-

Posts

408 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alross2

-

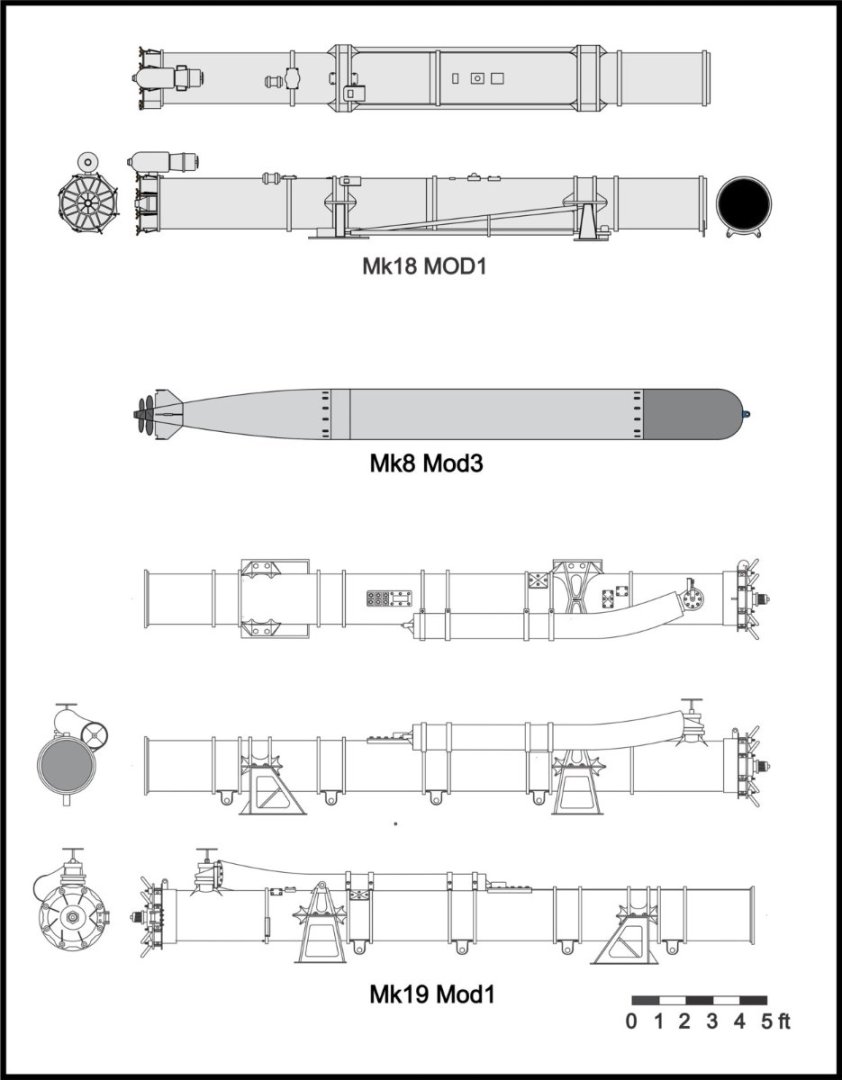

The MK18 (upper) used the powder charge and was fitted to ELCO and Huckins PTs. The MK19 (lower) was the Higgins compressed air tube.

-

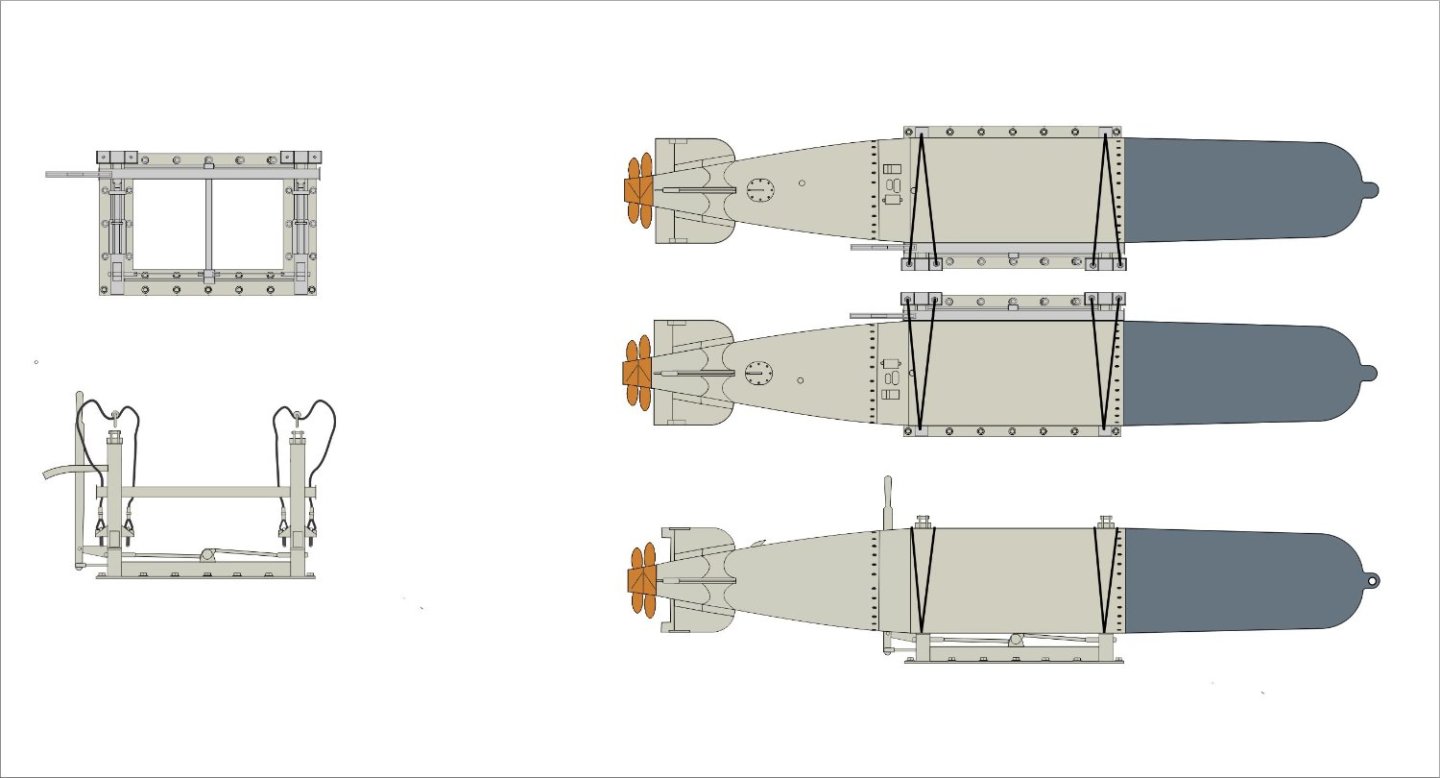

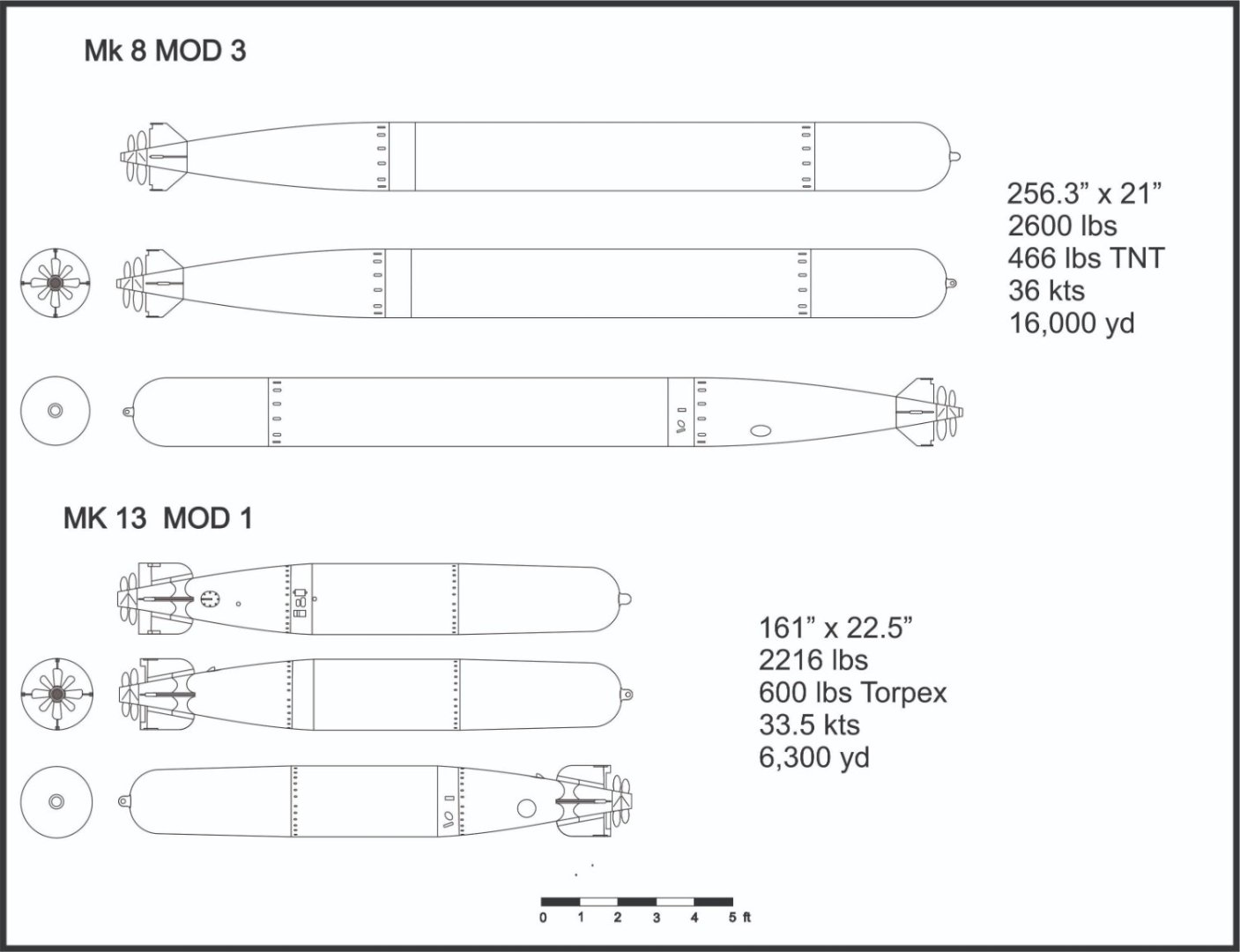

Here's a comparison between the MK8 and the MK13, as well as the MK1 rack for the MK13. Typically, the torpedoes came from the factory with flat medium gray (like Ocean Gray 5-0) warheads and everything aft of the warhead in a yellowish brown preservative. Props were bronze.

-

Did the kit have the CD? It has about 100 images of the build of the display model from start to finish. You can still get one from BlueJacket.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

100 in 2005. They were gone in a couple months, most being sold before the catalog came out.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

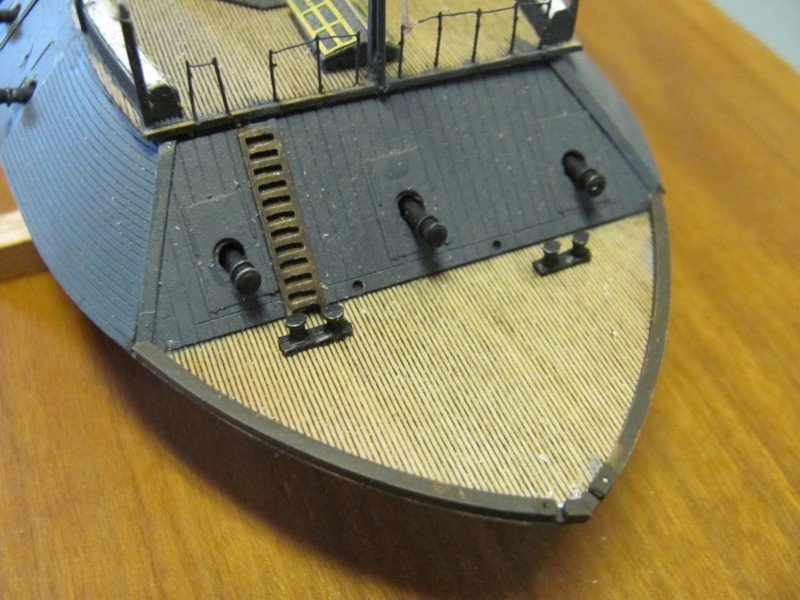

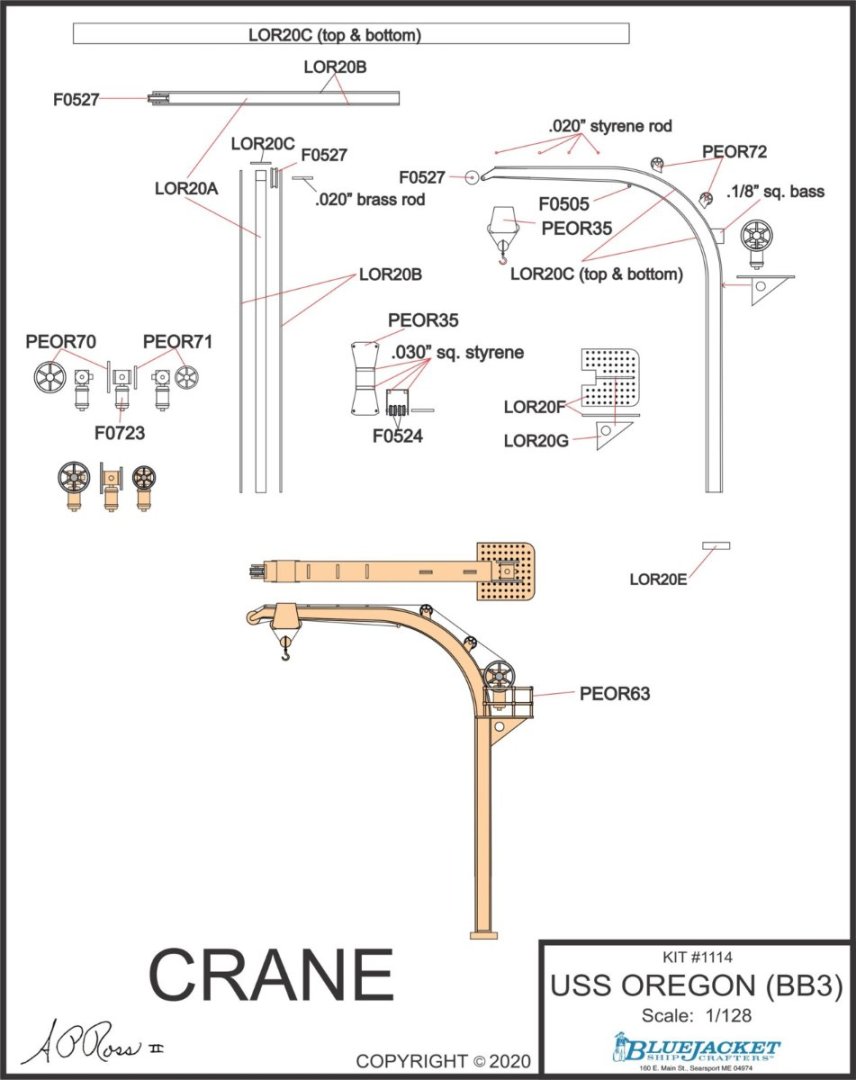

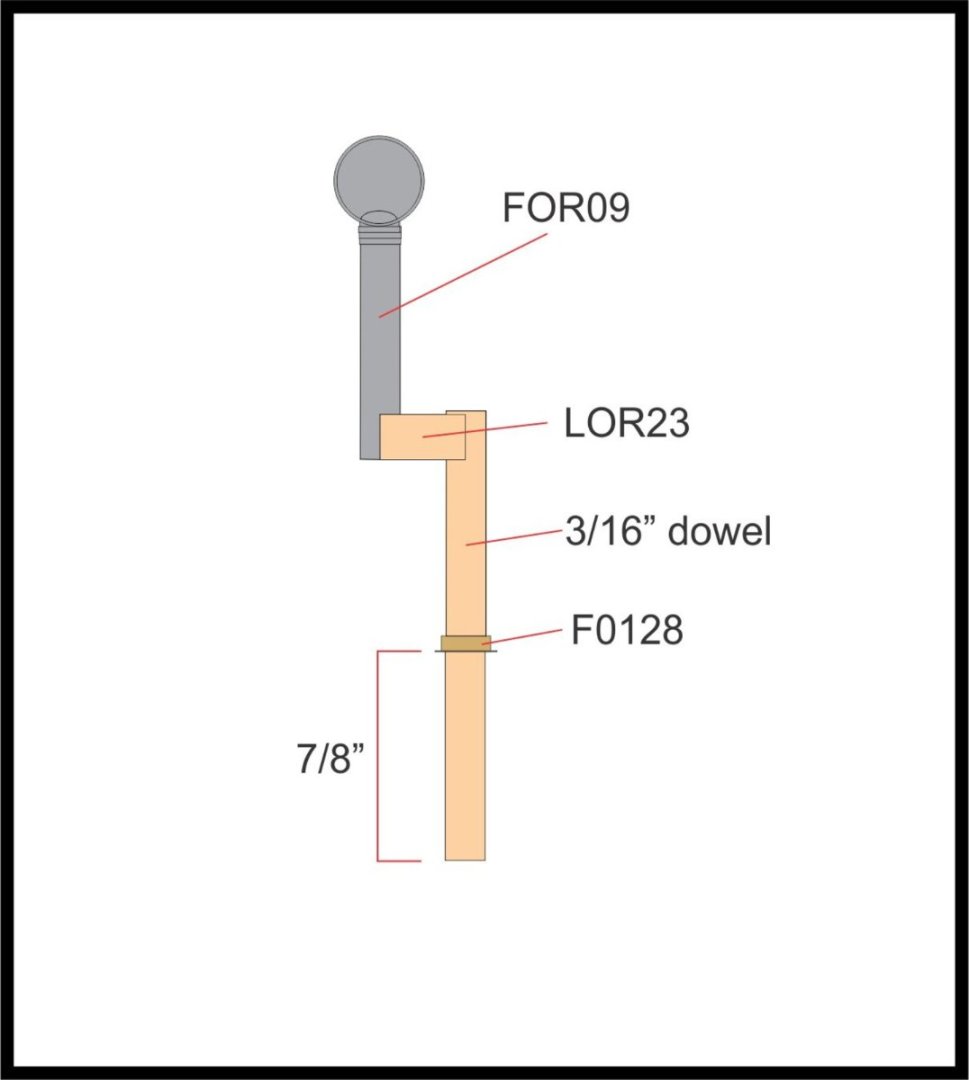

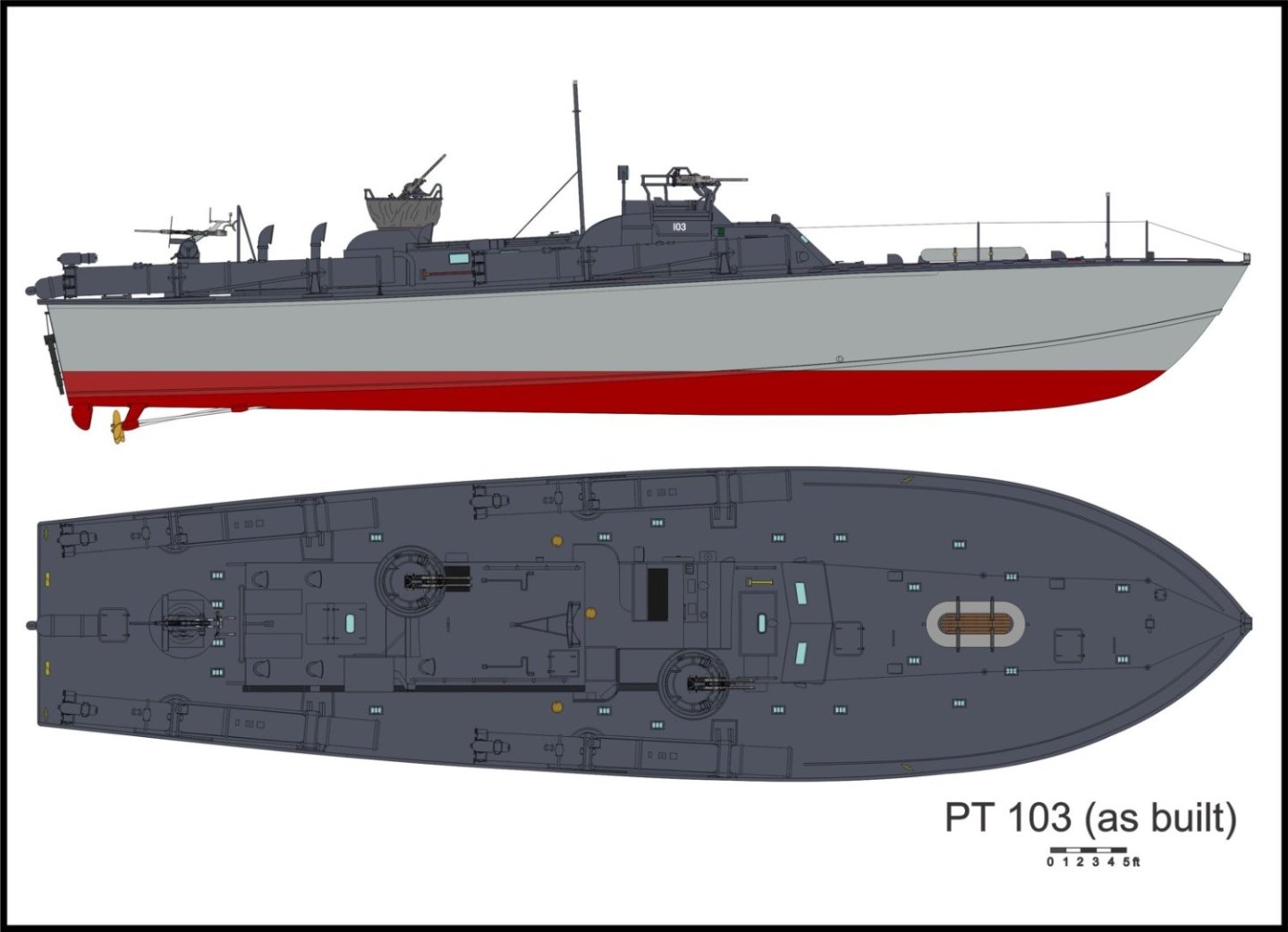

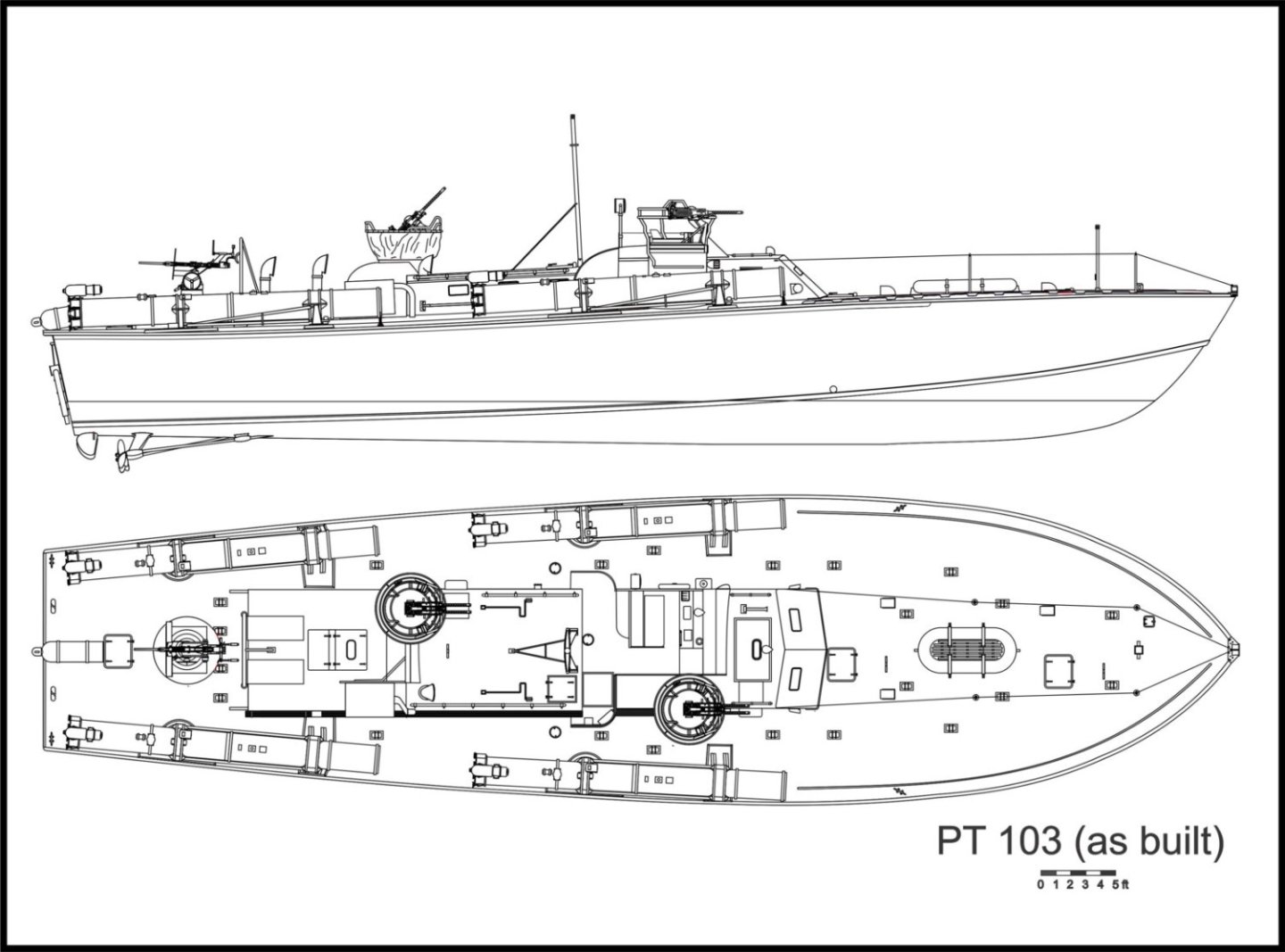

I designed it back in 2005, so if you have questions, feel free to ask. If you break or lose anything, we still have the stuff to replace it.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

a drafting tool or paper weight

alross2 replied to garyshipwright's topic in Modeling tools and Workshop Equipment

I have 18-20 (that's about 80 pounds!) of these and haven't used them in several years. They were a great tool when I drew ink on mylar, but now I'm using CorelDraw and haven't touched a drafting pen in about four years. Probably should get rid of them. -

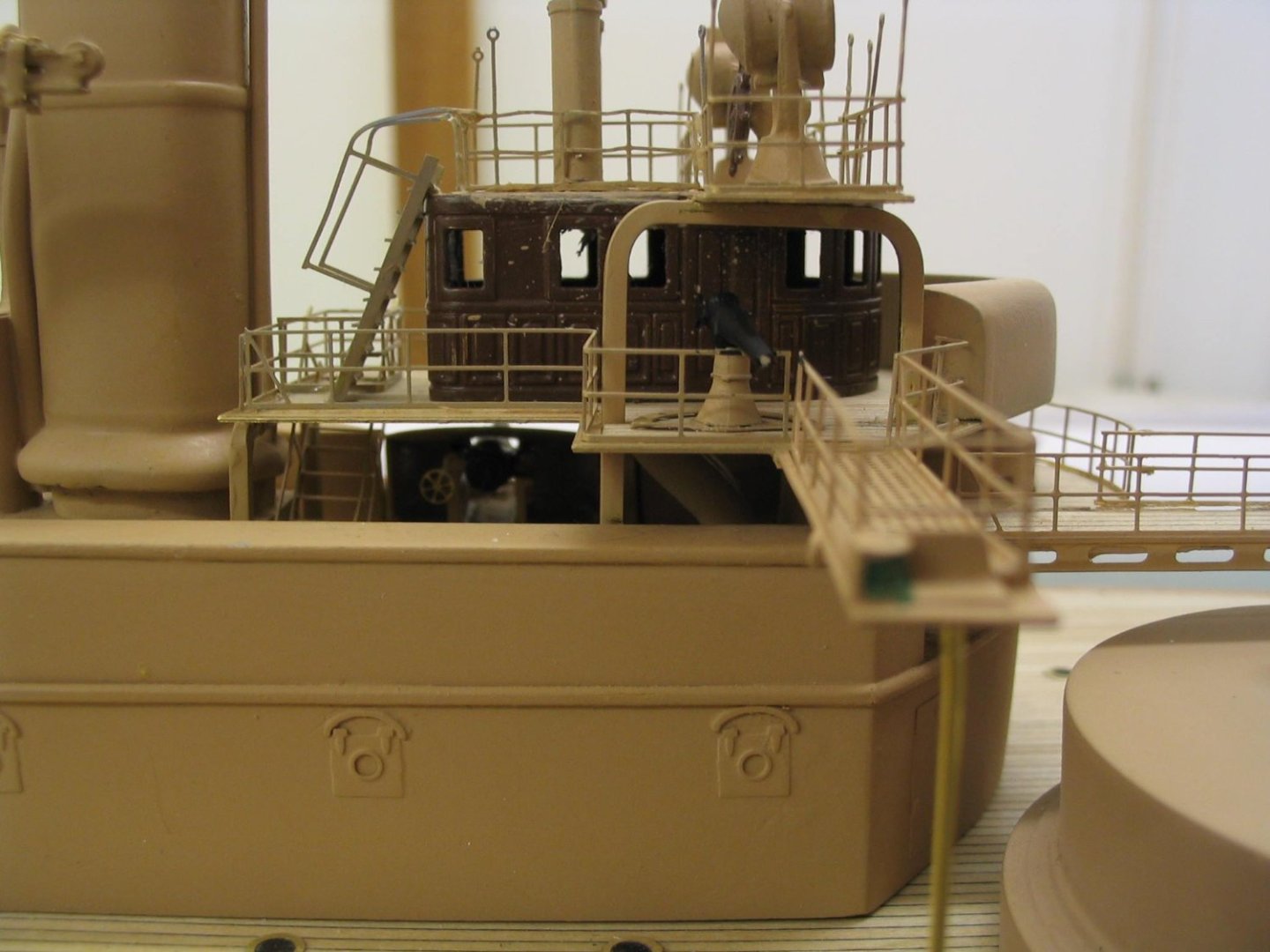

OK, the display model is done. Next week, I'll look it over and do any necessary touchup. It's always better for me to leave a finished model for a few days and look at it with fresh eyes. It's still on the building board as the case isn't done yet and the case base needs to be in place when Josh puts in the glass. Once she's mounted on the case base, I'll get some better photos.

-

Doing my favorite thing - rigging (grump...). There are two bow scrolls in the kit - one photo-etched brass and one printed paper. The brass one is for those with really, really, really fine paint brushes. The stripes and stars are raised. The paper one is for those of us who want really nice sharp paint lines, but can't paint for crap...

-

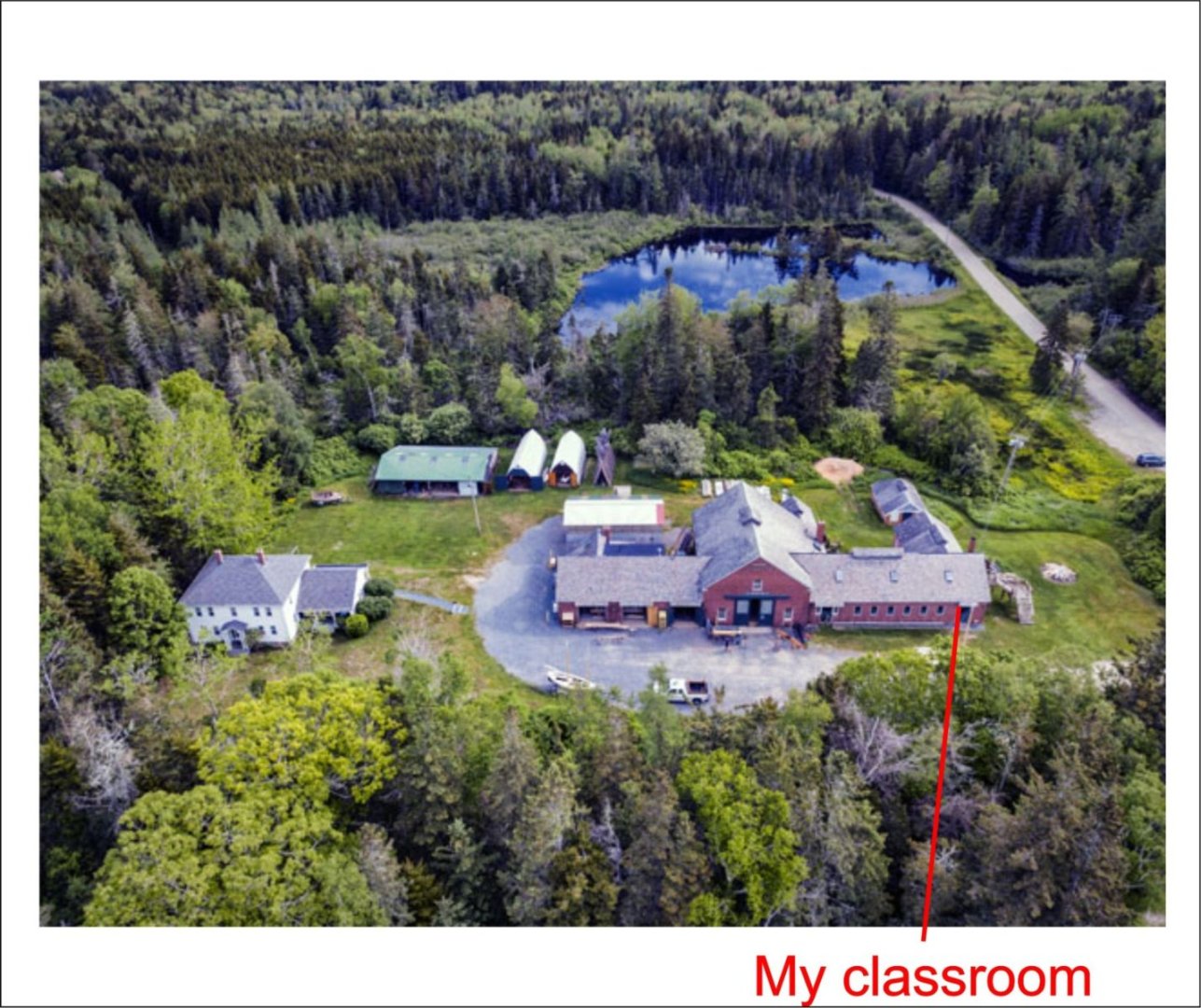

Back from a great week teaching ship modeling at the WoodenBoat School, guess I have to work on OREGON.... Boat skids are all in and the boat cradles attached and painted. The boats are drying and will have their thwarts attached sometime today. Also attached one of the 6 pdrs on the hurricane deck.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.