-

Posts

531 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bensid54

-

Good point Bob, I have a Chevy HHR that will have no trouble transporting it however it will mean myself and only one passenger. I will be using it at our complex pool a fair bit so I will need to make a proper carrying case for it, looks like another project for this winter.

-

22 per side making a total of 44 oars Bob. I've been mulling over how to make them detachable for transport because with the craft being over two feet wide and 42 inches long I want to minimize the possibility of damage when transporting to the local pond. I have been thinking of making the oar rack two piece, bottom half to stay in the ship and the top half to be removable that will contain the oars.

-

Bending of the wood for the raised parts of the stern and bow. Sorry about the cannon in the picture but I couldn't resist showing some of my other builds!

-

I think I am, I've used Firefox before and it has it's own list of problems so I would rather not go back to it. Guess I'll just have to let people on this website know where to find the video. Thanks for the info mtaylor.

-

I've tried that mtaylor and I've tried to paste other things on the posts but if I copy from anywhere outside of this website and try to paste the file or dialogue I can't do it, the paste option isn't high lighted when I right click.

-

Plank bending time! First I start with a boiling pot of water then I feed the planks into the water bit by bit until I have the desired bend. I hold them in position until cool now all that's left is wait for them to dry before I epoxy them in place.

-

Please keep it up I don't mind at all then at least the video does get posted. Thanks for the help! Aren't computers wonderful things they just confuse the hell out of me then all it takes is one right move and I say to myself now how did I do that.

-

Thanks Omega. How did you do that? I can't seem to post videos here, I tried to put the link in then soon as I did the screen went pale and it appeared nothing was happening so I closed the window. I tried to copy and paste on the post but when I try the paste option doesn't come on the menu.

-

If you want to see the video it's on You Tube under Big Bireme. I would post it here but it is no easy feat.

-

I'll see if this works posting from You Tube. Nope can't do it nor can I download video from my computer looks like I can only do still photos that's too bad because videos are always more informative.

-

Can you download video from You Tube? I will wait for an answer and if it is not possible I can direct you to the video on you tube.

-

They do look small don't they. The torque those motors will put out could easily break the parts they are moving if something jams so it's going to take some dry runs before I put it in water. Videos are going to come when I start with the moving parts now that I have a plan in mind that should work well.

-

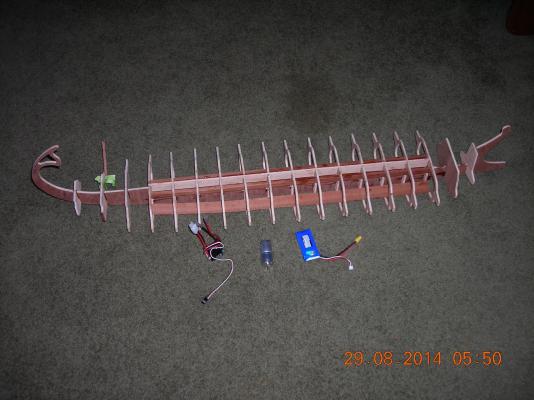

Thanks Bedford! Two pictures to give you an idea of the size of the motors, ESC and battery when compared to the boat. The top motor speed is a little over one second per revolution. The ESC are reversible which opens up more control options along with more natural fluid motion of the guys at the oars, once the hull is planked I will start of building the propulsion system.

-

The motors, ESC and battery finally showed up yesterday after being in transit for two months. The motors are 75 to1 reduction which should make the speed of the oars just right.

-

The African Sepili hardwood I cut on my converted tile saw. The saw was a lot cheaper than a small or hobby size table saw all I had to do was a bit of blade modification.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.