-

Posts

1,492 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

- 1,136 replies

-

- 1,136 replies

-

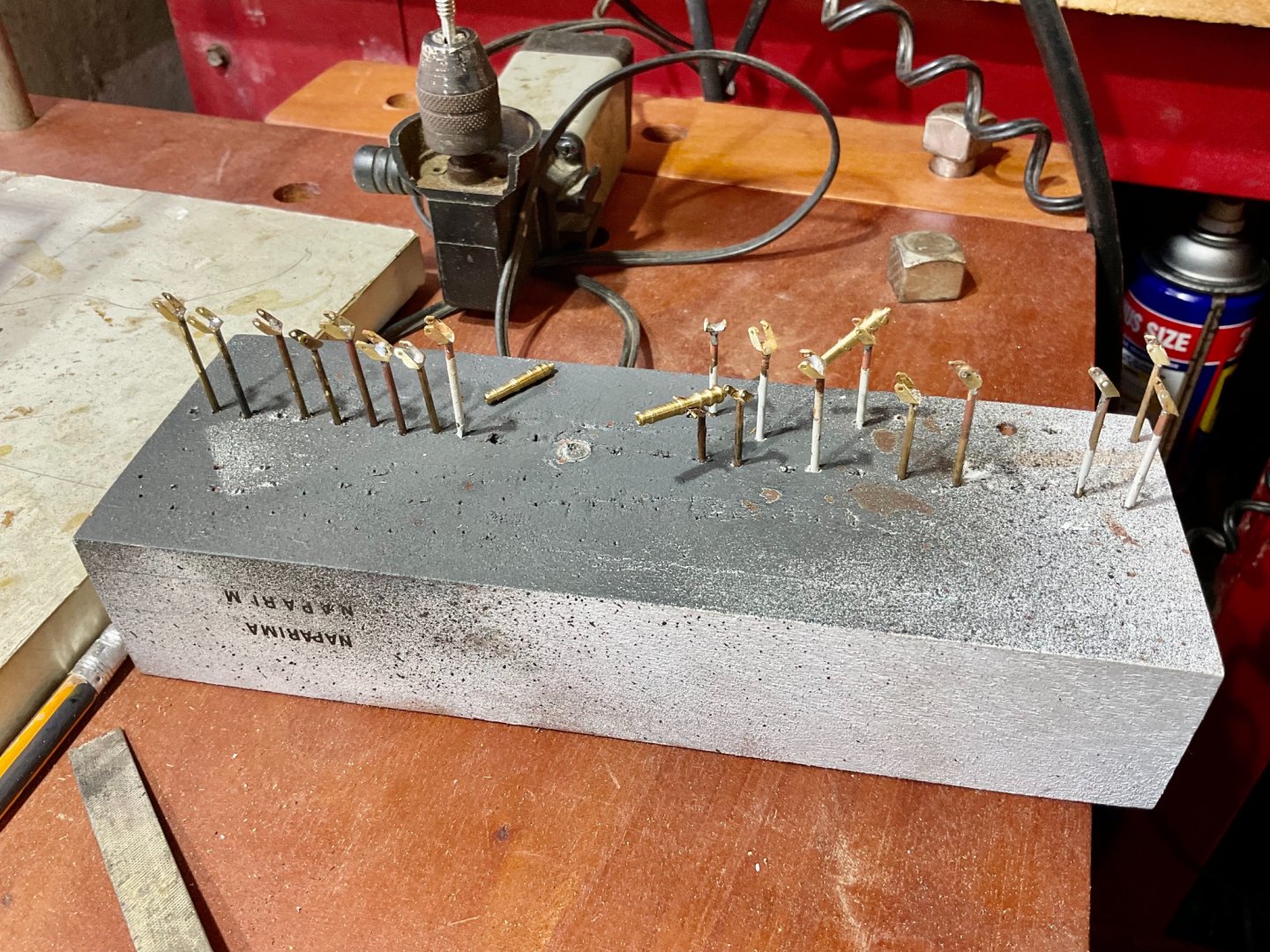

Now working on the swivel guns and the swivels in particular. This is my first attempt. Also yesterday the new Ipad pro arrived along with some new toys for the shop. The solder past will be essential in building the cannons and fitting the monograms. I have wanted to upgrade my soldering iron for a long time.

- 1,136 replies

-

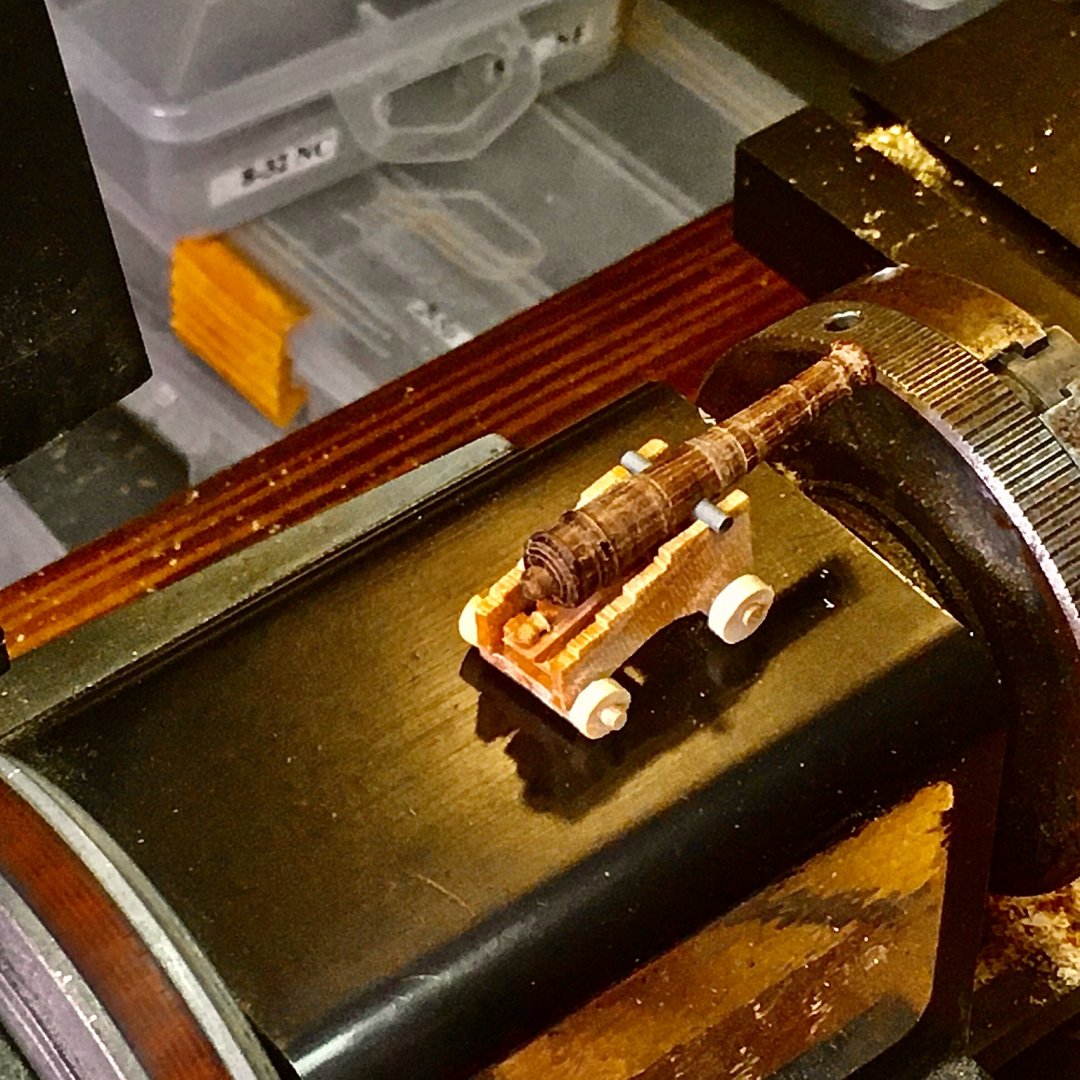

Just did a count and found there are 70 individual pieces that make up a cannon and it’s stand not including the tackle used to hold it in place. I decided to only use 30 pieces.

- 1,136 replies

-

- 1,136 replies

-

- 1,136 replies

-

Termite treating the assembled cannon carriages, wheels and cannons. This is probably over kill as they are all made from hard wood. The cannons should not be subjected to insect damage, lignum Vitae and Wamara.

- 1,136 replies

-

Termite treating the assembled cannon carriages, wheels and cannons. This is probably over kill as they are all made from hard wood. The cannons should not be subjected to insect damage, lignum Vitae and Wamara.

- 1,136 replies

-

Update. Just thought i would update you all who have so kindly offered to help. I have located the model and more importantly the curator of the Science Museum who has agreed to help me locate all the possible information the museum has on the model and its builder. She has also offered to help locate the original plans that the model builder must have used to build the model of the SS St. Patrick. The models will become available for viewing some time 2022-24 so that good. this has been a wonderful exercise with so many offers of help from so many quarters. The hobby is alive and well. Thanks everyone for participating. Best regards kevin

-

You are correct, some were sold, some were returned to the persons who had loaned them to the museum and the balance are now stored at dedicated storage at an old airfield near Swindon. So i will get one of my UK friends to get in touch and see if they can trace the model of the St Patrick. Its very exciting to be on the hunt for a possible piece of my countries history.

-

- 1,136 replies

-

- 1,136 replies

-

- 1,136 replies

-

I’ve had my first Vaccine, the second due in June

- 1,136 replies

-

We are now in total lock down for the next two weeks as our Covid cases are exceeding India, we are actually the highest per capita in The WORLD. Local post office is now closed. so back to making more cannons.

- 1,136 replies

-

- 1,136 replies

-

Took up your suggestions, reduced the size of the muzzle, sanded and polished the cannon barrel and it is now more in scale. I could polish it more but do not plan using these on the model. Now to complete 20 more carriages. Had trouble cutting the wheels, they often split. Used different wood but it did not seem to matter. Then treated the finished blank with thin CA. This worked perfectly. The contrasting wood is interesting but feel that i will use similar colour.

- 1,136 replies

-

- 1,136 replies

-

- 1,136 replies

-

- 1,136 replies

-

- 1,136 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.