-

Posts

1,485 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

I have lots of their miniature tools and they are all great. I mounted the miniature vice on my existing work bench. I did not see the dogs. Ill have to check them out to see if they will work with the holes i already drilled. The miniature marking gauges are also back ordered to November. I Recommend them unconditionally . kevin

-

- 1,129 replies

-

- 1,129 replies

-

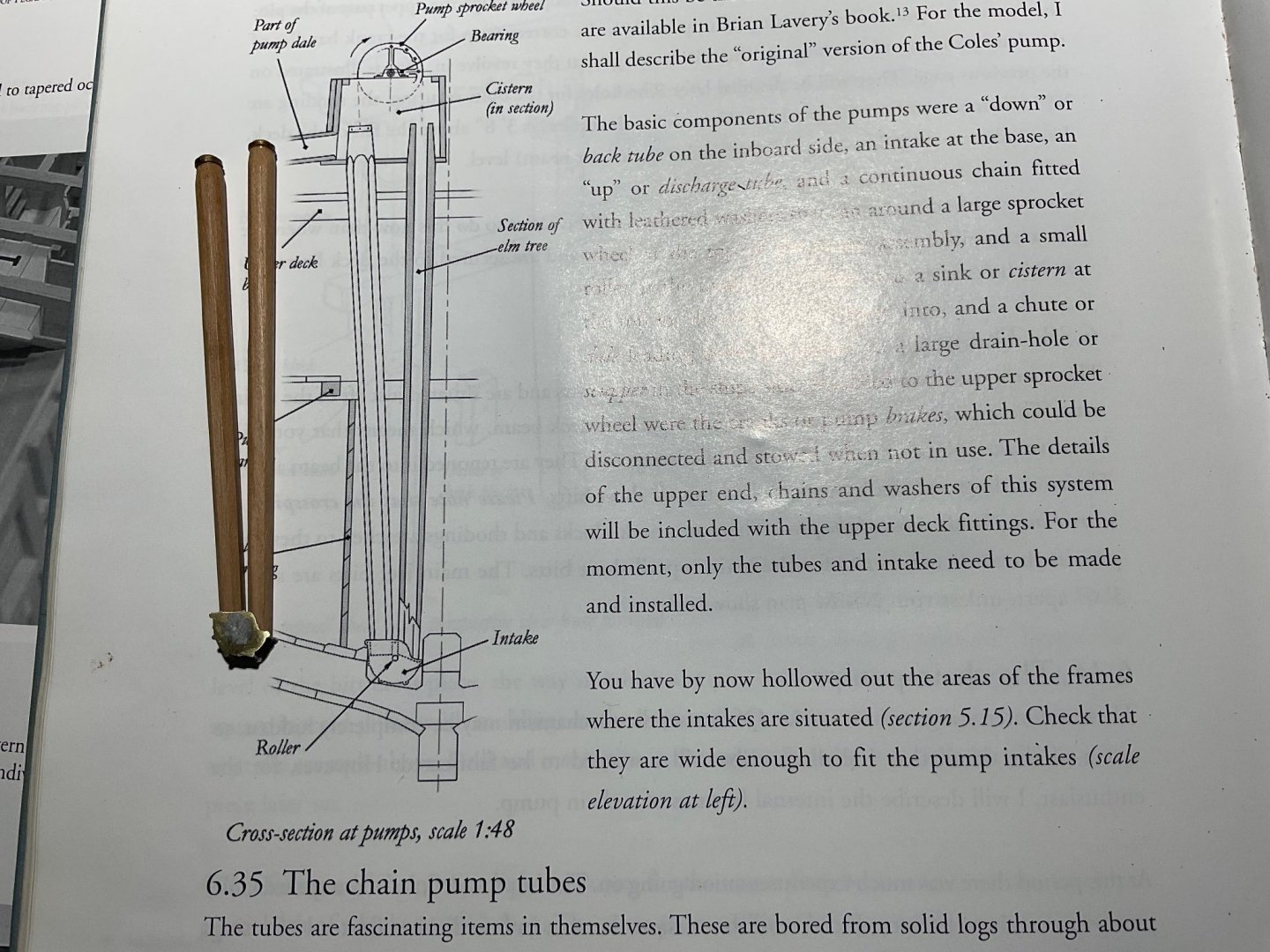

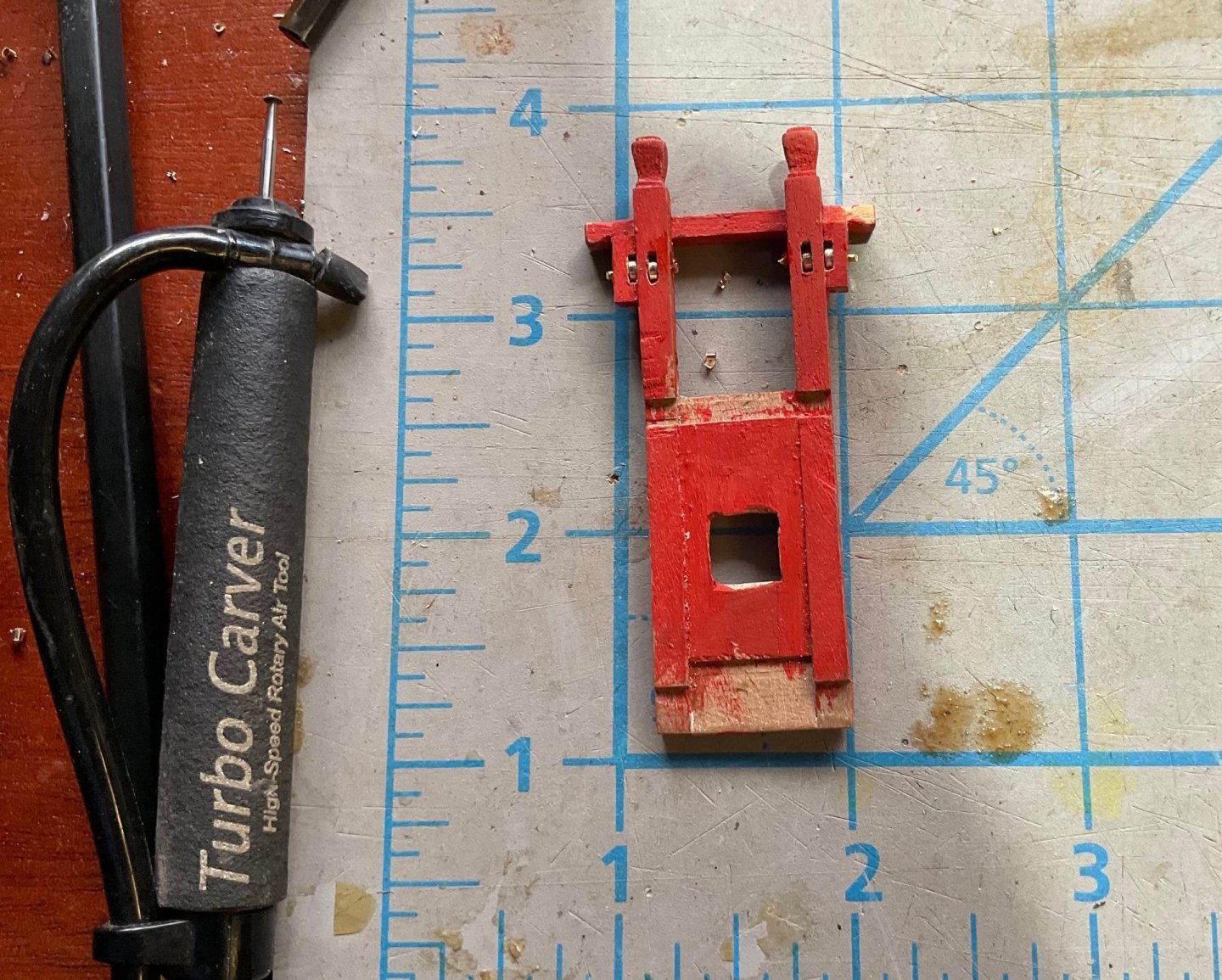

Just made my first chain pump and having difficulty fitting it through the main mast partner hole. The book says the hole is 9” wide. I have opened the hole to 9” but this is the result. I am curious what you did. My instincts tell me to reduce the pump housing to fit the 9” hole. The second shot shows what happens when i pass it through a 10” hole. kevin

- 475 replies

-

- 1,129 replies

-

- 1,129 replies

-

She is looking good. I decided to ignore the scuttle covers as no one would see them and if i wanted to build them i would just scribe the lines and highlite with pencil.

- 475 replies

-

- 1,129 replies

-

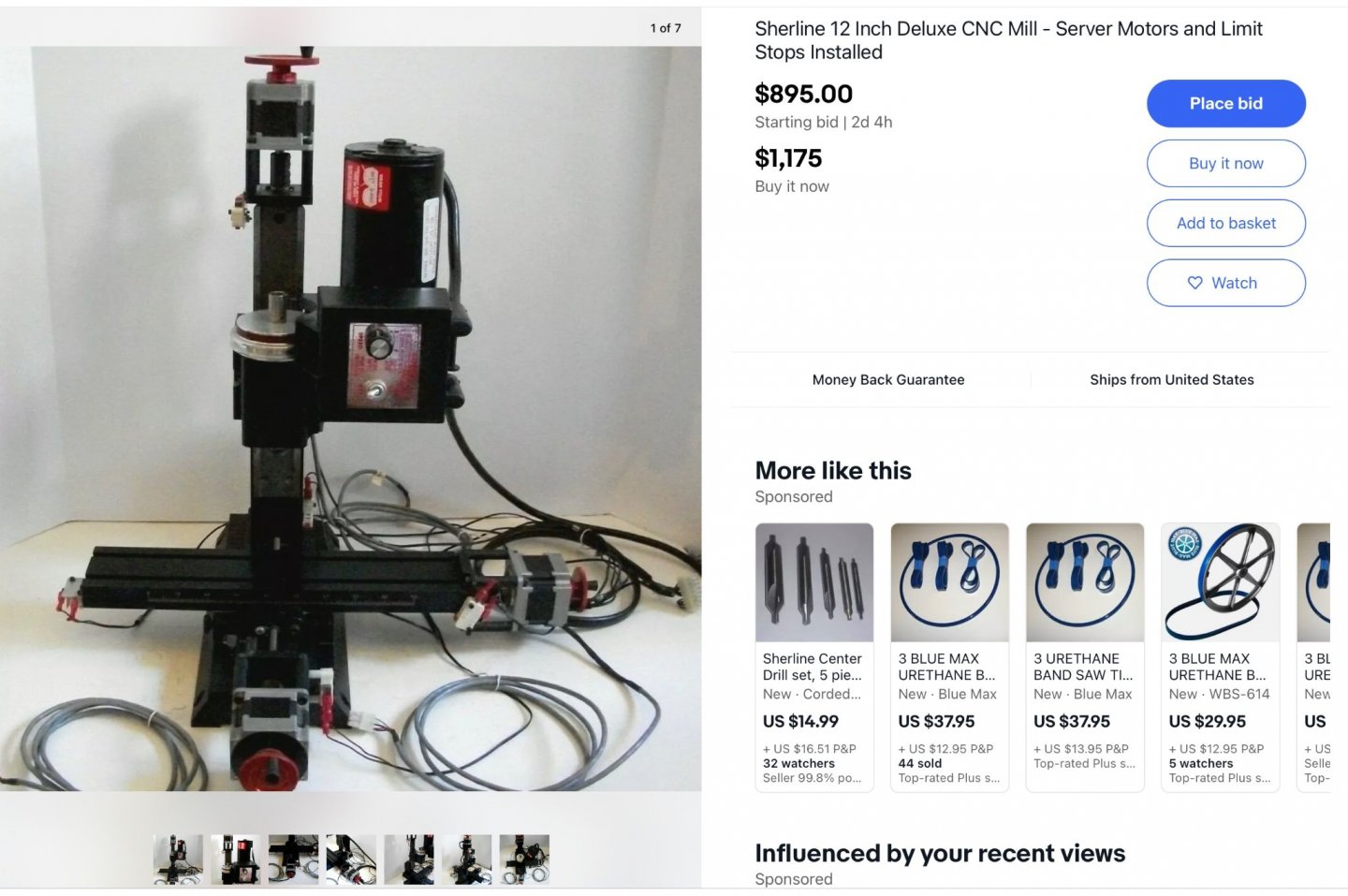

The base is 6” long by 4 1/8” wide, so if it will fit on your xy table it should work . It uses theses bolts to hold onto the table. It can be drilled to position it on the table.

- 1,129 replies

-

New stock of “ Juniper “ arrived for the outside framing. I had hoped that i would have gotten much more but the price was right so i am great full.

- 1,129 replies

-

I knew that there had to be a good explanation. Ill have it easy to do the rest of the deck planking and then to start the outside planking. Right now i need some easy stuff.

- 1,129 replies

-

- 475 replies

-

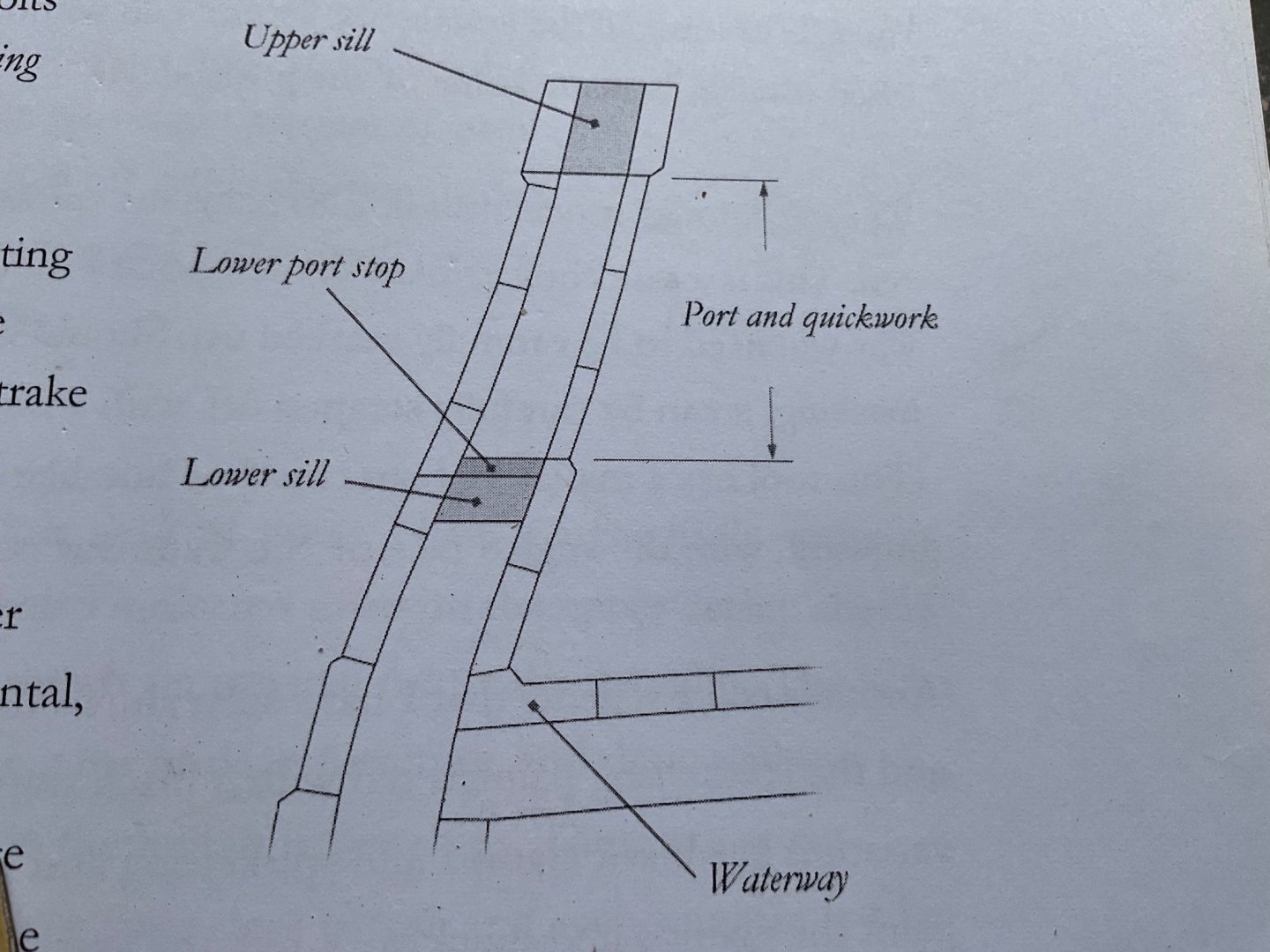

Just curious if you catered for the slight increase on the outer edge of the waterway which touches the frames. I am struggling to do this on the waterway for the upper deck where the plank starts at 4” then reduces after the spirketting to three inches

- 475 replies

-

Making sheaves for blocks and bitt pins

Kevin Kenny replied to Kevin Kenny's topic in Masting, rigging and sails

Phil thats a very useful site. Ill keep it for future projects. -

-

- 1,129 replies

-

Something to distract you from your more important build of the Swan

- 475 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.