hdrinker

NRG Member-

Posts

232 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hdrinker

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

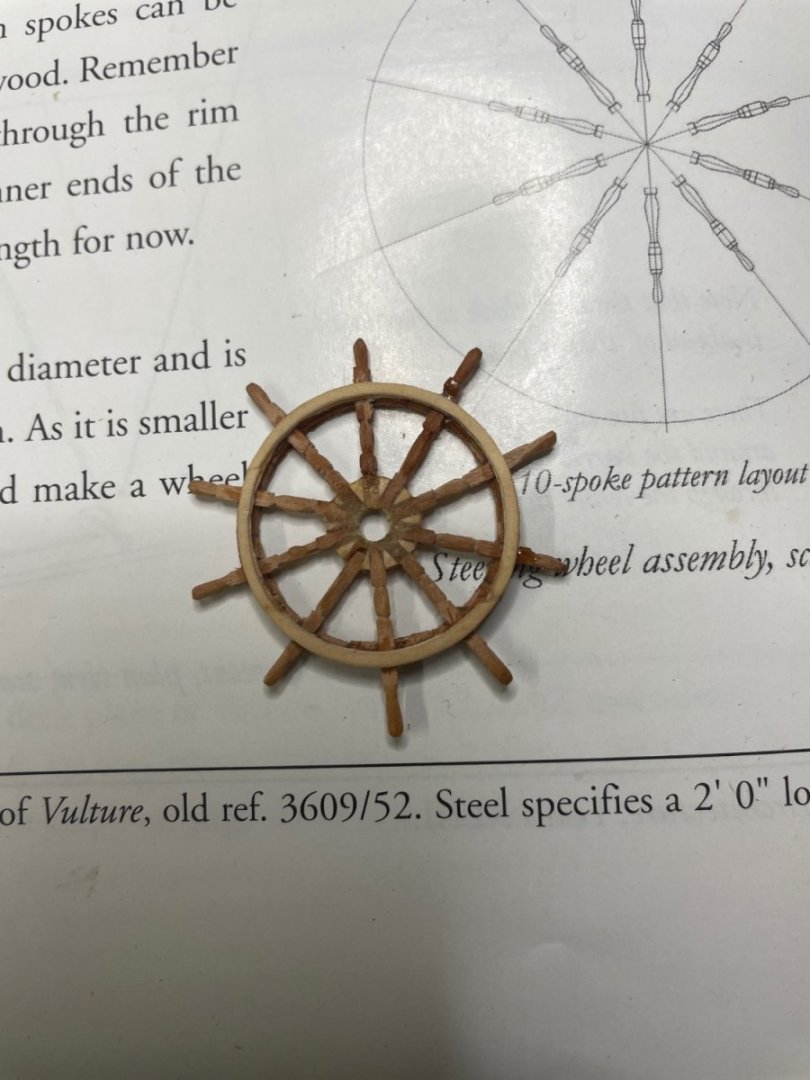

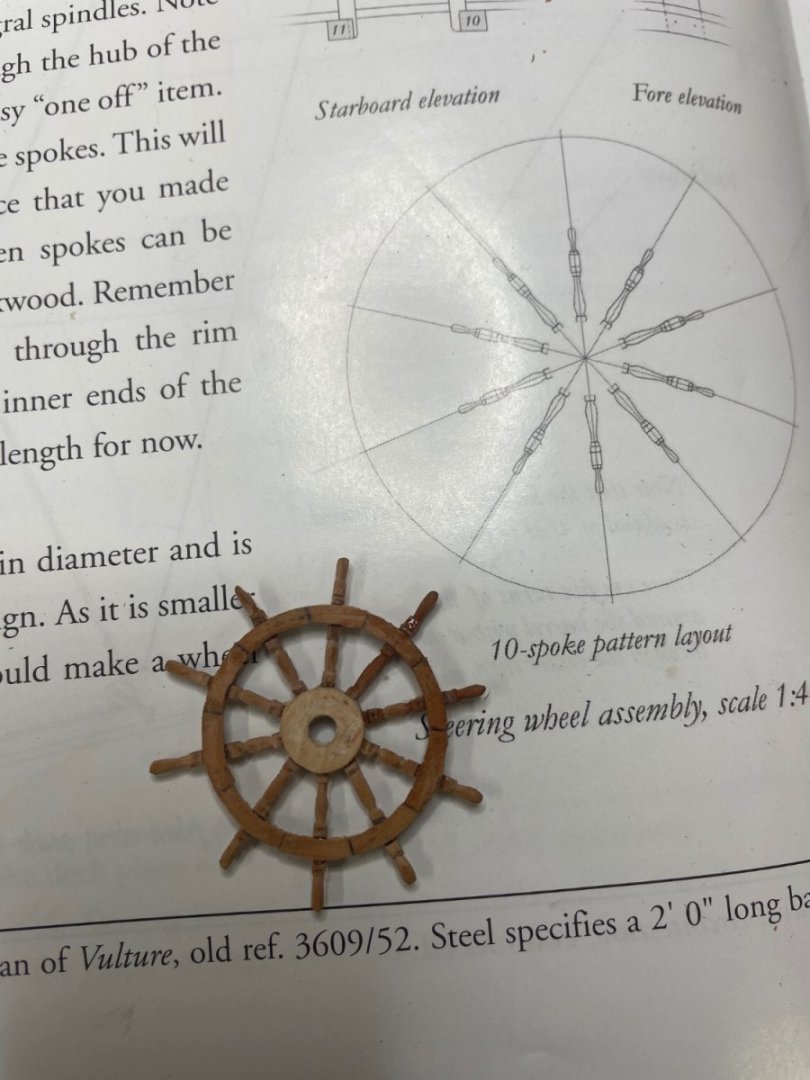

Progress on the quarterdeck. Starting the wheel, using Greg’s method, which so far has worked really well. I found that making the spokes by hand is easier for me than using the lathe.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Where does one order coffee wood in sufficient bulk to accommodate a figurehead carving? Qq

- 1,127 replies

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

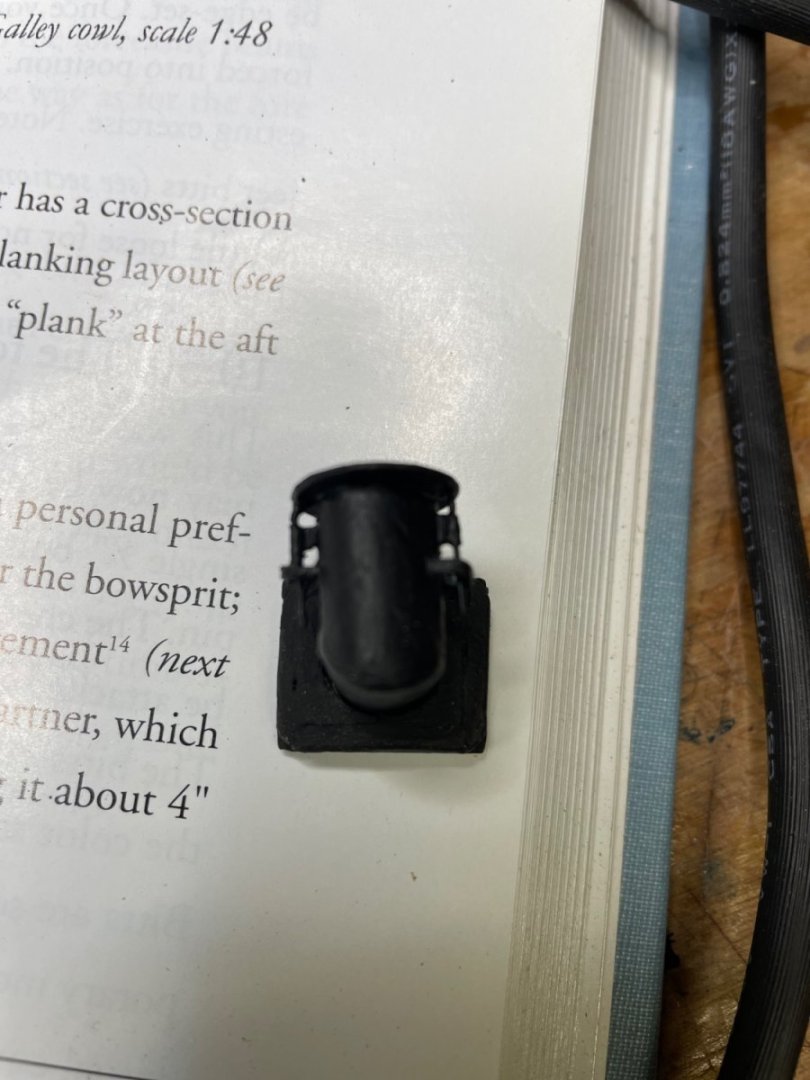

I put the cowl away somewhere so I wouldn’t lose it, and of course, I couldn’t find it…..so, made a second one. They’re soldered brass made over a dowel template which I left within.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

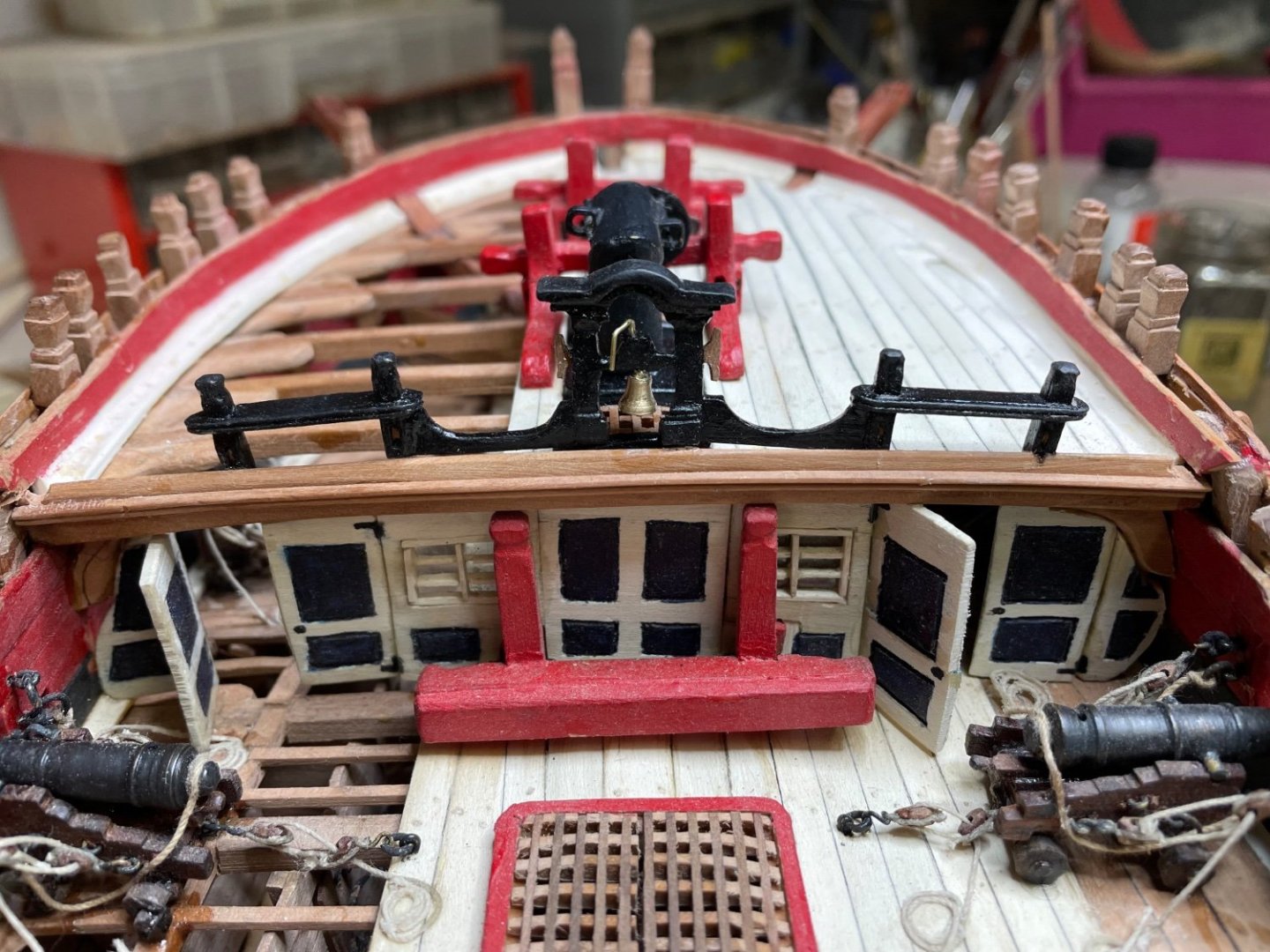

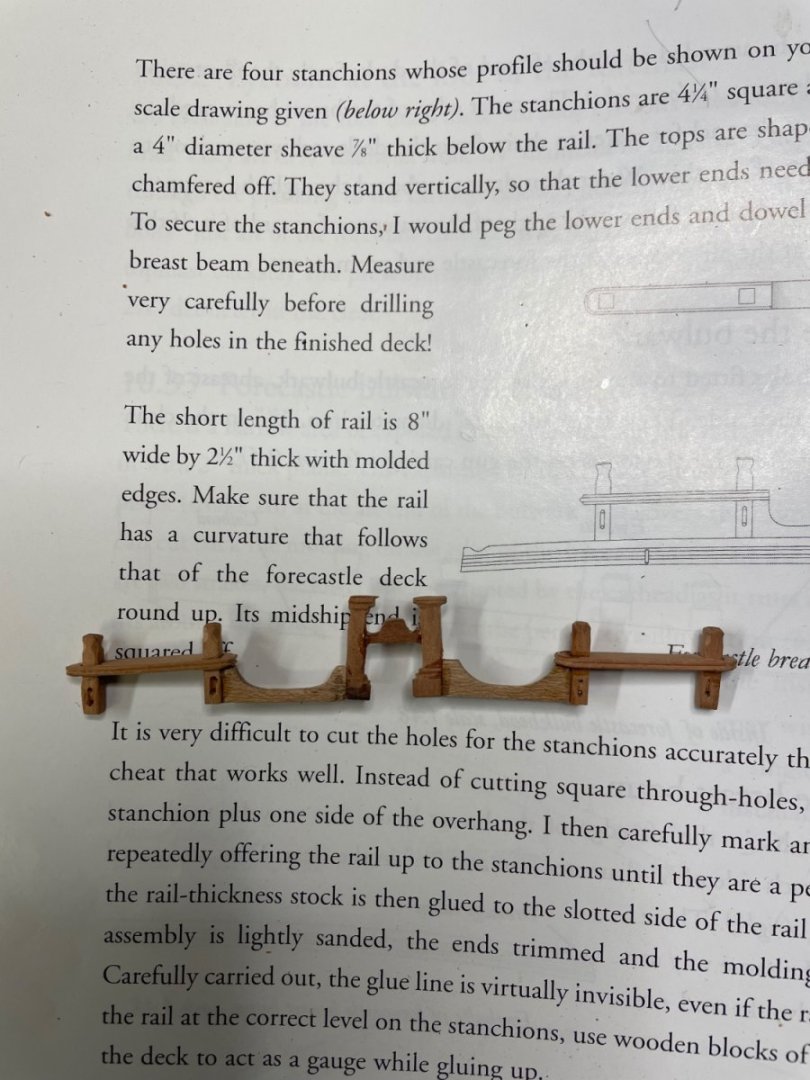

Aft bulkheads added. I found these a challenge. The construction varied a little from the book. I found it worked OK to use holly of the prescribed thickness and make the beveled panels with a #11 blade cut in at an angle. Getting the right fit to the inner sides was done first for the fore and aft bulkheads using heavy cardboard. These were then incorporated into a cardboard blank which provided an exact pattern of the whole bulkhead. The section and panel lines could then be drawn on this template. I used the band saw to cut the sections so the kerf of the saw blade had to be considered, as subsequent assembly of the various sections together would otherwise result in a shortened bulkhead. So a new pattern was made in cardboard redrawn to a greater length with the kerf lines added. The pattern was then transferred to a wooden blank with all the lines drawn and the sections and doors cut out. The result was a pair of bulkheads very close to the necessary width with the lines for the panels straight all across. The final challenge involved the fore and aft bulkhead between the transverse bulkheads. This joins the transverse bulkheads at the inner frames of the starboard doors and is meant to be parallel to the center line of the model. To accomplish this, the starboard doors of the transverse bulkheads need to line up with each other accordingly. This required that the door positions of those bulkheads be drawn in the right location initially. That location, moreover, needs to be close enough to the center line to accommodate the ring bolt of the gun tackle between those two bulkheads. I admit to not being aware of this last detail when I drew the original lines for the doors and panels. As a result, my fore and aft bulkhead does not lie parallel to the center line. Not a big deal since it won’t be seen anyway. But for the perfectionist these considerations might avoid redoing the bulkheads after the matter is discovered. It will be noted in the second image that the gun port lid tackle has been added only for the port gun lids. My plan is to tackle the focs’l next before completing the deck beam construction.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Have started the gun carriage tackle. Not including the hardware on the carriages themselves, there are a total 96 blocks, 96 eye hooks and 80 ring bolts. All to be blackened and lacquered. A daunting task of which making the metallic components alone occupied the day today and will do so for another several days for blackening, etc. Haven’t begun the blocks.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Taking encouragement from Kevin Kenny, I embarked on the scrolls with some satisfaction in the results.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Kevin, my wife, who is an artist, and I watched your frieze video and were blown away. You’ve inspired me once again to tackle a part of this build I thought was way beyond my skill level. Henry

- 1,127 replies

-

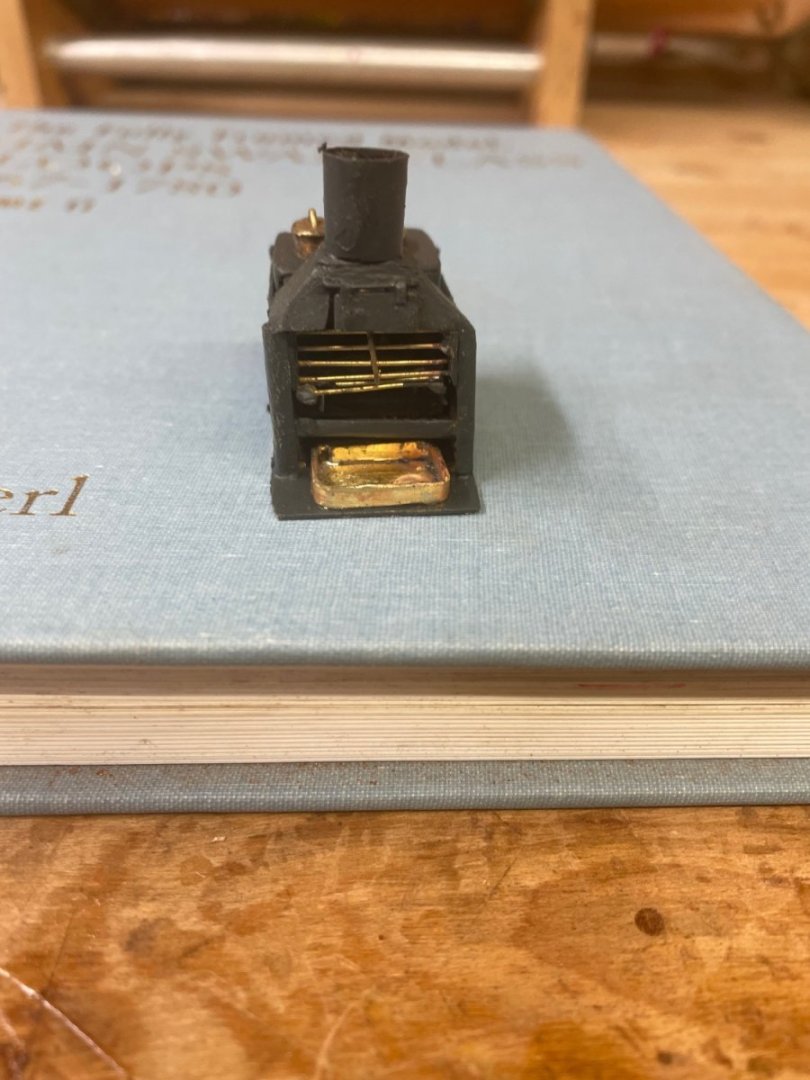

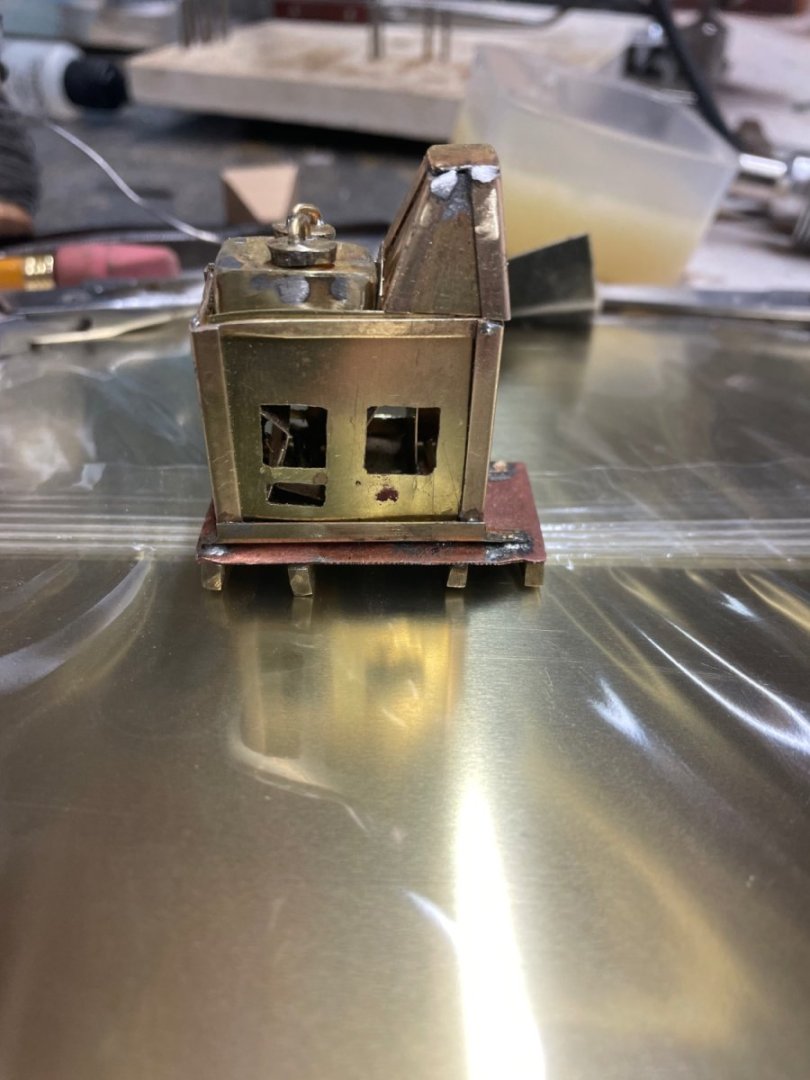

Second iteration of the stove, the first not fitting between decks well. Ready to begin blackening the cannons.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

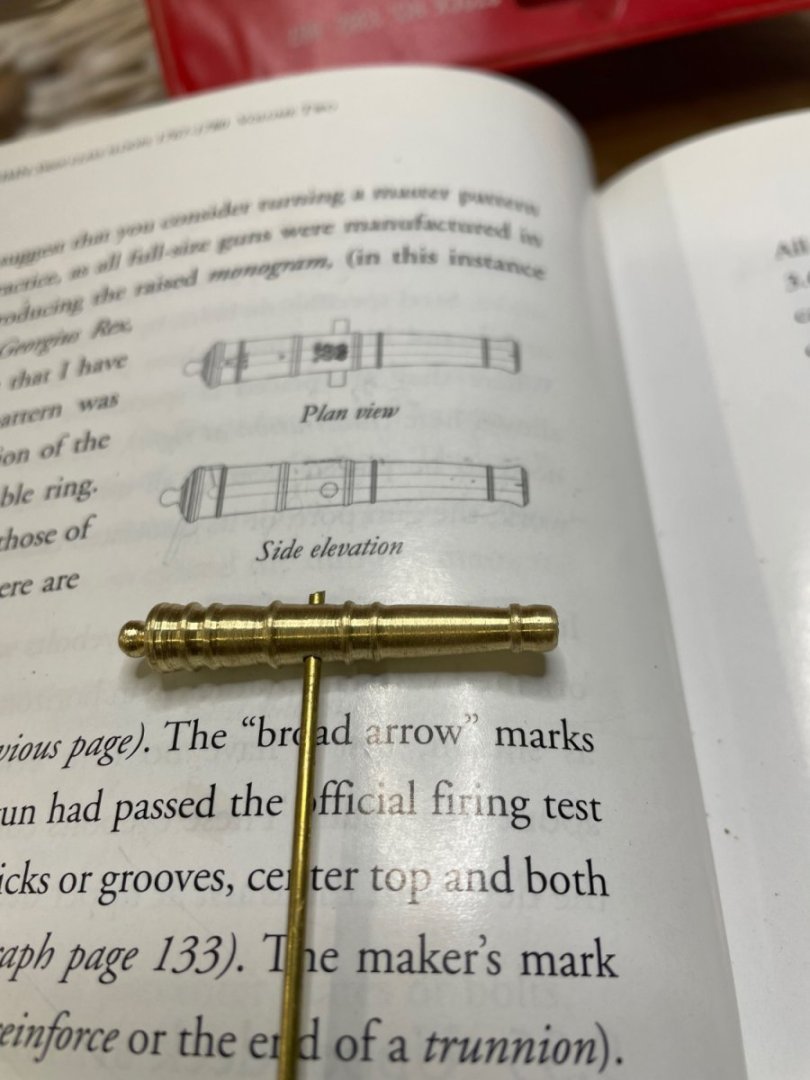

Cannon barrels turned on my MicroMark mini lathe using a follower set up. They’re not as exactly identical as those made from a casting but once blackened it’s difficult to tell.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Beginning work on the stern lights while I await delivery of narrower brass rod for turning cannon barrels.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

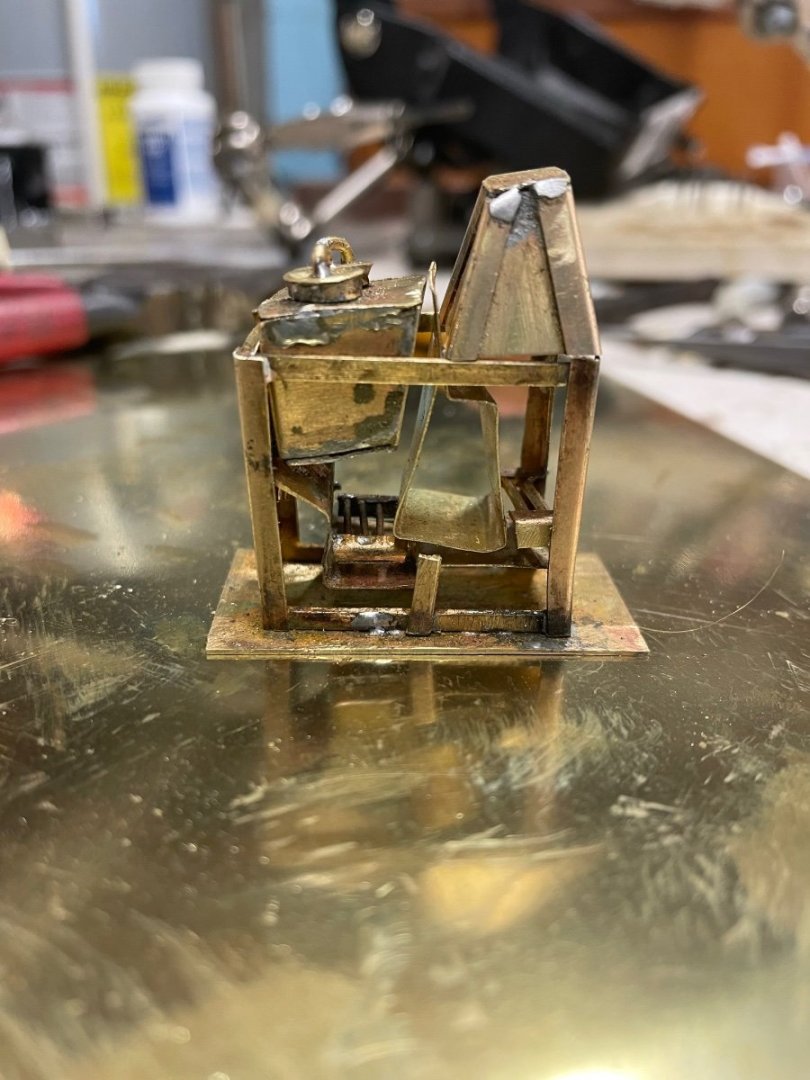

Thanks Kevin. As it turned out, I used a blackening solution which after several applications undid much of the fine detailed soldering. So several steps back, I persist. But I no longer shake in fear at the soldering process. I’m using resistance soldering almost exclusively and find that with a sharpened tip, the heat can be applied to a very small area without threatening adjacent joints. When there’s an issue, yellow ochre paste applied to the joint at risk works well .

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Progress, although not of the standard set by Captain Giampierocicci!

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

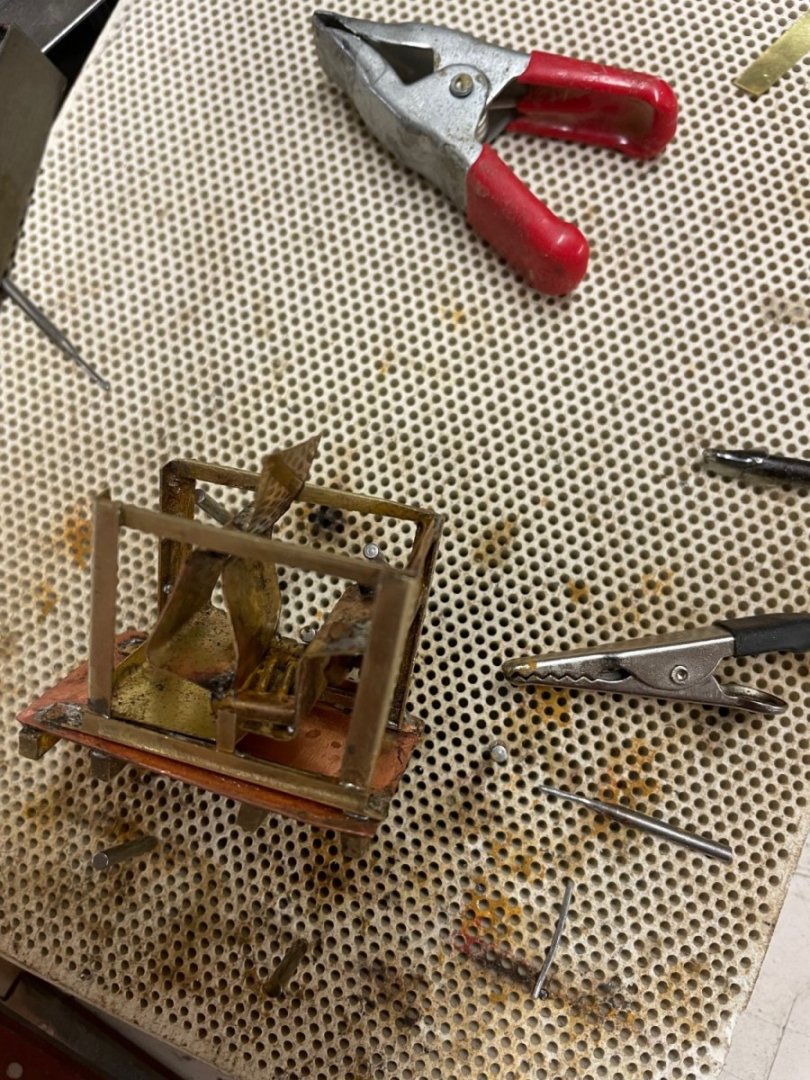

First real attempt. Very challenging! Inside grates didn’t line up correctly and things a bit askew, so am starting again.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.