-

Posts

736 -

Joined

-

Last visited

About ChrisLBren

- Birthday 11/08/1969

Profile Information

-

Gender

Male

-

Location

Barrington

Recent Profile Visitors

-

Archi reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Archi reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

dvm27 reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

dvm27 reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

ChrisLBren reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

ChrisLBren reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

AnobiumPunctatum reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

ChrisLBren reacted to a post in a topic:

Le Chebec by Yvesvidal - CAF Model - 1/48

ChrisLBren reacted to a post in a topic:

Le Chebec by Yvesvidal - CAF Model - 1/48

-

BradNSW reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

BradNSW reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

Archi reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Archi reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

Archi reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Archi reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

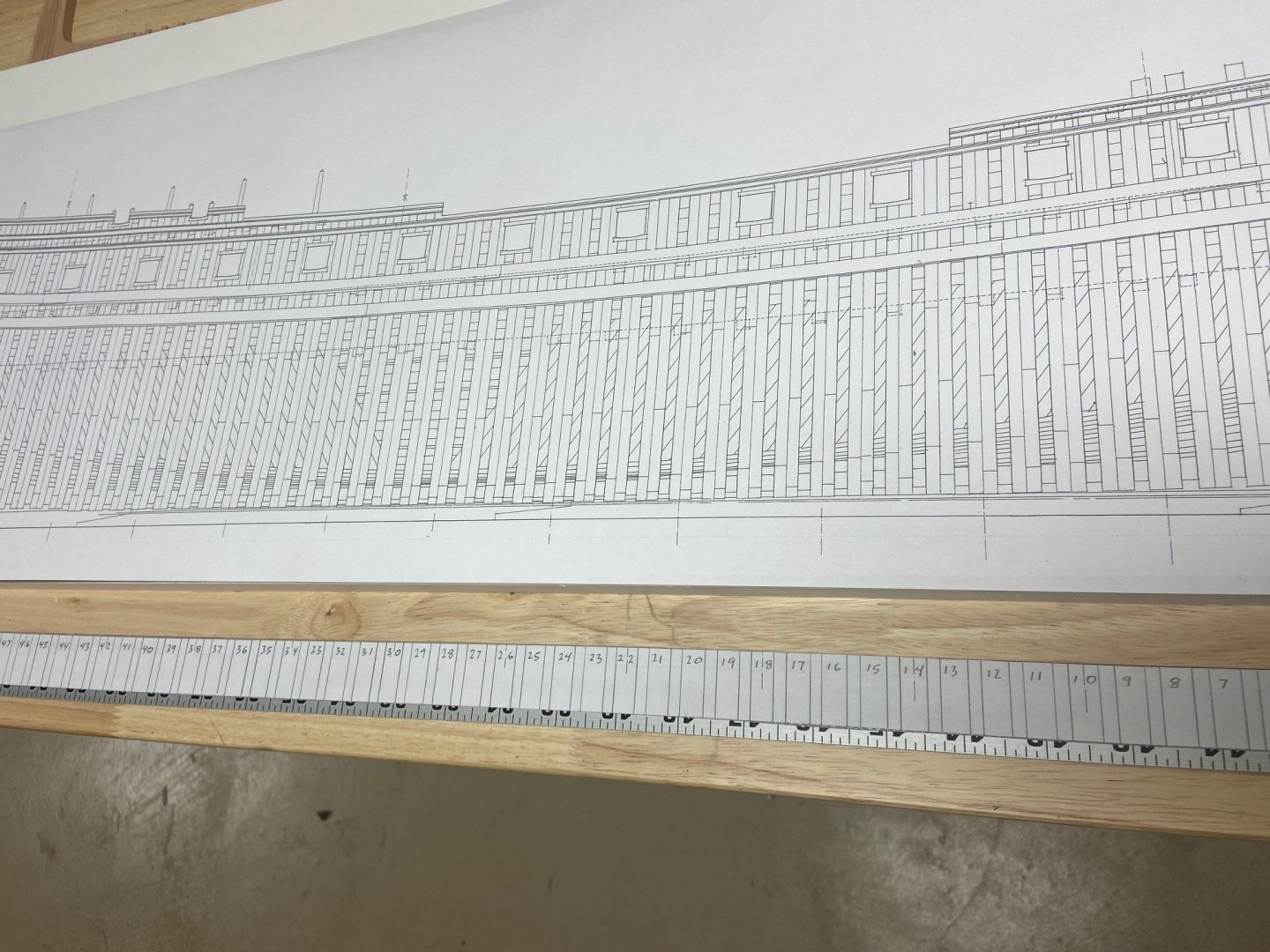

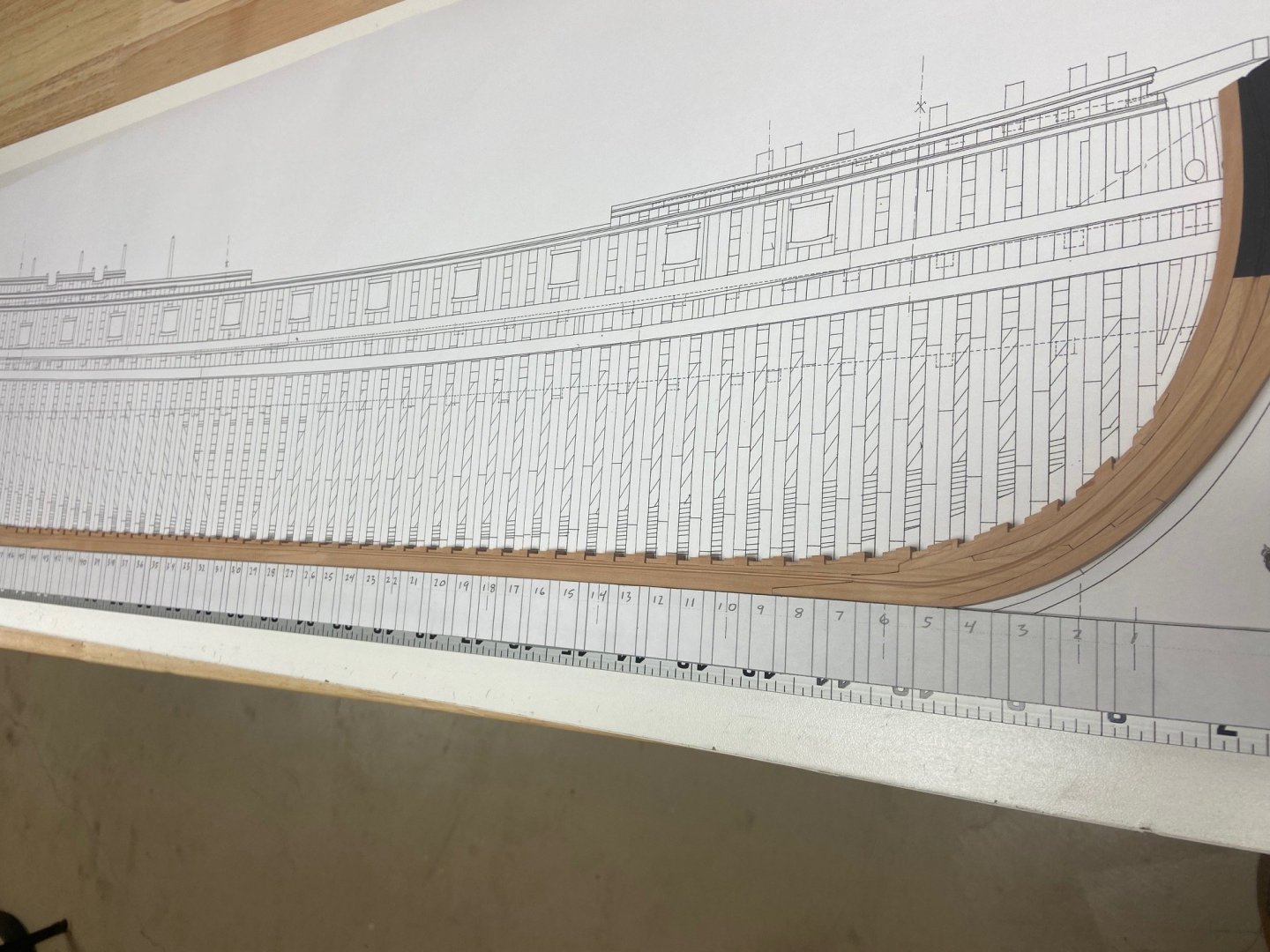

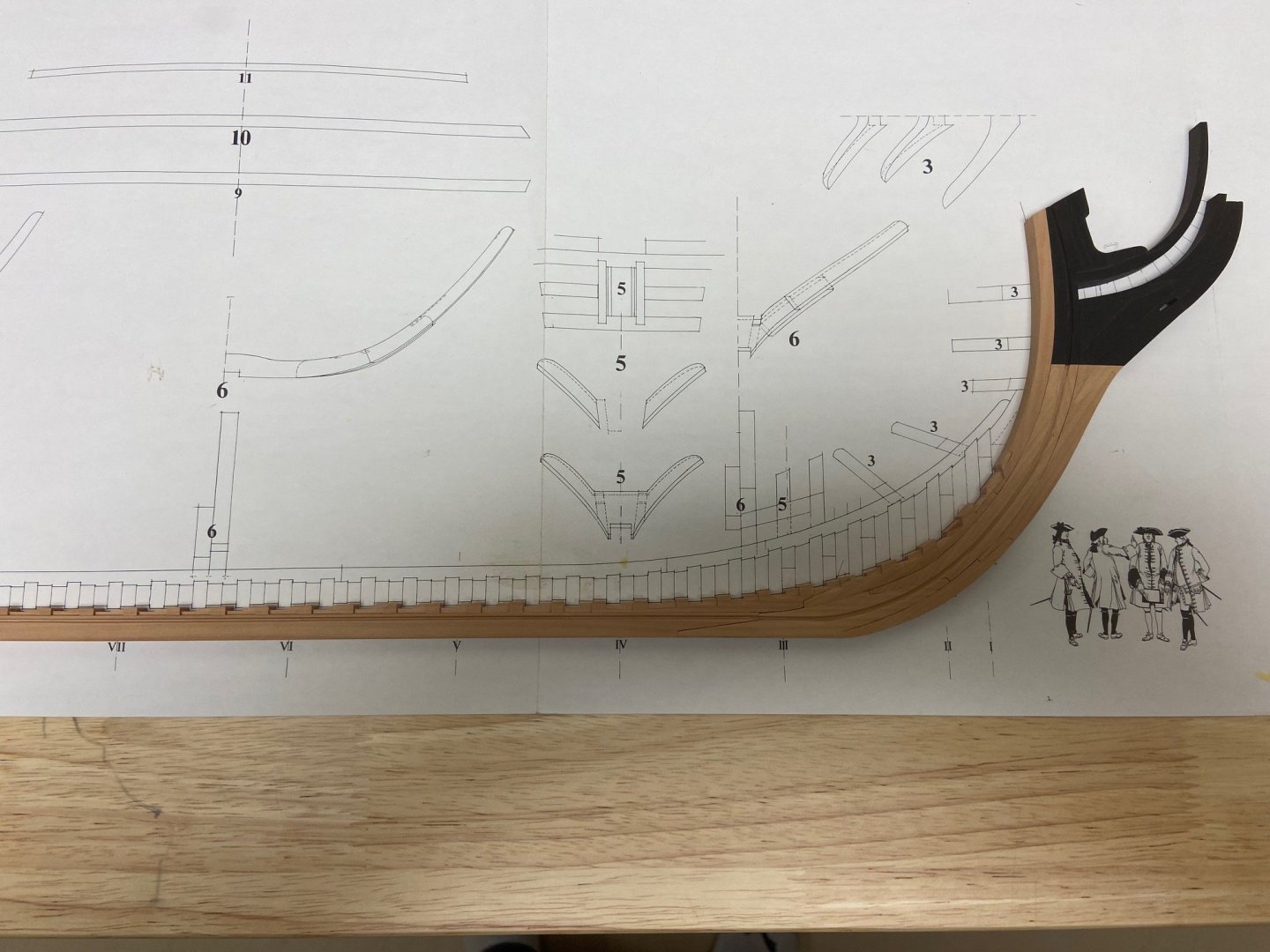

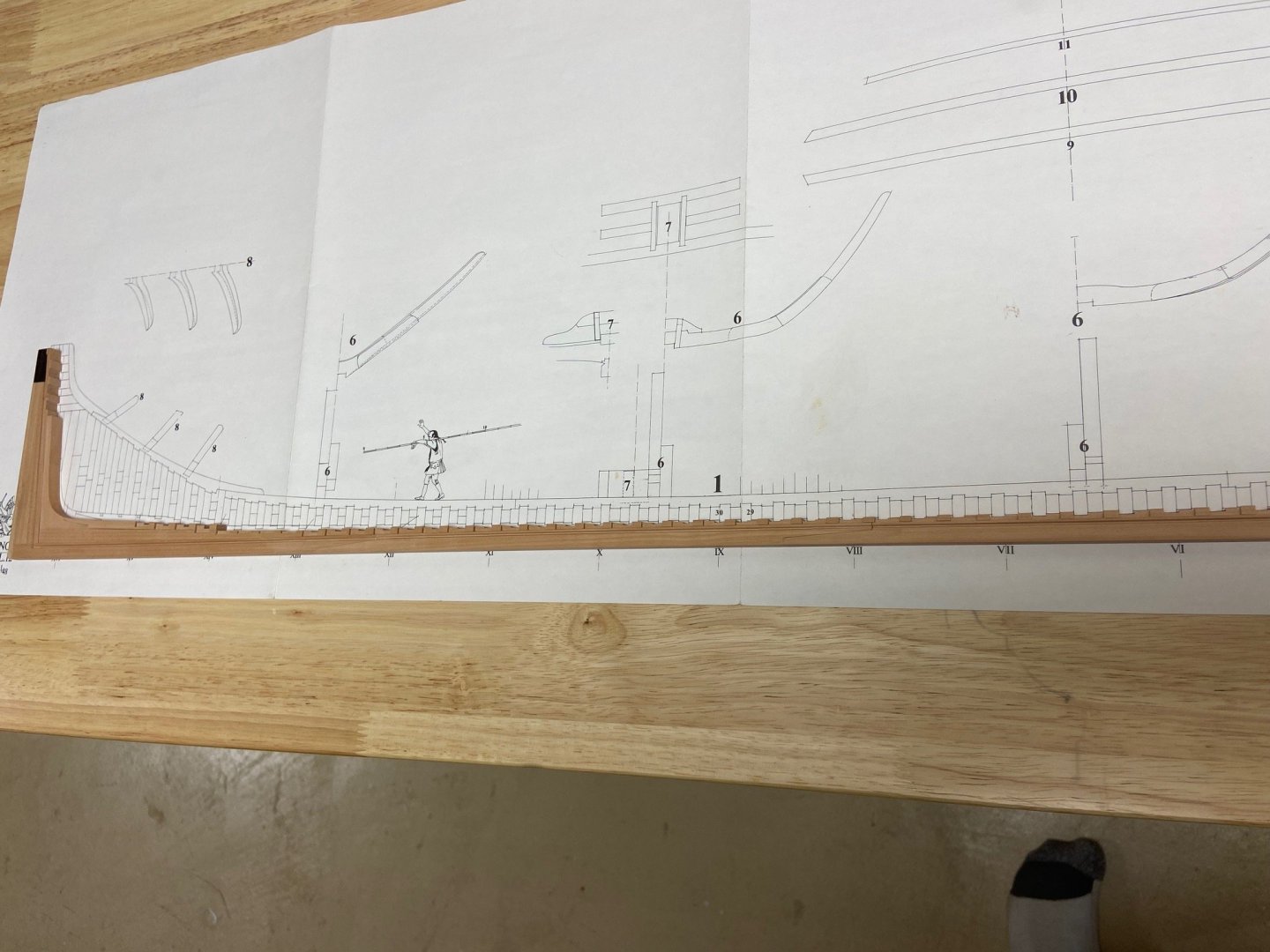

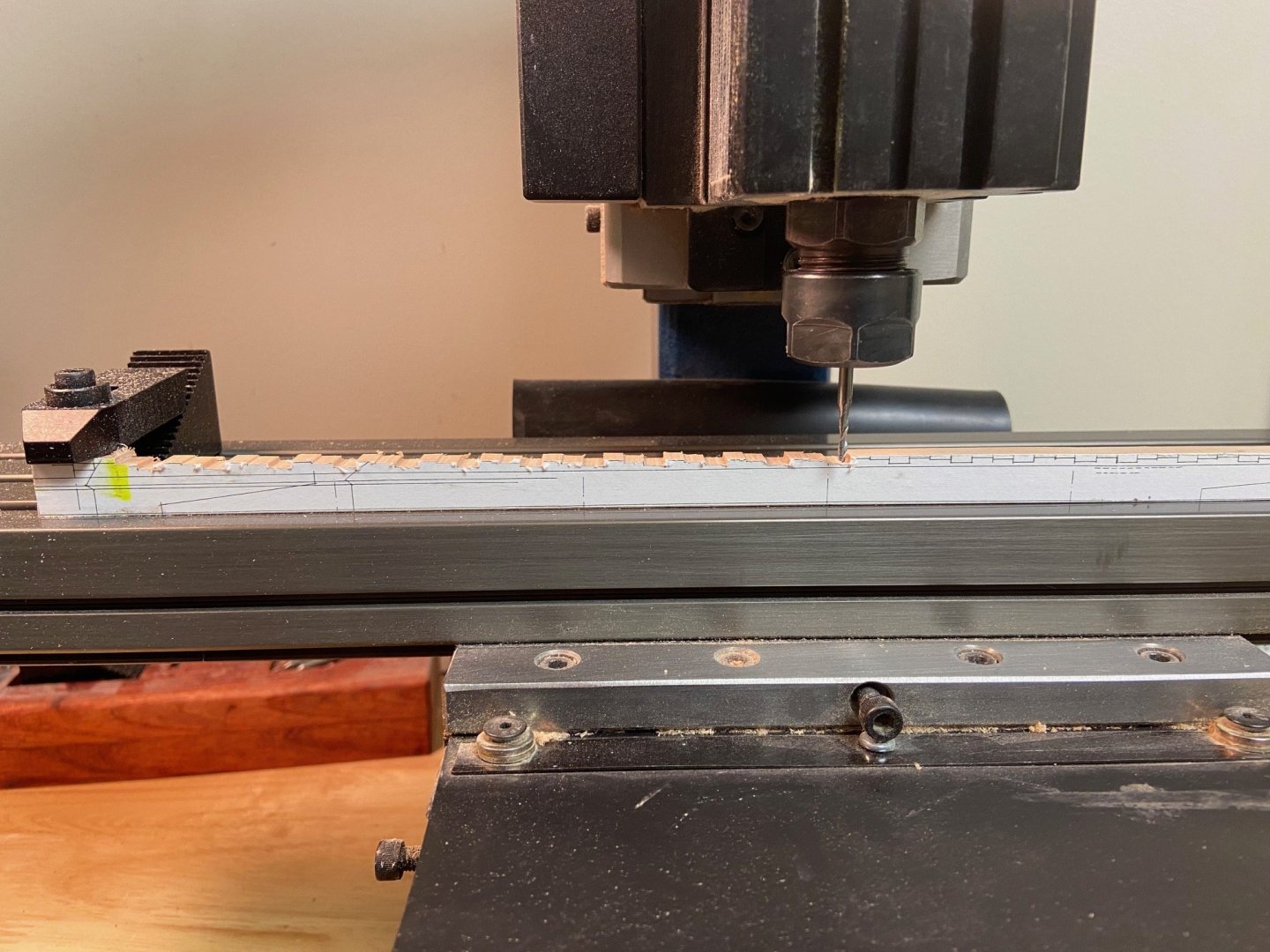

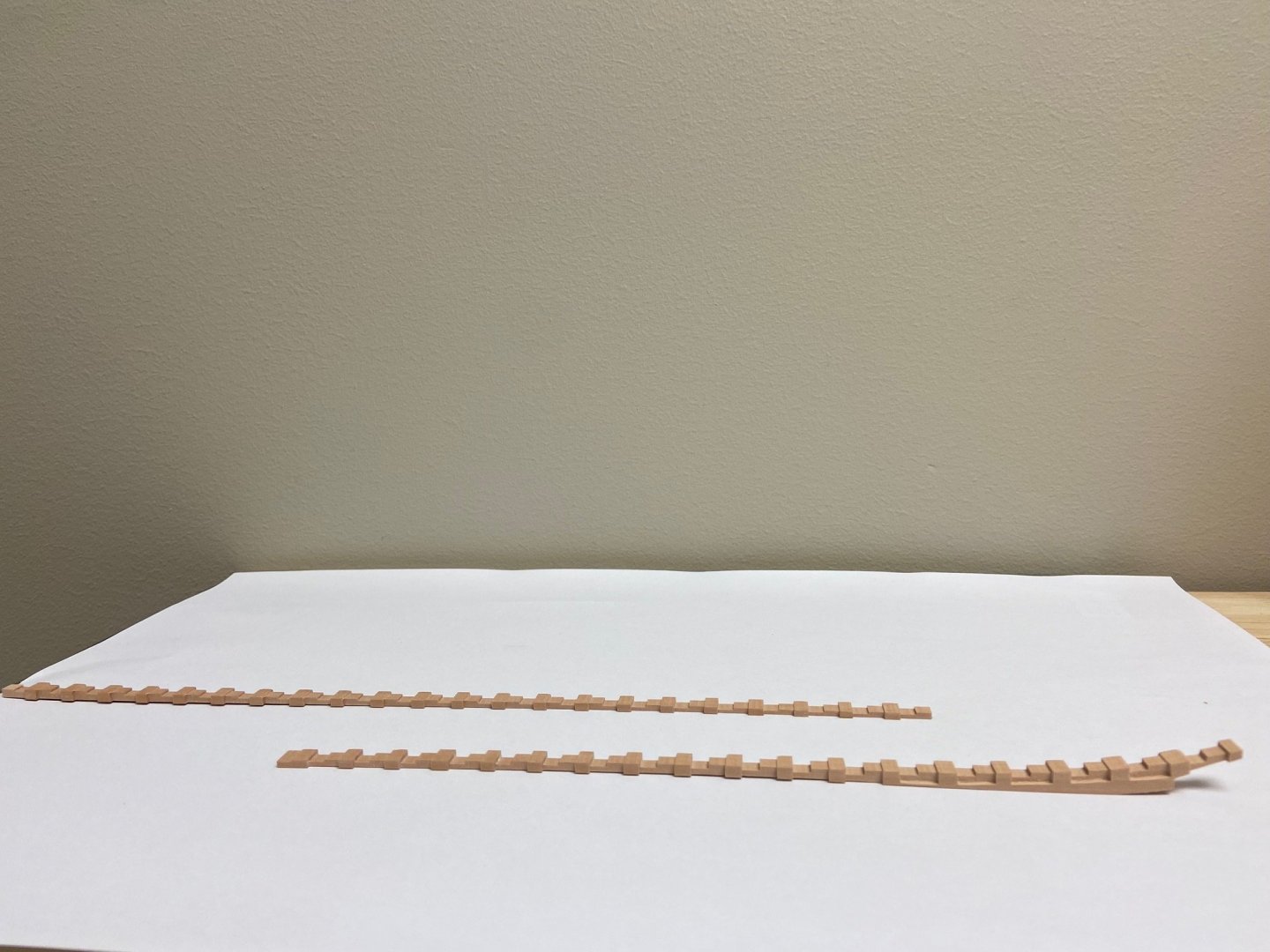

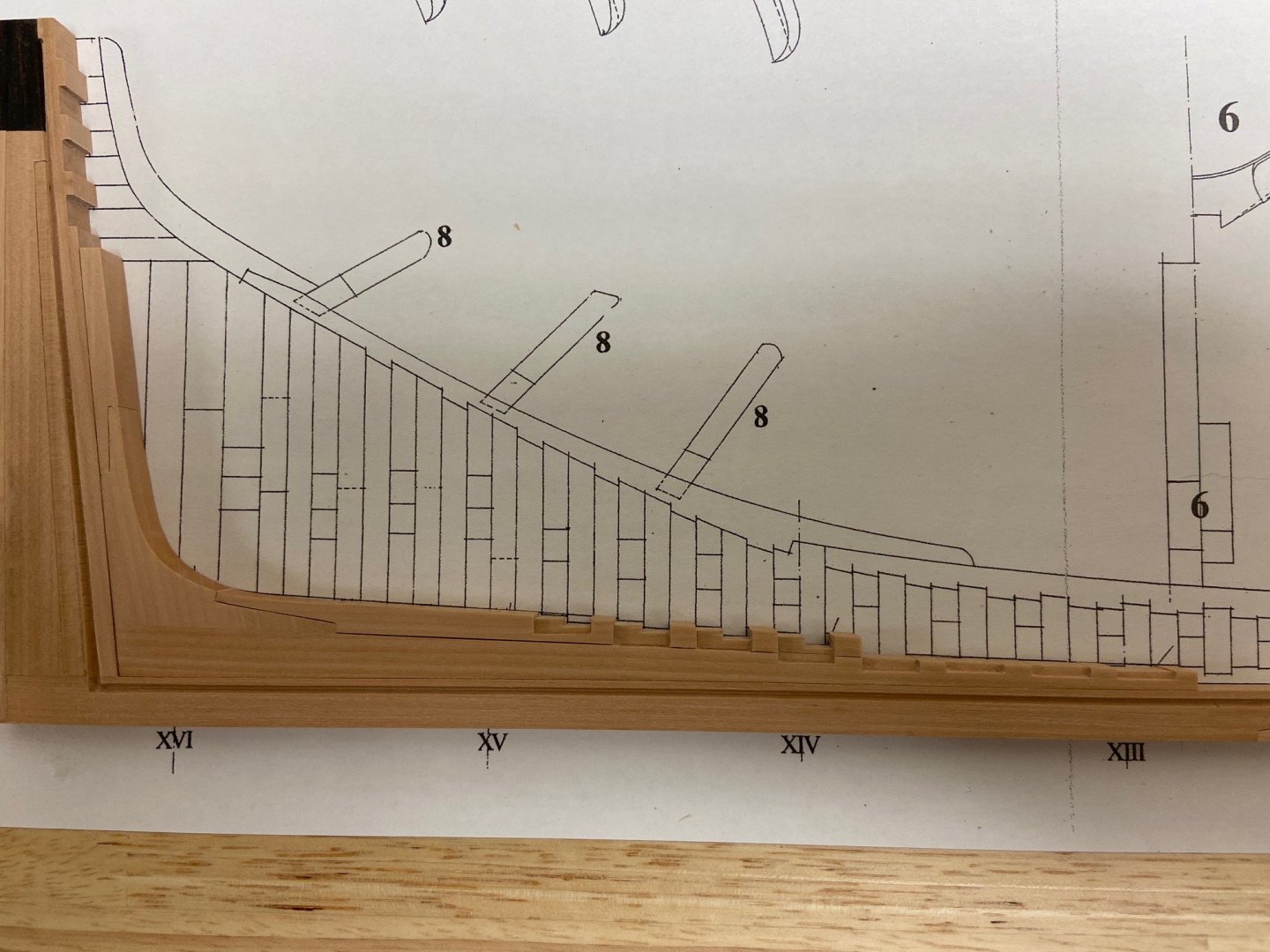

Here's a simple yet brilliant idea - a frame calibrated ruler. The applications including the creation of a construction site are many. Take the lines off the frame profile plan and apply it to a yard stick using double sided tape. I borrowed this one off a French site I have been referencing for my build.

-

ChrisLBren reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

ChrisLBren reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

L'Amarante by marsalv - 1:36 - POF

ChrisLBren replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

It does - thank you V !!!! -

L'Amarante by marsalv - 1:36 - POF

ChrisLBren replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

Looks really nice ! Question - it does not look like you simulate caulking on your models or if so its very subtle ? -

ChrisLBren reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

ChrisLBren reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

ChrisLBren reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

ChrisLBren reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

ChrisLBren reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

ChrisLBren reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.d84ec4dad1d7791e855dca06210ab6f3.thumb.jpg.f45209242e851d4409eca1a09293165b.jpg)