-

Posts

7,730 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CDW

-

The first of what will eventually be three clear coats went down today. With tomorrow being Thanksgiving, will give this coat a couple of days to cure before laying down the decals, then two more clear coats following the decals. There are a few more parts to attach but don't want to handle the body until the paint is thoroughly cured.

-

Put on the orange base coat today. Will give this time to cure before the clear coats to come later. This was a custom orange I mixed more than a year ago when I built a Can Am McLaren M8B and wanted a match for the McLaren paint. I had plenty of it bottled up and thought it looked good for the Orange Crate. Nothing I had on hand looked the right shade of orange straight from the bottle. Can't recall my formula for this mix as primarily, I did it by eye not by specific ratios of colors.

-

Bracket races! I couldn't recall the name of them for nothing. Thanks for jogging my memory! Bracket racing was a blast. So much fun. But consistency was the key. You had to run your best qualifying time consistently. Whoever did that eventually became the "top eliminator" that evening. Rail dragsters ran against completely stock cars.

-

My brother raced NHRA sanctioned matches in the early '60's with his '55 Chevy, competing in a stock class. I don't recall him even wearing a helmet back then. He took top of his class in a number of matches including the state championships. My old boss ran in one of the stock classes in his '62 Biscayne 409. He held some stock records for a period of time with that car. After he wore out that 409, he became a Mopar man and bought a Dodge with a Hemi. It was another stock class demon. The early 60's to mid 70's were golden years for drag racing IMO. I have so many good memories of drag racing on the weekends. Our local track held handicap races, so you could "run what you brung" on Fridays. For those who were never involved in these types of drag races, the following is a basic summary of how it worked: All competitors ran three qualifying races. Your best time of the three became your ceiling. The lights were timed so that each pair of competitors were evenly matched. In other words, if my best quarter mile time was 14.0 seconds, and my competitor's best time was 11.0, my light flashed green 3 seconds before his light turned green. If by some chance you clocked a faster time than your qualifying time in a match, you were automatically disqualified and thus eliminated. These matchups continued until there was a top dog at the end. They were so much fun because everyone could compete even if you were driving the family station wagon.

-

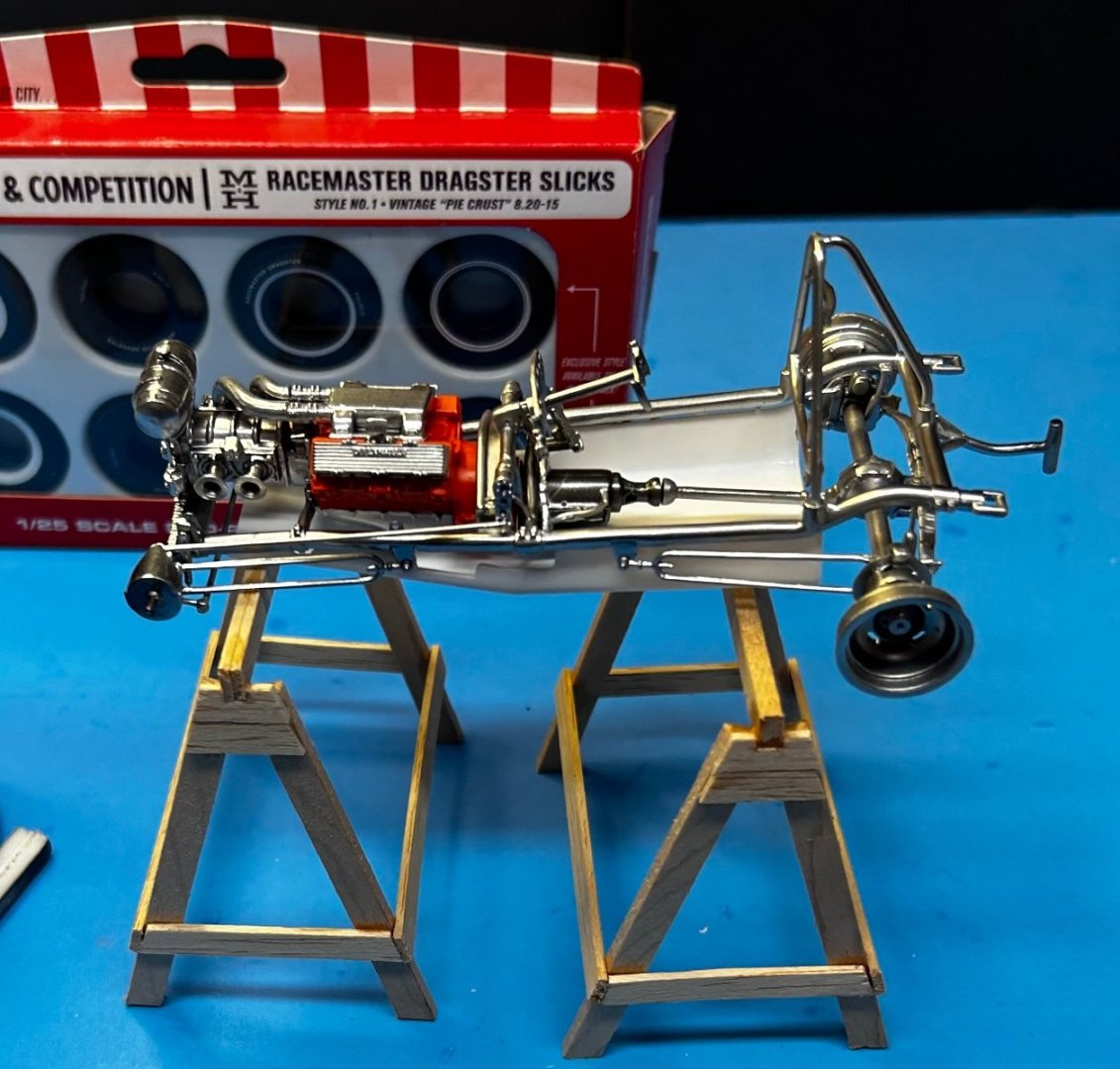

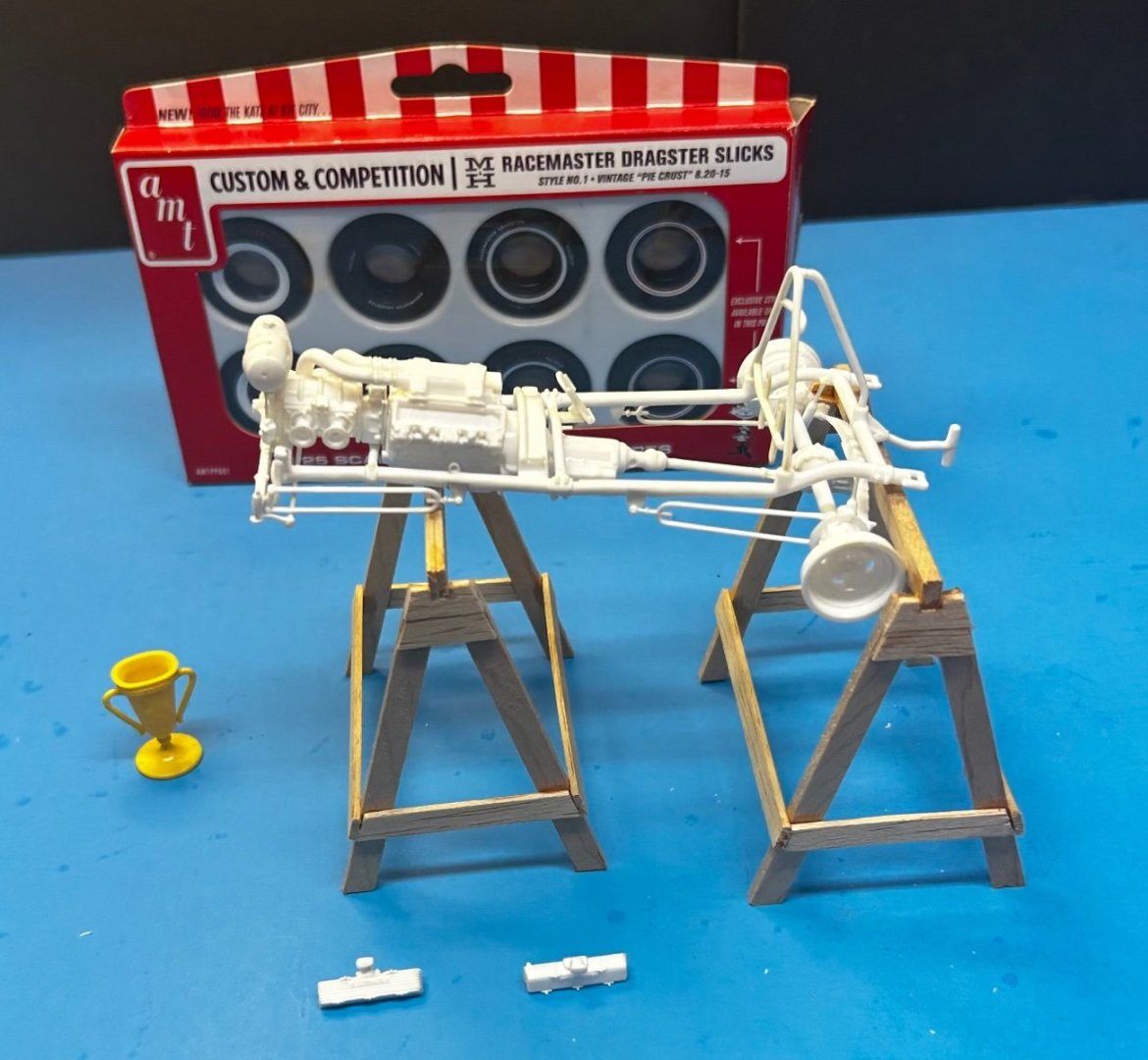

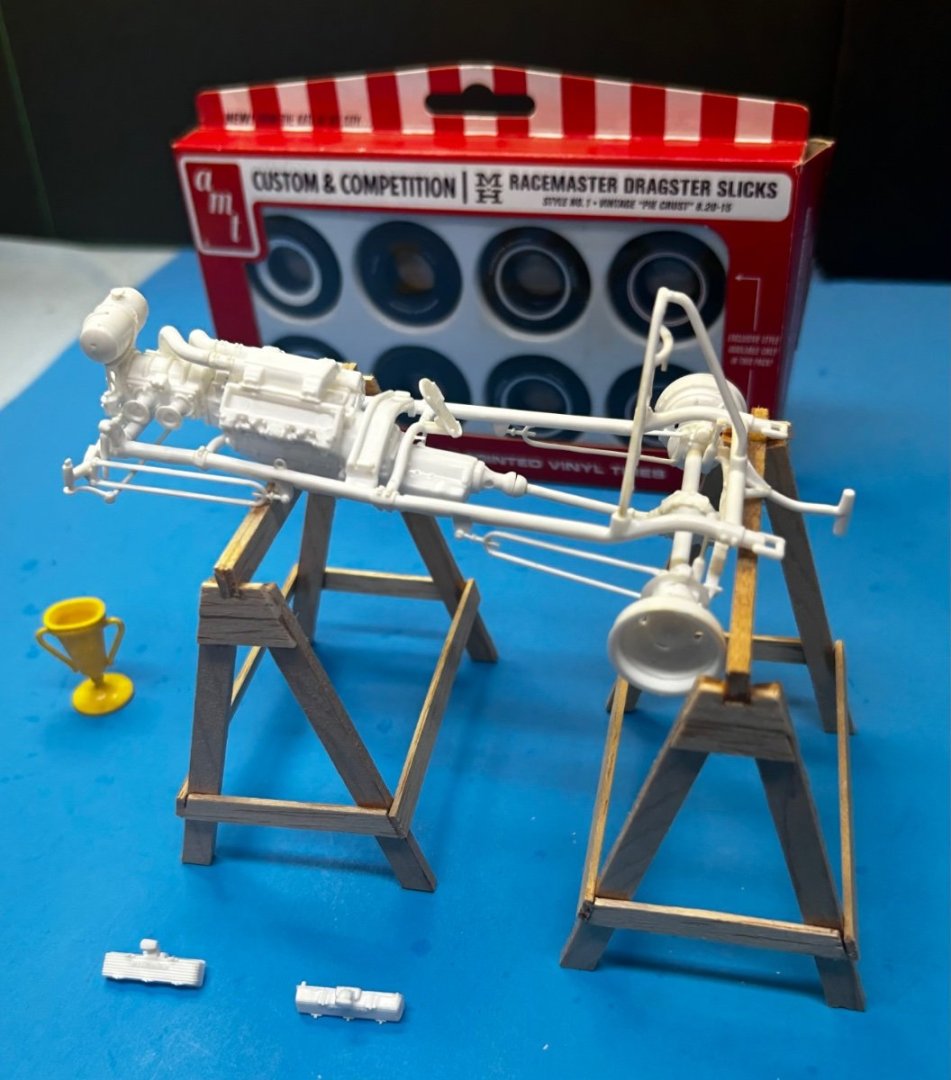

I thought I was going to have a more difficult time getting the exhaust headers to fit, but it was easier than I imagined. There's one little issue that some minor filing and sanding can correct where the belly pan meets the chassis. The exhaust pipe on number one and number five cylinders rub against the pan causing it to pinch a bit. This is why so many dry fits are needed. Sometimes you can't tell where problems lie until you get further along in the build. If you're wondering why, I decided to go ahead and use the custom raised white letter slicks after all. I had already enlarged the inside of a tire to make the wheel fit the tire, so it didn't make sense to not do the same to the other slick and use the pair. Otherwise, they would have gone to waste. I'll just throw the stock pair of slicks in a large box I have that is slap full of tires from many, many model car kits I've built or scrapped over the years. The toothpick is used to prop up the body as this is the way the model will be displayed when it's finished. This was all that frame and engine assemblies can easily be seen. The finished model has a folding prop mechanism that holds the body in a raised position and folds down if you want to display it closed. Same for the radiator shroud and bonnet. She's a hinged folder. The mechanical body props won't go on until the model is painted and finished. They are fairly delicate and would easily break if mishandled.

-

Loarre Castle (Spain) by King Derelict - Aedes Ars 1/200

CDW replied to king derelict's topic in Non-ship/categorised builds

Beautiful, Alan. How much do you estimate this castle will weigh once it's all finished? What are the finished dimensions of it? -

Yes, indeed it does. It takes a lot of experimentation, trial and error to figure out the ins and outs of all this stuff. So many products, so little time. There is a guy on YouTube who goes through great pains to test and video things like this. Unfortunately, his videos are so long and tedious, I often quit watching before it's all said and done. I wish he would learn to be more concise and to the point.

-

Thanks Gary, but I still have a lot to learn about it. I should have used a clear coat before the Alclad. The gloss black was not sufficiently slick for the best possible Alclad chrome finish. I think this looks much better than kit chrome tree parts, but it can be done better than I've done here. I also must say that it's imperative to use very light coats of the Alclad chrome. It's one of those products where "less is more". I have been reading some rave reviews of the Green Stuff World airbrush chrome paint. It's an acrylic and looks very convincing when done properly. Alclad is not a forgiving paint, that's for sure. With practice, trial and error, great results can be had but I'm still working on it.

-

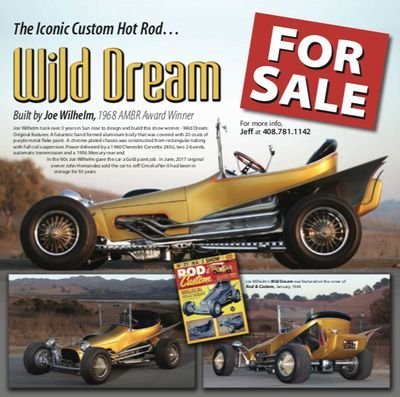

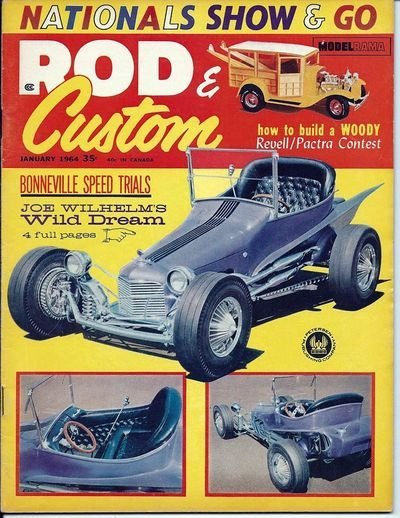

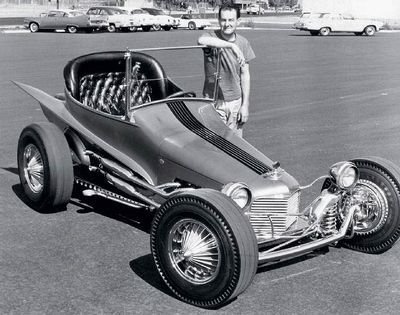

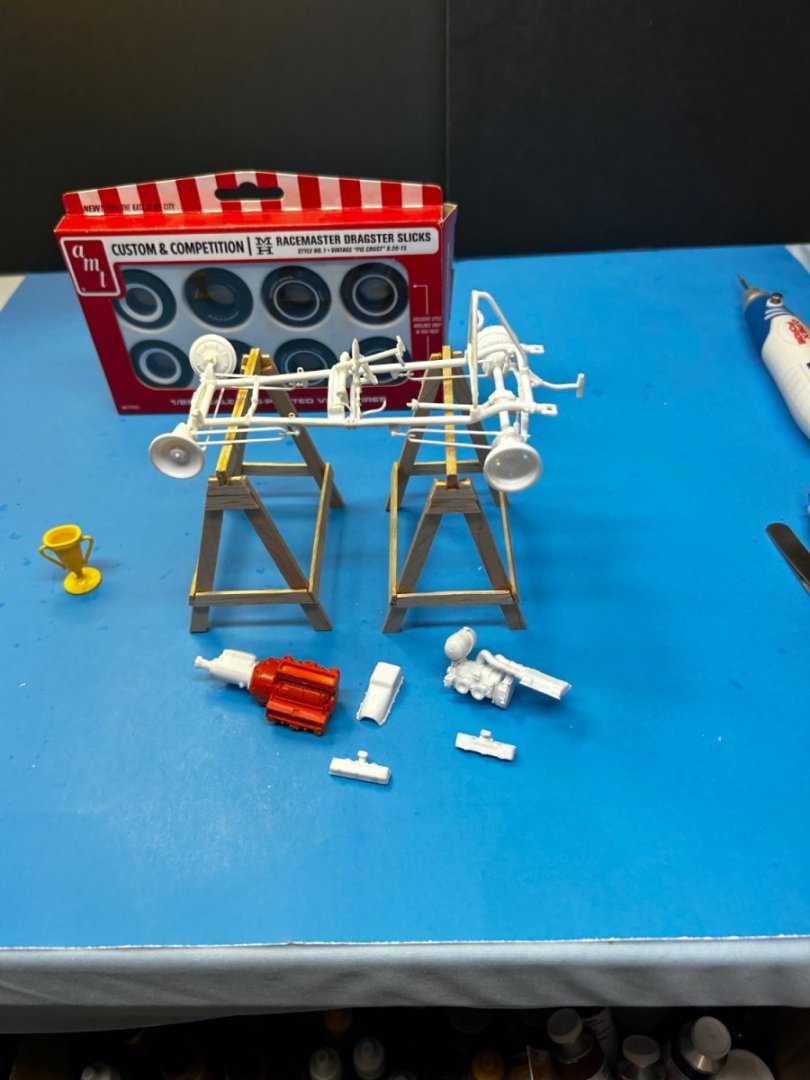

Joe Wilhelm's Wild Dream custom show rod from the mid-sixties era is my next project. This old MPC kit has been in my possession for decades and the kit box shows the wear. The good news is, the kit plastic is all there, only the tires are missing. I probably took them out and tossed them in the bin somewhere along the way. Over time, old model kit tires are notorious for 'melting down'. The first time I saw this kit was in the mid-sixties when it was released by AMT as a double-kit. The kit contained the Wild Dream and another well-known show rod from that period named Tognotti's T. Shortly after, MPC reboxed the Wild Dream and gave it the title, Wilhelm's Wonder. Same kit, same plastic, only in a different box. Here is a short description of the car I found on the net: "Wild Dream is a show rod designed and built by Joe Wilhelm at Wilhelm's Custom Shop for John Hernandez. Built over a three year period, the wild rod featured a futuristic hand formed aluminum body that was covered with 20 coats of purple metalflake paint. A chrome plated chassis was constructed from rectangular tubing. The chassis featured full coil suspension. Power was delivered by a fuel injected 1960 Chevrolet Corvette 283 cu. in. engine, a 1961 Chevrolet four speed transmission and a 1956 Mercury rear end." My build is on deck, waiting for the finish of my current Orange Crate project before starting this one. This will give me time to search down the "grape metallic" lacquer paint I want to start and finish this project.

-

I wish I could make bad models look so good as you do Chris. My one and only card model experience was with what I feel was a poor design, but it's probably more the fault of the modeler in my case than it was the kit. I dropped mine into the bin and counted it up as a learning experience. Looks to me like you're going to wind up with a fine-looking model on your shelf due to your skills to make a silk purse of a sow's ear.

-

Great looking airplane and a fine model Andy. I used to play a MMO aerial combat game and this was a favorite plane for me to play. A dive bomber but also a very stable gun platform. It was slow but maneuverable. Could take a lot of punishment but give it out as well. Not sure how closely its game performance matched reality but it was fun to play. You could drop the flaps and easily turn inside the faster fighter planes. Excellent low speed handling. With that big wing area, it’s no wonder it was so stable in flight.

-

Dry fit (again, for motivation). The chassis fits right down on top of a belly pan. The pan will be orange eventually. I love those Offenhauser valve covers. WhennI was a teen, I bought an Offenhauser triple single barrel carb intake manifold for my ‘51 Chevy, and the matching Offy valve cover, too. I thought I was the cat’s pajamas with that setup back then. My dad throttled me back more than once. I guess a lot of us my age went through that stage back then.

-

Here is the full article I found about the Orange Crate in internet archives: The Ultimate Dual-Purpose Hot Rod The Story of the Orange Crate By Calvin Mauldin Photography: The Rod & Custom Archives As any rodder knows, a '32 Ford of any body style never gets thrown away. Short of being run over by a freight train, a Deuce will just keep coming back in one configuration or another. Owners may change, engines may be swapped, but once this ever-popular Ford model has been hot rodded, it stays that way. Such was the case when Portland, Oregon's Bob Tindle bought a solid, albeit modified, '32 sedan in 1959, and over a period of five short years, dazzled the difficult-to-impress car-show faction as well as magazine editors. Bob's '32 came complete with such rodder's touches as a radical chopped top, a gutted interior, and rear fenders that had been bobbed and molded in for that mean and hungry look that could intimidate the competition just by standing still. Bob's younger brother, Terry, remembers what his brother purchased. "Man, that was a long time ago," he says, "but I remember the body was in excellent shape and covered in light-gray primer. It had a real hot flathead bolted in, but the guys Bob bought the car from wanted to keep that engine. Dave Bell had built a heated late-model Olds engine with six carburetors and put it in his '57 Corvette, and that engine would really run. Bob bought the Olds and had it put in the '32. We ran a Cadillac/LaSalle transmission with Second and High gears. I'll never forget sitting at the starting line, ready to go. The whole car shook, and really took off when the flag dropped." Keith Randol kept the '32 tuned to a razor's edge for drag racing so the Tindles made a good showing at the strip, but Bob wanted to get more into the car-show side of the hobby. As Terry tells the story, "The car was painted lemon-yellow. It looked nice when it was entered in the Portland Roadster Show in 1960, and it did well. Then Bob decided to create an all-out show car. Keith Randol had just started up a shop, and Bob took the '32 there for a drastic rebuild. I should mention that Keith was a machinist, and years later went to Indy with a rear-engined racecar owned by Rolla Vollstedt. This was a short time before all the teams made the big move to rear-engine cars. Keith was a real pioneer. I don't know if Bob intended to go all-out with the sedan, but he would dream up an idea and Keith would take that idea a step or two further, making the '32 very innovative and far ahead of what was being built at the time." The reconstructed show 'n' go Tudor turned out to be a quarter-mile, straight-line competition sedan riding on a Sprint Car-style chassis. The chassis itself was almost jewel-like in construction, having been fabbed from 3-inch-diameter, 0.120-inch wall seamless Shelby tubing, bent at curvaceous angles by Randol with a torch and tube bender. Adjustable suspension was added, along with a complete front axle assembly and Halibrand quick-change setup pulled from a 20-year-old Sprint Car that also gave up its Halibrand wheels. Obviously, Randol was honing his skills for future forays on circle tracks, but the blending of the two styles gave Bob's '32 an unquestionable "Wanna race?" attitude. Dick Maris rebuilt the Olds with meticulous attention to detail. Case in point: After hours of porting and polishing the heads, the combustion chambers were slicked up and given a final polish with jeweler's rouge. Enlarged to 417.63 ci, the mill was equipped with Hilborn injectors, using a front-mounted Potvin blower. A B&M Hydro trans capably handled the 600-plus horses that Marris concocted with the trademark wham/bang shifts. The chassis/engine package was treated to a liberal dose of chrome plating and polishing, which made it a shame to cover it up with the body and hood panels. Therefore, Bob gave Randol another engineering puzzle: make the all-steel body tilt for display. Keith, the wizard machinist, went through the body, adding anti-flex support members. It was a strain on the average muscleman to raise the body, but the extra grunts and groans were worth it when the eye-popping engineering was revealed. What the completed showpiece chassis needed was an equally exquisite body, and Von's Body Shop was assigned the task of getting the panels straighter than Henry ever made them. Reproduction fiberglass Ford parts maker Dee Westcott was given the job of building the top insert. When the metal was deemed worthy to paint, Von's covered the panels in Naples Orange (minus the peel), and thusly, the tart, tangy Orange Crate was officially born. The fresh Orange Crate blitzed the '61 Winternationals, handily took the America's Best Competition Car trophy at the '61 Oakland Roadster Show, and graced the Feb. '62 issue of Hot Rod magazine. This was quite an accomplishment for the Orange Crate Gang from Portland, Oregon, considering that at the time, California was considered the leader of the pack when it came to hot rods. For the 1962 show-business encore, the Orange Crate was treated to some additional, point-gathering details (as if it needed any more). It also competed once again at the Winternationals before Bob sent the wild, trophy-winning sedan on a whirlwind tour of car shows throughout the U.S. Afterward, Revell sent an engineer to Bob's high-performance automobile dealership, where the Orange Crate was diligently measured inch-by-inch for a model-car kit that would become a solid seller. In 1963, the hot rod celebrity made what was to be its final showing at the Oakland Roadster Show, once again winning the coveted America's Best Competition Car trophy. Then, the Orange Crate was retired from show business and touring to a space at Bob's hot-car emporium. The details of the story after that become vague. As Terry says, "One possible thing that led to the Orange Crate being retired was the fact that we opened a Chrysler/Plymouth store that year. That took up a lot of extra time." Being a competitive dealer also meant there was less time to keep the Orange Crate in tip-top show condition. Terry continues, "In 1964, I bought my own Chrysler/Plymouth store in McMinville, Oregon, and moved there. I sort of lost track of what Bob was doing with the Orange Crate, and by 1965, he'd sold the '32 to a couple of guys he knew who were in the used-car business. That's really the last time I saw the Orange Crate, though people still ask me about it. That's how famous that car was, and still is." Could the decision to sell have been a response to a gentle nudge from officials at Mopar? After all, here was a famous Oldsmobile-powered Ford sedan on a lot where stock Chryslers and Plymouths were being touted as the latest Michigan giant-killers. No one will ever know. Over the years, the Orange Crate could be seen occasionally, whizzing by on the custom trailer Keith Randol built for it, or on hand at a used-car auction or swap meet, each time its once-dazzling appearance a bit more tarnished. Terry states that Bob looked at the sedan a few times, but never expressed any interest in buying the Orange Crate back for old times' sake. Besides, nostalgia drag racing hadn't been born yet, and few of us were very nostalgic about anything in the early '70s. An old competition sedan was virtually useless. Shortly after, the Orange Crate disappeared. Over the last two and a half decades, rumors have abounded about the whereabouts of the Orange Crate. Paul Duchene, an enterprising writer for the Chicago Tribune, recently found the missing Crate. It's alive, if not too pristine, and living in rural Washington, owned since 1975 by drag racer Ted Gord. Gord knows what he has, as well as what needs to be done to get the old warrior back in show condition. He plans to build a shop for just that purpose and have the venerable sedan ready by the end of this year. Wouldn't it be a stupendous comeback if Gord took the Orange Crate back to the Oakland Roadster Show just one more time? Sadly, Bob Tindle wouldn't be there, as he passed away recently, but we're sure Terry could be coaxed into coming to Oakland. He might even sign a few Revell Orange Crate kits (recently re-released from Revell-Monogram) for old fans that remember the unforgettable '32 from the early '60s or for new fans taking their first look at this resurrected classic.

-

Just in case you were wondering about it, the Orange Crate engine is a tricked-out Oldsmobile built to 418 cubic inches, a front mounted Potvin blower with Hilborn fuel injection. B&M hydro transmission. The engine is said to have produced 600 horsepower. The article that I learned this information from said the engine was from a late model Oldsmobile but did not specify what particular engine or the year model of it. Suffice it to say the time period the article was written was very early 1960's. So, it can be reasonably assumed the engine was anywhere from 1959 to 1962 vintage.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)