-

Posts

1,492 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

This is my challenge for January. Your job looks great. I `plan to use some very dark greenheart wood that i have and will still stain them black.

- 475 replies

-

I decided to update my table saw video on safety to include Kurts advice and my subsequent additions. .

- 1,136 replies

-

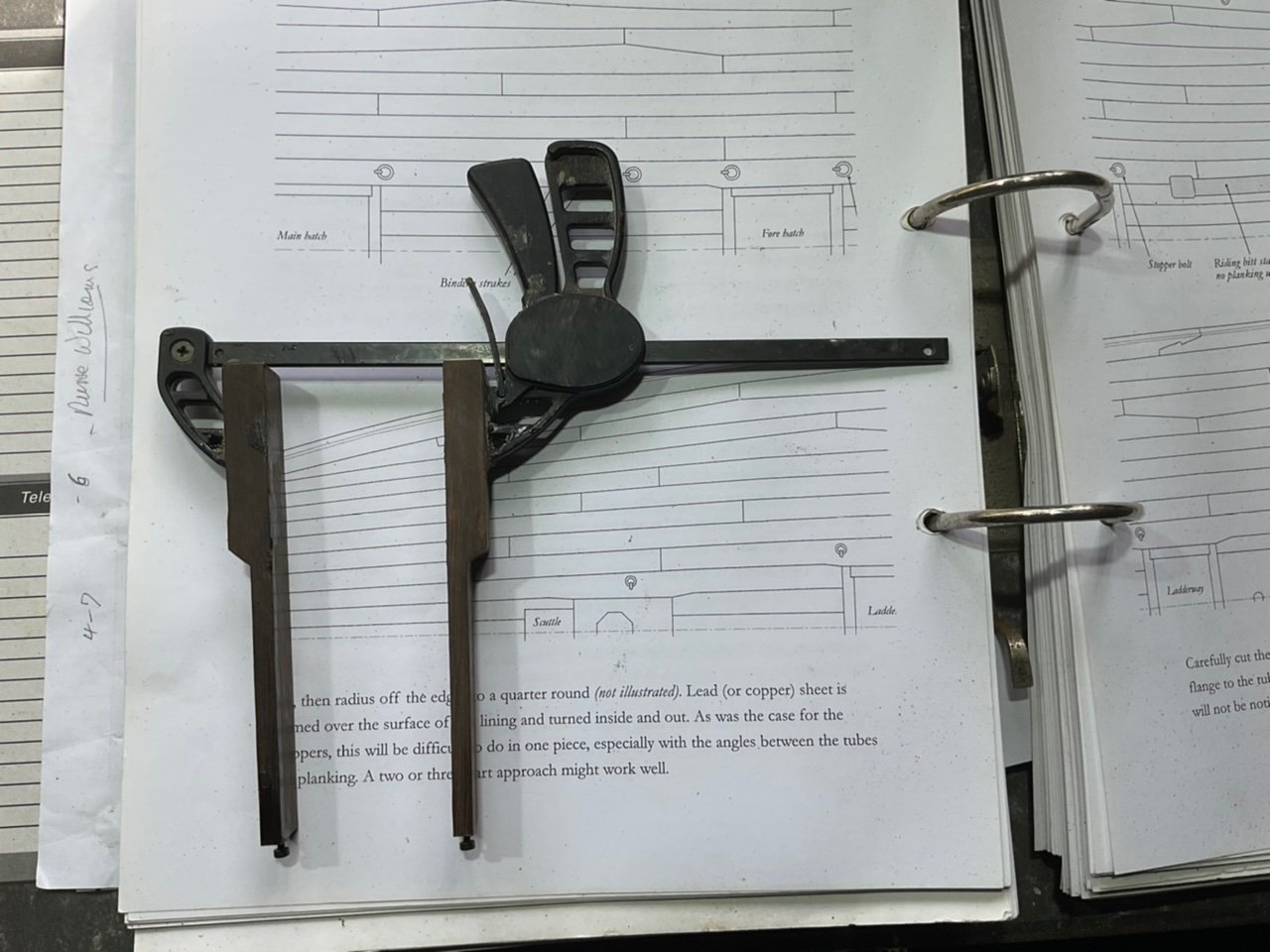

Tom, i did not make a video on the clamp extension arms but it was easy to make. I used some hardwood, in my case some green heart, cut a slot so the original clamp ends can fit down inside the slot and filled with epoxy. When a lot of pressure is placed on the arms i do get some bend. I plan to make two more using aluminum arms to see how they work out. I also feel they are too long and will make up a set that is only 3” deep. Also i added sand paper at the very end as when a lot of pressure is used they tend to slip. Once the sand paper was added that problem disappeared. I also made up some extensions which help me get into close up situations.

- 1,136 replies

-

In the tropics all untreated wood is subject to damage from dry-wood termites and woodworm damage. I have actually had one of my finished models attacked and had to treat the internal wood with liquid fluid and then gassed the model and case to kill all insects under the cover. Liquid termite fluid cannot penetrate painted surfaces while gas penetrates everything but leave no residue and so does not treat. It just kills. So now to make sure that does not happen again i treat all the wooden parts before i paint or apply any finish.

- 1,136 replies

-

the joinery really comes up when i added the termite fluid. I can wait to see the rub on poly effect.

- 1,136 replies

-

The clamps with the long arms were made by me using some green heart. I had to add sand paper to the ends as they tended to slip. They were easy to make

- 1,136 replies

-

The planking patten gives the deck lateral strength.Greg says that it’s an area where there is a lot of wear caused by the cannons going back and forth. He also says that these deck planks are often changed due to the ware.

- 1,136 replies

-

its called anchor stock planking, i suppose as it looks like the top wooden piece or stock of an anchor of the time.

- 1,136 replies

-

- 1,136 replies

-

- 1,136 replies

-

- 1,136 replies

-

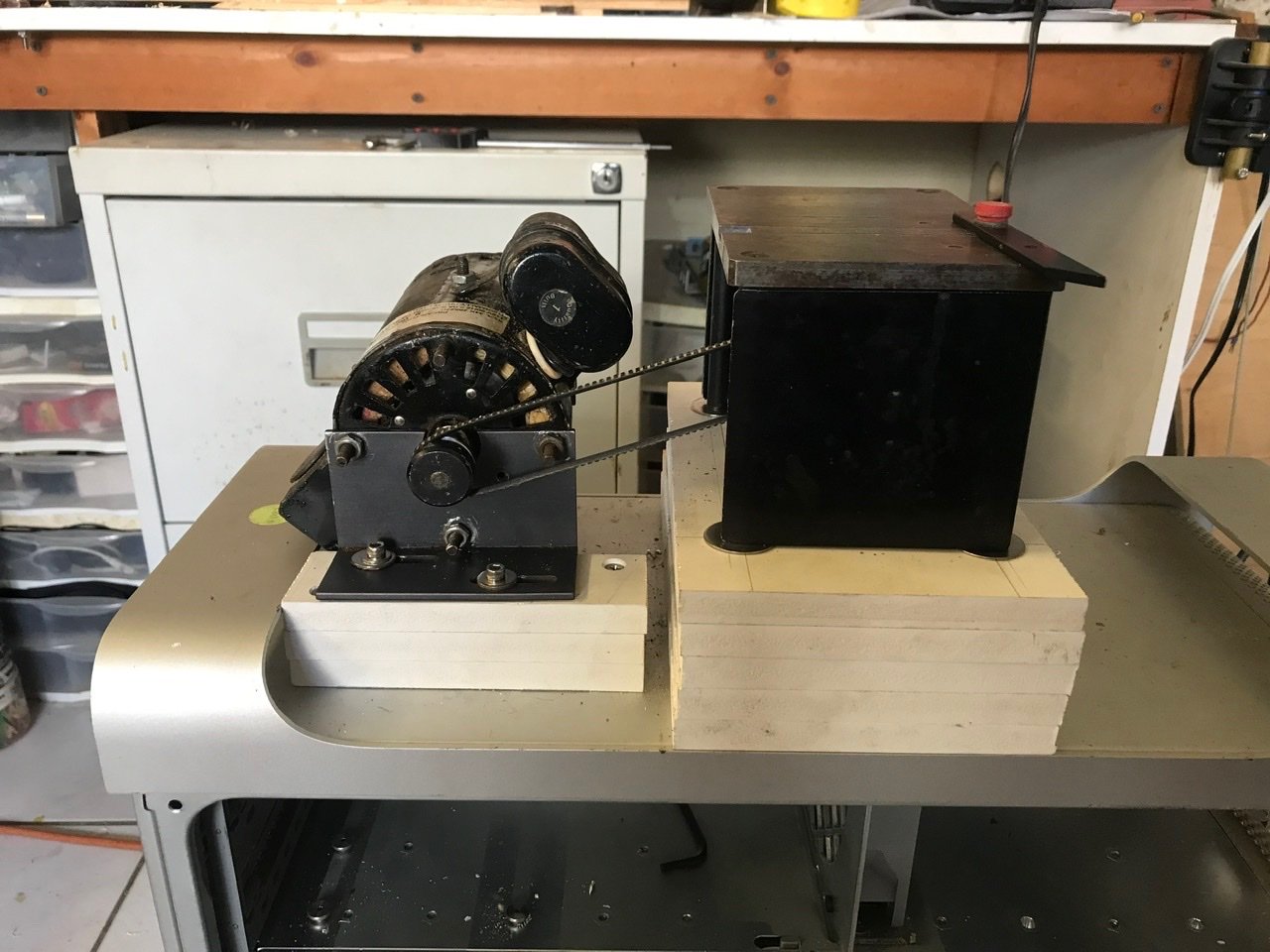

Apple has put out a new modeling table saw. kidding. I have long wanted to upgrade the Preac to roll on its own and to keep all its accessories. I gutted my old Apple pro computer and mounted it on the top. Now looking for another one for the Proxxon chop saw.

- 1,136 replies

-

- 1,136 replies

-

It make me feel i should have included these details in my model. Looks great. The good news is that you will not have to include some or the difficult floor planks on the outer edge of the upper deck.

- 475 replies

-

- 1,136 replies

-

I went to look at some old tools and came away with a lovely selection of Sphinx drills, centering tools, reamers etcc.

- 1,136 replies

-

To simulate corking you can use black paper stuck between the two planks or in my case i use a soft pencil to colour the joint which makes it look like scale corking.

- 1,136 replies

-

I was still getting slipping issues so had to modify the tips by removing the screws and adding sand paper. That solved the problem. Then made up some extenders that lay flat on the deck and allow further reach. Now its doing what i hoped it would do.

- 1,136 replies

-

- 1,136 replies

-

Coming along nicely. I might have softened the edges of the post a bit. It is always a difficult decision as in miniature sometimes it is better to leave them sharp to show the detail. Looking great.

- 475 replies

-

I have developed a new long reach clamp. It is evolving. I added a 2mm allen key bolt at the bottom which made a big difference.

- 1,136 replies

-

Made a very small angle gauge to measure the angle on each plank. I had made one along time ago but i guess it was so small it disappeared. The screw came from a broken pair of glasses.

- 1,136 replies

-

- 1,136 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.