-

Posts

1,308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

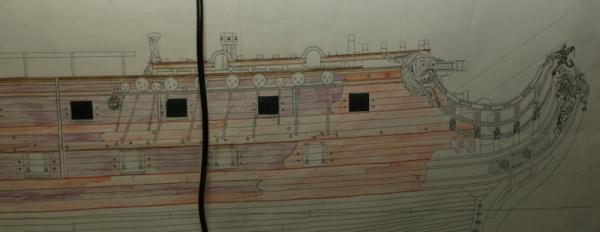

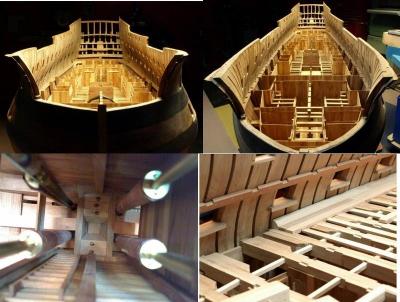

To change the last habit, 6 months in the hold of the Fleuron, the work moved outside to continue the planking on both sides. First picture shows 1 side on wood and the other side with Tung oil. There are 2 deepness levels as in the both colors of the second picture. The third picture shows planking where 2 kinds of woods were used: pear and cherry wood. The grain pattern for the cherry is more presents and seems more accurate than pear which has much less grain pattern. I wanted to do try a comparison between these 2 woods and seeing this picture I prefer the use of cherry which is probably, just a matter of choice. The last picture combines 2 views of the bow, the one to the right with few more details. To make sure the side walls won’t move, I preferred to redo now the basic bow wood framing.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Michael, for this work I used soft solder On the picture, there are 2 kind of solder. The difference is the temperature needed to use each one: Soft solder, silver bearing lead free (we reach the temperature by using Butane) Hard solder, silver 45% (we reach the temperature by using acetylene) Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

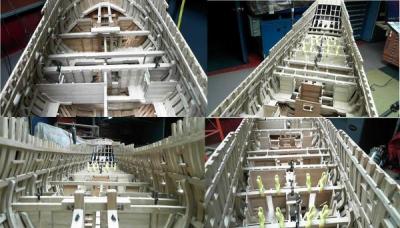

Druxey, something had to be done now because there would be regrets later when checking to have 2 symmetrical sides with asymmetrical sculptures, correcting today to make it easy for tomorrow. In this case, replacing by less than .25 inch on first deck, corrects error (which is quite high in this case) at the top aft beams where the maximum displacement occurs. I remarked on the 74 guns that it is better not to do all the deck beams at the same time, because the length can changed for some.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

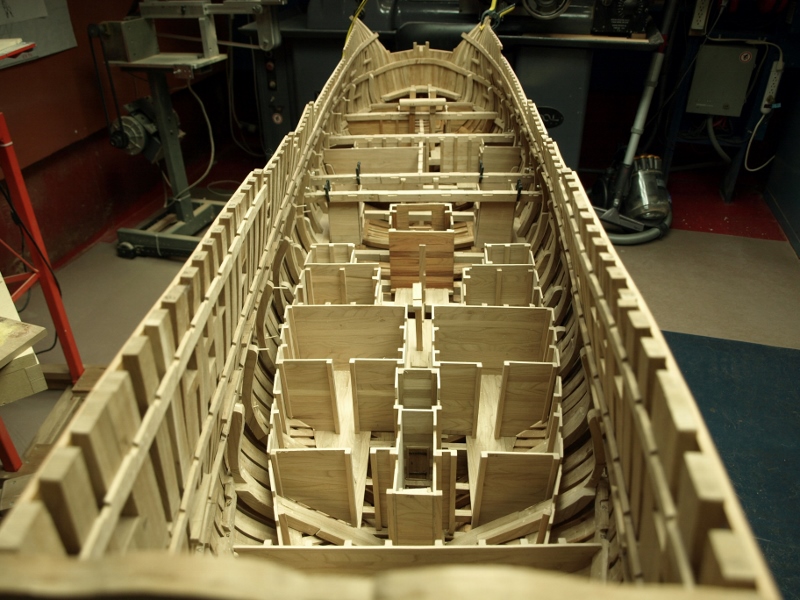

Thank you Mark, Metal fitting installed completes the hold level. The model began 1 year ago, 6 months for the framing, 6 months for the hold.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

I noted since a certain time that something was wrong in the aft part. Not knowing what to do, I did not touch anything. Today, I wanted to identify the problem by putting the vertical laser line on the longitudinal axis to establish a center line. Then the center finding rule is placed over the center line and, for each side, the distance is taken from center to the side. A difference of .75 inch larger to starboard is noted. A correction of the top aft starboard frames which bends too much inside is required. The picture shows how to move the starboard side only by taking support on the keel. The spacer will be left there until correct curvature of the frames. Clamps are also use for 2 reasons, realign few frames and on the starboard side, it allows the whole set of frames to move together. Unfortunately all the work which was done in the aft parts had to be disassembled and scrapped.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

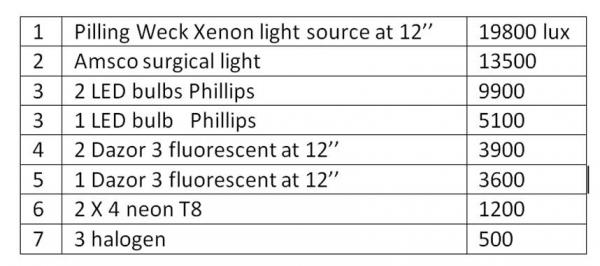

LED Lighting I received an e-mail from our electricity company, Hydro-Quebec, they pay $10 for each LED bulbs that we buy. Also, lighting on the working desk was not satisfying enough. I paid a visit at Home Depot of my area, this is where I saw the best choice with LED bulbs. Yesterday I bought the best bulbs they had a beam light by Phillips 19.5 watts, dimmable, a fixture and a dimmable switch with a remote. After installation verification with the Luxmeter gave surprising results Test are done at 4 feet except for 3 which are done at 1 foot. Beam width and strength, in a way are not comparable at different distance, but here are the results. LED bulb is more expensive than an ordinary bulb but the performances are more than ordinary. In comparison with the best light Amsco I have, which is halogen (the light is white not yellow as a standard halogen), 2 Phillips LED can produce 13500/19800: 68% of the lighting level. In conclusion, LED is coming with results we could not hope to reach few years ago. Actually, I would say without hesitation that Led lighting is the best way to see what you do.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Gluing by fusion or capillarity Welding is done by metal fusion. Temperature over 1500°C is necessary and, a heat source over 3000°C is required to reach it. Oxygen and acetylene can produce a temperature of 3100 °C but the price to be fully equipped for this type of welding with ‘’The Little Torch’’ use by the jewelers can easily reach over $1000. 45% silver solder can be use but the price of silver is very much surprising and can be quite expensive. For the small parts that we use, option below $100 is possible. Brazing is done by capillarity and alloy temperature is lower than the one of brass. Butane micro torch can reach over 1000°C which is plenty sufficient to do the job. Silver bearing solder uses an alloy with silver and lower temperature is required (around 500°C). I do not think that this alloy does not produce toxic fume like cadmium as in photography and it is no lead product. Pencil size torch will do the small jobs and a Blazer micro torch by example will do the big job as for this one. With that, an alloy like silver bearing lead free can be use with flux also lead free and some are water soluble. To blacken brass I use product Gun Blue in few ounces bottle. For over 1 year it was not possible to buy it because no French instructions included for Quebec Province. I turned towards blackening metal for the industry and bought 1 pint which makes 1.25 gallons from http://www.caswellcanada.ca/shop/black-oxide/ , so I should have enough for a long time when I will receive it this week.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

HMS Pandora 1779 in 3D

Gaetan Bordeleau replied to ppddry's topic in CAD and 3D Modelling/Drafting Plans with Software

Hi Jingyang, thank you very much. I like the colors I like the angle of view It is surprising how close from reality their effect can be. There is a lot of work behind your work. You have a fantistic tool to evaluate dimensions of parts in relation one to the other. Congratulations for your work! Gaetan -

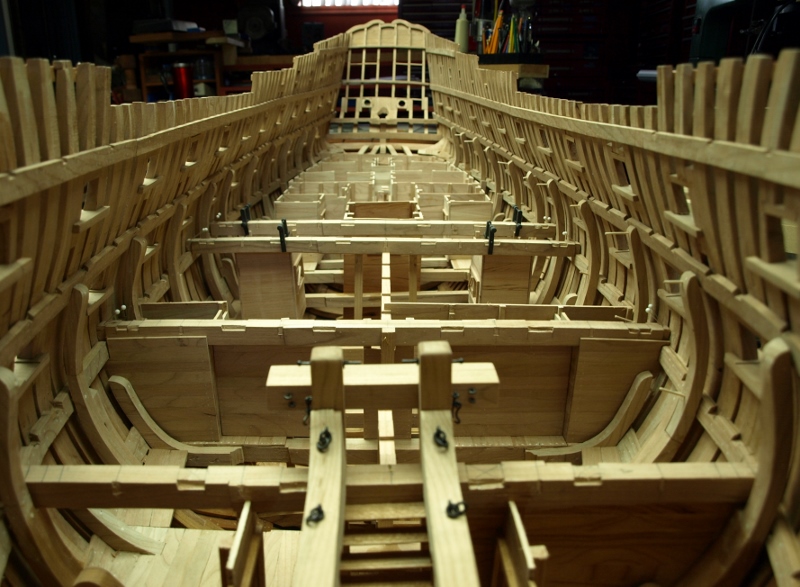

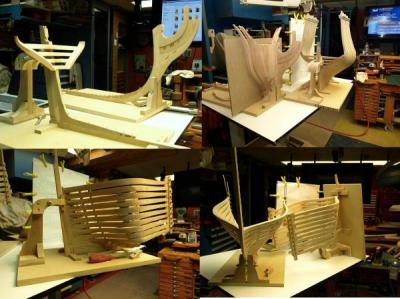

Gluing partitions walls. To be able to work with the portable close to the desk, the last picture shows a support for it. Already built with angle adjustment for the keyboard, another angle adjustment is added to make sure that the keyboard is perfectly horizontal which was not before because of the weight of the portable.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

HMS Pandora 1779 in 3D

Gaetan Bordeleau replied to ppddry's topic in CAD and 3D Modelling/Drafting Plans with Software

Jingyang, you have a marvelous tool to work with and you use it as a master. It would be a charm to build HMS Pandora with this set of drawings. The problem with 2D drawings is that it is sometimes difficult to visualize a piece in 3D but with the extractions that you can do with the drawings it makes everything easy to understand. I do not know if you are still working on this model, but would it be possible to show us a drawing just like if somebody would be inside the ship? Thank you Gaetan -

Foredom or Dremel Fortiflex ?

Gaetan Bordeleau replied to Mcdood's topic in Modeling tools and Workshop Equipment

foredom is for big work, model ship building is not big work flexshaft is not desirable it is always a nuisance to work rotary micromotor are much more easier to control without the rigidity of a shaft and they are much lighter here is an example therea are many other kinds price begins around $100 and over http://www.gessweincanada.com/category-s/10555.htm -

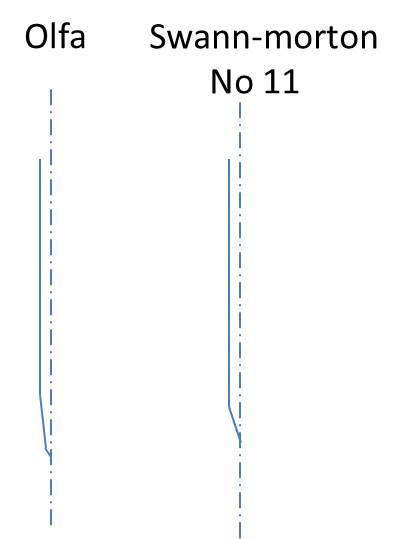

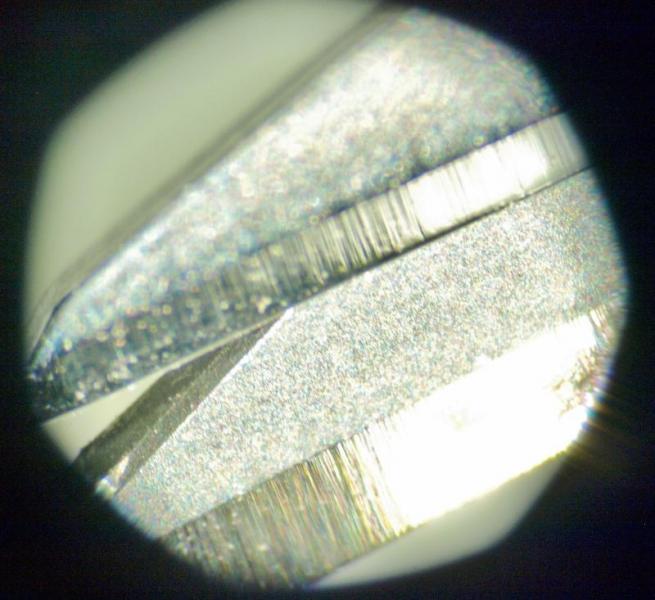

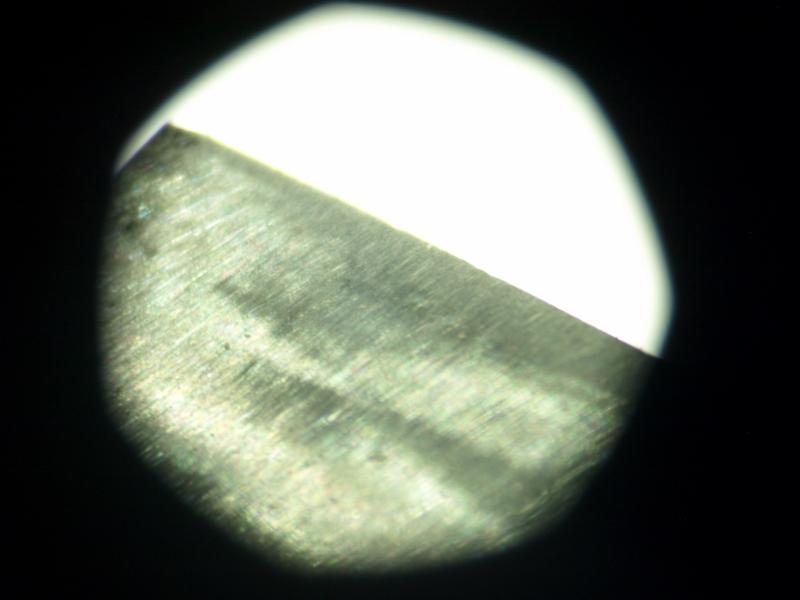

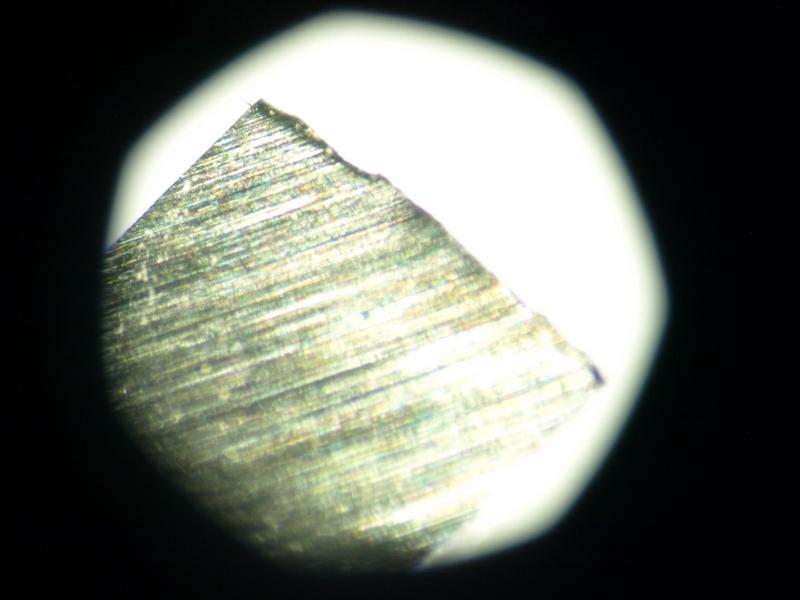

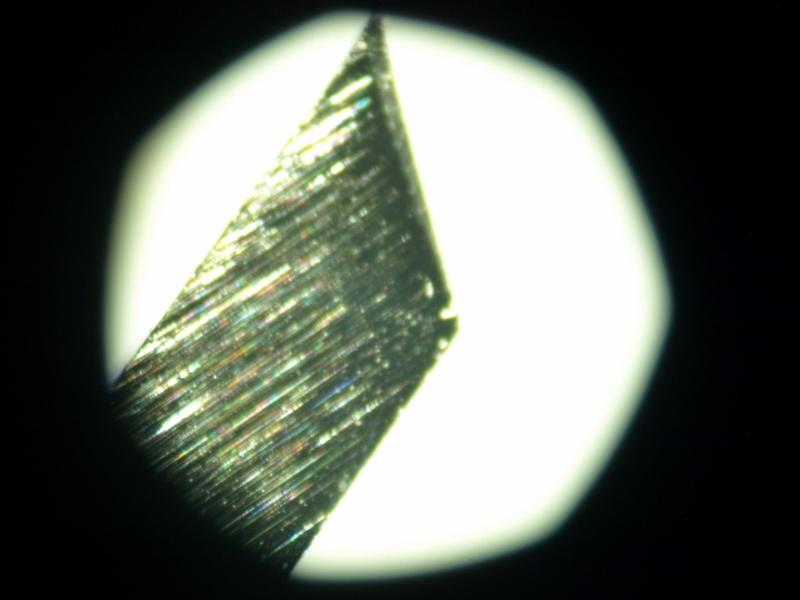

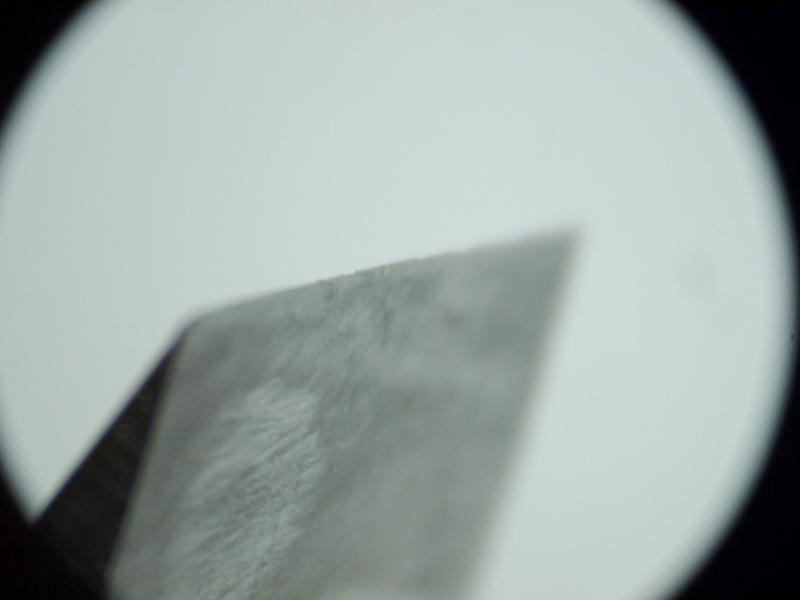

Hi Druxey, you are right about extensions. Actually the set up is to take 1 by 3 inch, 8 feet long and cut it in 2 feet lenghts, make 2 adjecent sides perpendicular, and make the remaining 2 opposites sides parallel, obtaining a 2 feet long piece perfectly straight. Many blanks are prepared this way. When I need a specific thickness , I use a blank of 1 inch thick, and cut to the desired thickness plus few millimeters extra.To get the the desired thickness at few millimeters close, the piece is pass at the thickness sander. I used microphotograph to see why a knife did not perform well even after a fresh sharpening. If we look the front of the end of the blade, we should see one line, but in few cases one side was thicker and was not coming at 0. This side was not cutting. After correction, it is a joy to use these tools!

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

After sharpening some knives, a lot of notches are done on the beams. On the last picture, addition of an extension at both ends of the jointer.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Here are some blades under the microscope. First 2 are exacto blade and a number 11 blade. A comparison does not explain well why one is sharper than the other. The only significant difference I saw is that exacto blade has a second relief angle of sharpening. Other are sharp chisels to the eye but when looking closer we see that it is very easy to burn some steel while sharpening or why we need not to hit the blade on hard object.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

What is your favorite hand tool(s)??

Gaetan Bordeleau replied to Modeler12's topic in Modeling tools and Workshop Equipment

The last tools I bought are 3 small sharpening diamond stone coarse medium and fine for about $25. Diamond is very efficient and fast for a fresh sharpening with water not oil. Although these are not this model, it shows the idea: https://www.fine-tools.com/ezelap-diasharpener.html Atually, my favorite tool is the proportionnal divider, the only use of a ruler after using it, is for tracing a line. I use it almost every day. You can calculate an angle, divide, multiply. More accurate than a ruler to measure and it is easy to repeat a distance with it. -

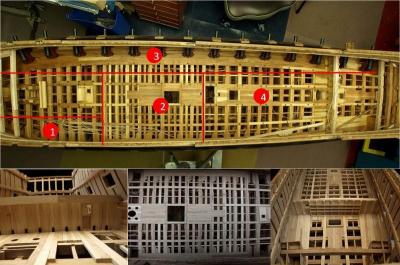

Mark, For the 74 guns, there is a copy of the log in Microsoft Word about 540 pages. For the 74 guns, there is about 1000 pictures, the most significatives ones, around 130 pictures were extracted for the last Collage. For the last picture, the background can be whatever color you wish, I have tried many colors, but black is the one! Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

From the 200 pictures of Le Fleuron, I selected 80 pictures and made 20 groups of 4 pictures. Pictures are in the order as it is build.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.