-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

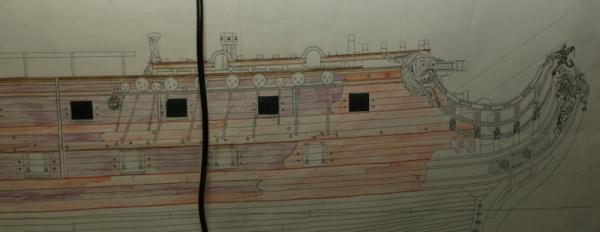

Thank you Peter even if you have some exaggerated words. Here is an idea of the outside representation with the black still wet. Asphalt powder diluted in turpentine plus tung oïl Black water tint Samona

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Ideal Mill

Gaetan Bordeleau replied to Gaetan Bordeleau's topic in Modeling tools and Workshop Equipment

The idea is not so much to buy it but more to dream of what this could do with so many composites angles -

Ideal Mill

Gaetan Bordeleau replied to Gaetan Bordeleau's topic in Modeling tools and Workshop Equipment

Last one Rawler, 4 first ones Aciera F1 with différent accessories. Possibly Aciera can still be bought new today. I do not know about the others -

-

Thank you Druxey, you got the word and you have a very clever method that I will surelly try the scalpel

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

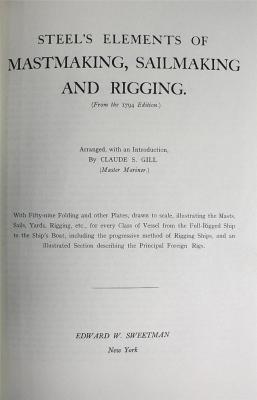

Hi Mark, thank you to help me thinking. My understanding is as follows, until about 1750 tar was black in 1780 they used Stockholm tar which was reddish-brown. May be it is a mistake to use the term tar or bitume. Tar as we know it today is used for waterprofing the roof or it is a component of asphalt. In fact we can use asphalt in powder to age wood. The tar they talk about I do not think it was coming from asphalt. It is a vegetal source, the resin from the pine tree which was obtain as follows. Vegetal tar A soft resin escapes to the foot of pine trees. This gum is boiled and when enough bake, the tar escapes by a canalisation at the bottom of the container and is collected in barrels. Depending of the time of cooking, the tar can be a clear liquid, thick or recooked. Tar is obtained by pine wood distillation by similar procedure as wood charcoal fabrication. This tar is a dark brown color, reddish-brown. Moscovy tar has a clear-yellow-color and darkens when cooking The French also fabricated tar, but they were skimping the quality to make more money. So the north tars were of better quality. Swedish tar maker introduced the fabrication in France. The best tar came from Scandinavian forest. It is clear, fine and a bit red. All the rigging is tarred except royal ropes. The resistance of tarred ropes is not as strong as white (not tarred) ropes. The only ropes not tarred are the tiller rope (to keep all his strength) and the breeching tackle in the great room for aesthetic reasons. In the 1600 period, ropes were immerged in a hot tar bath and then steamed. In 1700, every strand is tarred before to make the cable. Vegetal tar had many colors (black, brown, brown-red and probably other colors too) according from where and when it came from. So I will probably use some kind of brown below the wales, wales will be black and a softer color higher.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Unfortunately, coppering the hull was not generalize before 1780. It cannot be applied to Le Fleuron. In 1730, a second layer of fir 1 inch thick was applied over the keel up to the first wale was applied for protection against bite worms. Then a layer of black tar (tar plus sulfur) covered this protective planking. How will I represent this? Some thinking required.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Sherline mills

Gaetan Bordeleau replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

-

Druxey, I want to try this way for a better color. I just bought Tamiya tape to try. Up to now, the bad side of the dyes is that it pass through every kind of tape I triied. I had good results with Saman dyes up to now but it is not a real dyes. Dyes seems to have capabilitites to penetrate under ecery kind of tape I used up to now.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Thank you Grant and Michael, I appreciate your good words. For the outside planking in the curved area, curving this thickness is out of question. I used a different approach than the first try where multi layers were used. In this actual build, each curved plank is cut with the same curve as needed in a solid piece of about 1/4''. No bending required and it is easy to be glued when applied. This method is easier to use, it gives more precise results but it needs a lot of wood. Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

New cherry stock, for new projects, must be American cherry some planks were 10’ X2’’ X 15’’. Next, a stick which is put between wood layers when the wood in the dryer, first time I saw this. Planking on the first deck has begun. Planks will be glued later; I stopped to begin outside planking on 1 side. When I began this build, I wanted to use only cherry, to obtain 1 wood color. After some thinking, I prefer more than 1 color because I do not like the one tone effect. Some dyes will be use and coppering will be the next stage. Although coppering is a big work, the look and the color surely make it worth to do it.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Microlux Tilt Arbor Saw Problems

Gaetan Bordeleau replied to capnharv2's topic in Modeling tools and Workshop Equipment

Similar problem happens with the arbor of bench grinder, different diameter of wheels and arbor. To fix it, they sell plastic adaptor as the blue and red on the picture. -

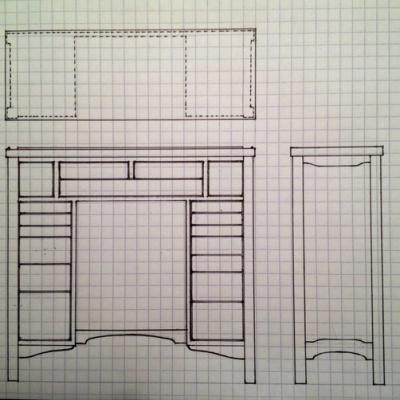

Harbor Freight Workbench

Gaetan Bordeleau replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

This workbench is suppose to be used when assembling furniture. For model ship construction I would prefer something like a Watchmaker's Bench where a lot of storage for small parts is available. Here is as an example a small project to make one. http://www.custommade.com/custom/watchmakers-bench/37076/ -

Thi is the first time I see somebody building a modelship with bones, very inpressive. Gaetan

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

The fastest procedure is to use the end mill as a drill bit and make a hole, advance half the distance of a hole, sink the end mill and so on. At the end, you can run from one end to the other without fear to break the end mill. This procedure is fastest than to make many successives pass each one deeper than the other.

-

Congratulation Karl It will be a nice presentation to see the model in 3 parts with the main advantage to be able to see inside, very clever idea. Gaetan

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Space and cost Space 1/48 is the largest scale for easy manipulation of the model and it is not surprising why it was the mostly used 1/36 although I did not try it, it could be very interesting 1/24 for a 74 guns you need a circle of 8'circumference to easily move the model 360 degres 1/12 for a frigate of about 30 canons was 9' long I built the same 74 at 3 different scales and after this, there is 1 major observation: the bigger the scale, the easier it is to hold a piece the easier to hold the piece, the better are the results This means that if I built the same ship at 2 different scale, the best results will be on the bigger scale used. Cost wood: cherry at a low price and use of exotic woods, over $1000 for a 74 tools: bigger the scale, bigger the tools: table saw, band saw Finally, you need to ask yourself one other question? where are you going to put it when completed?

-

Gun Stock Checkering Tool - moved by admin

Gaetan Bordeleau replied to anima's topic in Modeling tools and Workshop Equipment

I saw a gunsmith using this tool. It is more a scriber than a chisel. You scribe a straight line and then you can scribe 2 or 3 lines at the same time while bearing the cutter in the first line which become s a guide line and so on. Dockyard micro carving tool would be a better choice. Works faster and would have more utilities. -

Thank you Juergen Mark you could be right. The shoemaker said that he was never using the dye alone. He was always putting a protective coating in a wax form. But nevertheless, dye and ink looks like grey in comparison. In fact, the error is to put ebony side to side with something else. Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

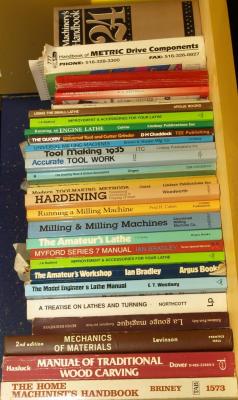

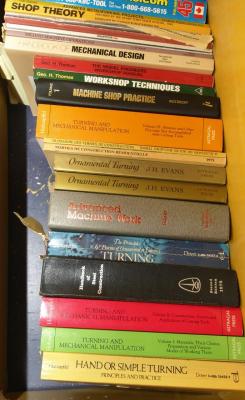

First picture is a participation to encourage people to have a hobby. Few days ago I read a report concerning pictures on Internet. Here is a summary of my understanding. If I put new pictures on line today, these pictures become the property of the public domain. If I add a pseudonym on the picture side, it means nothing concerning intellectual property. Other statements like copyright expressing my will to appear as the author of the work of the mind should accompany the picture. I saw Fiebing leather dye at the shoemaker store. Here is a comparison between ebony, leather dye and chinese ink. For the ink and dye, 1 layer to the left and 2 layers to the right. On this picture ebony look like charcoal. For what I see, black is black. I began to do joinery for the first deck planking.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi Garward When you write world cup, and European superiority in a class C, are you taking about world championship organized by Naviga? 1- Could you explain some of their policies, by example, they call this world championship but only European countries participate. 2- Models should be built exactly as on the plans even if plans contain errors. About the last sentence, here is what I think. I do not know how long Naviga has existed but let’s say they have been there for 25 years and that they have never changed rules. This rule would have been true at the beginning because nobody was able to contradict plans because knowledge was not widely spread yet. Today, it is no longer applicable for 2 reasons: books and Internet and forum such as MSW widely spread access of knowledge.

- 216 replies

-

To change the last habit, 6 months in the hold of the Fleuron, the work moved outside to continue the planking on both sides. First picture shows 1 side on wood and the other side with Tung oil. There are 2 deepness levels as in the both colors of the second picture. The third picture shows planking where 2 kinds of woods were used: pear and cherry wood. The grain pattern for the cherry is more presents and seems more accurate than pear which has much less grain pattern. I wanted to do try a comparison between these 2 woods and seeing this picture I prefer the use of cherry which is probably, just a matter of choice. The last picture combines 2 views of the bow, the one to the right with few more details. To make sure the side walls won’t move, I preferred to redo now the basic bow wood framing.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.