-

Posts

7,719 -

Joined

-

Last visited

About CDW

- Birthday 04/16/1954

Profile Information

-

Gender

Male

-

Location

Tampa, Florida

-

Interests

Scale model building of all types; American and world history; science; religious studies; flight; grandchildren; travel; antique car and motorcycle restoration

-

Canute reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

Canute reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

robert952 reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

robert952 reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

Landlubber Mike reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

Landlubber Mike reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

king derelict reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

king derelict reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

Jack12477 reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

Jack12477 reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

Old Collingwood reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

Old Collingwood reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

DocRob reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

DocRob reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

Thanks guys. There is a lot to learn on this subject but most of it will be by trial and error. I have learned about another resin type that may be more shatter resistant. The resin I used will shatter if dropped on a hard floor or is flexed too much. Like I said, trial and error. Don't even think about setting up one of these printers inside your home without a big investment in proper ventilation. It really needs a separate building with ventilation and climate control. -

Baker reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

Baker reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

cotrecerf reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

cotrecerf reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

Canute reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

Canute reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

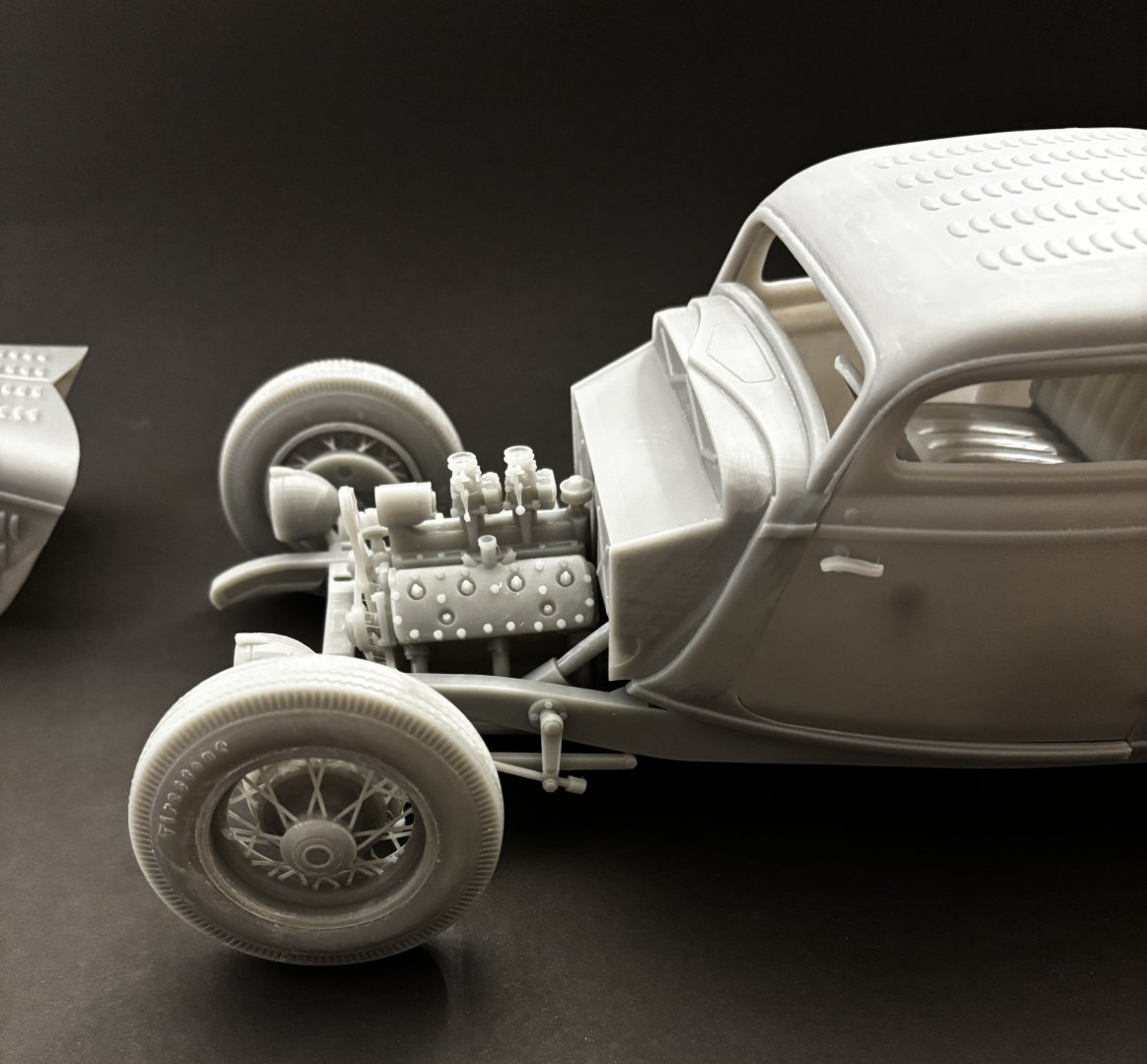

I printed out the model in 1:12 scale, then put it all together with a water soluble acrylic glue to check the parts fit. Needs fine tuning, but that’s to be expected with a 3D print. There was an option for the body to be printed whole or with the doors separate. I think the former would have been a better option in retrospect. -

CDW reacted to a post in a topic:

Phantom of the Opera by MisterMeester - FINISHED - Atlantis - 1/8

CDW reacted to a post in a topic:

Phantom of the Opera by MisterMeester - FINISHED - Atlantis - 1/8

-

CDW reacted to a post in a topic:

Phantom of the Opera by MisterMeester - FINISHED - Atlantis - 1/8

CDW reacted to a post in a topic:

Phantom of the Opera by MisterMeester - FINISHED - Atlantis - 1/8

-

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

-

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

I once used it to inquire about a specific canon law. It went on to tell me what experts believed about that particular law, slanted in a particular direction. When I followed up by asking if there were experts who took a different slant on the same question, it admitted that yes, there were experts who saw it in a different way. So, I agree there must be follow up questions to avoid bias, I'm not sure exactly how or why it deals with bias in the way it appears to do. We do know that humans have had a role in developing the code for it to operate, so it may be inevitable there will be bias or perhaps errors as well. -

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

Correct me if I'm wrong, but mass and size are two entirely different things, are they not? -

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

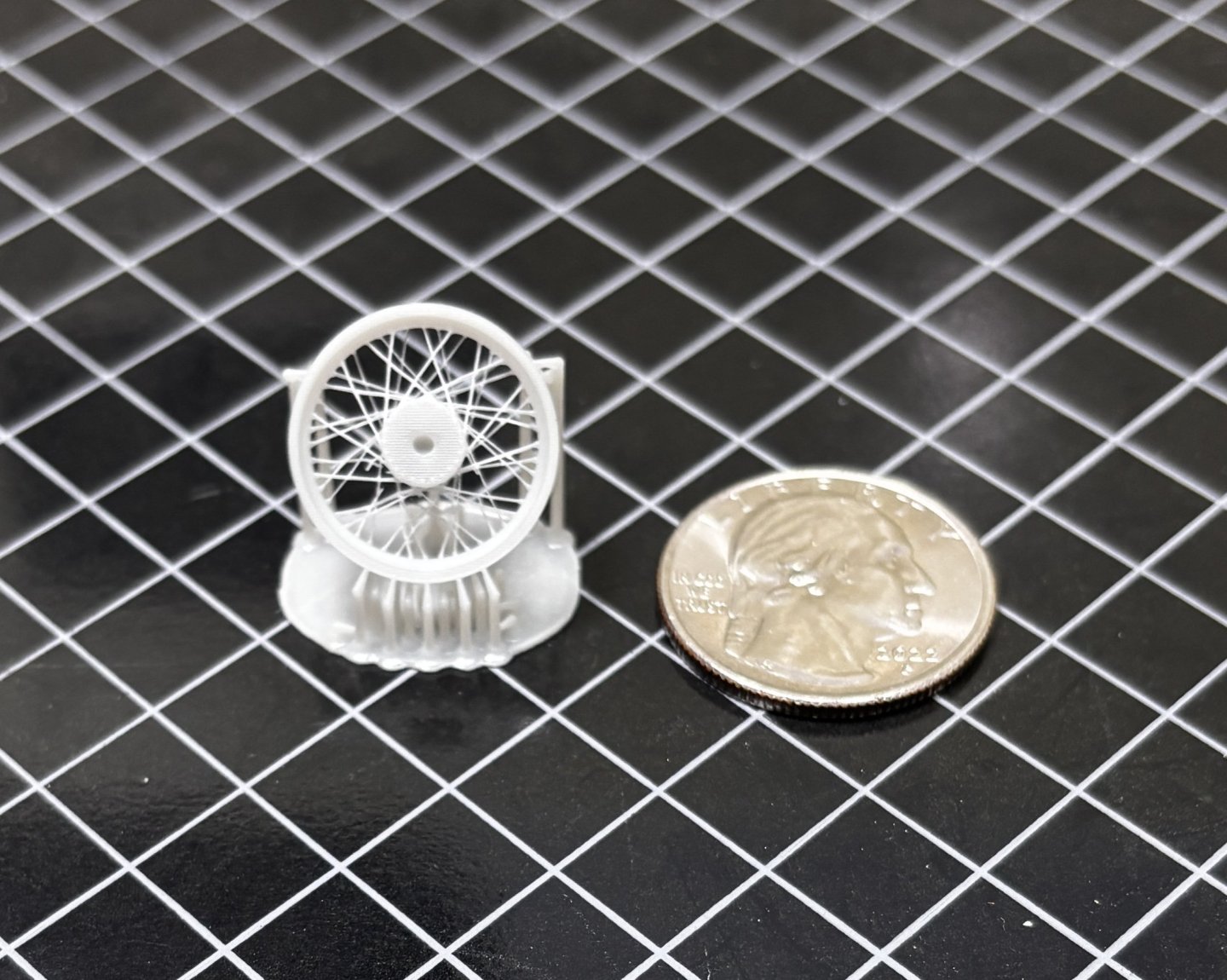

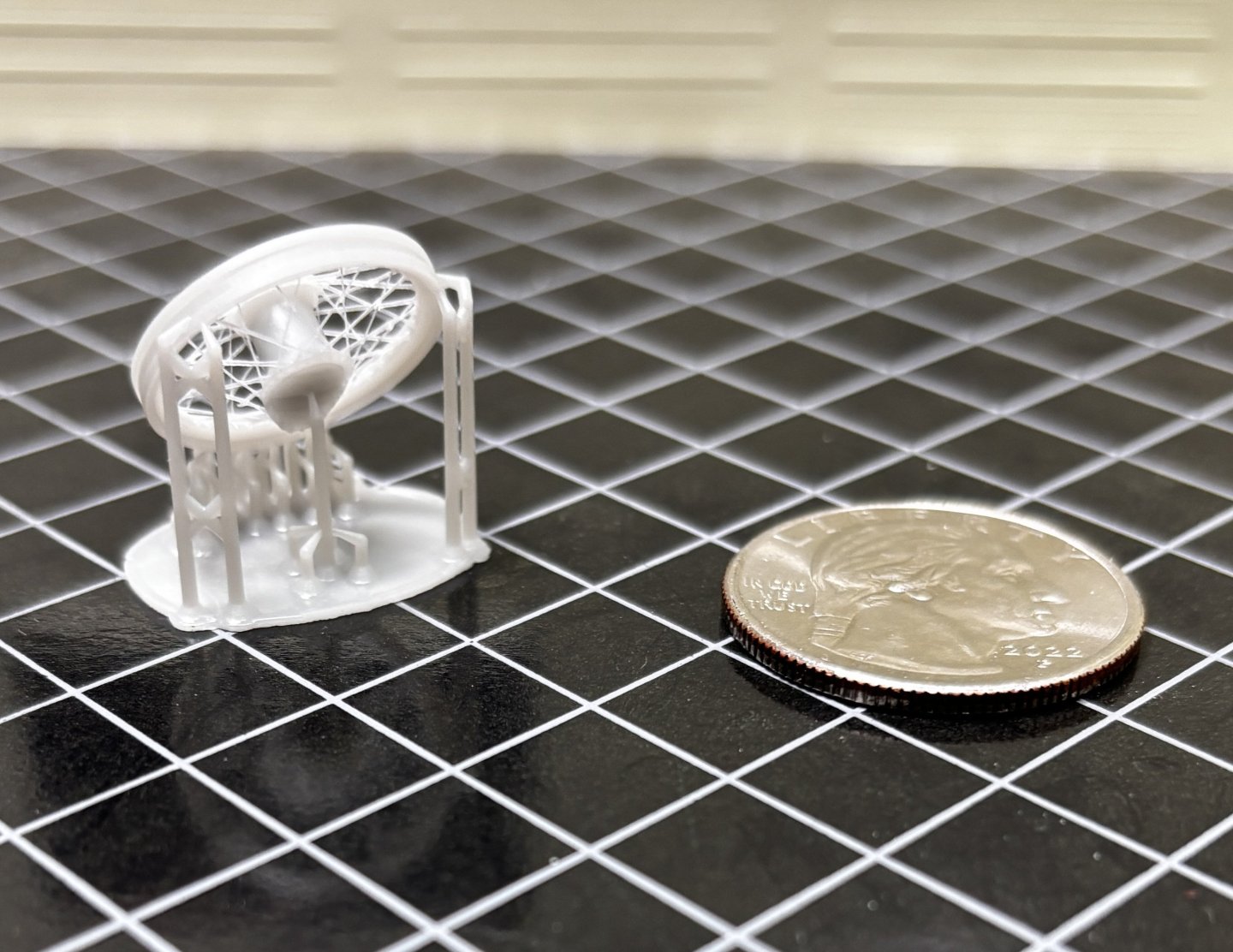

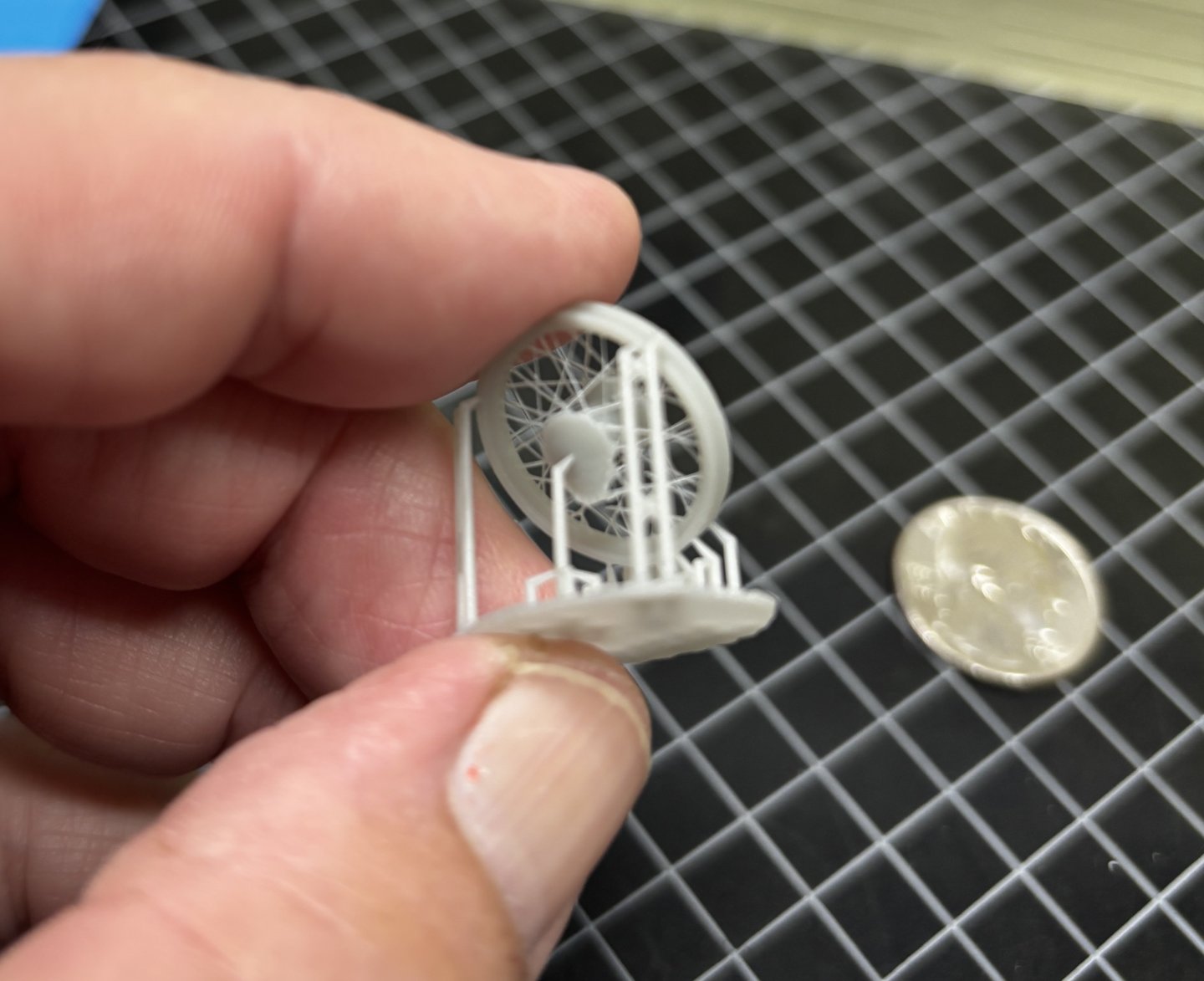

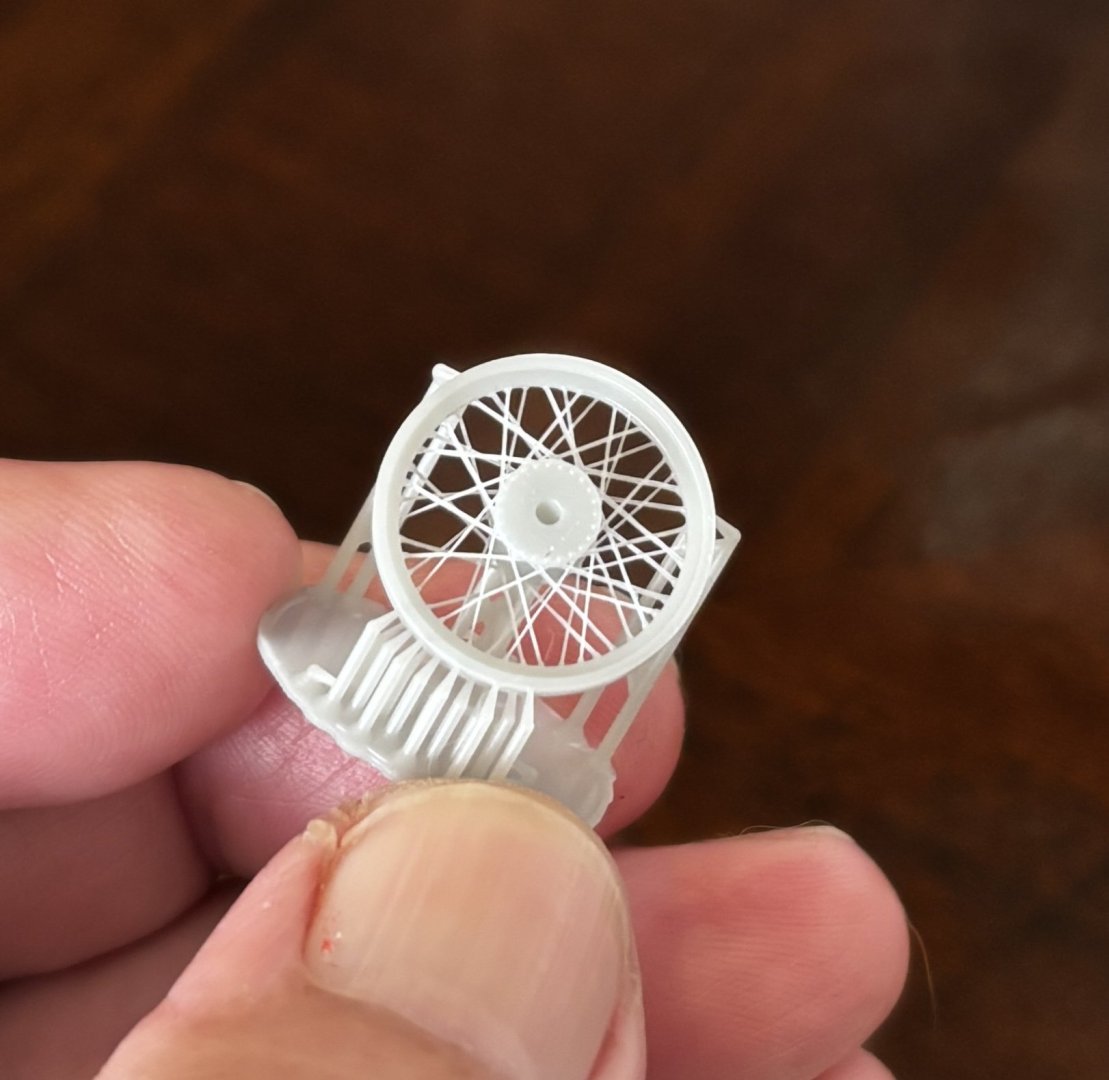

My first test print for this dragster wire wheel was mostly okay, but there was some sagging at the bottom of the hub which in turn caused several spokes to fail. After this first test, adjusted my second test print to include two additional supports at the bottom of the hub. This solved the sagging issue on the first print as well as the failed spokes. Not entirely perfect, but very close now to production status. The interesting thing is, it makes no difference whether you are printing one wheel or thirty wheels all at once, the print time is the same. About four hours. -

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

Another way to learn your new 3D printer can be the ChatGPT Ai platform. After asking the basic questions about printing wire wheels, ChatGPT gives this detailed recommendation. Pretty cool. I have the test print going as I write this, using the ChatGPT recommendations. This helps take a lot of guesswork out of the equation. "using the elegoo saturn 3 and chitubox software, what are the optimum settings and orientation to print wire wheels" ChatGPT said: Printing wire wheels with an Elegoo Saturn 3 using Chitubox software requires careful setup to preserve fine detail, ensure structural integrity, and prevent print failures. Here are the optimum settings and orientation recommendations, tailored for delicate parts like wire wheels (typically 1/24–1/8 scale for modeling): ⚙️ Printer Overview Printer: Elegoo Saturn 3 (12K resolution, 7” mono screen) Software: Chitubox (latest version recommended) Resin: Use a high-detail standard or ABS-like resin (e.g., Elegoo 8K/12K resin or Siraya Tech Fast Grey/Build) 🧭 Optimal Orientation Goal: Balance print success with minimizing support contact on visible detail. Angle: Tilt the wheel at 30–45° on its vertical axis (like a coin tipped sideways), with the inner hub down and outer rim up. This allows resin to drain and minimizes suction forces. Do NOT print flat on the build plate; it causes layer lines across spokes and high failure risk. Face spokes slightly toward the build plate to reduce overhangs and preserve detail. 🧷 Supports Use custom supports to protect details: Support type: Light and medium supports Density: Medium (80–120 points depending on size) Touchpoint size: ~0.3–0.5 mm Placement: Focus supports under the hub and back of spokes, not on visible outer faces Add a few heavier supports on the base side for structural integrity Raft/Base: Use a skate raft or large base to prevent warping 🧪 Resin Exposure Settings (Baseline for Elegoo 12K resin) Adjust based on your specific resin’s MSDS or test prints Setting Value Layer Height 0.03 mm (for finest detail) Bottom Layer Count 6–8 Bottom Exposure 30–35 s Normal Exposure 2.2–2.5 s (resin dependent) Lift Distance 6 mm Lifting Speed 60 mm/min Retract Speed 80 mm/min Anti-aliasing Level 4–8 Light-off Delay 0.5–1.0 s 💡 Additional Tips Hollowing: Not needed for small wheels. For large-scale wheels (1/8 or bigger), hollow with 1.5–2 mm walls and add drain holes. Mesh Checks: Use Netfabb or Chitubox’s built-in repair to ensure spokes and rims are manifold and error-free. Test Print: Always print one wheel first, inspect for warping, loss of detail, or broken spokes before batch printing. Curing: Post-cure with minimal exposure to avoid brittleness. 1–2 minutes per side with proper rotation. Would you like a visual diagram or STL orientation preview mock-up for your wire wheels in Chitubox? I can generate one for better reference. You said: yes ChatGPT said: Image created https://sdmntprwestus3.oaiusercontent.com/files/00000000-9ad4-61fd-81b9-c69aba8b62b2/raw?se=2025-06-10T18%3A55%3A50Z&sp=r&sv=2024-08-04&sr=b&scid=49646a2b-c71c-59ad-a69f-5f4c8f88053d&skoid=9ccea605-1409-4478-82eb-9c83b25dc1b0&sktid=a48cca56-e6da-484e-a814-9c849652bcb3&skt=2025-06-09T22%3A13%3A46Z&ske=2025-06-10T22%3A13%3A46Z&sks=b&skv=2024-08-04&sig=xr0992qv7eBAYtKF7ooRcSM6yyX7t%2BtWtnZXJ1AvXys%3D https://sdmntprsouthcentralus.oaiusercontent.com/files/00000000-7a74-61f7-964b-017654b18fd6/raw?se=2025-06-10T18%3A55%3A31Z&sp=r&sv=2024-08-04&sr=b&scid=c4de8a54-a504-50c7-97d9-65caeeabff11&skoid=9ccea605-1409-4478-82eb-9c83b25dc1b0&sktid=a48cca56-e6da-484e-a814-9c849652bcb3&skt=2025-06-10T10%3A04%3A38Z&ske=2025-06-11T10%3A04%3A38Z&sks=b&skv=2024-08-04&sig=fwmkmJ%2Bfk3vkyBdeDX2cSM2RUFbNv99eKncmhFMv6Fo%3D -

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

-

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

-

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

CDW reacted to a post in a topic:

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

-

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

Learning where and what size supports, what orientation of the part to the build plate, what settings to use for the particular resin type, just to name a few, are all part of the learning curve for printing the parts. It will take time and practice to achieve acceptable results. No way around that trial and error process. -

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

-

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

Make sure you have an appropriate environment for your 3D resin printer to live and operate. Outside in a separate building is ideal but a well-ventilated room inside can be done. Read up on it first. -

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

After a successful trial run in 1:25 scale, it is my intention to scale this up to 1:12 scale and add even more detail to build a street rod model I want that's unavailable in injection molded kit form. -

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

And one rabbit hole leads to another 😄. Another is an Ai program called ChatGPT. For instance, you can go into the ChatGPT program to ask specific questions about 3D printing, and it will provide near-instant answers. When this latest "BBB" was created by the House, I uploaded the entire bill into ChatGPT and asked it to give me a summary on each specific part I was interested in, and it gave me a complete rundown in just seconds. It can read thousands of pages or scan hundreds of photos to give immediate feedback on whatever you want to know. Technology is changing at an exponential rate, Jack. -

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

CDW reacted to a post in a topic:

'34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

CDW started following '34 Ford Chopped Top Coupe by CDW - 3D Resin Printed - 1/25 Scale

-

This month, I took the plunge and bought my first 3D resin printer, the Elegoo Saturn 3. Along with it, bought the appropriately sized Elegoo Washer and UV Light Cure Station to match up with the printer. After unboxing and setting up the printer, wash station/curing station, printed out my first test print which came out rather perfect. I found a near-ready-to-print shape file/s kit for the 1934 Ford Chopped Top Coupe. The shape files include most every part needed to build the entire kit. A time-consuming chore for me as a first-time user was to set up the files for proper orientation and to add supports. I cannot over stress how important it is to watch tutorial videos on this subject if you ever decide to give 3D resin printing a try. Following are photos of my first attempt at printing out my own model kit. There are a myriad of different combinations of settings and resin types that could be tried, each combination requiring its own unique series of print parameters and usefulness for the project at hand. Overall, I am satisfied with this first attempt, although there are improvements which I will incorporate in later attempts to refine the process. I am particularly pleased with the way the wire wheels printed out. This technology is amazing and open near unlimited opportunities to take my modeling to the next level with highly detailed 3D resin printed parts. These are not all the parts for this kit. I still have more to set up and print before actually building the kit.

-

I'll pass on that. As it is, I have four models that have not been previously entered somewhere. There's no real prohibition I know of to enter a model multiple times, but since I have taken medals with them, it doesn't seem sportsmanlike to do that, so I won't. This Chevy is no show winner, it's just something to help fill the display tables and support the show. I'm glad there are people who take enough interest to spend the time, money, and effort to put on shows like this. Our new great granddaughter is taking up a lot of our spare time nowadays. She's already 4-months-old!

-

Brabham BT45 by DocRob - Model Factory Hiro - 1/12 - multimedia

CDW replied to DocRob's topic in Non-ship/categorised builds

Very nice progress. Are you following the MFH paint guide or using your own choices? Whichever, it looks very authentic.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)

.thumb.jpg.c459ce4140b54c12eddb8eedfd446df3.jpg)