-

Posts

129 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Carlmb

-

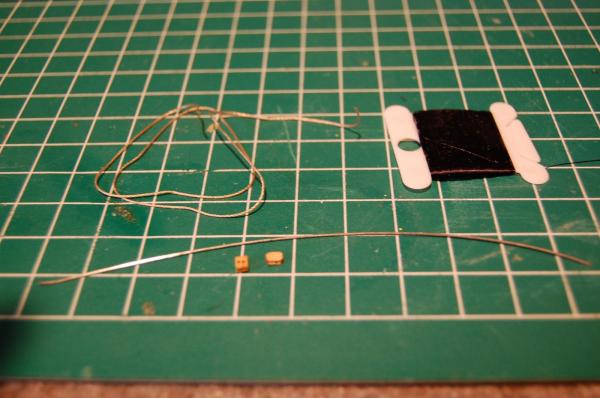

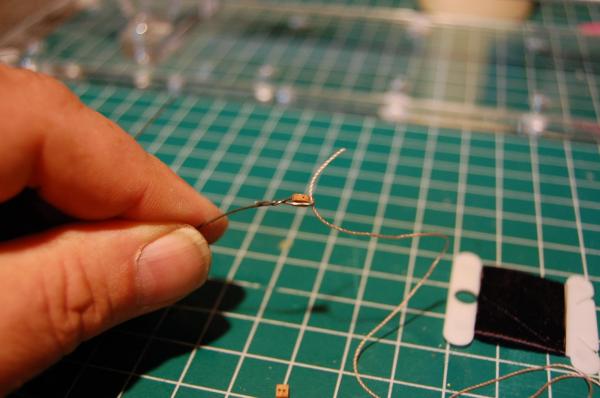

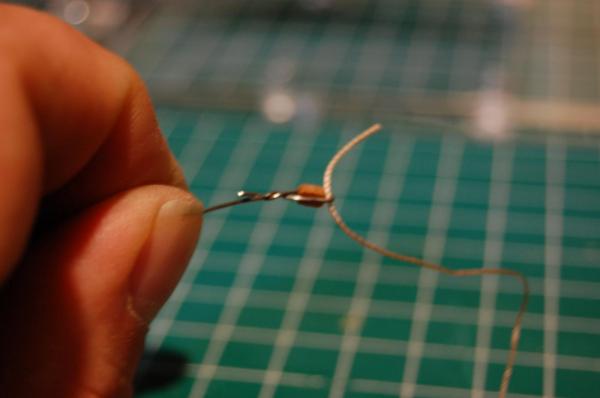

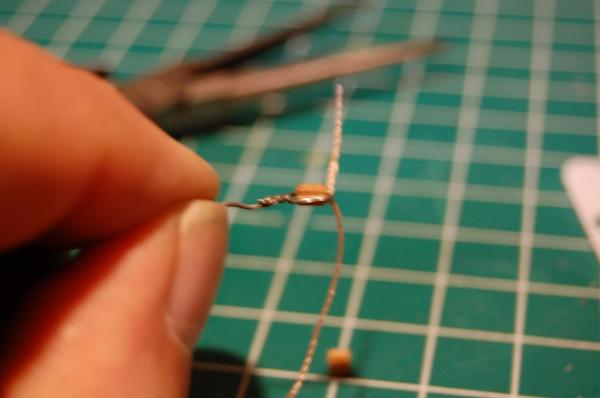

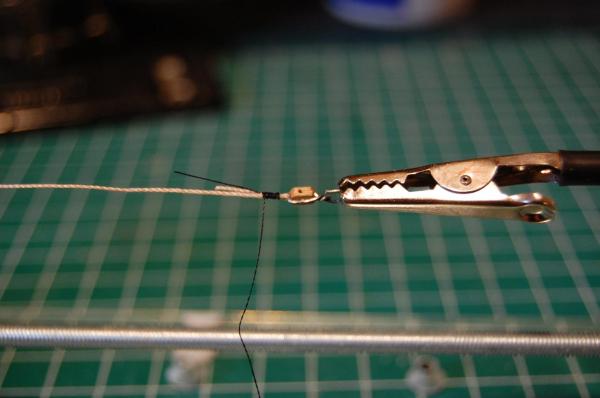

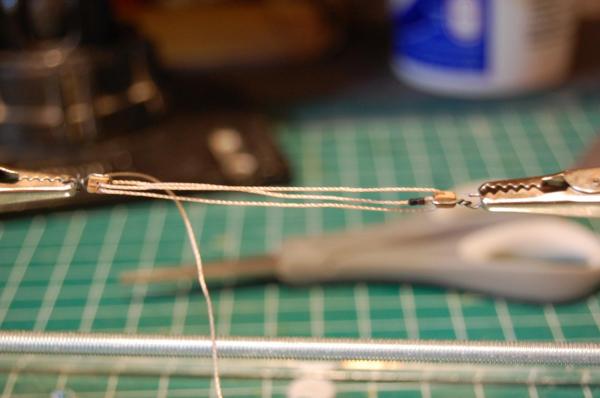

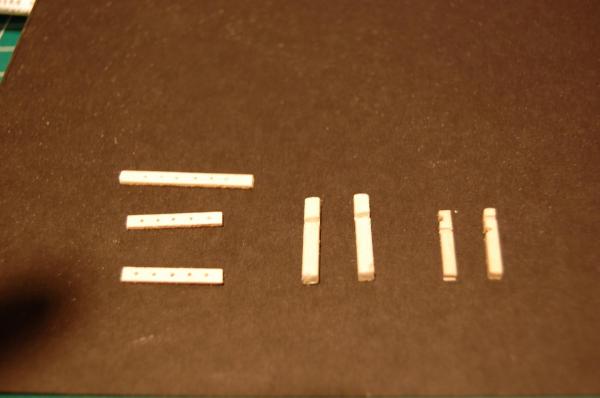

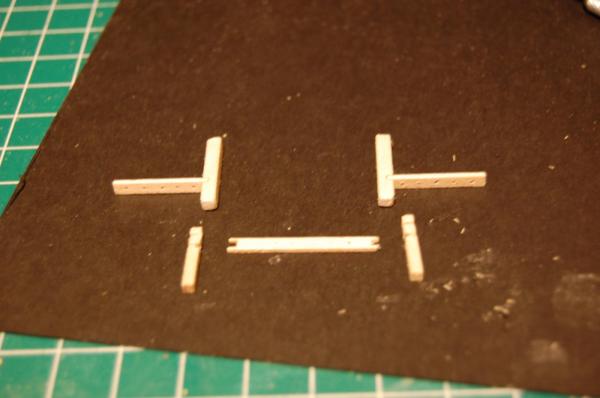

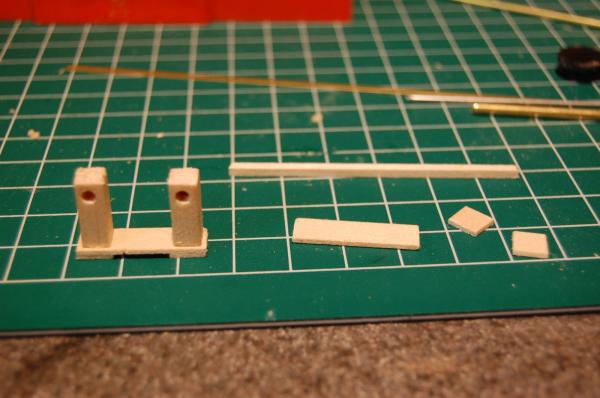

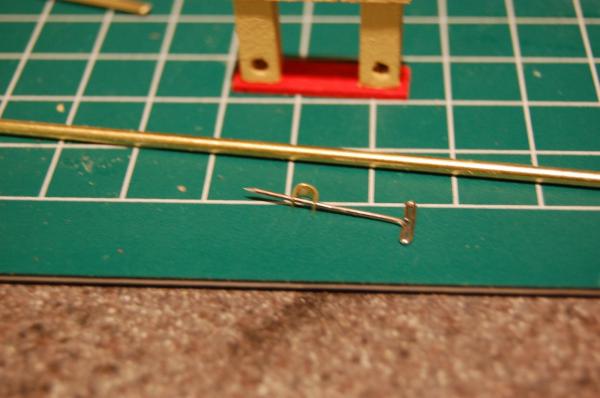

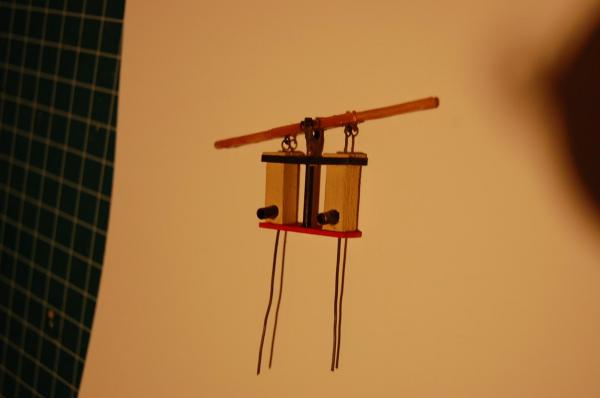

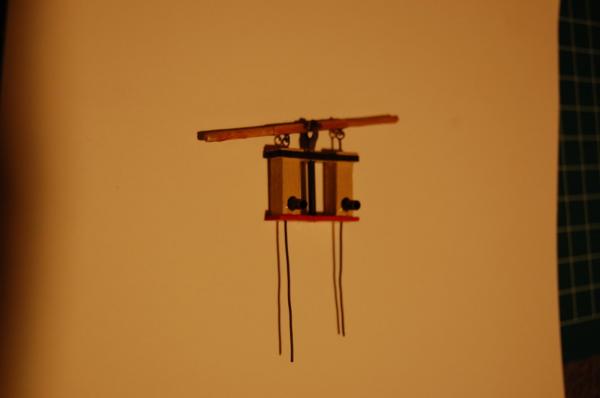

Hopefully this does not become to irritating. As I learn I am trying to document everything for others. I am in the process of rigging the cannons. At the cannon side you have a single eye and at the bulkhead you have a double eye. According to Niagara paperwork there is a hook at each end. 24 gauge wire will go through the small eyelets. I am starting with 13 inches of rigging which will go through both ends and allow me a nice coil of line. I am using 4 of these for each cannon times 20. 2 done, 78 to go. Hopefully these pictures will help.

-

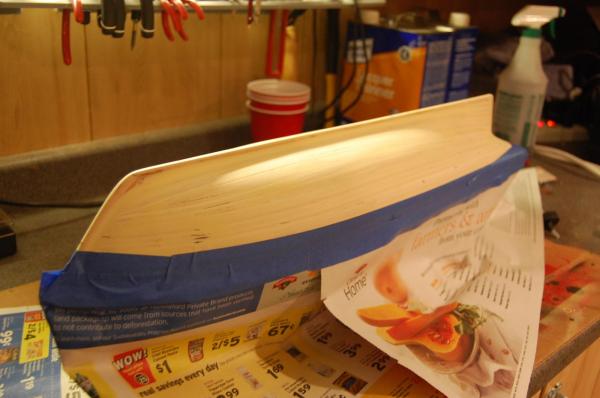

At this point I have sanded the deck with 400 grit sandpaper and applied 2 coats of Minwax pre-stain conditioner. This helps fill the pores and helps prevent the stain and urethanes from soaking in to the wood. (especially with the soft woods we generally use). In the last picture I am wondering which stain to use. I can put a satin urethane directly over the wood or apply a stain/satin polyshade from minwax. The one on the left is oak and the one on the right is pecan. Any thoughts?

-

Beautiful build. Congratulations and good luck in your future builds.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

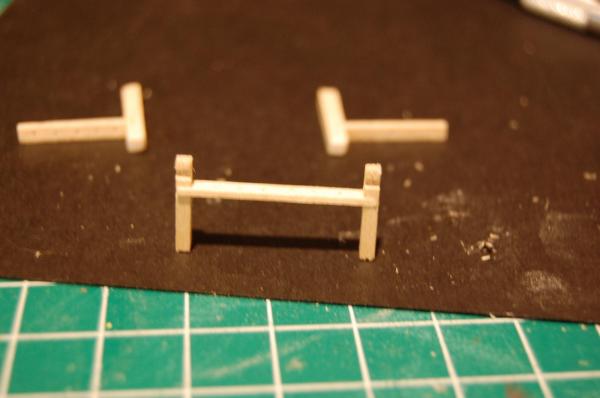

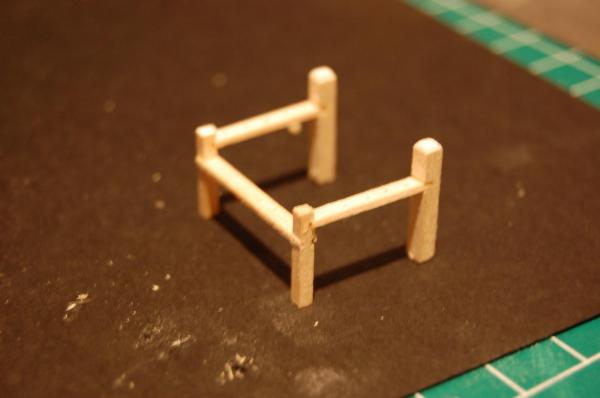

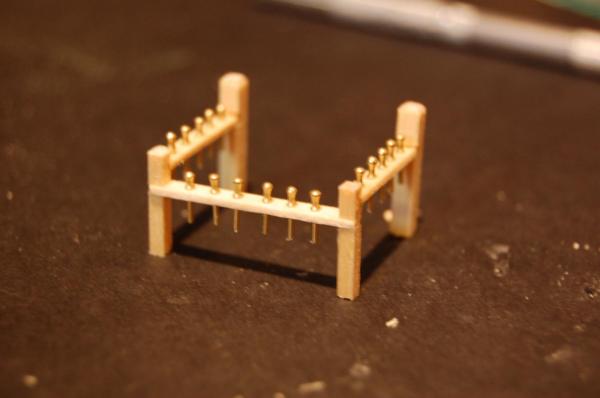

Everything looks awesome. On your stand what did you use to cut the joints (mortise?)? Thanks

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

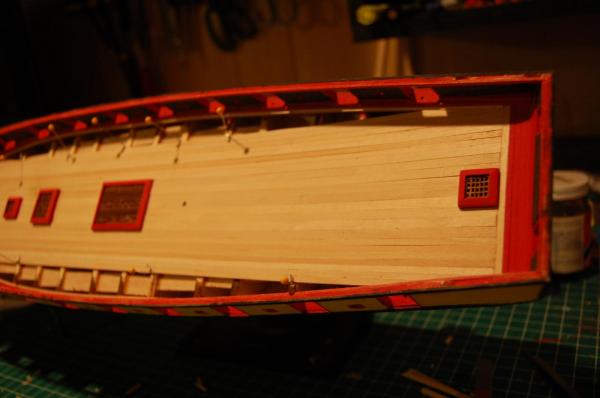

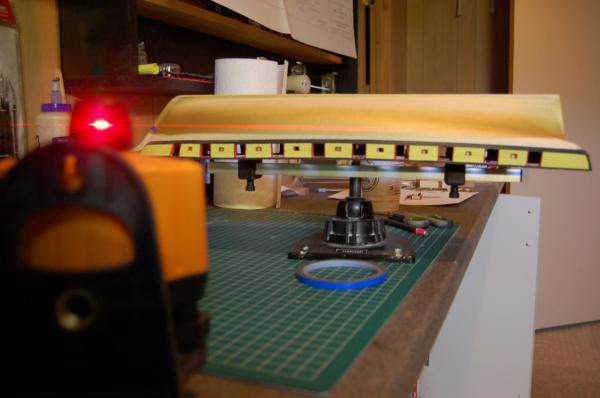

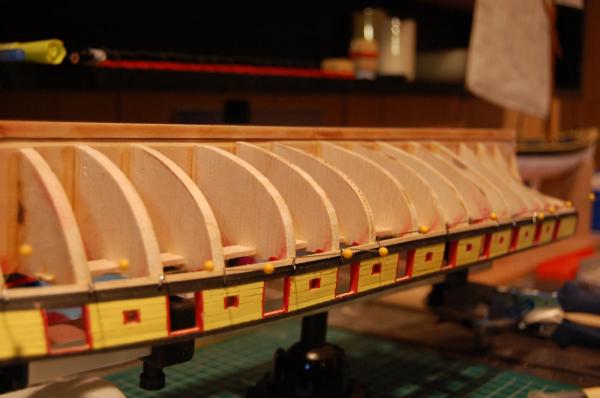

I have now begun the paint work on the hull. I started by using Elmer's Carpenters wood filler for interior. It go's on awesome and sands off just as easy. Sanded with 180 grit then followed up with 400. I decided to paint the hull black and green with a gold stripe at the water line. I taped off the top off the ship then painted gold around the water line. I then used a 1/4 inch tape and applied it at the water line. I use a laser level for tile work so I figured now would be a good time to use the level due to the uneven shape of the sides. At this point I taped off the top of the ship and airbrushed on the green for the lower level. It will now have to sit for 24 hours so the green hardens and I can apply the black.

-

If you are referring to the trim that goes on top of the hull. I used the template that the boat popped out of. I traced the ship on to a piece of balsa. Trace all the way around the ship then move the shape about 1/8 of an inch over and retrace all the way around again. That way when you cut out you have the inner and outer shape. Hope that made sense.

- 468 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.