-

Posts

1,492 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

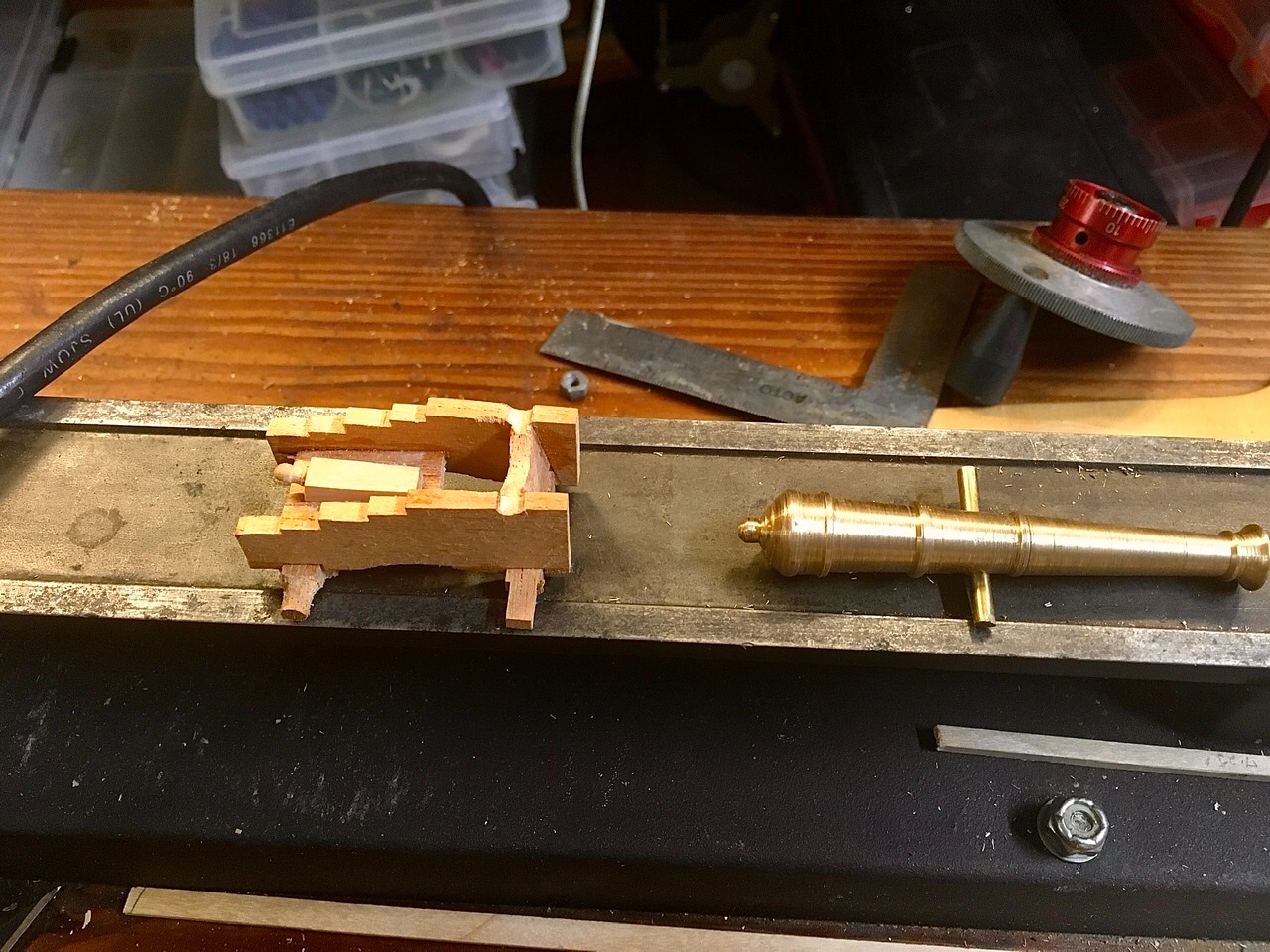

These are temporary trunnions which are two small, out of scale. Hoping to find the correct size, if not ill machine them. Will spend the next day or two on the tackle.

- 1,136 replies

-

- 1,136 replies

-

I have some cannons coming from Greg. I’ll compare and adjust the flare. Thanks for the feedback.

- 1,136 replies

-

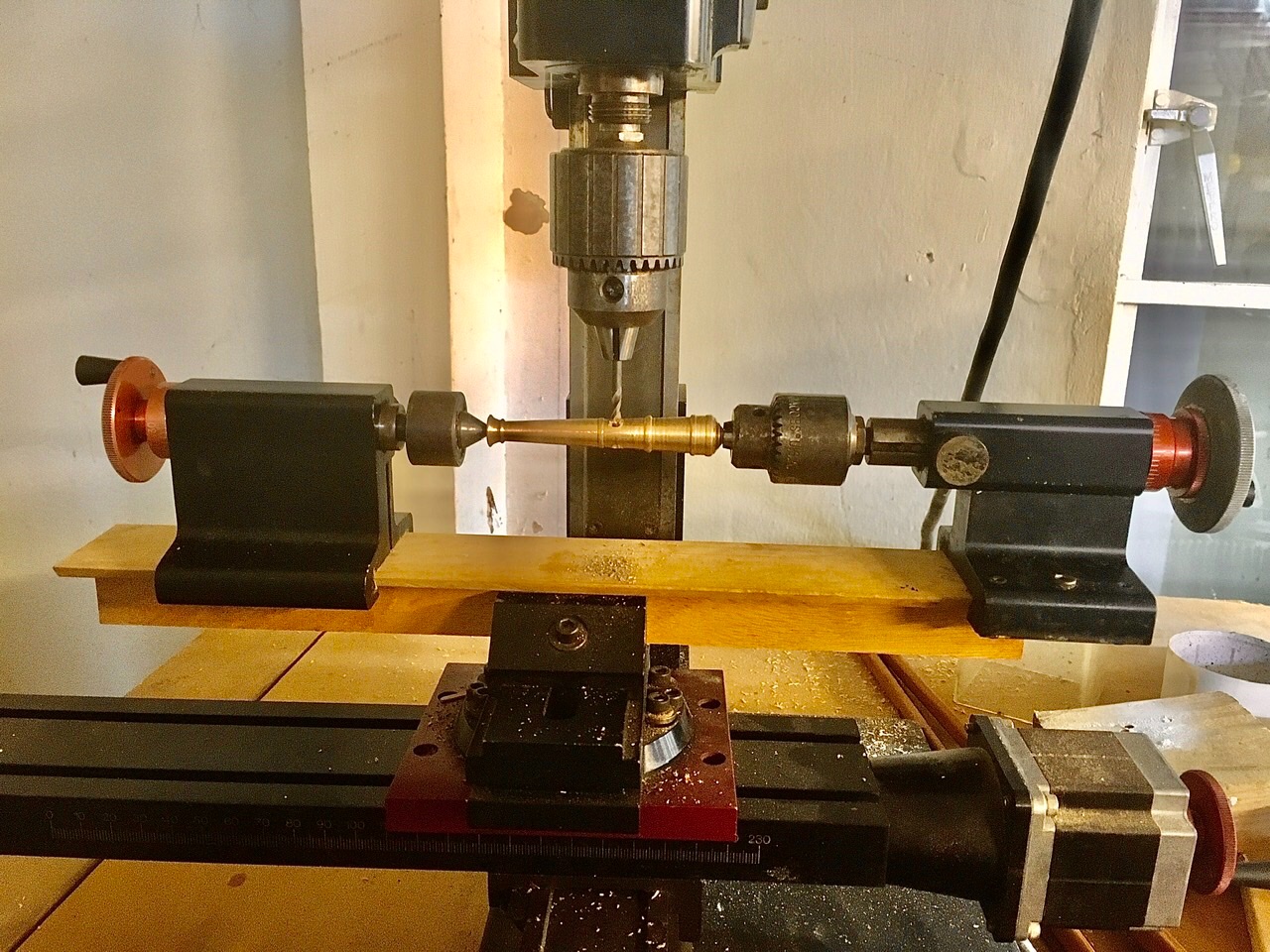

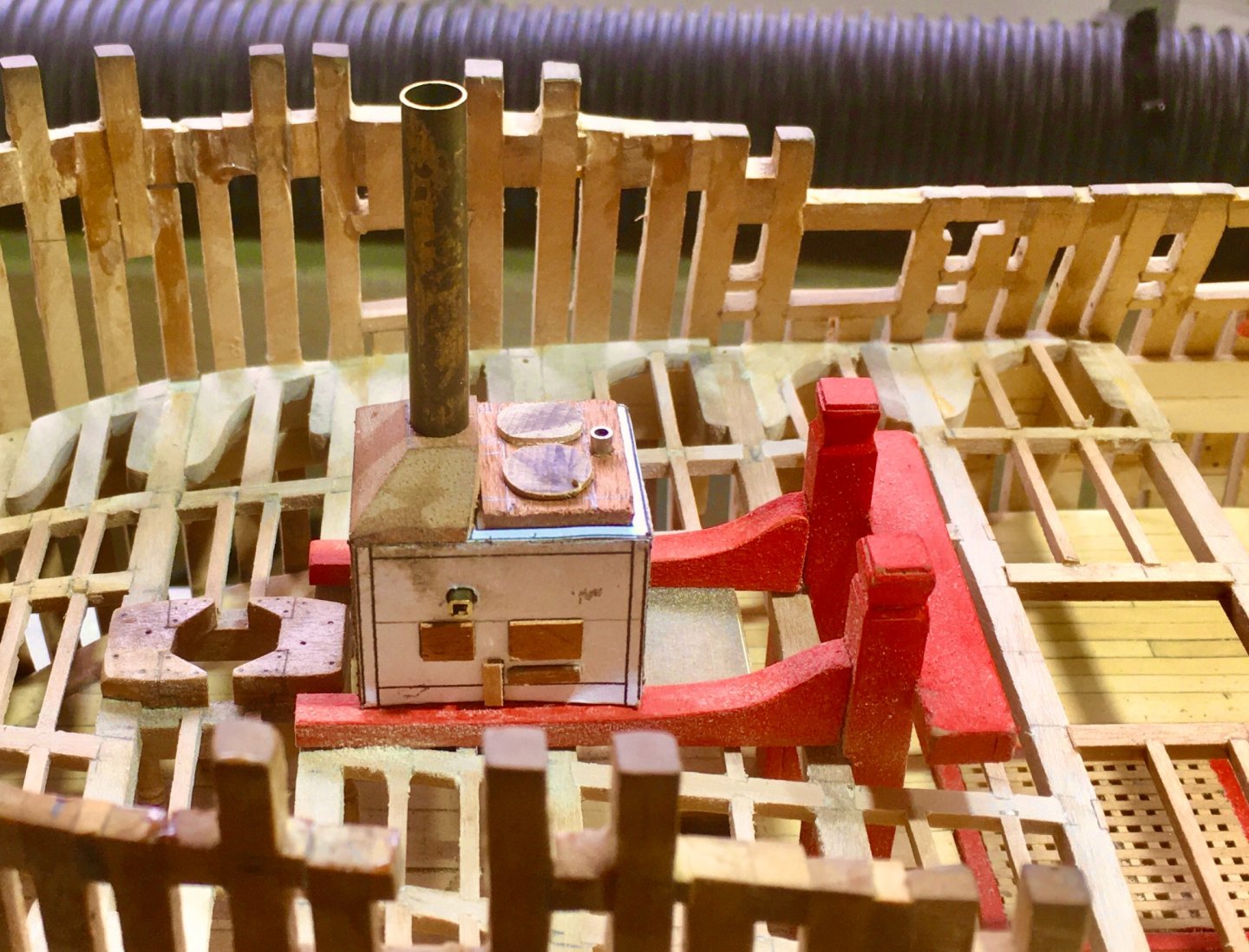

I decided to make a larger cannon and carriage to better understand the process and to decide on the jigs. I finally got a solution to accurately drill the trunnions using the Sherline mill..

- 1,136 replies

-

Its always such a relief and most times a disappointment when a model get completed. Perhaps the most interesting memory is looking back on those times when you could not figure our something, or when everything went wrong. Now you think back and wonder what the fuss was all about. congratulations on a very fine model. Now for the case.

- 162 replies

-

- america

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 1,136 replies

-

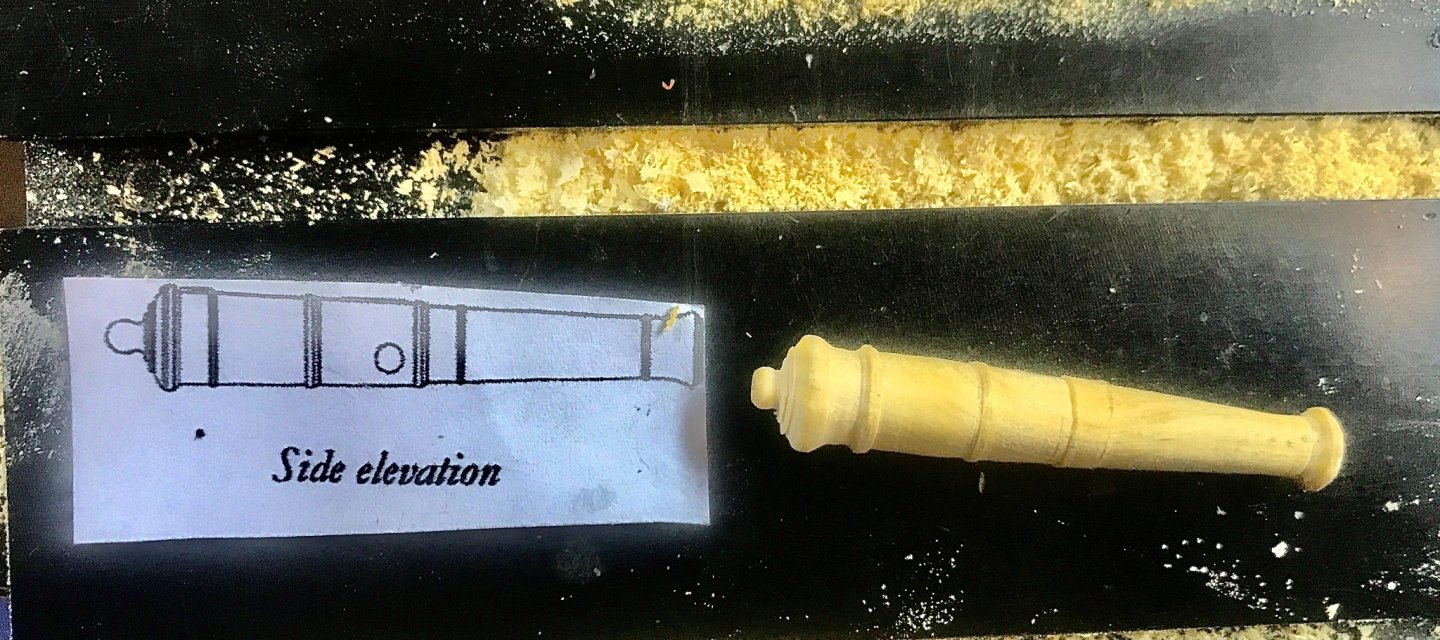

This is my first attempt at making a cannon on the Sherline lath. Not a bad first attempt, used the Lignum Vitae. Fantastic for this fine work.

- 1,136 replies

-

Already done Maury. I have been collecting wood for. Long time now and have friends in the lumber business so have experienced the problem when the ends dry out before the center. I have had problems with the coffee wood and with Sea Grape that cracks so easily. Recently i decided to keep the new stock of coffee wood in branch form and not cut it until it dries. It splits terribly. Sea Grape is the worst.

- 1,136 replies

-

Just back from Tobago and settling back down. I have been collecting modeling wood for a number of years and just got my first large piece of Lignum Vitae the most dense wood in the world. Not sure how long it needs to dry but will leave it for at least a year in the drying shelf. As would be expected the grain is very tight but i was disappointed that the heart was not darker and more consistent in colour. Oh well, just glad to have it in my collection of tropical hardwoods. The woods grown in the caribbean and usually found in very thin trunks because it grows so slowly. It should be excellent to cut on the lath to make cannons.

- 1,136 replies

-

- 1,136 replies

-

If you read the history of this boat early in your build you will realize that no one knows for sure what she looked like when she won the race in 1851. I only found this out close to the end of my kit build. There are a few photographs over time that show different deck layouts. All the early paintings were done without the artist even seeing her. This caused me to do two models, one is the Constructo kit and a second scratch built of what i think she would have looked like when she raced the British.

- 162 replies

-

- america

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 162 replies

-

- america

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

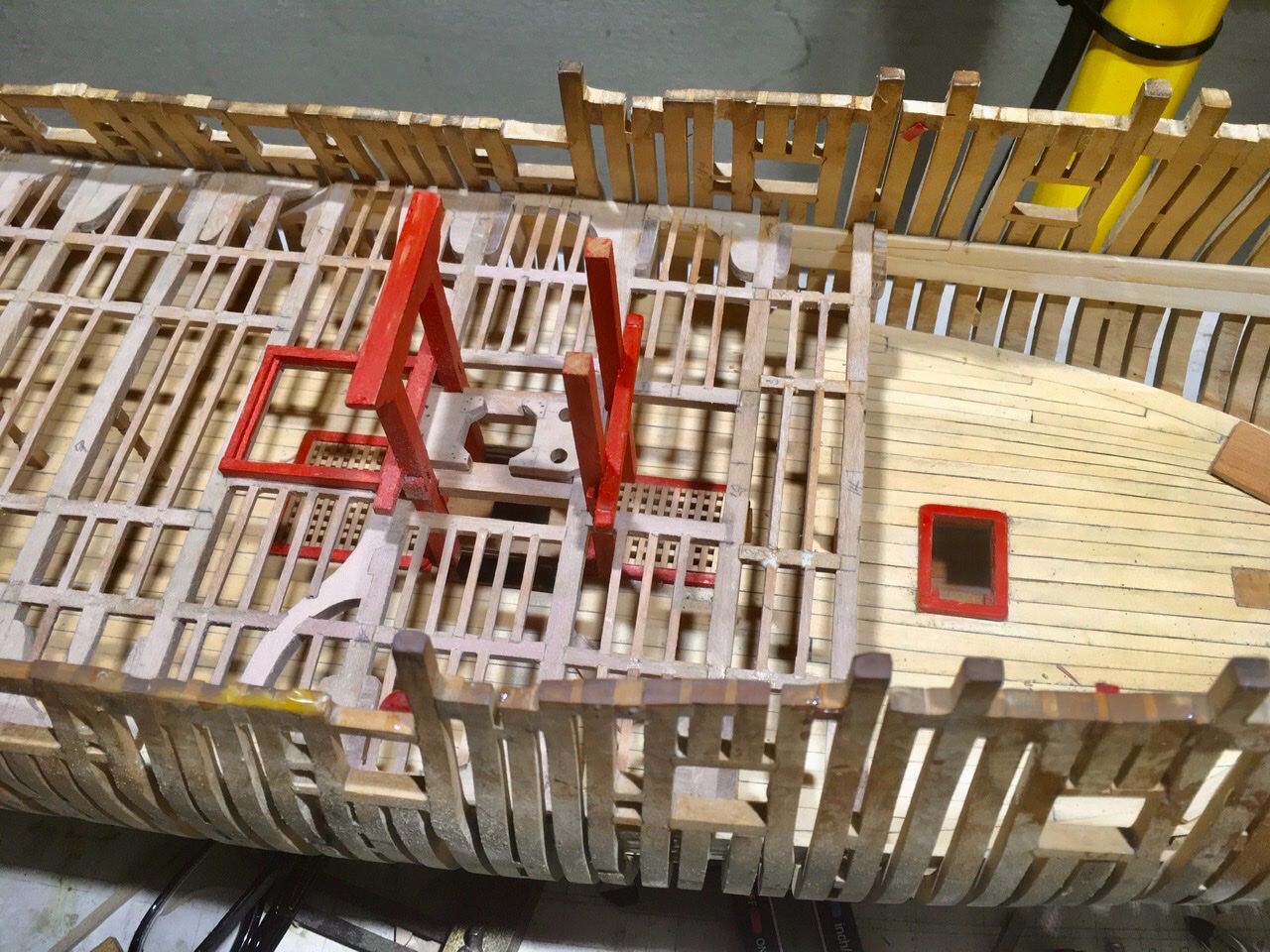

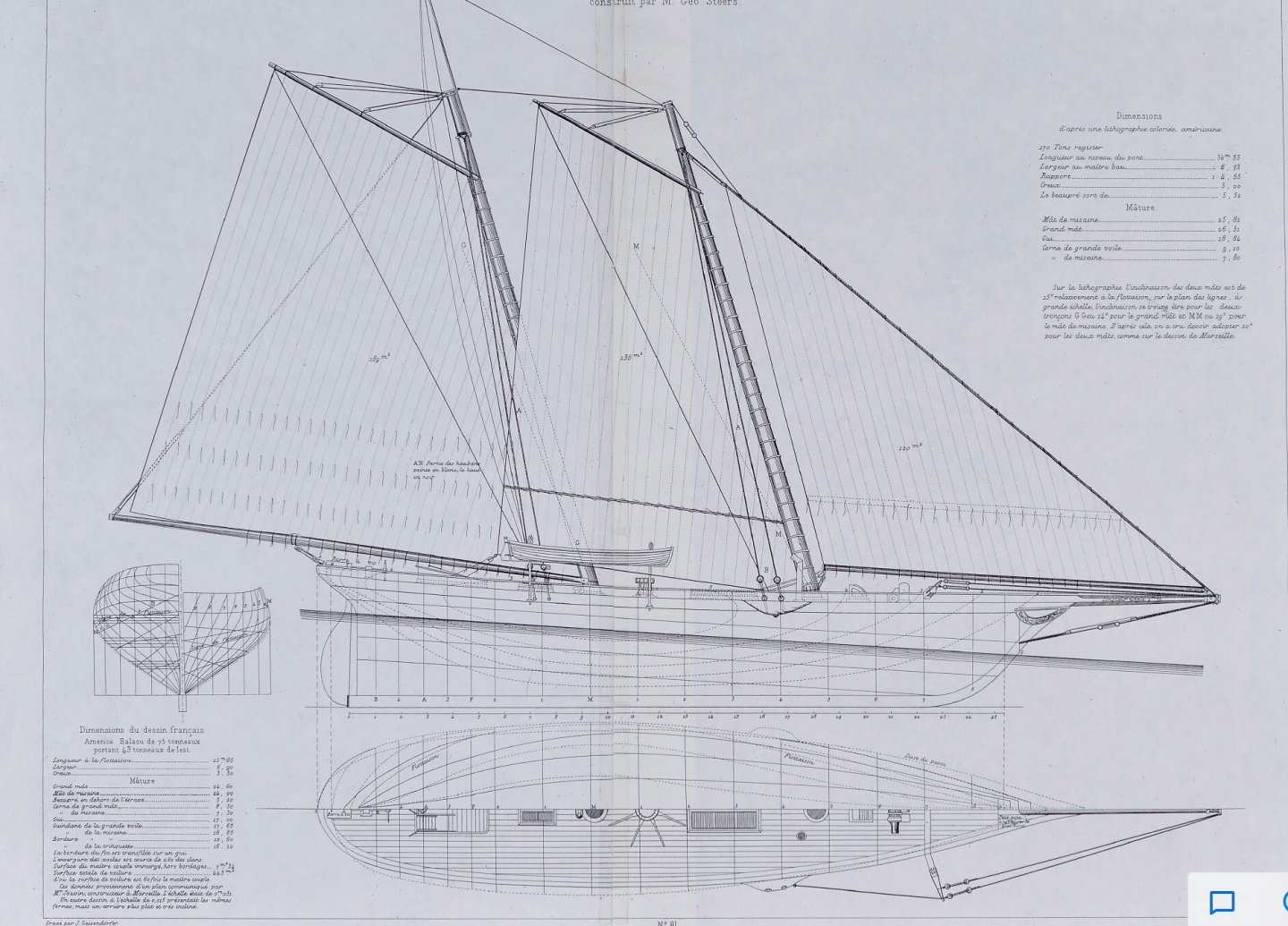

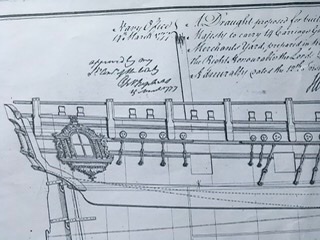

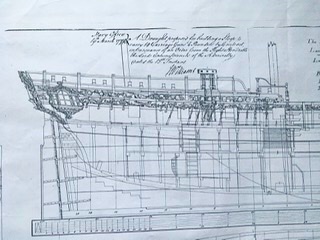

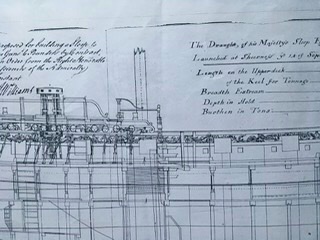

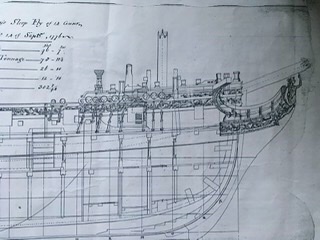

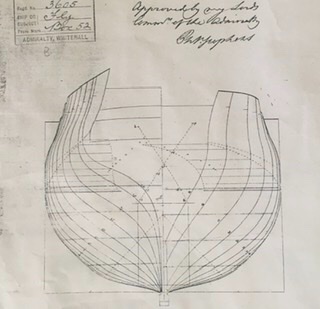

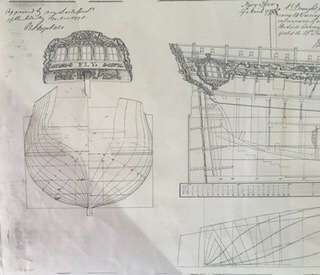

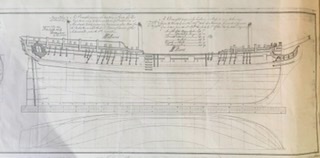

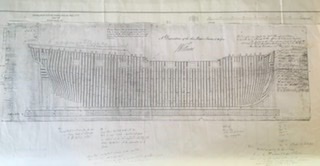

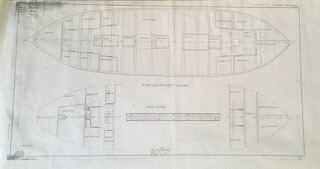

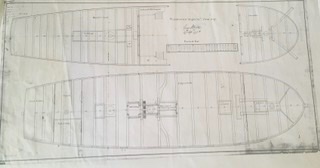

Here is a sample of the drawings available. The frame layout is the only referenced document to the Thorn

- 1,136 replies

-

Hi Phillip as you must know having tracked me down, that the Thorn was a Swan class ship. There are lots of pictures of models of various Swan ships. I have only one written document that makes direct reference to the Thorn and that is the frame layout. I too am currently trying to access ship logs of the vessel but so far have not found anything. I plan to keep looking so if by some chance you do come across any data i would be most interested. The National Maritime Museum has numerous plans of different sister ships. These are beautifully illustrated copies of which would make wonderful wall decorations. Since there are no ships names written on the side, displaying these drawings would depict what she probably looked like. best regards kevin

- 1,136 replies

-

I am constantly taking breaks with my models, either for work, or because i am having a skill issue and get fed up. Walking away has always resulted in a better finish to the model when i start back.

- 162 replies

-

- america

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

This is the fun part so enjoy it

- 162 replies

-

- america

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 1,136 replies

-

- 1,136 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.