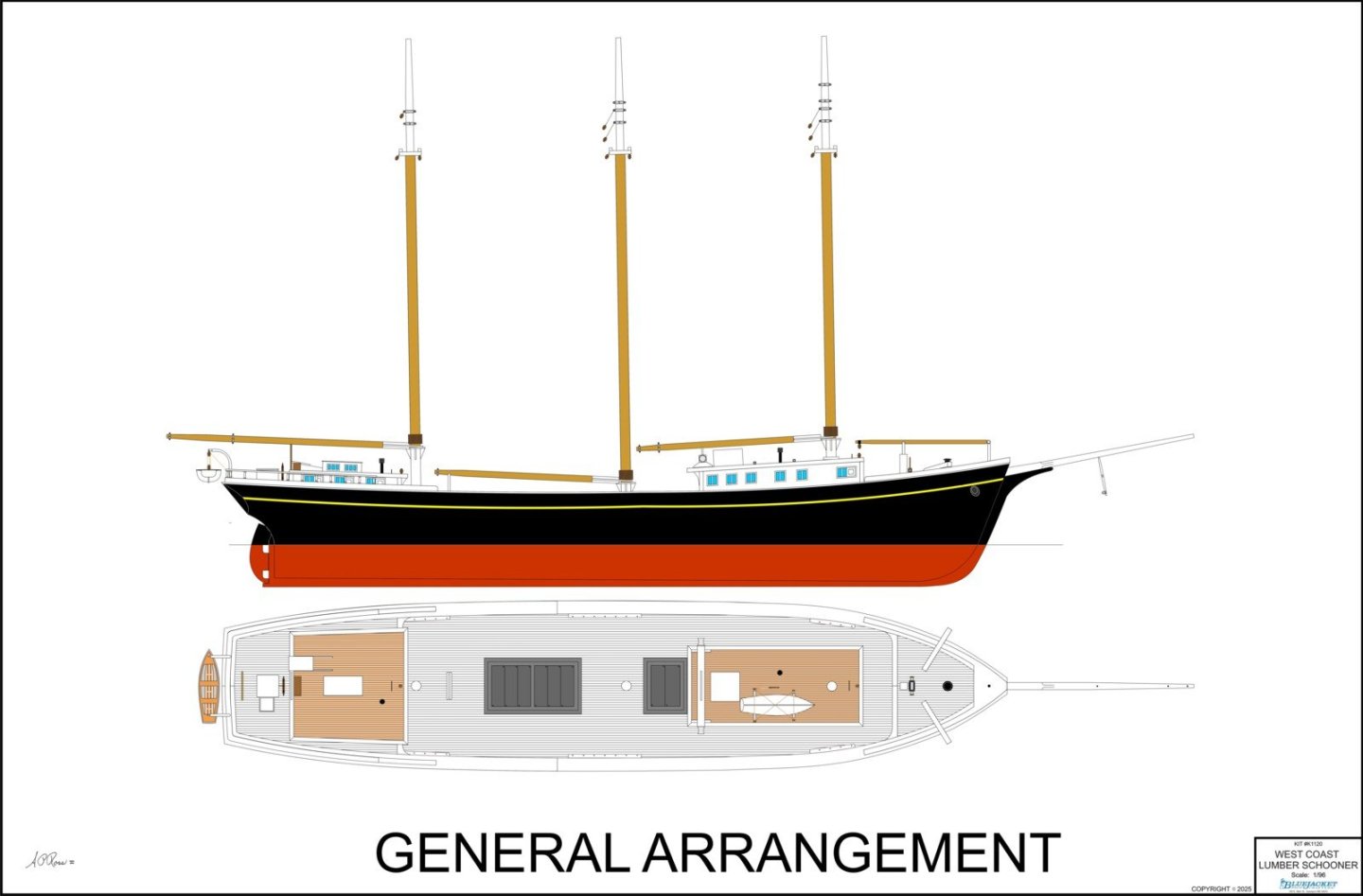

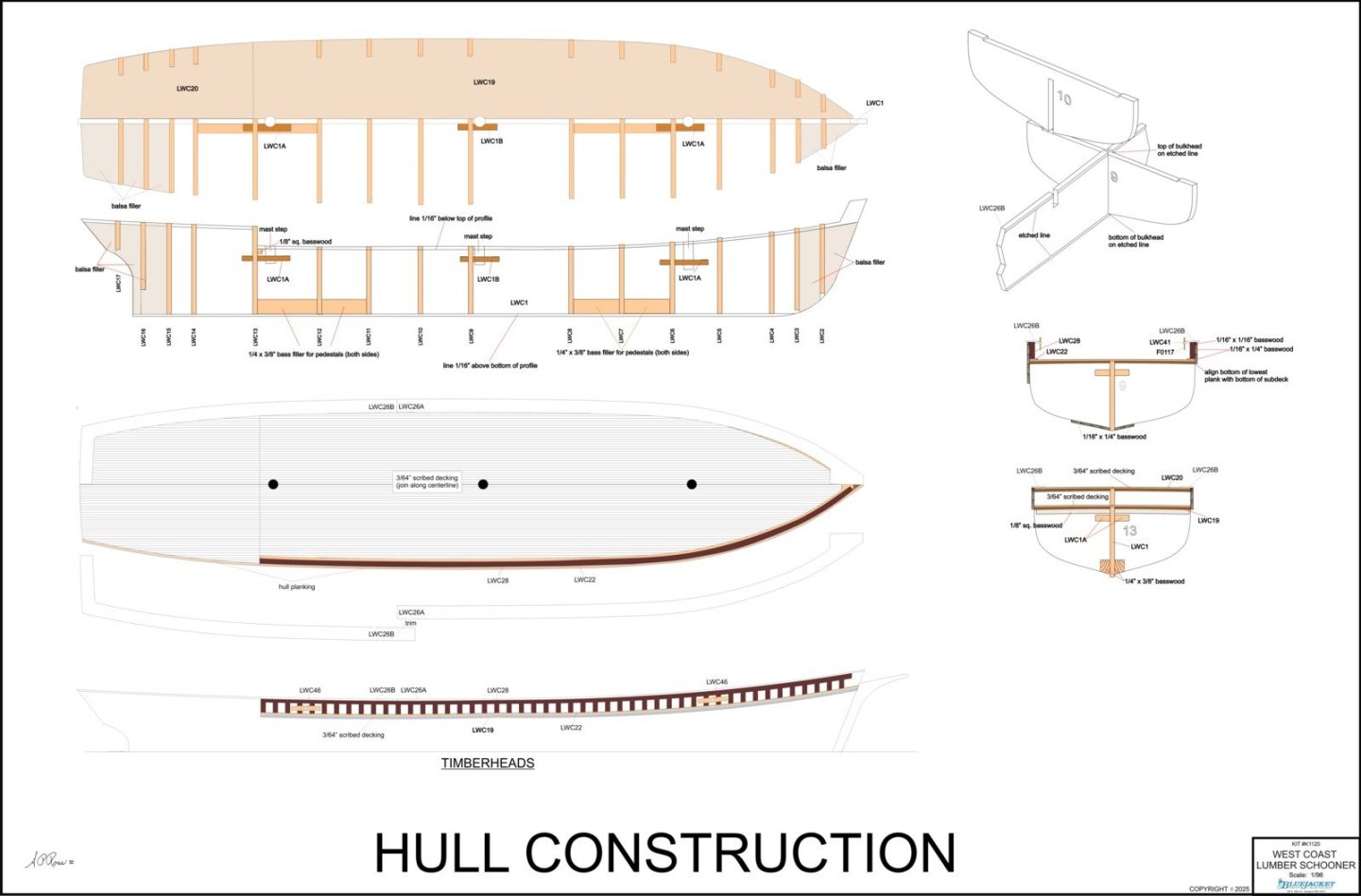

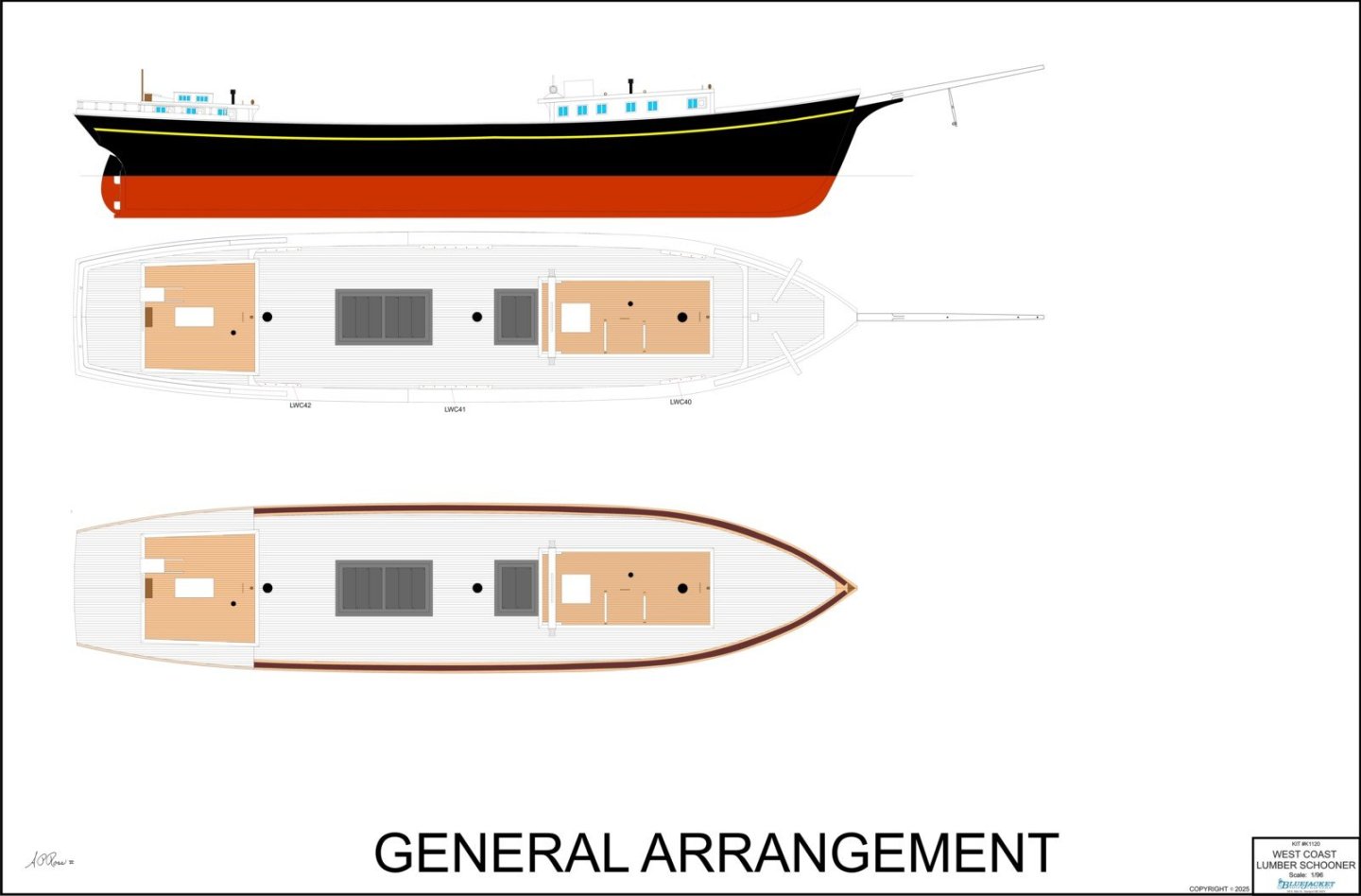

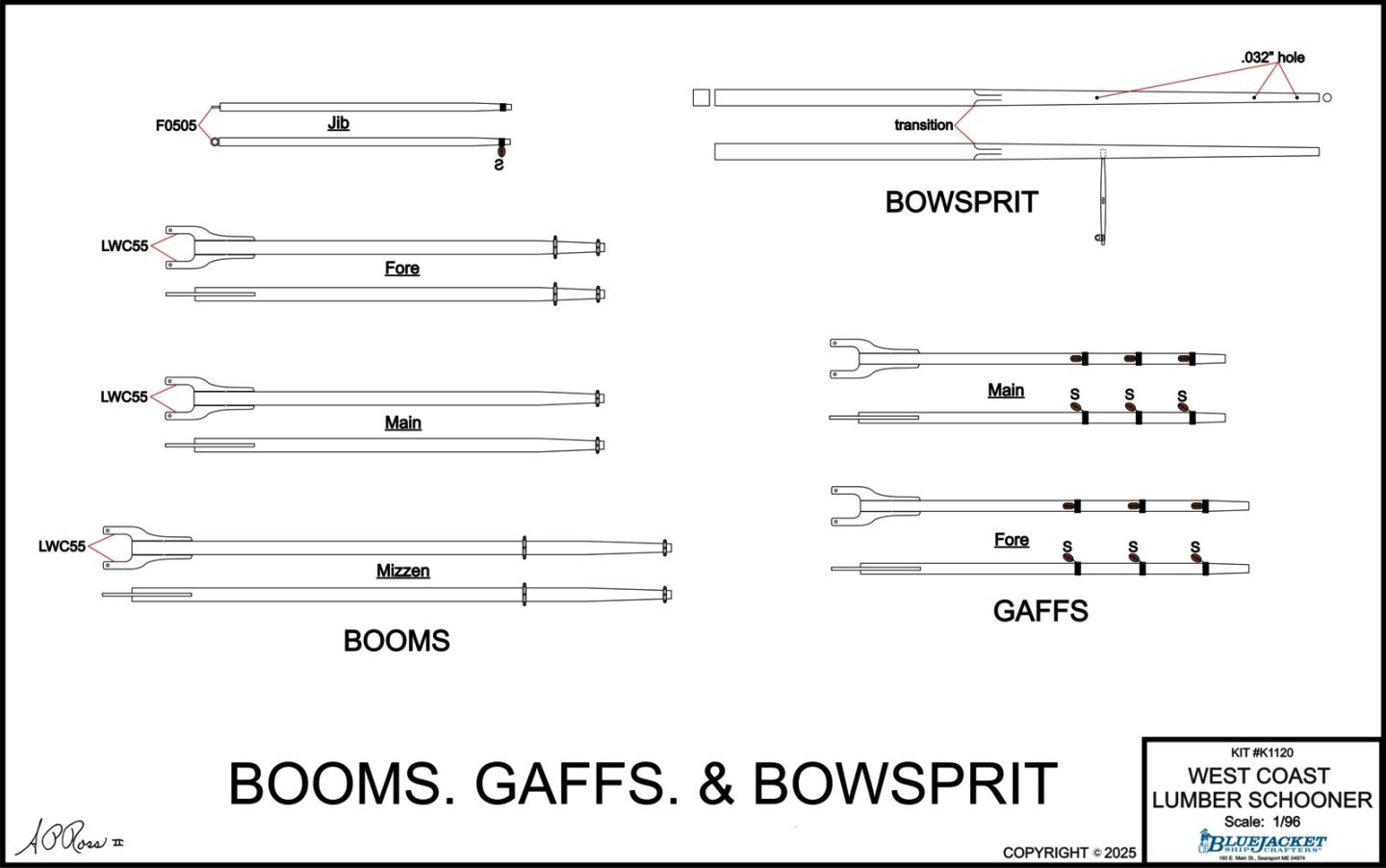

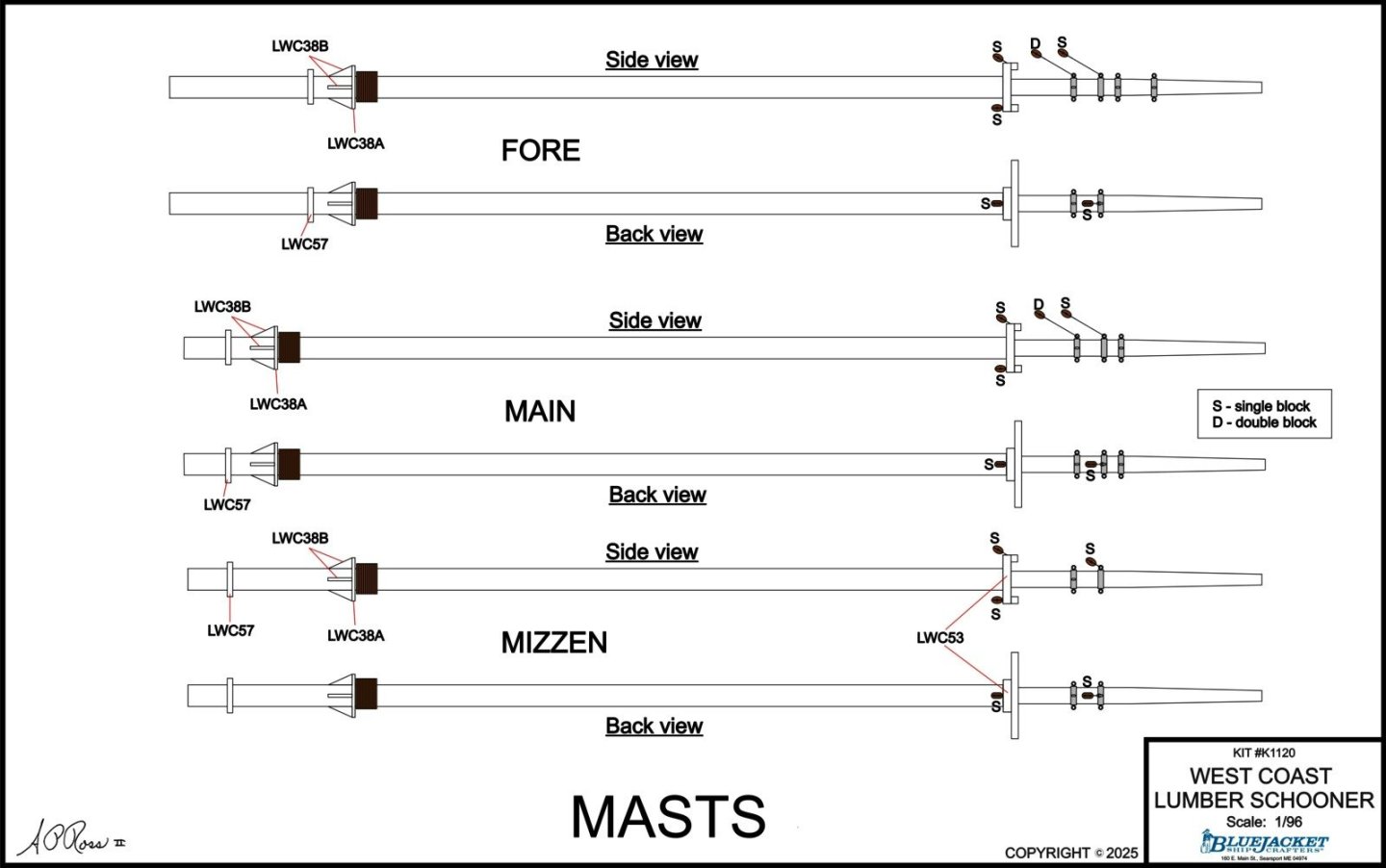

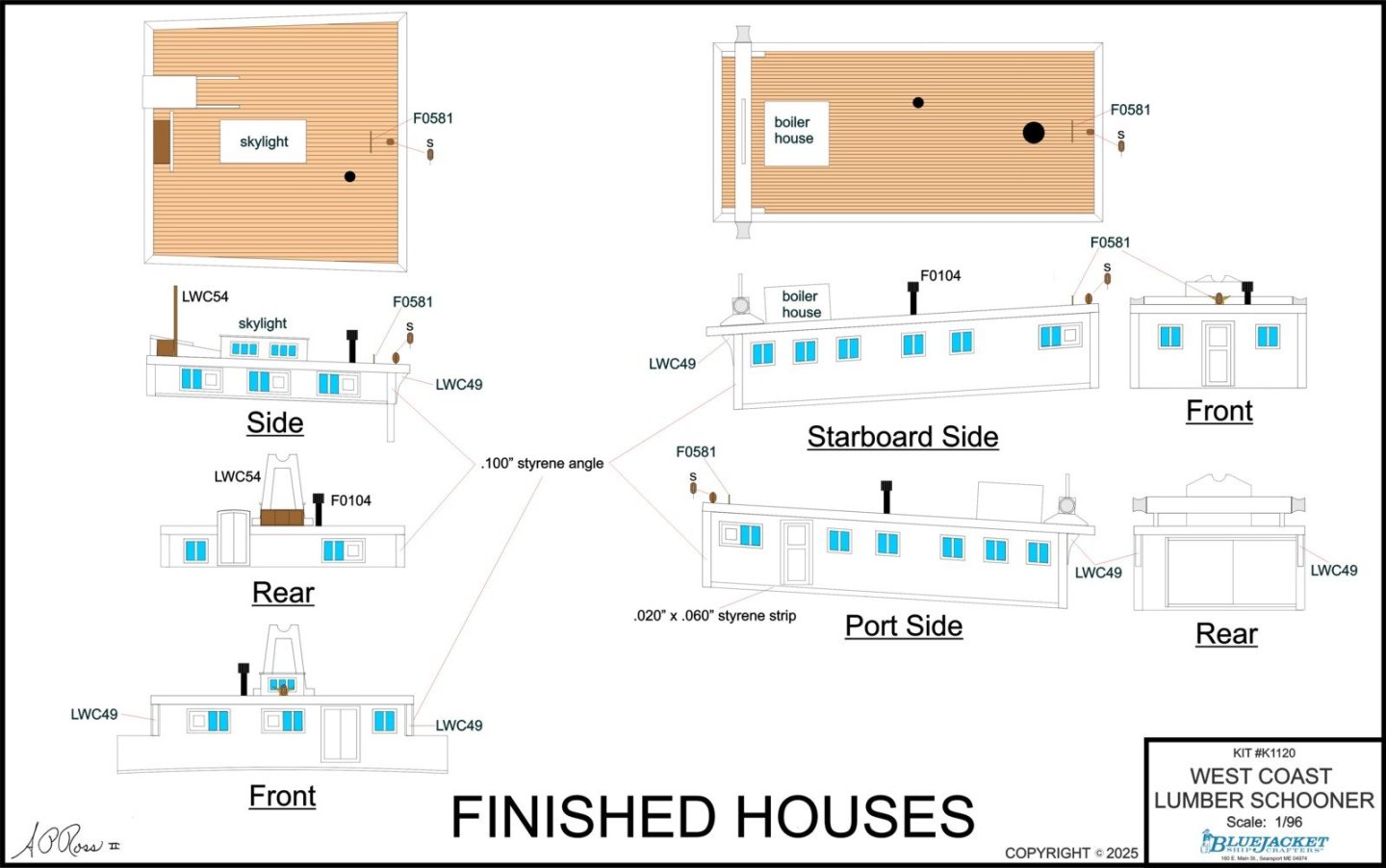

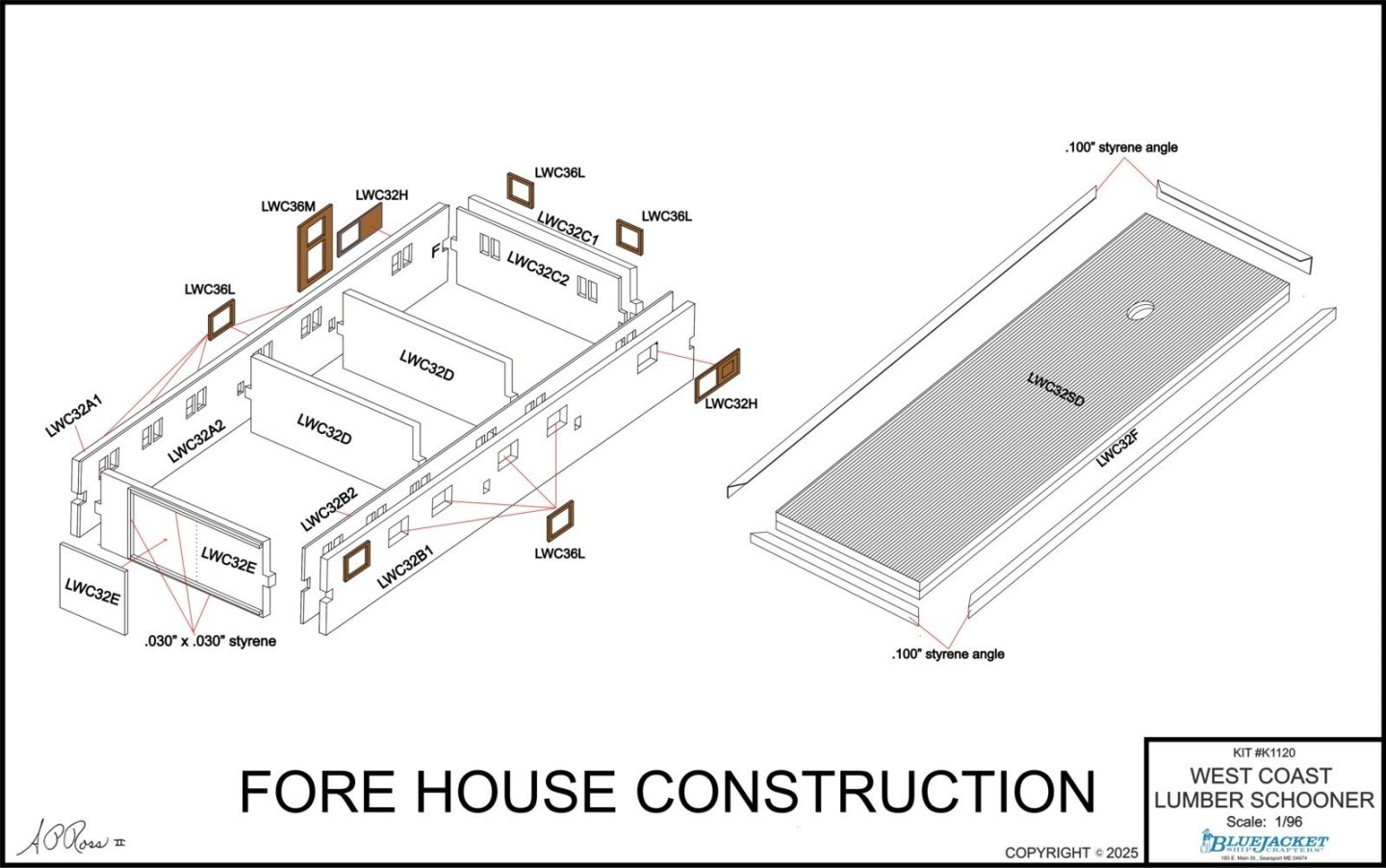

OK, the West Coast Lumber Schooner display model is boxed up and going to Nic for rigging (he enjoys rigging, I don't) 😎. I still have to do the sail plan, write the instructions, and, when he's finished the rigging, add a few more items to the display model. Since these boats had the slat ratlines, we've included the laser-cut ones in this kit - real time saver.

-

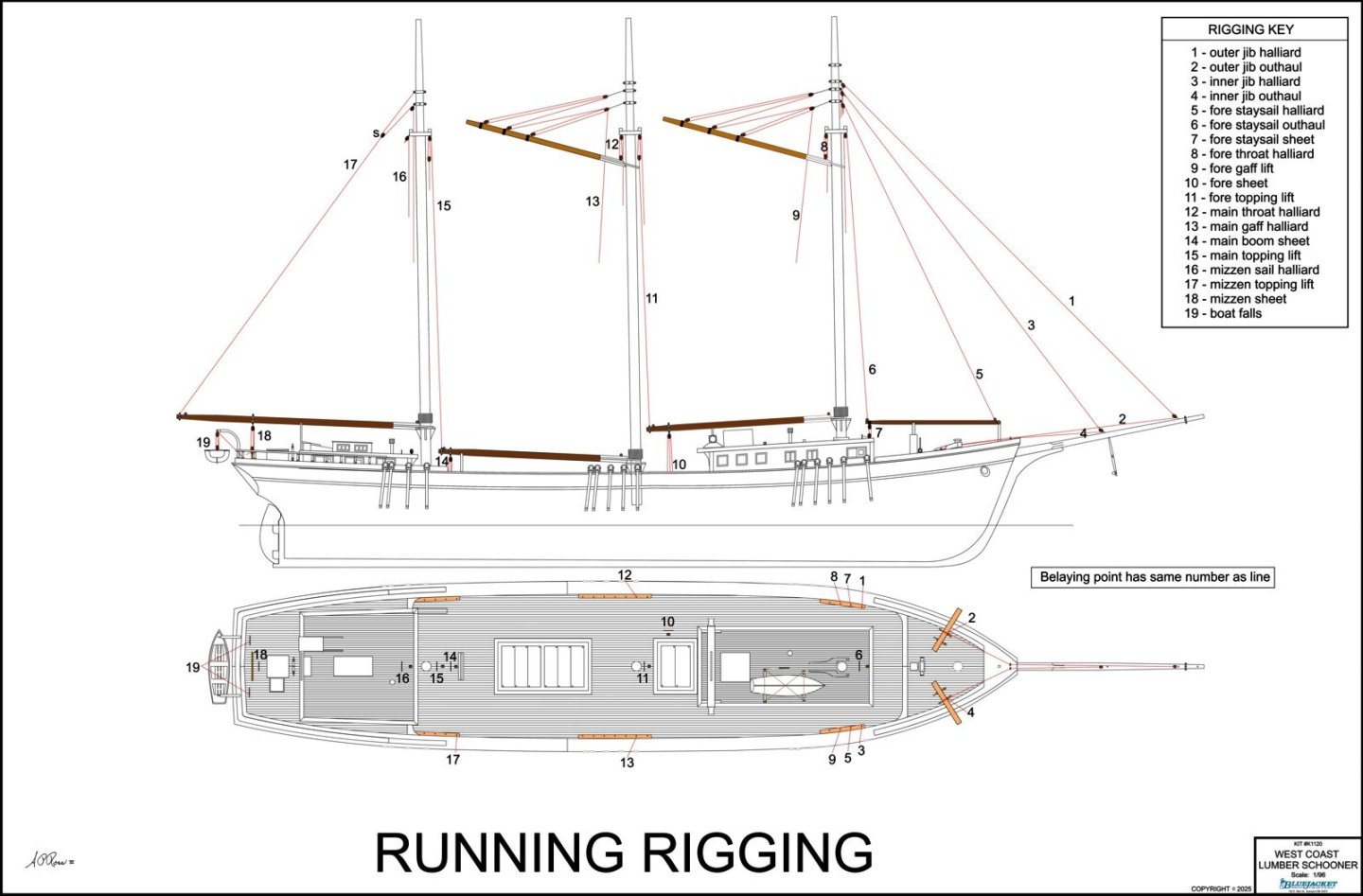

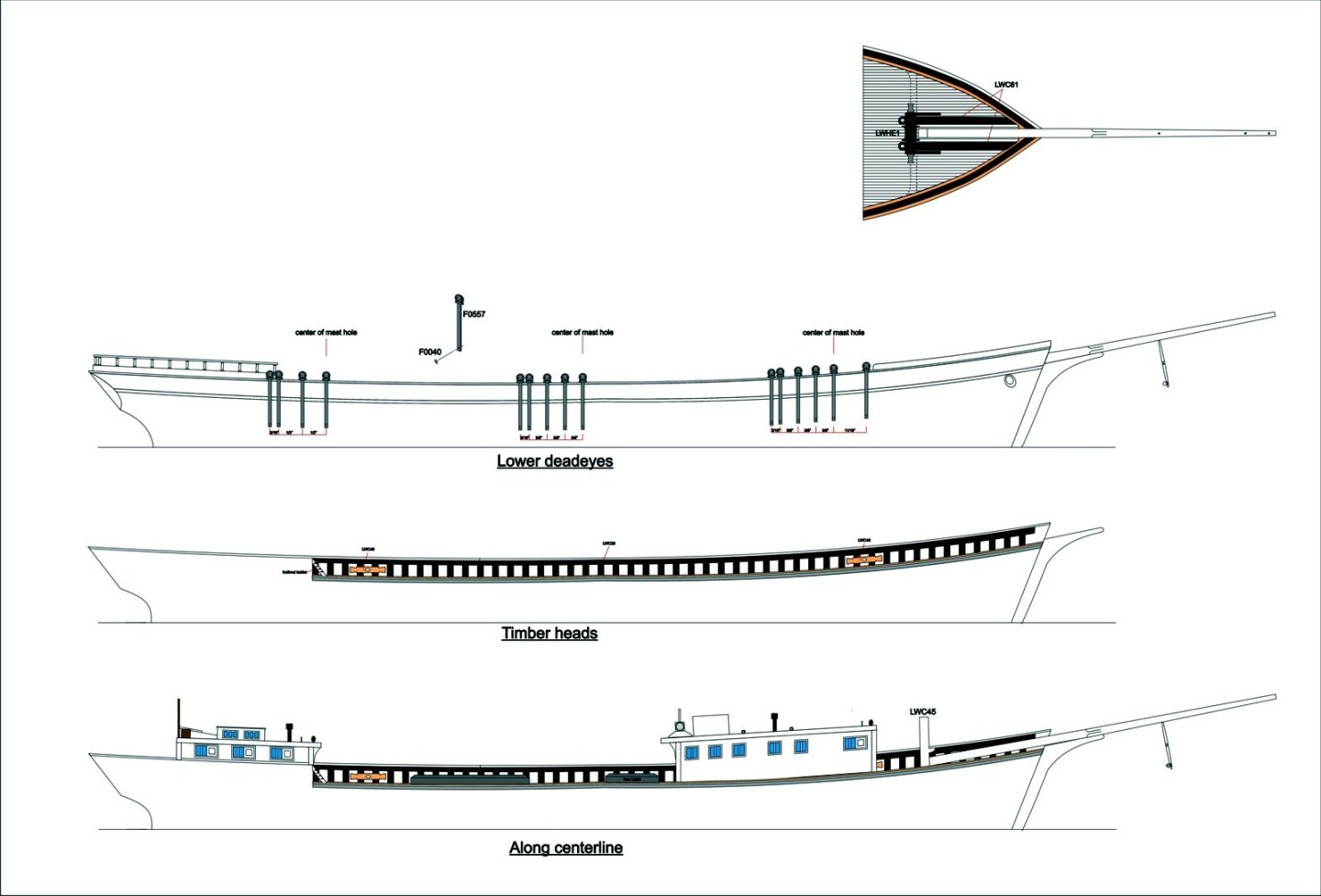

Mostly-finished Running and Standing Rigging plans. Both are greatly reduced from their original 24" x 36" format. I prefer to do separate rigging plans as it makes them less confusing for the builder with limited familiarity with rigging. Because the original vessels used slats for ratlines, I've used the same laser-cut ladder format as I did with WYOMING, NOTMAN, and a few other kits.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.