-

Posts

2,633 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

To fabricate the fore mast opening in the spar deck, two structural members were installed between bulkhead Beams C and D offset equally from the centerline by the width of the fore mast dowel. The dowel, sitting in its seat on the gun deck. restrained in its side to side motion, was now perfectly vertical to the beam of the model. Next, a piece of scrap wood’s edge was cut to 3° from the vertical. The scrap wood was now a 3° mast gauge. Placed on the beams, the dowel was pivoted aft back against the gauge and a cross beam glued into place to restrain the dowel’s aft movement. The dowel still has a little forward movement to facilitate removal and then its final placement. Once the foremast is seated again and leaned against the cross beam, it will at the proper rake of 3°. It is to be noted, that the position of the foremast on my model, is not exactly in the same position as shown on the MS plans. The MS plans have the fore mast seated in the C-bulkhead just under the spar deck planking. My fore mast is completely behind the bulkhead C and obviously seated in the gun deck’s extended keel. Why the slight aft position shift, I don’t know. And just for grins and giggles I took a photo with the bowsprit and foremast dowels to get a sense of size of the model. That sucker is biiiigggg!

-

I am not a sailor. I have zero experience on a large sailing ship, especially on a vintage one. Obviously, I have boarded the USS Constitution and all the lines were neatly tucked away for the safety of the public. The only working commissioned naval vessel I have been on believe it or not was a Soviet destroyer on a good will tour in the mid 1970's in Boston Harbor. You didn't see too much, but that ship was as neat as a pin because it was on public display. In pictures of vintage sailing fishing vessels I've seen, there were rope lines all over the place. I assume once the boat was returning to port with its load of fish, they made everything "ship shape." The guns on my model are at the ready, in firing positions so I can't imagine the crew taking the effort to make things visually neat like spiraling rope coils, but probably workable neat. That's why the ropes are simply coiled and in position to be used for firing and reloading the guns. This set up is my best guess and you may be totally correct and I'm totally wrong. Jon

-

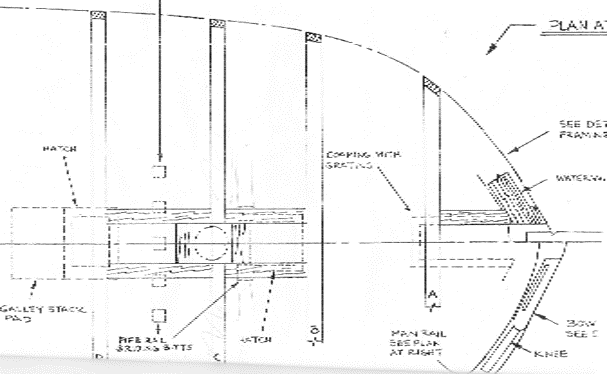

Finally, using the US Navy plan No. 022-06-2011 - Diagonal Rider & Knee Layout Revised 2011 (a minor revision of 27772, 1996) for the elevation view and No, 17636 Spar Deck Planking Removed 1926 for the plan view, I fabricated and added diagonal knees to the bulwarks around the gun ports of the rigged guns. Additionally, the three vertical stanchions around the stove were also fabricated from 0.032” music wire (for rigidity) and installed. Before I can move aft to the next section and while the gun deck is still accessible, I want to create spare deck structure to ensure the foremast will have a 3° rake when it is installed. As I have it presently planned, this portion of the spar deck is expected to be planked.IMG_1479.HEIC

-

Moving aft, the gun rigs and recoil lines for three sets of guns after the dummy guns had to be fabricated. The three gun sets of fully rigged guns were glued into position with their recoil ropes secured to the bulwark with a small nail through two eyebolts. I initially planned to trim the nails so that they would be shorter and have a blunt end to more closely resemble the actual pin. This proved to be very difficult to use when attempting to thread them through the eyebolts and looped recoil rope. I just used the plain nail utilizing the pointed end to facilitate the installation to the bulwark. You would need a sharp eye to notice any difference.

-

You did an excellent job and you should feel proud of your workmanship. Just so you don't feel too bad, Ken Forman (xKen) is a professional model maker so he sets a pretty high bar to match. He designed the Model Shipways cross section kit of the USS Constitution, the Model Trailways Allerton Steam Fire Pumper, and written books on making brass models. So yeah, you did a fine job. Jon

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I think you hit the color perfectly. Nice job! Jon -

DAR - Because the hull is going to be painted, I think I have a simple solution. On the subsequent strakes, increase the width a bit of a couple of planks in that area until the 'waviness" disappears. Add a little wood filler if needed and the smooth it out so the wood strakes blend and you can't see any creases. The paint will cover any evidence of the unevenness and it will disappear. Hope this helps. Jon

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Just so you know for comparison, The MS kit provides 37mm long guns and 23mm carronades. How accurate they are to the actual guns at scale, I don't know. Speaking of guns, the actual ship does not have her original guns but replicas mostly installed in 1927. By 1897 on her 100th birthday, she no longer carried any guns. The carronades that most likely represented the ones used in the War of 1812 (an 1808 design) are the ones with a screw adjustment for raising and lowering the barrel. These replicas were installed in 1981. The ones using a wedge for that purpose are of the 1840 era and are more technically called gunnades. As I understand it, the idea is to eventually replace the gunnades with the more accurate carronades sometime in the future. Just thought you might want to know, Jon. -

This is in essence how I planked my hull. A lot of “How to” articles and build logs use the tick mark method and proportional wheels or dividers. I just could not draw a pencil line on the hull that precise and get a strake to properly taper and fit. Like you I mathematically determined the width of the strake at every bulkhead point and sanded away, checking with the micrometer. I just didn’t do it with a nice spreadsheet. I worked each strake, one at a time, marked the determined widths on a piece of scrap paper. Once done, I discarded the paper. You did a fine job. Jon

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I did a similar method only I didn't have a mill cutter lying around, so I used my Byrnes Saw. You made that process look so easy. neat, and clean. Well done! Out of curiosity, where did you get your brass cannon barrels from and what size did you get? Jon

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.