-

Posts

94 -

Joined

-

Last visited

About Tossedman

- Birthday 07/11/1960

Profile Information

-

Gender

Male

-

Location

Calgary, Canada

-

Interests

Historical Nautical Fiction, model building of any kind, RC crawlers, cars and gliders, stick and tissue airplanes, Japanese N scale trains, photography, travel, mountain biking and so on...

Recent Profile Visitors

-

Tossedman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Tossedman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Tossedman reacted to a post in a topic:

Carving from Belgorod

Tossedman reacted to a post in a topic:

Carving from Belgorod

-

Tossedman reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

Tossedman reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Tossedman reacted to a post in a topic:

Ramble Intro

Tossedman reacted to a post in a topic:

Ramble Intro

-

Tossedman reacted to a post in a topic:

Portland Scale Ship Co. news and updates

Tossedman reacted to a post in a topic:

Portland Scale Ship Co. news and updates

-

Tossedman reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

Tossedman reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Tossedman reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

Tossedman reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Tossedman started following Tally Ho by AntonyUK , New sponsor: Hobbymill.EU / precision milled exotic woods , Modelers Sawmill Permanent Closure and 7 others

-

Joe V reacted to a post in a topic:

Modelers Sawmill Permanent Closure

Joe V reacted to a post in a topic:

Modelers Sawmill Permanent Closure

-

thibaultron reacted to a post in a topic:

Modelers Sawmill Permanent Closure

thibaultron reacted to a post in a topic:

Modelers Sawmill Permanent Closure

-

Keith Black reacted to a post in a topic:

Cutters, Choppers, Guillotines, Slicers

Keith Black reacted to a post in a topic:

Cutters, Choppers, Guillotines, Slicers

-

MintGum reacted to a post in a topic:

Cutters, Choppers, Guillotines, Slicers

MintGum reacted to a post in a topic:

Cutters, Choppers, Guillotines, Slicers

-

Cutters, Choppers, Guillotines, Slicers

Tossedman replied to MintGum's topic in Modeling tools and Workshop Equipment

I completely agree with all that tmp said. You cannot go wrong with the Ultimation sander and slicer if your budget can handle it. The blade is flat on one side and give square cuts only on the left side of the blade. It's marked on the cutter. The cutting blade is a single bevel blade that is used for carpet trimming. Love both the sander and the slicer. Gave away my NWSL chopper when I got the Ultimation tools and haven't looked back. Cheers, Todd -

Canute reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

Canute reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

thibaultron reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

thibaultron reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Chuck reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

Chuck reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Jack12477 reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

Jack12477 reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

thibaultron reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

thibaultron reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

Canute reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

Canute reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

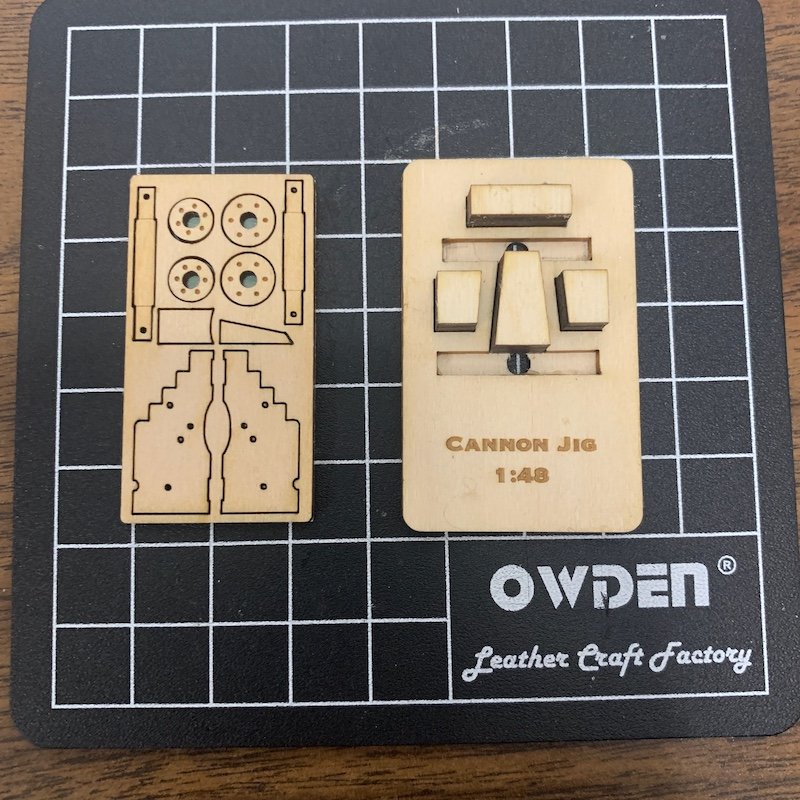

I had a Trotec Speedy 300 at work but have recently retired. Our local maker space has the same machine so I need to check them out. I've used Adobe Illustrator to great success over the past 10 years or so. The only thing I've used it for so far for model ships was for carronade carriages. Works a treat. Cheers, Todd

-

Yet Another Pandora 3D build

Tossedman replied to herask's topic in CAD and 3D Modelling/Drafting Plans with Software

That's really cool! Must have been some free beer up at the pub so the shipwrights have all left. Cheers, Todd- 119 replies

-

Yet Another Pandora 3D build

Tossedman replied to herask's topic in CAD and 3D Modelling/Drafting Plans with Software

Indeed!- 119 replies

-

3D Printing Cannons in Resin

Tossedman replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Looks great! I designed and laser cut an N scale engine shed. All of the parts such as window frames and mullions were separate so many more pieces than yours. It was fun to do. Learned a ton doing it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.