-

Posts

129 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Carlmb

-

If you are using a Dremel 120 makes sense. I used 60 but did it by hand. Good luck.

- 468 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

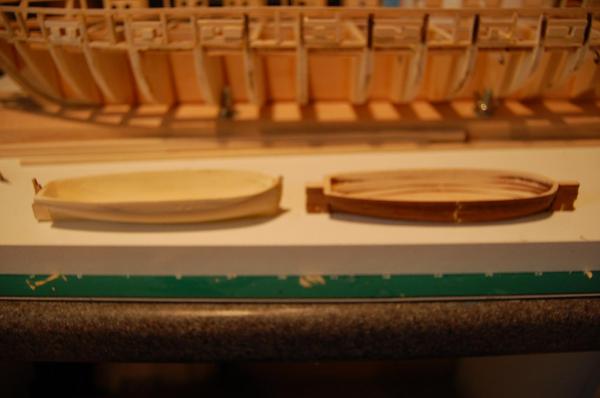

I used 60 grit sandpaper until the parting lines were gone then hit the whole thing in and out with Elmer's wood filler. Resand after 24 hours.

- 468 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Would a smaller paper clip be the right diameter for the hammock stanchion? I haven't made it that far yet.

- 468 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

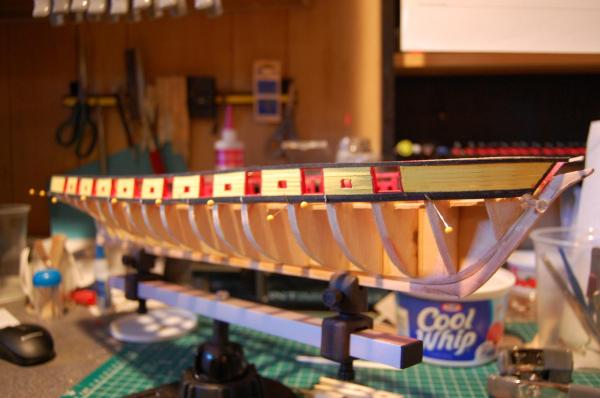

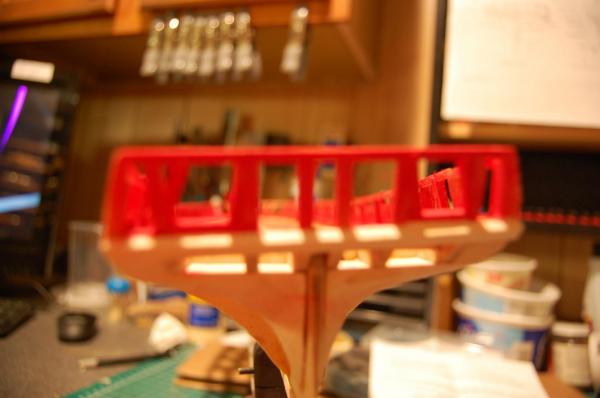

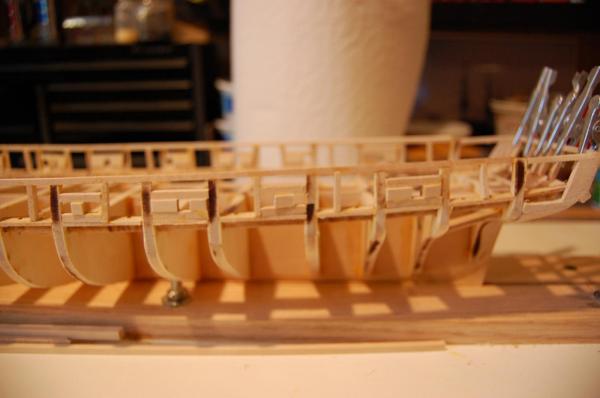

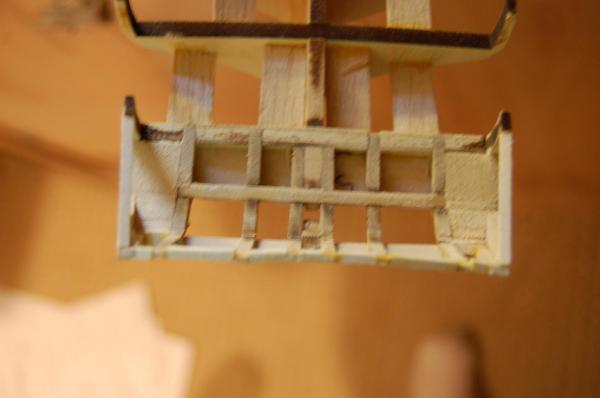

I finished the outer planking around the gun ports on the port side. Also completed the counter planks on the lower transom, added the fashion pieces on both sides of the rear and completed the final pieces on the inner transom. I am going to deviate a little bit from the original plans and go with red and black on the inner gun port areas but I am going with the green and black hull.

-

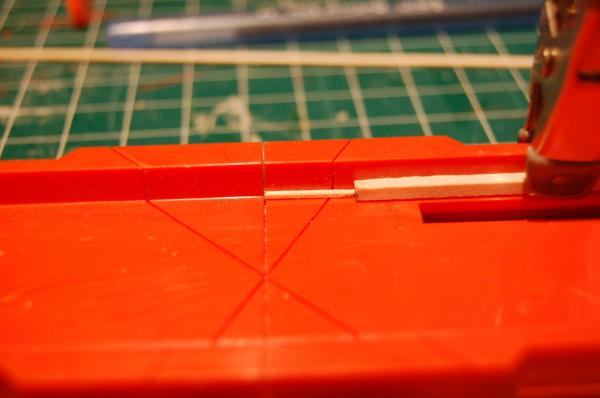

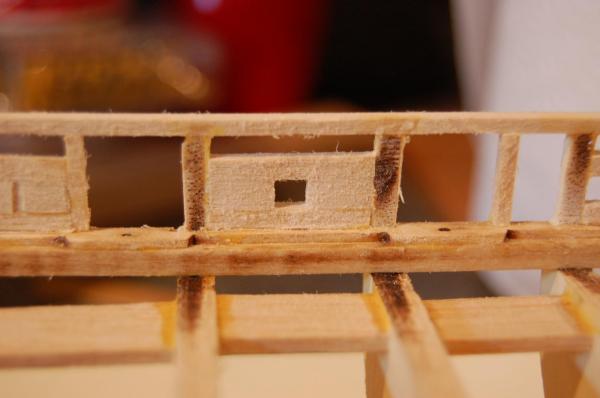

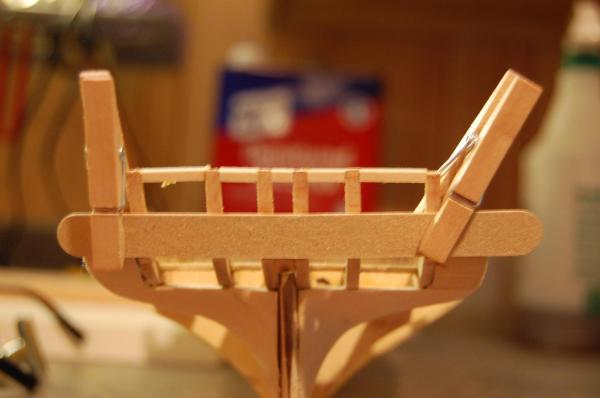

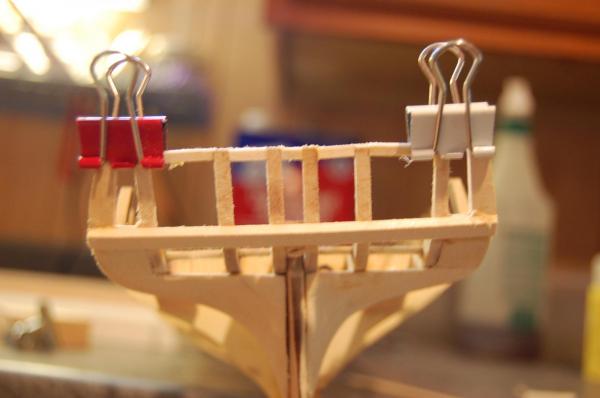

Time to add the 1/32 spacers around the gun ports. Added the temporary board at the top which will be removed before airbrushing. Used a small miter box and clamped on a spacer since we are going to need 80 spacers in this length. Not going to add the spacer for the oar sweeps now. Going to paint the spacer and add it after I've completed a couple boards from the top and determine the exact spot.

-

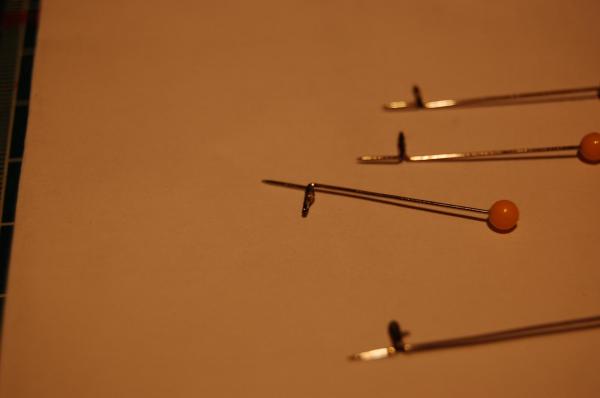

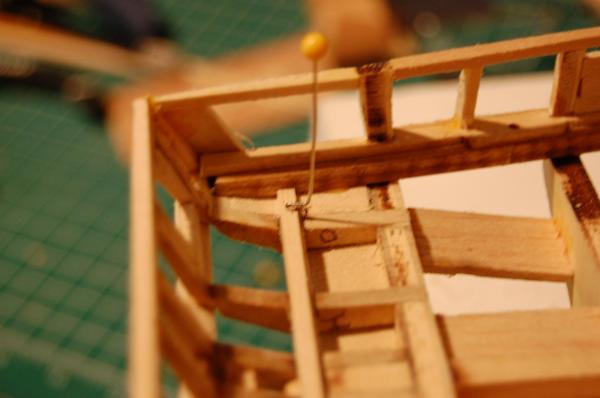

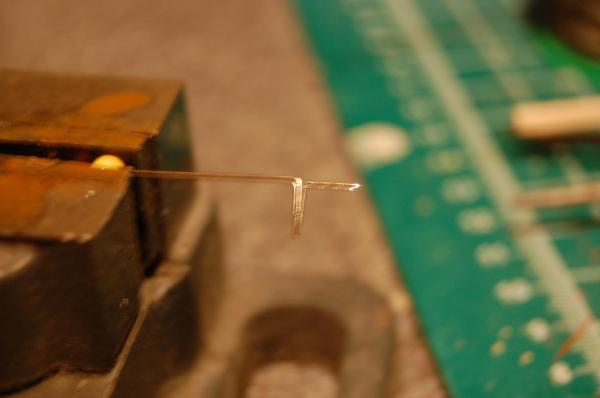

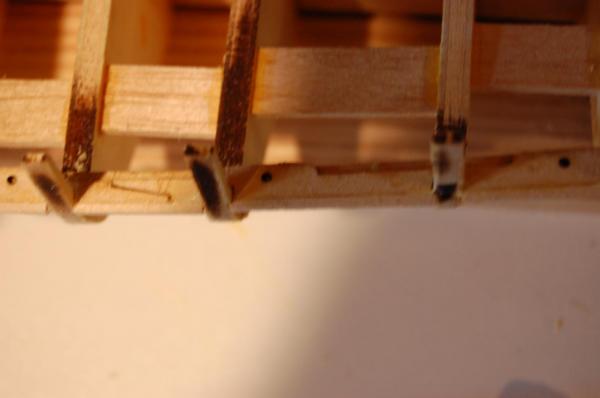

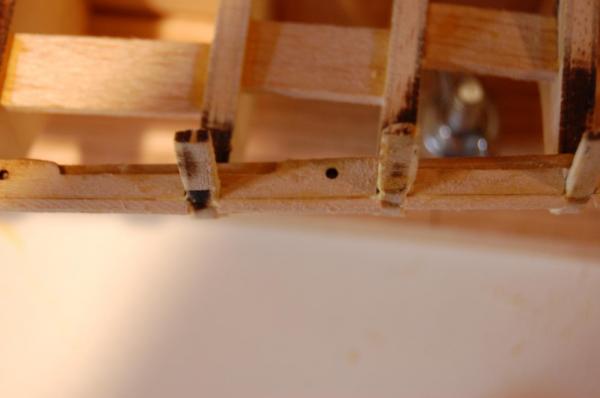

Cool plank pins. Saw these on greatgalleons Niagara build site. Don't know if he made them or bought them but I liked the idea. Start with a 1.5 inch quilting pin and bend it at 90 about a 1/3 up. Bend the pin back straight. Bend the center over on itself and hit it with some solder. Seem to work well. Sorry for the lousy pics, not enough hands.

-

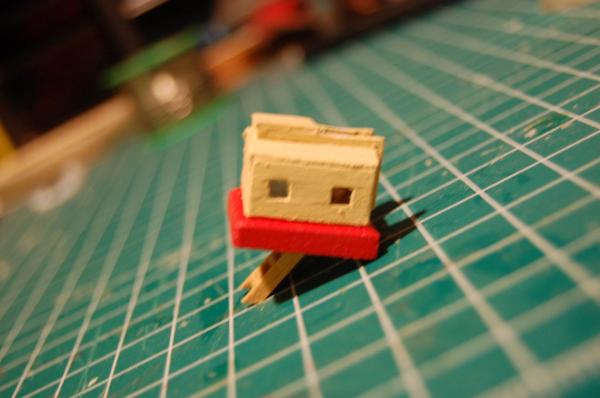

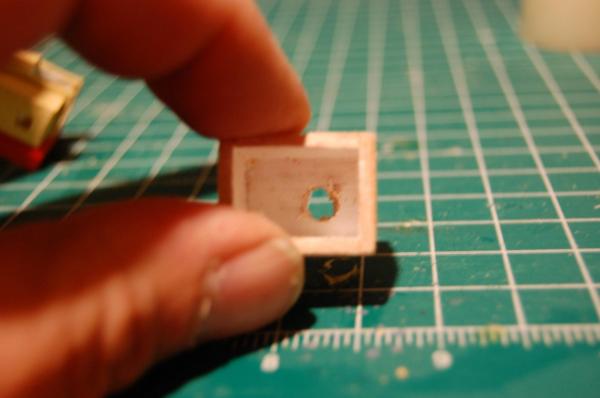

Here is something to kill some time if you are interested. On Ebay for $20.00 you get 4 flickering candles with a remote. Cut the candle to pieces and you get an LED, circuit board and a battery. Build a little ladder for your structure, a small box with a hole in it for the led, assemble it and you get a flickering candle controlled by a nifty remote.

-

Tom, wood storage looks great. Where did you find the 2" square boxes? Thanks

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

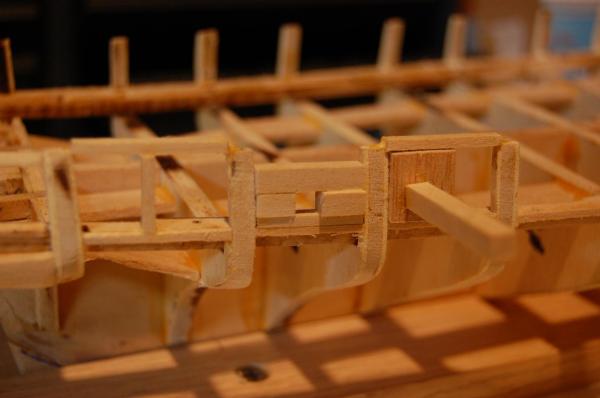

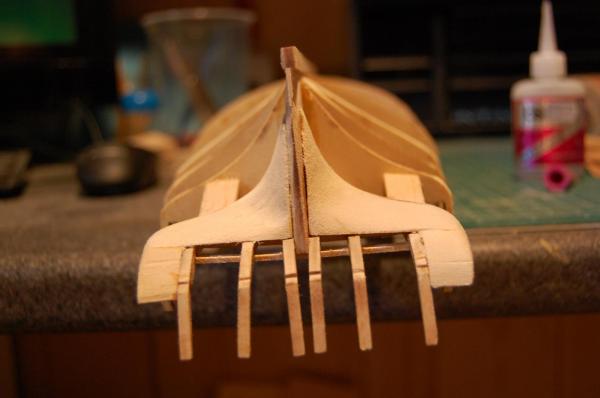

Planksheer fit was terrible. I am going to airbrush the planksheer after I have completed the gun ports and sweep ports and shoot everything in red. Here I have sanded the 1/16th filler between the bulkheads. I made a handy gun port/sweep port fitting device and with 3/16 square and 3/32 x 1/8 board I can frame everything.

-

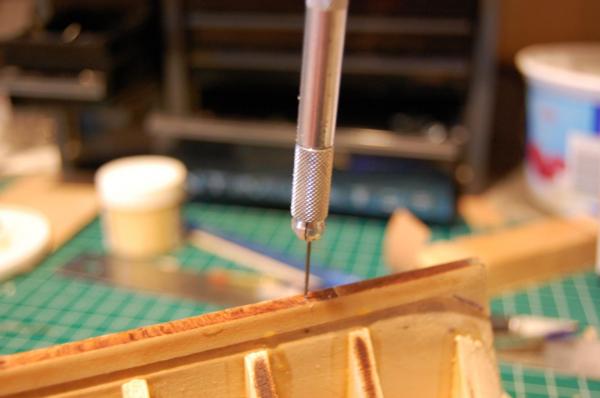

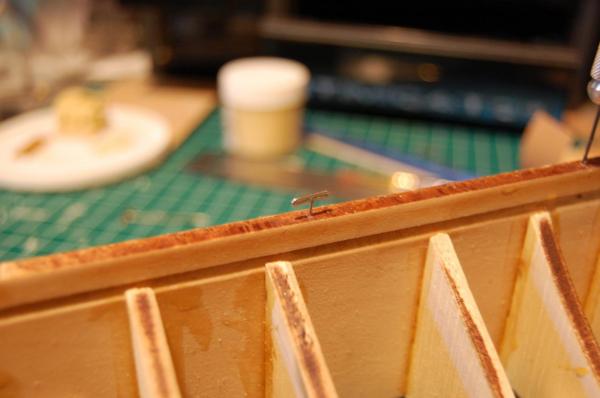

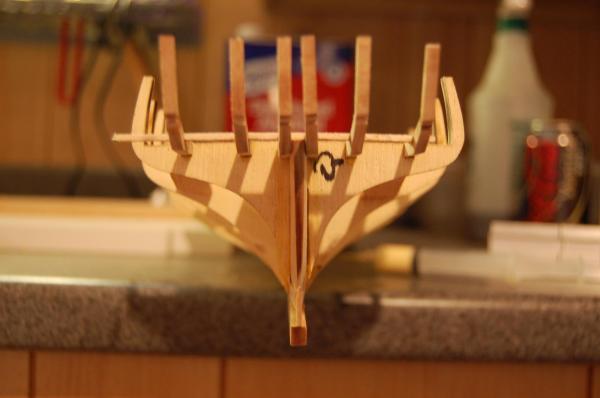

Now it is time to attack the bow. Added the front blocks and sanded them close with a Dremel and sanding barrel. Added the 2 supports and upper frame at bow. Added some scrap around the 2 mast holes. Also pinned the lower keel on using a hand drill and some small T pins which I cut with wire cutters. In the process of building the companionway and a ladder.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.