-

Posts

410 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alross2

-

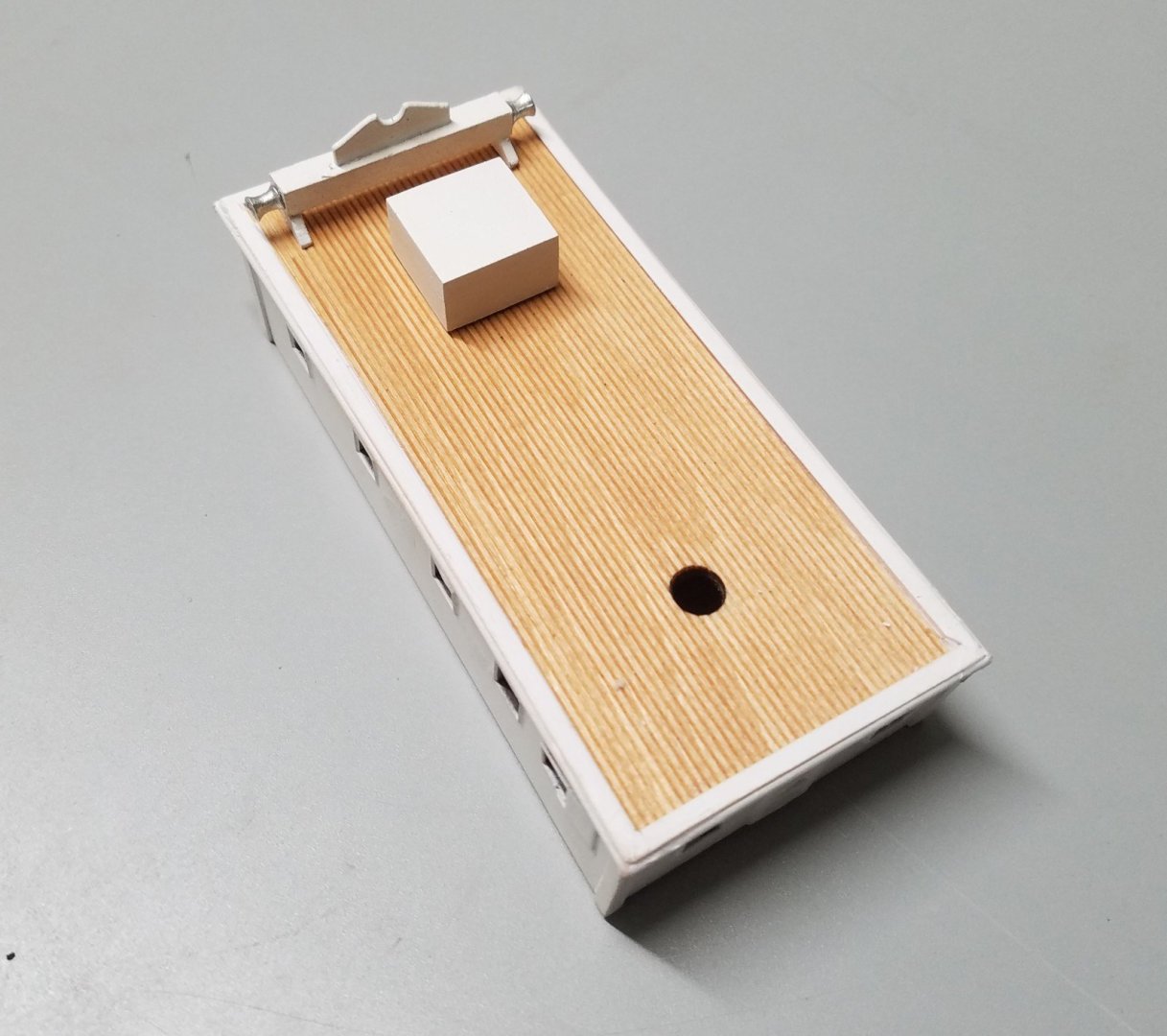

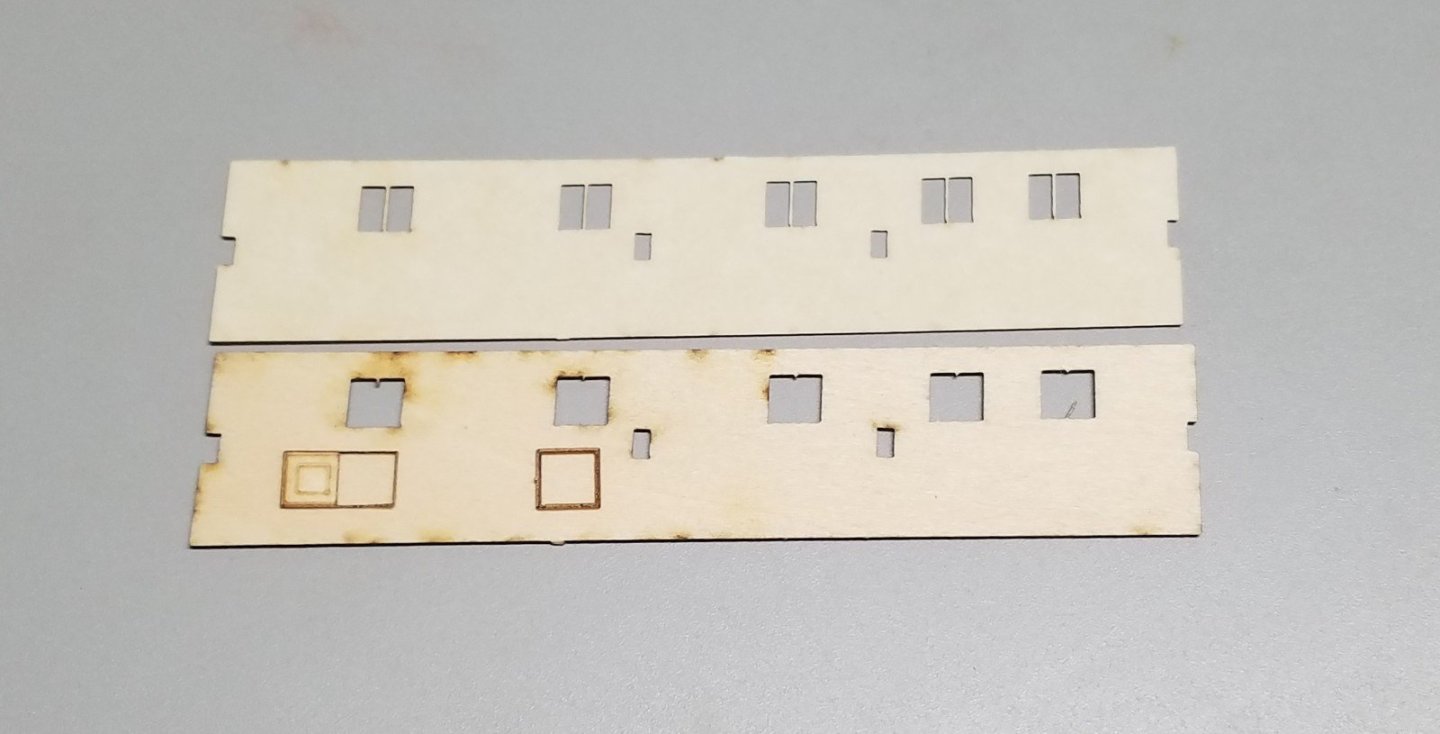

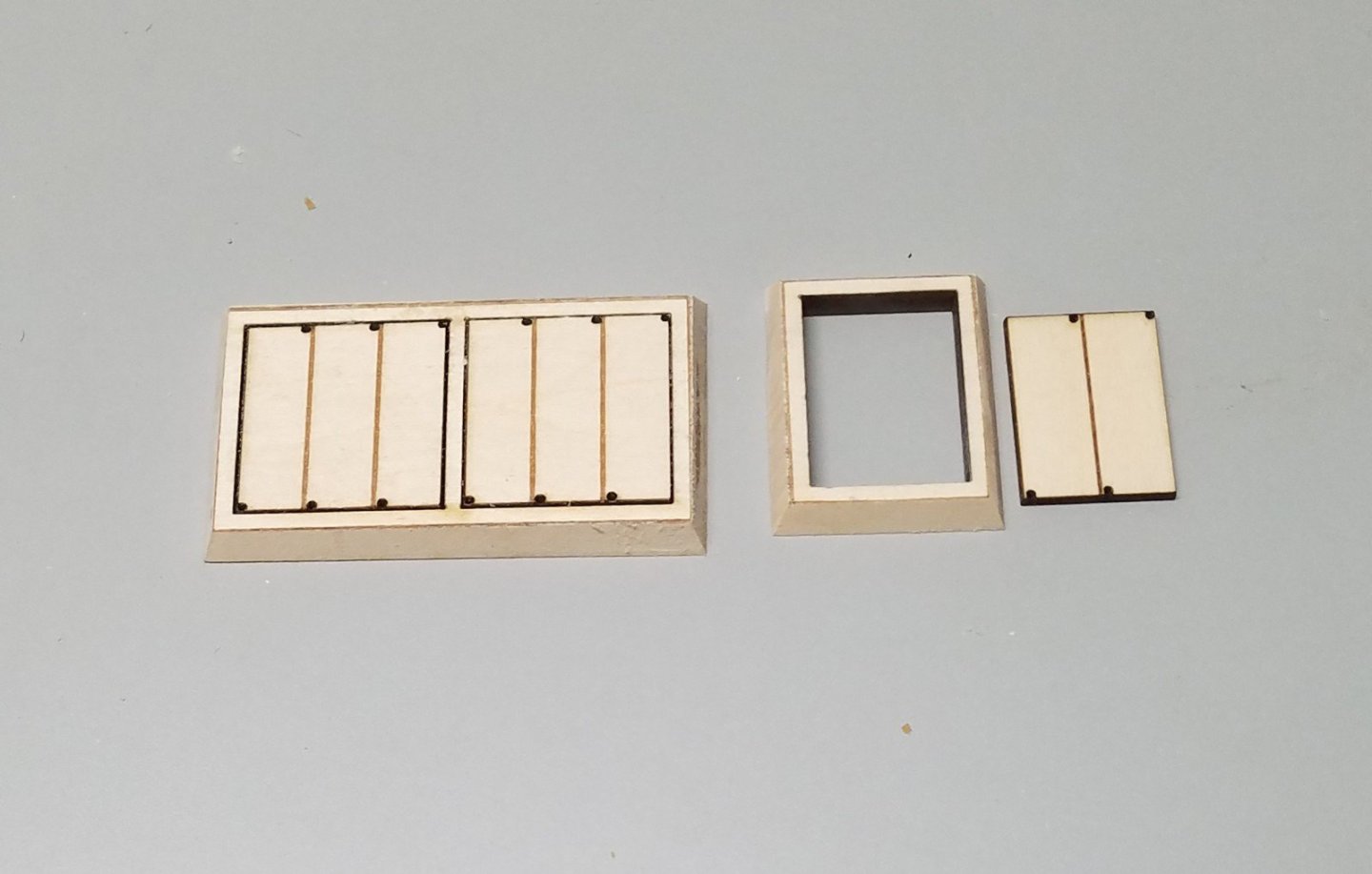

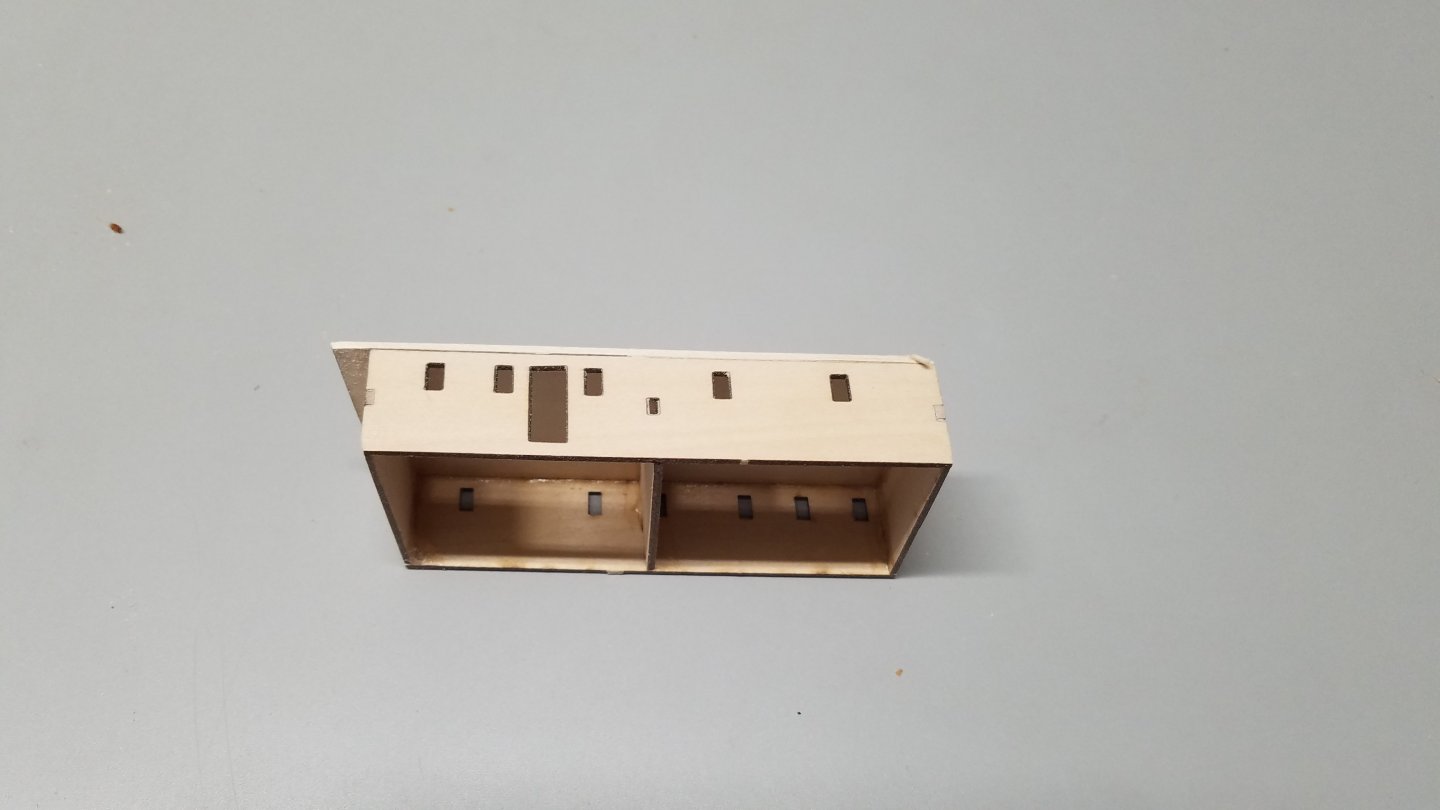

I love our laser. This is one side of the forward house. The top piece is .015" laserboard and has the mullions for the windows. It will be laminated to the inside of the bottom piece which is 1/32" basswood. The square and rectangle on the bottom piece are the window frames which are .015" laserboard. When the house is completely built and painted, .010" clear styrene with its back side painted black will be glued to the inside of the inner lamination. Both houses will be built this way.

-

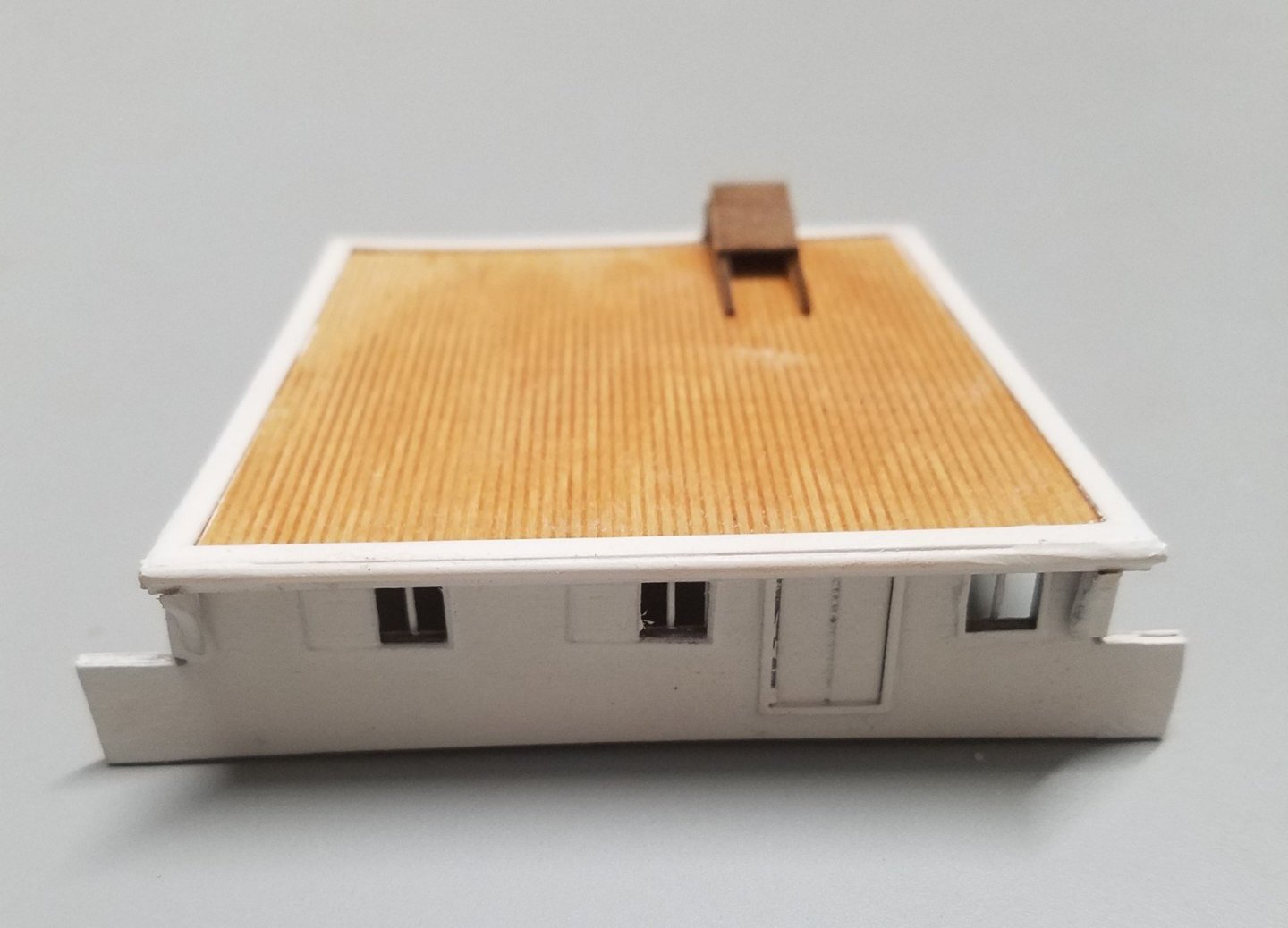

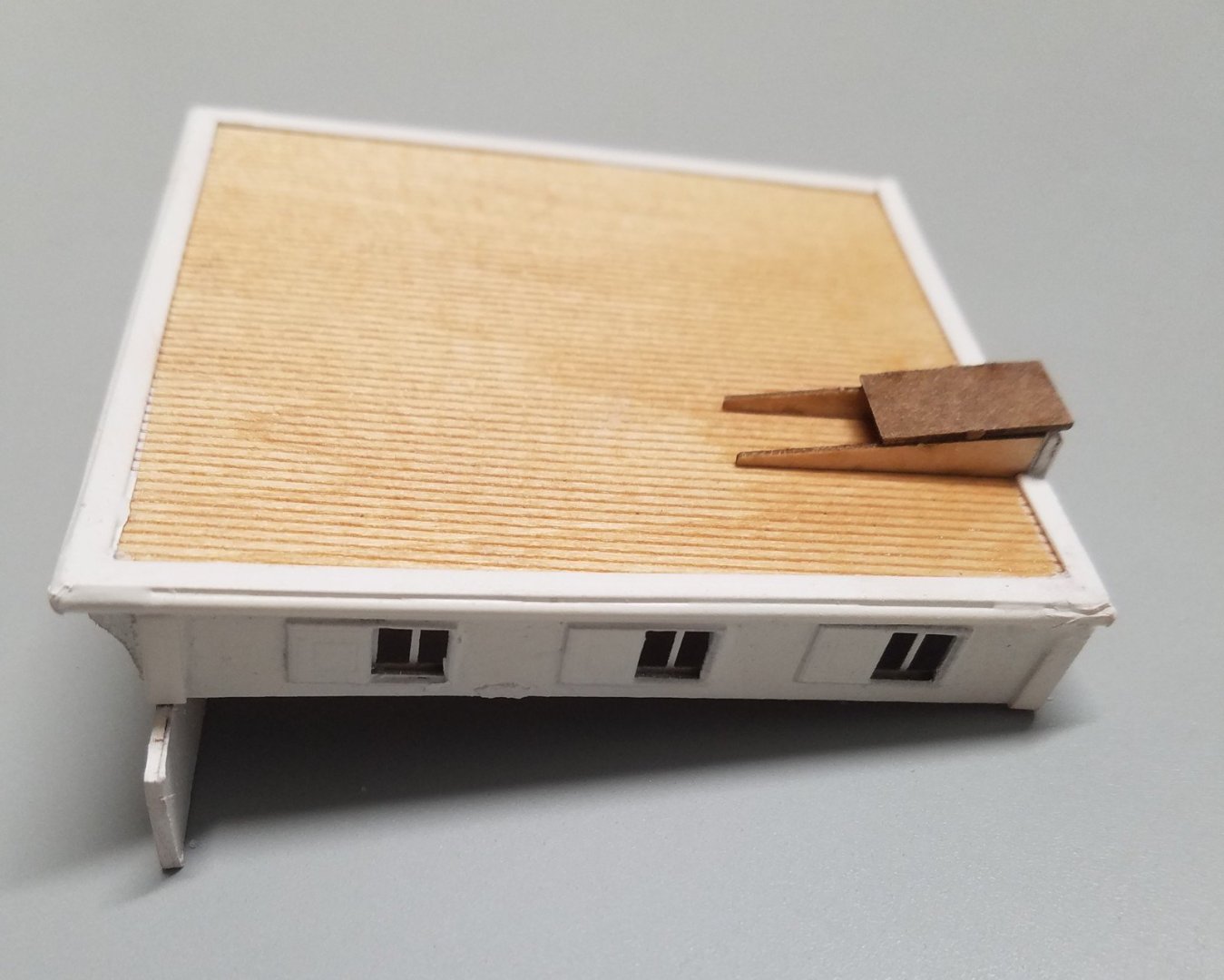

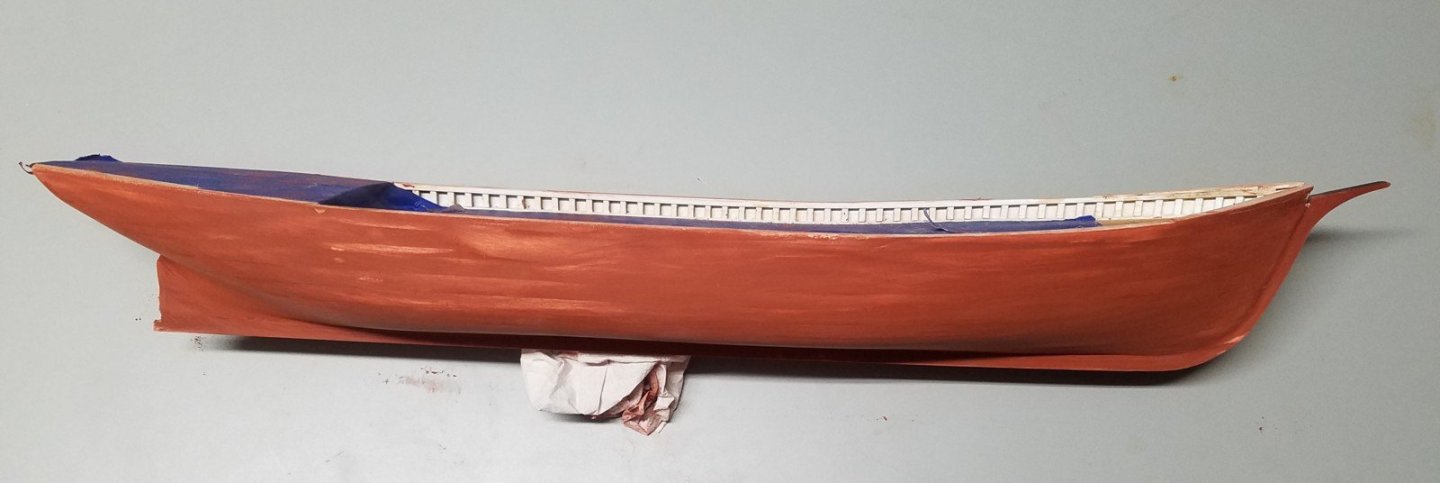

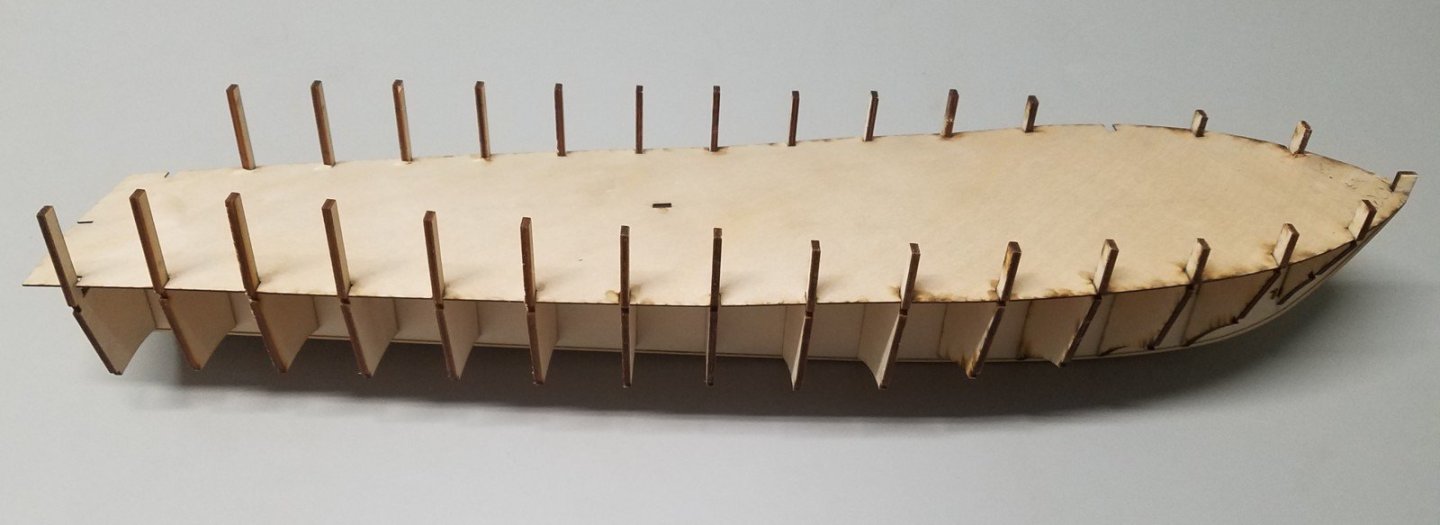

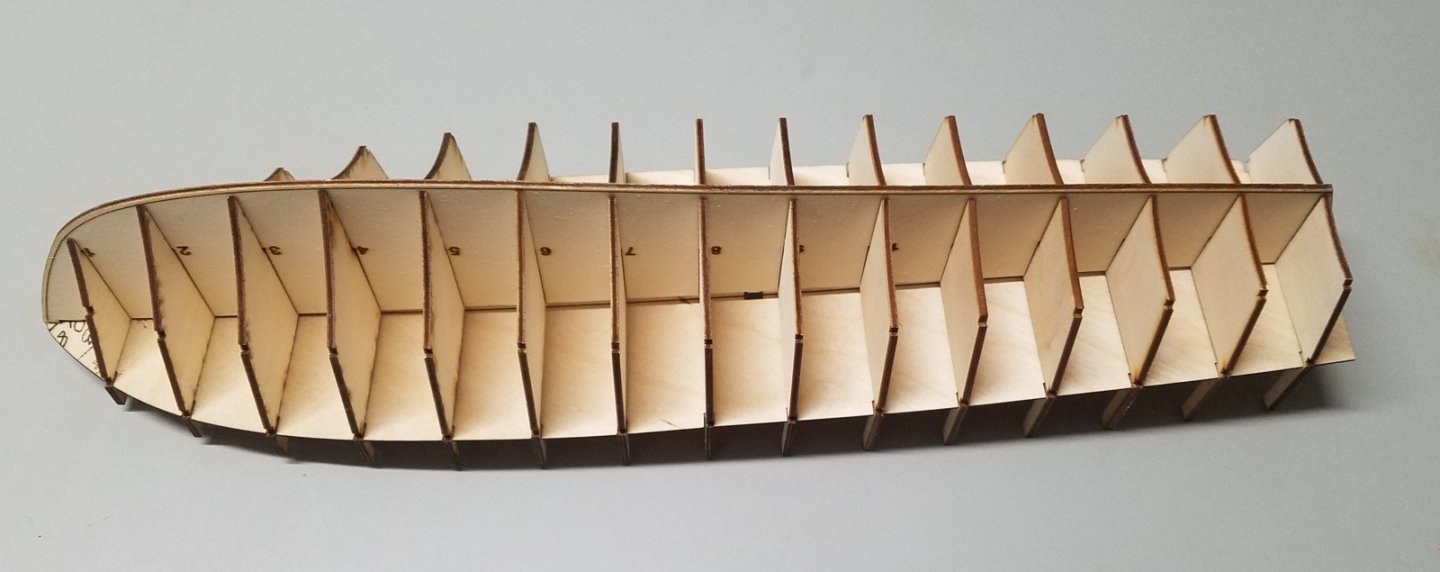

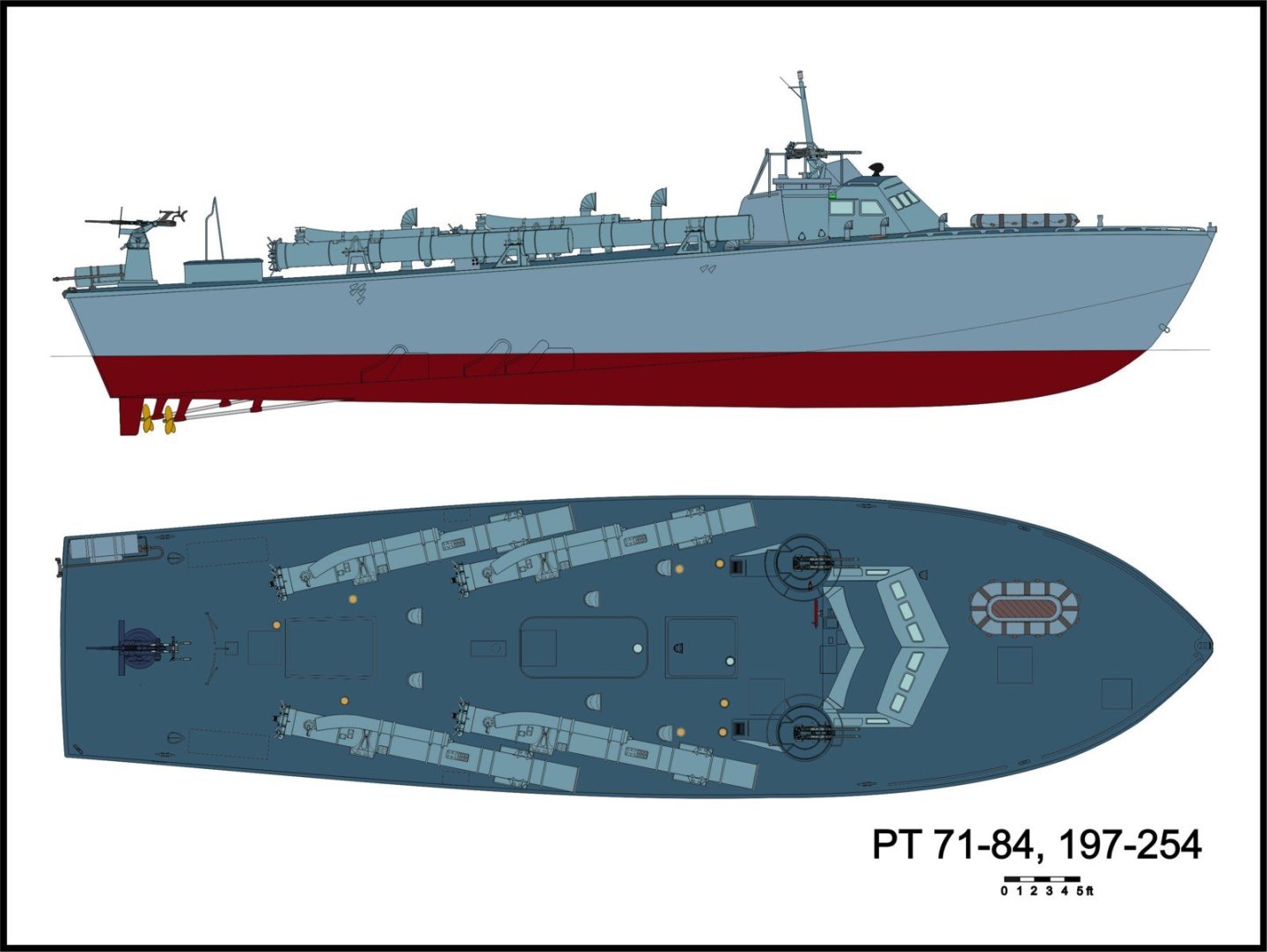

I know most of you folks are "stick and string" enthusiasts but am curious if anyone is interested in more modern vessels. Rather than watch TV in the evenings I've been slowly working on a potential 1/48 kit of a WW2 Higgins 78' PT boat. Structurally, it will be like most of the later kits I've done for BlueJacket - laser-cut planked hull built with the Hahn method, resin and britannia parts, etc. It will be an early boat with tubes and can be built as either a Mediterranean or Pacific boat.

-

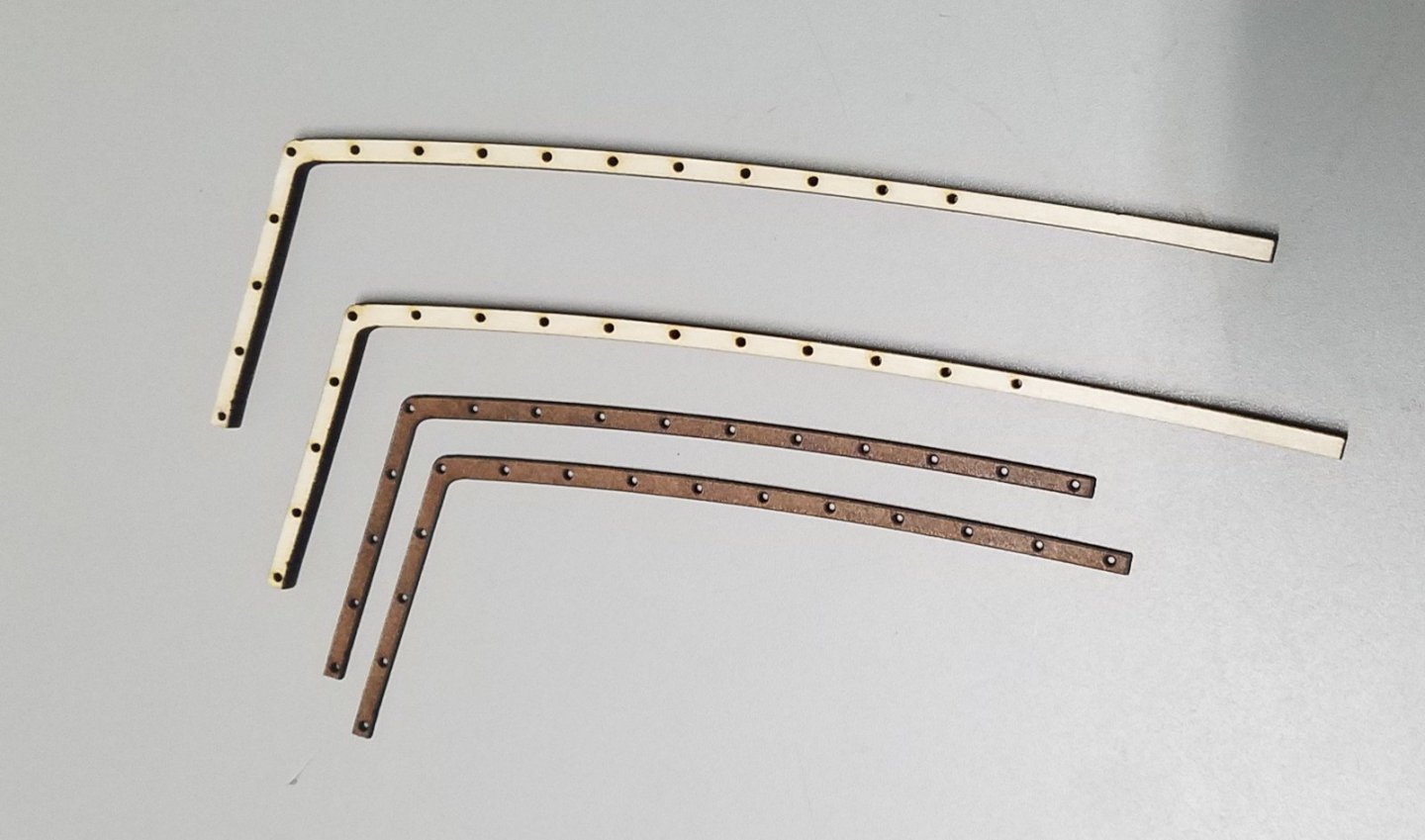

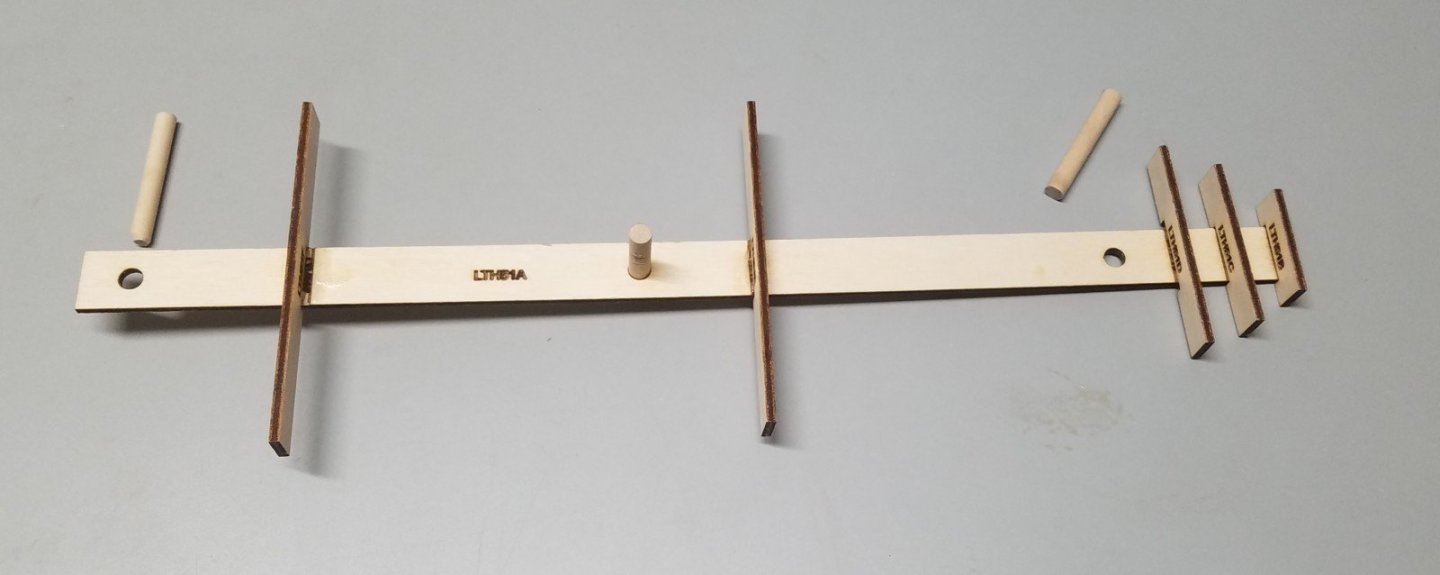

I'm getting too soft in my old age... These are the chock rails and cap rails for the aft section. There are about 24 cast stanchions, each of which has a pin on both ends. Rather than make the modeler measure and drill the holes for the stanchions, I've laser cut them in. The chock rail is 1/8" bass while the cap rail is .035" laserboard, the latter being far more robust than the original 1/32" basswood ones.

-

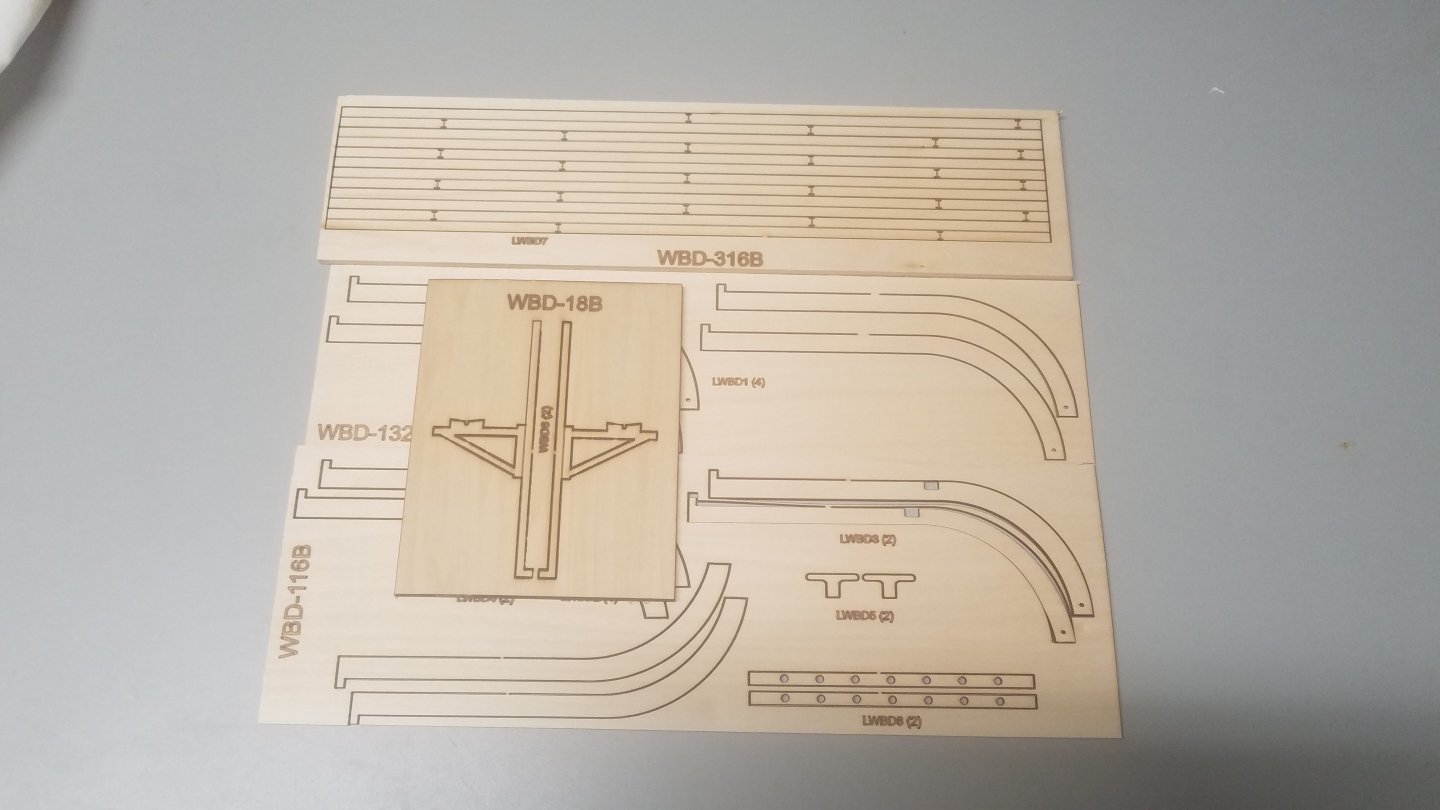

Well, we finished up the Whaleboat Davit kit today, so it is now available. It includes laser-cut parts (davit sections, deck section, cradles, and ladder rails), Britannia sheaves and blocks, strip wood for planking the bulwark, rigging material, full-size plans, and an instruction manual. Scale matches our New Bedford Whaleboat.

-

Since Chris wanted to expand the scope of this thread, here's some basic info. Scale is 1/96, construction is plank on bulkhead. Construction is essentially the same as ALABAMA, KEARSARGE, NOTMAN, and WYOMING - poplar ply bulkheads on a central profile although this time the bulkheads are one-piece.

-

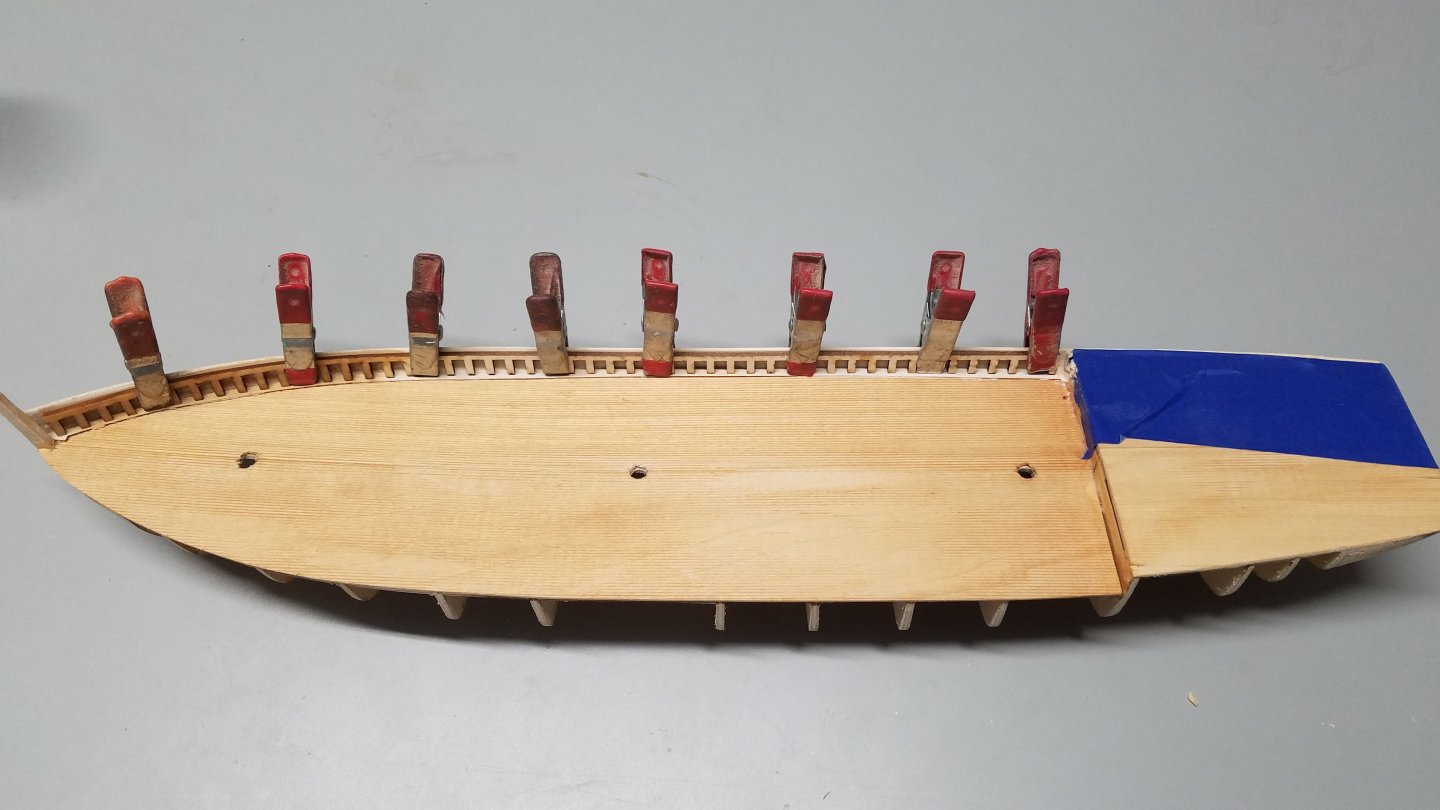

Chris, a skilled modeler such as yourself will be able to replicate the THAYER from this kit...😎 These are the revised timberheads on a new hull. They are clamped and drying out after soaking. I revised the planking sequence so that the top plank of the bulwarks is just a bit above the timberheads. The top plank will then be trimmed to the top of the timberheads establishing the correct sheer.

-

Looks like the lasered timberheads will work. In practice, the bulwarks will be built first. The timberhead strip will be soaked and clamped to the inside of the bulwark to preform. Once it's formed and dry, the modeler will have to CAREFULLY sand the bottom of the timberheads with a sanding block to form a slight angle along the section of the bulwark that flares a bit outboard. This photo was of the initial fitting and the timberhead bottoms were not sanded. I was primarily seeing if the strip would survive the bending and gluing. I had to make some height adjustments to the strip and am currently soaking one to fit to another test hull. Yuh, I go through a lot of laser...😱

-

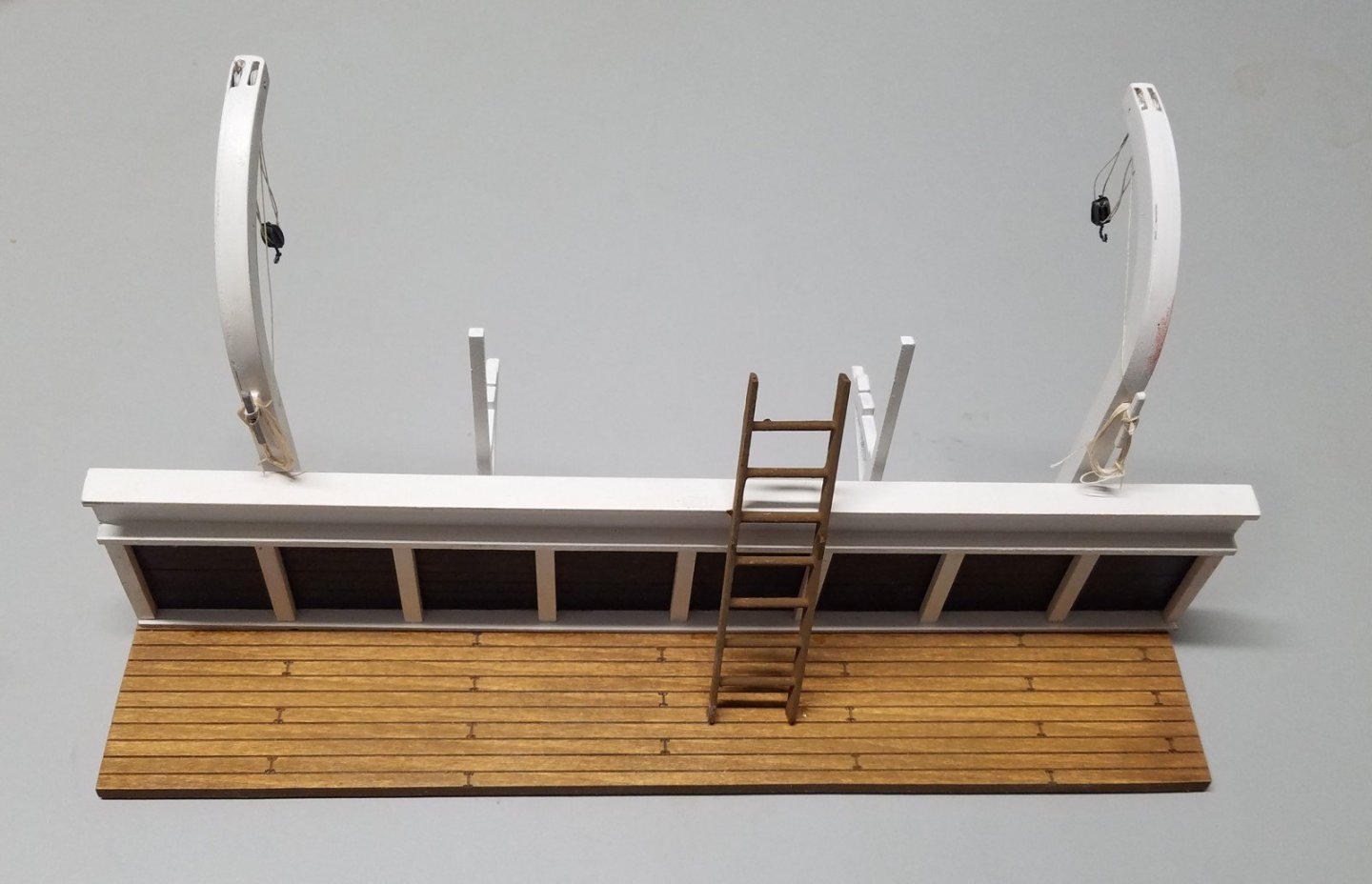

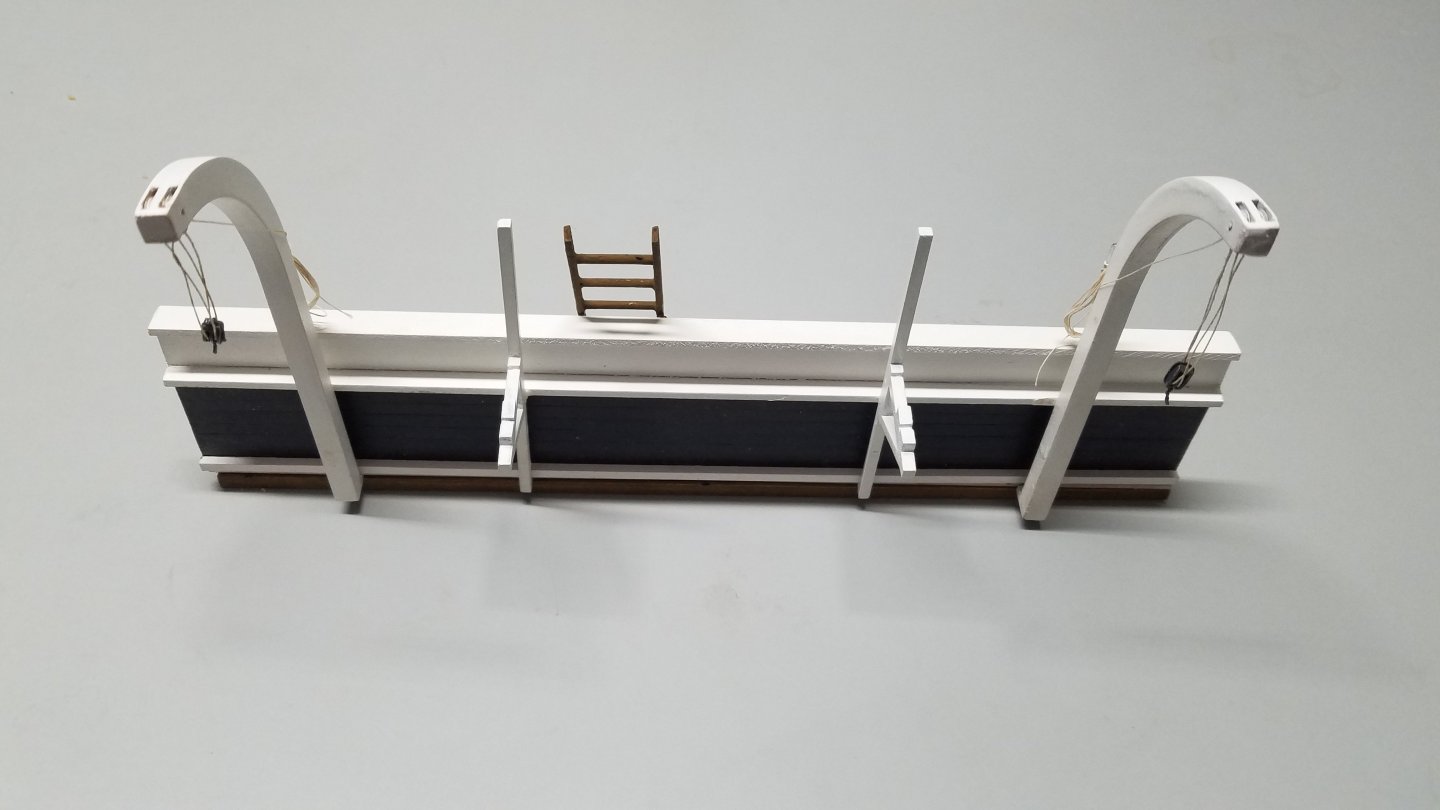

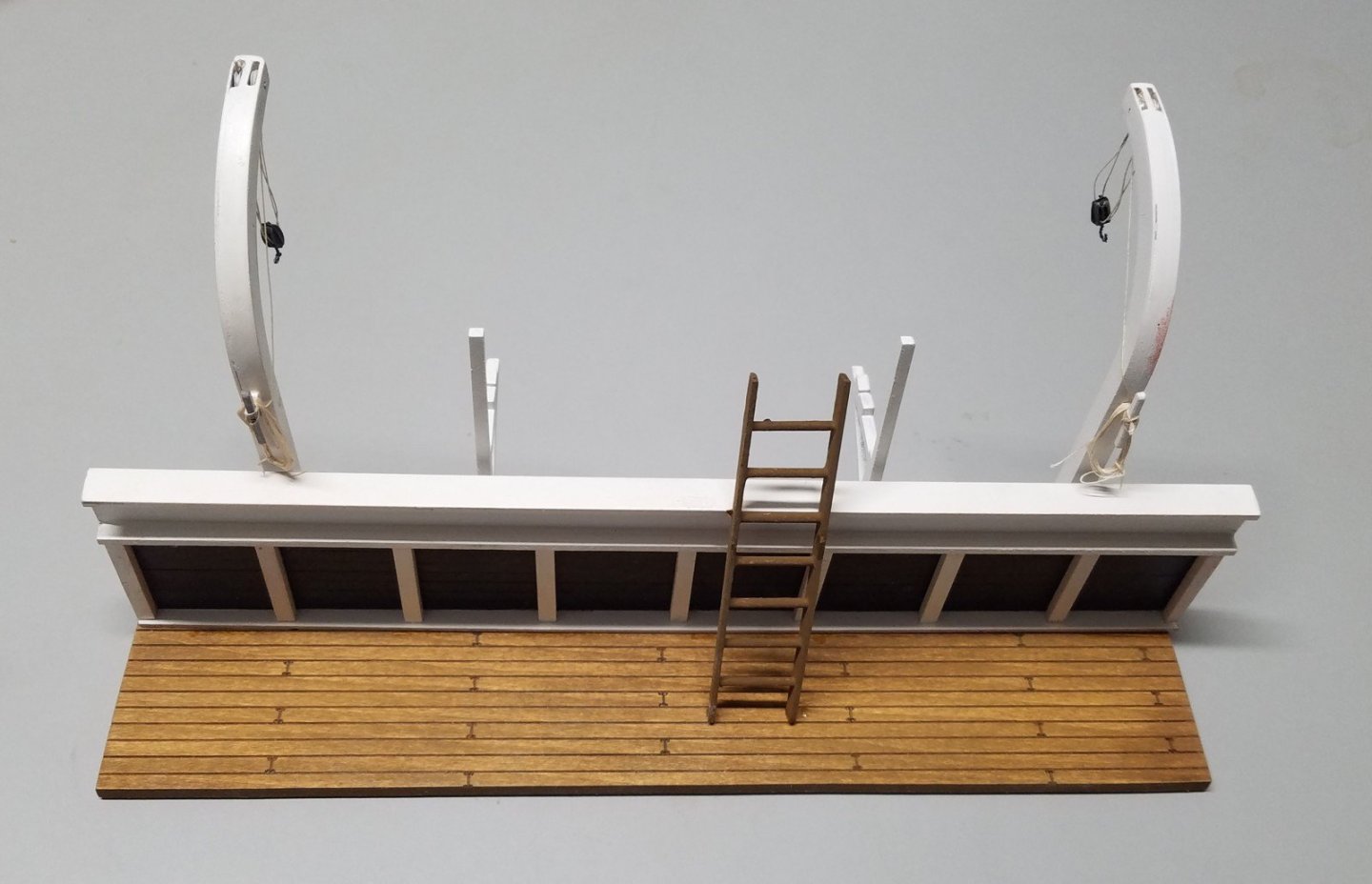

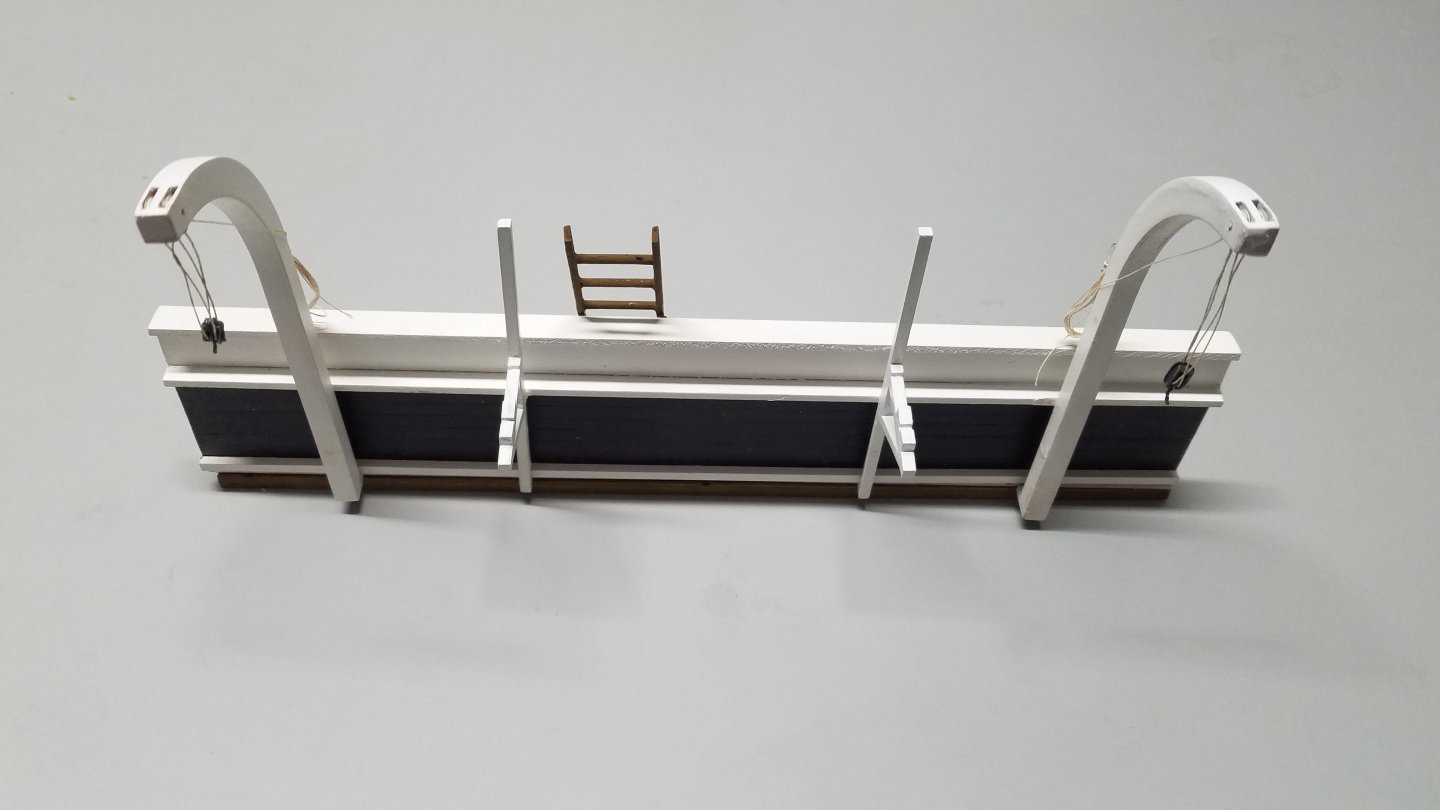

Some years ago, our late friend and builder Charlie Cook built one of our New Bedford Whaleboat kits for our gallery. Rather than mount it in its cradle, he built a partial bulwark with davits to display it. We've had a number of folks ask it they could get one, but we didn't make a kit for it...until now. I just finished building the display model using the production kit parts. The kit, KLW122A, will be available shortly. It has four sheets of laser-cut parts, the usual basswood strip and britannia fittings, an instruction manual, and one 24" x 36" sheet of plans. Scale is 1"=3' to match our Whaleboat kit and is 11.5" long. Price hasn't been set yet but will be soon..

-

This is an experiment. I'm developing a new kit that has exposed timberheads and am experimenting with laser-cut timberheads. In theory, the bulwarks and waterways will already be in place. The timberhead strips will be soaked for pliability forward and glued down to the bulwarks and waterways. I can see some potential issues but will find out once I get the bulwarks on the hull.

-

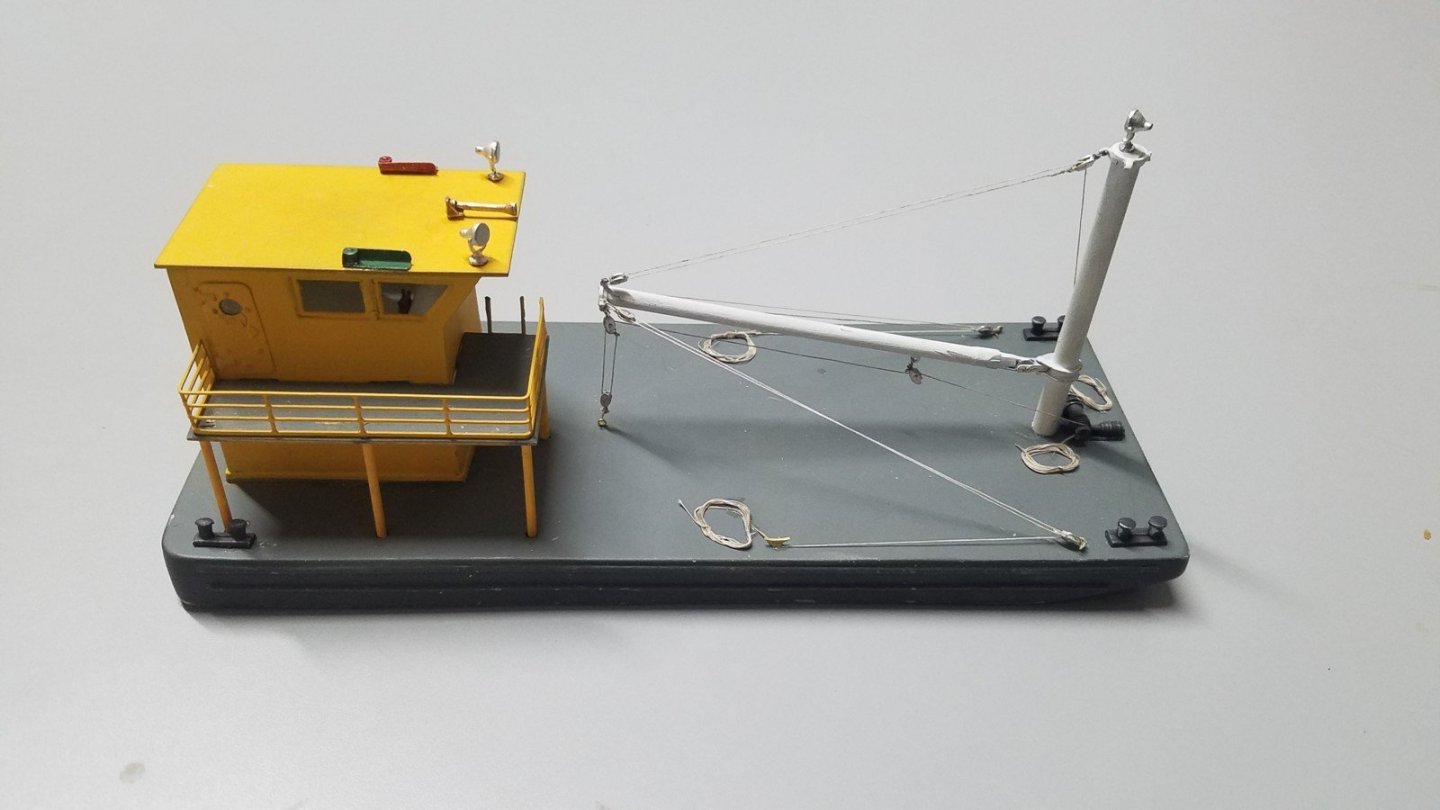

The three new HO scale kits are now available. All three have resin hulls and Britannia fittings; the sardine carrier and self-propelled barge also have laser-cut parts. These kits were designed primarily for the HO model railroad community, so they are waterline and have a lot of detail molded in. The sardine carrier and self-propelled barge can be completed in a weekend or two while the coal barge takes only an hour or so (including painting!). HO308 COAL BARGE - $35.00 HO309 SARDINE CARRIER - $98.00 HO310 SELF-PROPELLED BARGE - #98.00

-

BlueJacket Shipcrafters has a large number of metal and resin fittings that are specific to our 20th Century warship kits that are not listed separately in our catalog. Most are 1/192 scale with a few in 1/96 and 1/48 scale. If you have specific needs in this area, make a list that includes the ship's name, type, time period, and required fittings and send it to me ( al@bluejacketinc.com ). I'll send you back a list of what we can supply and their prices.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.4c43faea398bf64fceea4c8a3f9b78a7.jpg)