-

Posts

322 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rich_engr

-

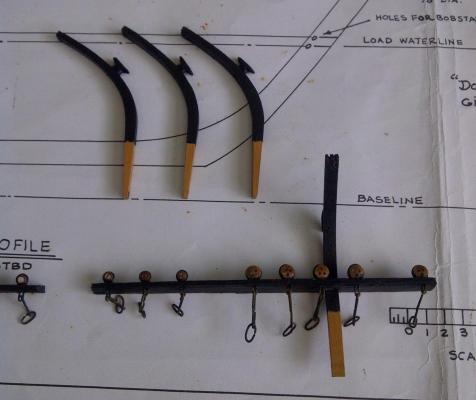

Thanks Patrick- these little bits seem to go a little easier than I thought, and they turn out ok for my first try. One thing I'm definitely going to rethink is the rigging line- I'll probably switch to cotton or something less shiny/more authentic than the synthetic that came with the kit. I want a softer, more natural feel for the rigging, not the stiff/plastic feel of the nylon stuff. Especially with how my "blackened" parts keep turning out- more of a dark rust than true black, so I want the rigging to reflect that look and feel. Clean (as clean as I can do anyway), yet worn/broken in. I'm also thinking of a simple way to make the hammock rails, with minimal or no soldering... maybe just some bent brass strips, etc...

-

I'll agree with Patrick- go ahead and paint the bulwarks first before laying the deck (less chance of getting red/green on the deck). And for making the nibbing strake- he's right in that you will need to soak the planks in water and bend. Due to how much they curve at the bow, use a wide plank (soak, bend, re-soak and bend some more. File or sand the curve to get it to match up to your waterway.) How you make the notches/nibs is up to you- you can do them in-place on the ship, or trace them directly from the plans (like I did). Whichever seems to work for you. The nibbing strake is the same thickness as the rest of the deck- 1/16" I believe. Also remember when you add the deck structures and gratings later, if you cut out holes for them, follow the plans for the correct heights. Otherwise, if you just glue them directly on top of the deck (without cutting holes), remember to trim them down the 1/16" in height. Which other ships has your father completed? Do you have any pictures of his work? So far your Niagara looks very, very good!!

-

Yay- finally a bit of positive news: talked to HR today and she said they're pressing forward! They'll be verifying my references this week and some other stuff, then should have an offer soon thereafter once all goes well! Once I accept, then begins the "probing" for interim clearances, etc... once that all checks out THEN I can start (if interim doesn't clear, then it's back to square one, which I doubt). Of course, she couldn't give a timeline or rough estimate due to all the gov stuff and shutdowns, recent security "issues" in the news, etc, so it may take a while. I may just take a 2-3 month contract gig to tide me over until I get the all-clear. So at least I'm still in the running and there's movement. Build update: I have the ladders installed and I'm working on the catheads. Once they're installed I'll get pics up I promise!!! I may hold off a bit on installing the main's channels and quarter davits (less stuff to break during a potential move, but re-attaching the smokestack shouldn't be a problem if it comes off). So I'll be working on the remaining hull stuff for now. Bowsprit, masts & spars will be a while (still somewhat intimidated by those for some reason- perhaps it's my tapering "skills," but no matter.)

-

Steven, Welcome to MSW and the un-official Niagara Club. All of us are sorry for your father's passing. Here, you will find that all are here to support each other, and not just with our builds, but with all aspects of our lives. The friendship, support, wisdom, and craftsmanship here is quite possibly the best you will find anywhere- the members here are quite fantastic in all regards! And you are not alone with a build in-memoriam, since I have seen quite a few that are being build in honor of a loved one. [Perhaps the mods could create a build forum for just that, but nevertheless the support is always here for those in need!] Now, on to business: Yes, Floyd is right in asking if you have all of the parts and plans for the kit. If not, just ask Model Expo (some of their staff are members here) for whatever parts you may be missing. Check the inventory/bill-of-materials sheets and check off the parts you have (some have already been used in the framing and planking that has been done thus far). Regarding the deck and gratings, fittings, etc., there are a few ways to do this. One, you could plank the entire deck (you would need to make the nibbing strake- check out my build for some ideas, and various builds also), with or without tapering the planks (narrow at the stern), or with/without butts. After planking then you would cutout holes for the gratings and their coamings. The other way is to assemble the gratings and their coamings first, install them to the deck (make sure they're aligned and square- just use a ruler), and then plank around them. But with either method, you would first need to make the nibbing strakes- they kind of set the pace for the rest of the deck planking in my opinion. After the deck is planked, then you can move onto the eyebolts & blocks on the bulwarks, etc. But that'll be a little while until then- just take your time and enjoy it! Have fun- that's what your dad would like to see! And as always, if you're unsure of something, just ASK!!! Look around, follow the builds, ask ask ask!!! We're all here to help each other!!! Good luck- we'll be following along with you!

-

I agree- honesty is the way to go, especially with how involved they get nowadays with background checks, etc... One teensy little white lie= you're out! Still, I just hope that the gov gets their act together and ends this shutdown and gets things moving again, and especially finds some resolution on the debt limit (which is absurd to me). [Yeah, that makes sense: if a person/family is about to default on their mortgage, credit cards, etc., instead of reducing their spending (shopping sprees, latte's, huge donations to organizations, keeps growing their family size, makes those who pay for their debt have to buy products they don't need, etc.), they just get the banks to increase their credit limit, and they have someone else pay the bill (and increase their payments) when it comes in the mail, with zero accountability and responsibility...] Sorry to get political, but unfortunately these days sooo much is inter-twined and it's all related... And we have to stop this looming trainwreck- both the gov and We the People (which, gov forgets that they work for us, since we elected them. We're the boss, not them.) Oh well... Build update: finished painting the quarter davits and last night I made the boarding ladders (will paint this weekend and install- gotta shift some gun tackle to get them in the right location on the bulwarks). I also installed and painted the steps on the outside of the hull. After ladders are installed, I'll work on the catheads other stuff at the bow.

-

Yeah, I see your point(s). But regarding "design experience", they want to see so many years (5-7 yrs) of it and what you did design, how good are you with the software, etc. I've been asked that during phone interviews, and I answer honestly, and also offer that I am willing to learn it, but they need someone who already knows it. And while looking for project engineer/manager positions, most require PMP certification, which takes a couple of years. Really, I'm just in a weird middle/grey area. I've even tried some entry-level ones, but no response on those (probably too qualified in some areas).... So, trying to think how to broaden the net and really stretch what's relevant. I'm even looking into the oil&gas industry here in TX, but again no experience there. And going back to school is out of the question, since I need $$$$ now to pay the bills, not additional debt. But still pressing forward and digging around. Something has to come up soon!

-

I see postings all over the place for embedded systems & designers (and application verification, whatever that is), but I have no idea what the hiring market is like (don't know anything about that area). I'm just in a weird spot, since I'm an RF/SATCOM/antenna engr, but with zero design experience (and certainly no software/programming- hated taking Java in school). So I'm a cross between technician and project engineer, but w/o the management certs... I can manage it, build and test it, but can't design it. lol~

-

Yes, I did take it apart and stuck my DMM to it- I think it's the relay switch, but I have no idea where to get the part and how much... so I just got a new one for $30. If I could have found the switch (and waited for it to arrive, since I doubt I'd be able to find one locally), I would have fixed it myself. I might fix it anyway in the future so we have a spare (like for when family visits- we can drink a few gallons of coffee a day). Heck, I don't think I've seen a Radio Shack in town (assuming they have the specific type of relay I need)... so onto Digikey, etc... But my MAIN concern at the moment is of course waiting to hear positive news about the job. But I think the delays (even HR is wondering why so long, according to her updates) have to do with all of the gov't stuff and the shutdown. I wonder if the company's people have been furloughed, since they are basically contractors doing work for the military, so who knows.... Still trying to find stuff to apply to (related stuff is coming up scarce lately) and hoping to hear from someone, anyone at this point... So back to hunting today- maybe get some building done this weekend or something (finish the quarter davits and then work on catheads, etc. Might use some small staples for the hammock rails, but we'll see...)

-

Speaking of sanding, I generally use a small sanding stick (#80 thru 440 glued to a block or stick of wood) for sanding large areas (hull, deck). For planing and lapping, I'll use a whole piece of sand paper taped to the bench- works well for planing parts down to a certain thickness and for ensuring parts are flat. For smaller areas, even beveling & shaping planks, I have used my files and riflers. Haven't tried the emory boards yet, but might once I begin work on masts and spars. Sanding: crushed rock + paper + wood = smoooooooth~~ ahhh~~~

-

Larry- awesome job! Sounds like you have it under control, and it looks good. You probably don't need to worry too much about adding glue/sanding on the inside for strength- once she's planked it's pretty solid. One thing I did was to give each plank a quick sand immediately after I glued it in place- this helped to fill voids around that area using the sawdust + still-drying glue. Then after the whole thing was planked, just grab a piece of paper and sand and sand away~~~ Your bow definitely looks better than mine did while planking- despite steam bending, twisting, etc., I had to sand the heck out of it to remove the clanker look. Yours looks really good! And glad to see you back at it and you're feeling better!!

-

I used the ropewalk from Model Expo- it has instructions for its use. I basically used the line that came with the kit and turned my own following the instructions (after several practice runs to get a feel for it). The drill definitely helps it go a lot faster. But I'm thinking of switching to some cotton thread for making the rest of the rigging (shrouds, lanyards, most standing rigging), since I'm not too excited on the look and feel of the synthetic stuff that came with the kit. But that'll be a ways down the road.

-

Yesterday I realized that before attaching the main mast's channels, the quarter davits need to be made first. So that's what I'm working on at the moment... oops~~ Today started off crappy, due to the coffee maker not working!!! So I just went to Starbucks after my jury duty (luckily no jurors were needed at all today), and tonight I'll go spend some $$ for a new coffee maker~~ grr~~ (course, it's definitely a work horse in my house!)

-

Yesterday evening I was able to attach the foremast's channels directly to the hull (no pins, etc.), and made the little sea steps that go down the side of the hull. I'll try to have those attached then painted today (before attaching the main mast's channels). Then, I'll install the eyebolts and other odds-n-ends that go on the outer hull. I am hoping to hear something on the job this week (according to an email from HR on Friday). I think the delays have to do with a combination of background check and the whole gov't shutdown/spending bills.... grr~~~ That's one thing that makes being a gov't contractor weird- projects/funding are all politically related... oh well- at least it would be a job, which is better than nothing! (Btw, my office would be in Dahlgren, but I'd probably go to Norfolk and San Diego for testing and the actual work.) So we'll see- waiting anxiously!!!

-

Lol- Sam, I have 2 cats (and 3 dogs). The one cat (see "How to Keep Pets off your Build") has been up on my bench a few times, but luckily hasn't gone near the actual ship in a few years. Larry- good to see you back! Sorry that the legs are numb and you're not fully out of the woods yet. Hang in there- we're all pulling for you too!!!!! Progress has been little here and there, and I'll probably have the channels 100% ready for installation over the weekend (pics to follow).

-

I think I'll just stick with attaching them to the sides as they are- no pins or mortise. They'll be flush up against the top rail, so hopefully that'll hold them there once the shrouds and backstays are rigged, with the additional tension of the chainplates. But the chainplates won't get attached until I have the masts stepped and angles/rake of the shrouds figured out. So for now they'll just dangle like earrings~~~

-

Sam- in order to get the correct 5/64 thickness at the inside edge (as called out in the plans), I laminated two 1/16 thick boards together, then sanded & tapered one side to get the correct thicknesses. The pins would need to be super-thin wire, which I doubt would add much additional strength. But yesterday I was able to paint and install the cap rail, and painted the channels. Today I'll attach my deadeyes/chainplates, the outer cover strip, then attach the channels to the hull. After that, it'll be making all of the stairs, ladders, and installing all of the eyebolts, etc. on the outside of the hull.

-

Adam, for the cannon color, it's really up to you. You could leave them their natural brass color, or blacken or paint them. If your kit came with the cast metal guns, they'll need to be painted (which is a little tricky since the paint doesn't quite stick- see the Painting forum for tips). But typically, guns were more of a black color, even a dark bronze. For some beautiful examples of blackening guns (with chemical solutions such as Blacken-It), check out Blue Ensign's build logs- he has some fantastic looking guns!! But I think most modelers stick with black. Check out my Niagara build log (or any of the Niagara's, Conny's, Victory's, etc.). Hope this helps! Good luck!

-

Augie- good point. I haven't thought of that yet, but may consider it. They may not need it, due to being supported on top by the cap rail, and on the bottom from the tension in the chain plates, but pinning may add a little extra support. Although, pinning might be rather tricky since mine are actually two planks laminated together, and trying to drill pin holes might split the wood....

-

Thanks guys- trying to be patient, whether it's a yes or no... but still looking just in case. Yesterday I was able to make the channels- did some edge-wise steam bending (very slight), and they look ok. Next up is to cut out the notches for the chainplates/deadeyes. I also blackened the lower straps and bolts (heads of some straight pins) for the rest of the chainplates. Think I might just dive in and put the cap rail on, add the channels (but not attach the lower chainplates to the hull), make the ladders, and then think about how to do the hammock rails.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.