hdrinker

NRG Member-

Posts

232 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hdrinker

-

Currant plan is to use a darker color for the outer planks, which were apparently of oak for better wear beneath the cannons, and to only plank one side.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

The sheeves for the stationary blocks are made from Ebony.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

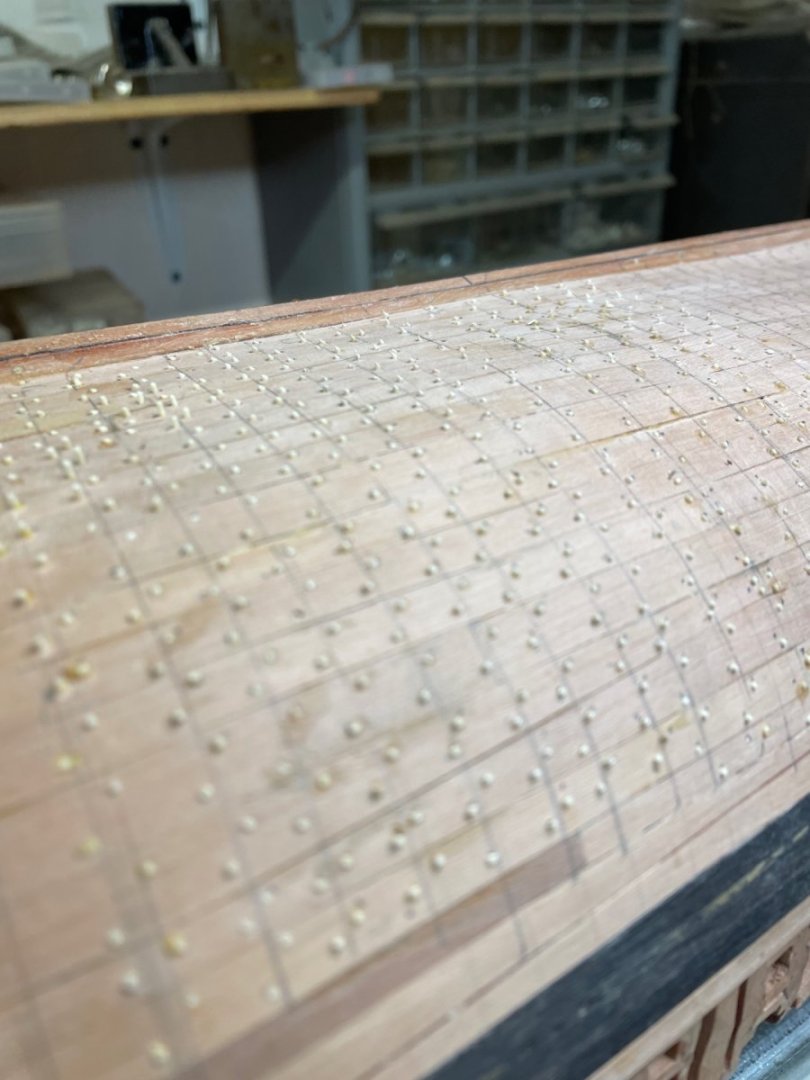

Outer hull complete. I found in the end that bamboo clear stock, not skewers, ordered online proved the best source for me for making tree nail dowels and was able to get them down to .020”, starting with very narrow strips cut on my Byrnes saw. Darker tree nails were made from Mansonia stock provided by Dave at the Lumberyard and drawn down to .030 from think strips.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Hi all, In my defense, I only put the stock into the draw plate from the countersunk side to get it in there. The taper directs the stock into the hole much more easily. I then bring the dowel all the way through to get it in position for the cutting step which, I’m well aware, is in the other direction. Also, by applying a slight angle to the plate, the cutting edge can be made to engage the stock more aggressively, removing a bit more stock. In that video, he stops at .036” which is a lot easier than going to .020”. Anyway, I’ve ordered some bamboo (not swizzle sticks) in hopes of getting stock without nodes, and will report on the results.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Are you using swizzle sticks, or some other source of bamboo?

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

The process of making the tree nail dowels has proven a challenge, for sure. I agree with Kevin that the Byrnes draw plate is exceptional for its accuracy and sharpness. However, any blade will dull with use over time, and this I have found to be true even with this excellent tool. After awhile the stock starts to compress rather than cut when drawn through successively smaller holes. More force becomes necessary and stress accumulates in the dowel, causing breakage and wastage. The solution for me has been (thanks Kevin) the sanding of the flat cutting surface with 100 gr. paper. This restores the sharp edge of the holes. Also, I started cutting the dowel stock narrow enough to just pass through the .059” (largest hole) in the plate. By the time I reached my goal of .031”, the length of the resulting dowel was drastically reduced, leading to more hours of rather tedious work to have enough material for application. By reducing the stock size on the table saw to .042” to start with, I found the process greatly accelerated with much less breakage and about 3 times the resulting amount of usable dowel by the time .031” was achieved.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Sign me up! Can’t quite face the other side for awhile. Planning on completing the starboard planking topsides for a diversion and then maybe the deck.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Nailing below starboard wale complete. Roughly 2K nails! Anyone know of a shrink who specializes in tree nail overload?

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

I’m using Holly for the tree nails. Of all the stock I have, this seems to work best. Found bamboo difficult because of the nodes. Swiss Pear to brittle. Can’t get Juniper. Got the Holly down to 0.027” on average. Settled for that size. HD

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

So far, so good with the light circuit. Starting the tree nails. Planking complete on both sides and preliminary sanding.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Note also the wires for lighting the lower deck laid in a trough cut into the deadwood and tunneled through the keel. Not sure yet what I’ll do with them from here, but will probably run them along the keel and rout them through the aft pedestal and through the mounting board and then out through the base of the case to a switch. Hopefully when completed there will still be an intact circuit.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Progress on port side interrupted by a frame faring error not appreciated when applying #11. No good options other than replacing that plank. This was a challenge! But with the help of Isopropyl alchocol, a Dremel router bit and small chisels, the plank came out. After cleaning the site with care not to damage adjacent planks, the replacement plank solved the original problem.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

What brand and jaw config would you recommend? I did. The one you recommended. Just following up on Druxy’s advice. In the meantime, I am trying to get Dave at the Lumberyard to tell me if my recent wood orders were quarter sawn and whether he has Juniper. Henry

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

What brand and jaw config would you recommend?

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

I hate it when the build falls off your lap onto the concrete floor.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.