rcmdrvr

NRG Member-

Posts

420 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rcmdrvr

-

It is always nice to stop and admire where we are in the build and all the work it took to get there. Beautiful.

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

You metal work is excellent. I started working on the framework over the wenches and it became a disaster. I was using a little torch and I soon had silver solder and stuff all over the place. I found that when I was working on one joint, other became loose. It was hugely frustrating. I will go look for some silver soldering lessons. You model is really looking great.

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

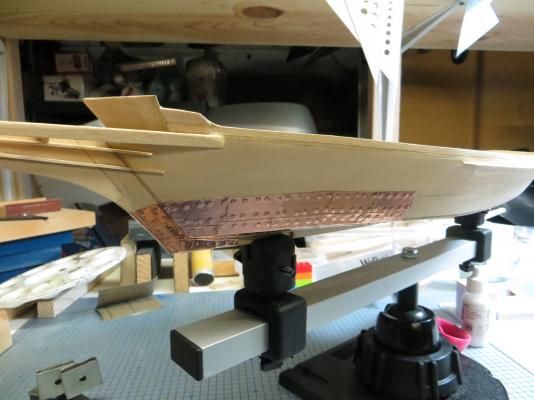

Final step of the weekend was to add the copper plating to the hull. I think this is to protect the hull from ice in the winter. Used the self adhesive copper plumbers tape.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

What a coincidence. I rode submarines when I was in the Navy. My last assignment (USS Gato) went into overhaul in Pasagoula Mississippi (Ingals shipyard). We used to use the services (medical, BX, etc.) at Kesler AFB in Biloxi while we went thru the overhaul. We would drive up the coast to the AFB a couple of times a month. The area was quite beautiful. I remember that there tree farms that made everything very green. That was around 1975.

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

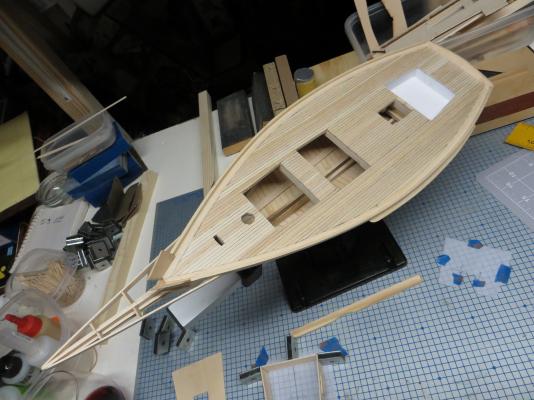

Well, I finally completed the deck and have scraped it down. Still have not decided on how I will finish. Will start building the deck cabins now.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Shoule (and the others), please follow along. I am new to this hobby and this is a learning adventure. Please feel free to jump in at any time with your hints and ideas. The whole scraping process was totally new to me. I quickly saw that this process is good to know. Thanks for the suggestions. I completed the decking and I am now working on some of the deck structures. Will post some pictures soon.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

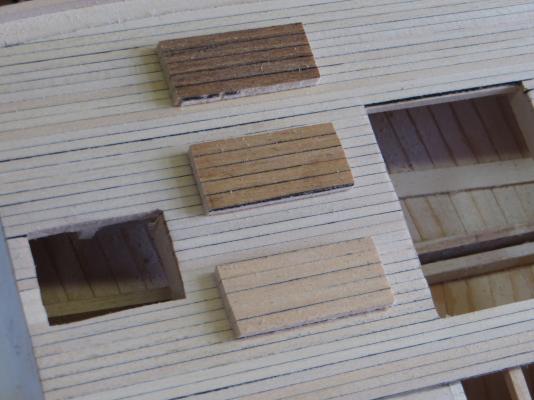

I have made some "deck swatches" The lightest of the three is the wood, not stained but sealed with clear polyurethane. The next is light oak stained and then sealed with clear. Finally, the darkest is stained with dark oak and then sealed. What do you think? Remember, the deck will be surrounded by white.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Well, I am getting real close with the deck planking. Thanks to" russ" and "capt n bob"; the scraping process really worked well. Most if not all of the grey dust that was all over the deck has been removed. You do go thru quite a few single edge razors.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Yes, I plan to build a few deck samples and then try different finishes.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

I will definitely try the scrapping before attempting any other method. I picked up the marker idea from another build log. Well learn and learn some more.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Well I have started planking the deck. To simulate deck caulking I am using a permanent marker to darken one edge of the plank before positioning and gluing. I am a little nervous how this will turn out. You cannot see the effect in the attached photo but as I sand the deck planking the grey saw dust from the edges is coating the decking and making it look greyish. Brushing and blowing off the decking removes some of it; but there is no doubt there is a grey tinge to the decking. Anyone else experience this? Should I try wiping the deck down with a tack cloth? Some cleaner like Windex? A light solvent? Help!

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Keep up the great work....I am following along behind you.

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

I am going to agree with mtdoramike. I am a newbie and spent several weeks reading build logs, articles, etc. before selecting the Willie Bennett. It looked very straight forward and it didn't require planking. Well, I have found out that for me it is a very challenging project. I had to adopt the attitude of taking it slow and building one step at a time. I also had to adopt the attitude that I am a nubie and I will make mistakes, perform many do overs and still end up with a model that is far from perfect. However, I am enjoying every step and learning from every mistake. There are lots of willie build logs and I pour over them every night. I am learning a lot having fun. Yep, open the box and start building.

-

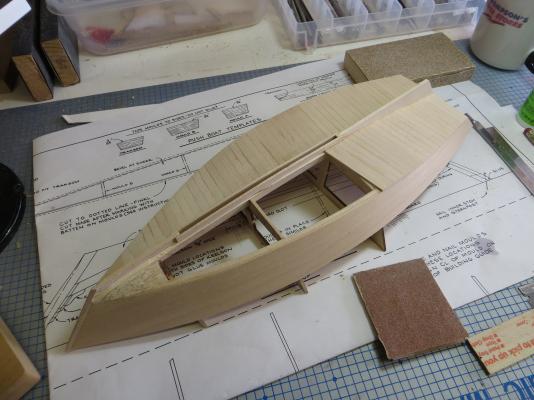

Well, the basic hull is complete. The time has come to begin laying the deck. Getting this far into the build has been a challenge but I am learning every step of the way. In building the bow, stem (or whatever the front of the model is called) a lot of basswood hit the floor to become scrap but I think I finally got it. I read the comments of new comers...my suggestion to them is keep trying because one of the joys of the building process is to get past a problem or difficult piece. Looks like the decking will be a bit tedious....still have to make up my mind on finishing the deck. I know I don't want to paint it; but stain or not to stain that is the question.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

What type of wood did you use?

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

I am approaching the point in my Willie when I will begin installing the deck. It look like you pre-stained your decking before fitting and installing. Is that right? Generally, how did you do this. Stain each basswood stick?

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

Well I finally completed the structure that will support the deck. Most of this was done by rough cutting 1/8" bass sheet and then a lot of sanding and fitting. It was not a difficult process but it took some time. I had previously said I was not going to do any detailing of the inside of the hull but I changed my mind slightly. I installed a deck and walls in the aft-most cabin. I might leave the door open to this cabin and would want the viewer to see a little detail. This really is turning into a challenging but fun project. For you Willie builders out there. Did you stain your deck before or after installation?

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

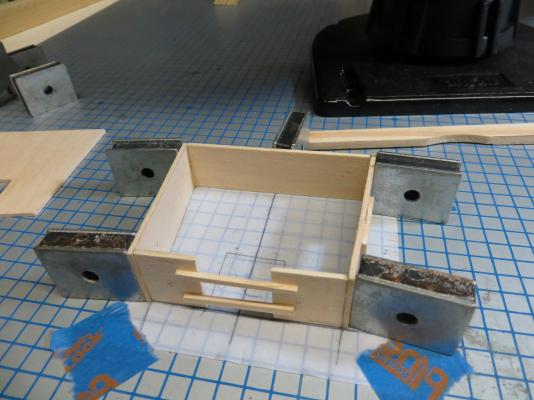

The building board is the "Magic Magnetic Builder" which was purchased 25 years ago. I don't think it is available now. It is 16" x 48" which can be a bit cumbersome when you have to turn it around. Similar magnets are available from MicroMark. They also have a 10 X 24 inch board. Which someone would make one in between. I like the board because the magnets are square and hold part vertical/horizontal.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

Nice work. I see that you have chosen to add a lot of "interior" detail that will not be seen when the model is completed. I have a build log progressing on my Willie but I chose to take the easier way out and concentrate on the exterior. I am new to the hobby but my model airplane days have helped me with the wood portions of the model. Such things as the wire and solder work, rigging and sails will all be new to me, so I will spend my efforts there. I will follow along with your Willie and learn a thing or two. Have fun

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

Model Shipways Willie L. Bennett Questions

rcmdrvr replied to FlounderFillet5's topic in Wood ship model kits

I am now a couple of weeks into the build of my willie (I have started a log). There is no doubt that the instructions are not a list of steps to glue part A to B and that takes some getting used to. At first I was very frustrated. I come from the world of RC model aircraft where we expect instructions to be detailed step-by-step instructions with color pictures. In the ship building world you have to employ a bit more building imagination and think the process through a bit more. I have spent a lot of time pouring over the instructions, the "plans" and other build logs, which are hugely helpful. After a while you get the idea that you are supposed to build something that looks like "this" and after awhile you begin to enjoy the creativity of it all. -

Model Shipways Willie L. Bennett Questions

rcmdrvr replied to FlounderFillet5's topic in Wood ship model kits

I received my kit about a week ago and began a build log. Have you made your decision -

I was able to spend almost a whole day in the workshop and got a lot done. First I completed planking the bottom of the boat and begin work on the interior. The plans provide the information to detail the entire inside of the hull. However, all of this would then be covered. I have looked over other builds of the Willie and I have decided that I will not detail the interior. I will concentrate on those portions of the model that will be viewed. My next step will be making the structure that will support the deck.

- 64 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.