-

Posts

213 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bender

-

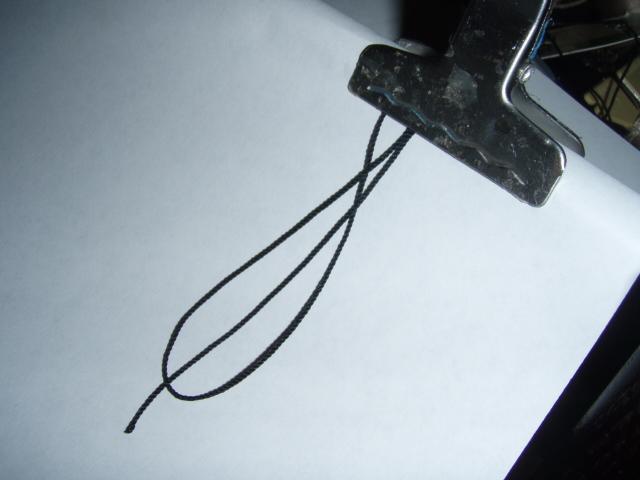

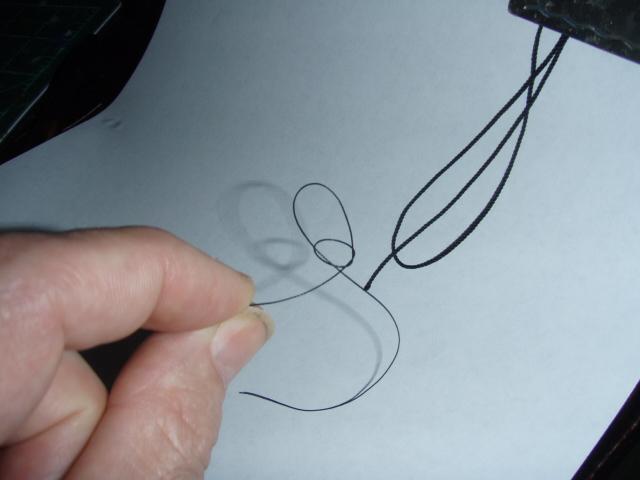

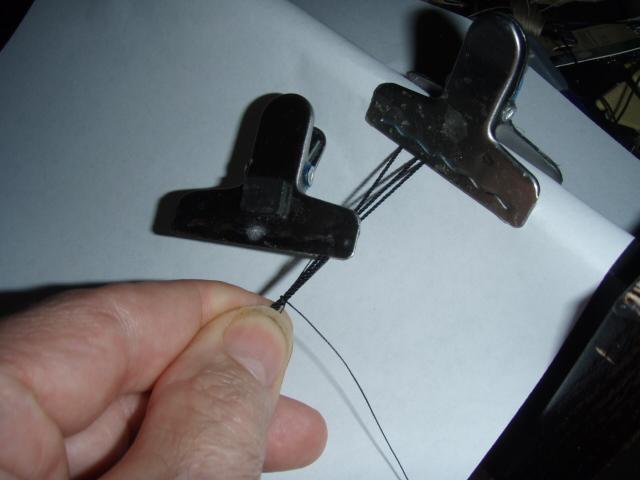

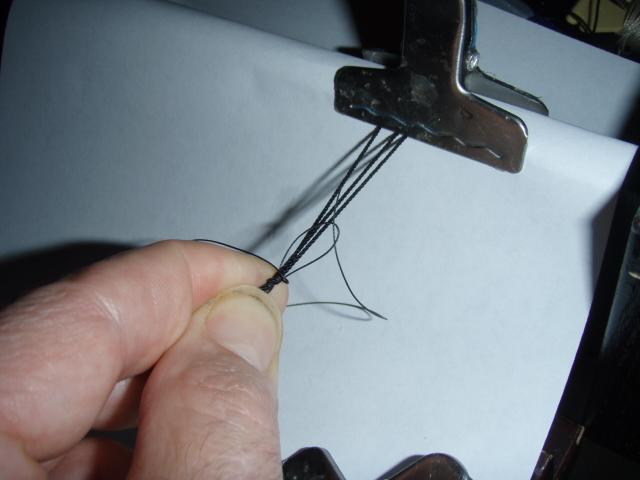

I was asked to repost this. This is an easy way of tying blocks to yards or mast. I have also used this to tie blocks to the underside of tops. I start out with thicker thread. A little trial and error with different threads to get the look I want. Notice I have the thread folded three times and use a clip to hold the thread tight. I use smaller thread to wrap around the thicker thread. I start out with a slip knot tied in the thinner thread, and stick the loop and loose end of the thicker thread through the knot. The thinner thread has two ends. The end that pulls the slip knot tight and the end the pulls the loop through the knot. I pull the loop tight against the thicker thread and use a second clip to hold the thinner thread in place. I start wrapping the thin thread (The end that pulls the knot tight.) around the three layer of thick thread and the loop of the thin thread. I make 7 to 10 or more wraps. Trail and error to get the look. While wrapping and after, you have to hold the wraps to keep them from unwinding. Remove the one clip. Take the end of the thread you've been wrapping and pass it through the loop of the thin thread. Still while holding the wraps to keep them from unwinding, pull on the other end of the thin thread to pull the loop tight around the end of the thin thread. Pull the thin thread tight but not too tight. If is too tight, it will be hard to pull the thicker thread through. Also, as you pull on the end of the thinner thread it will pull the loop and the other end on the thin thread into the wrap. You now have a loop and a loose end of thicker thread sticking out each end of the thinner thread. Pulling the loose end on one side pulls the loop in on the other side. Put a block in one loop and pull the loop tight. Slip the other end over a yard or mast. You can also start out with the loop already around something. Pull that loop tight. Add a drop or two of CA glue, and when it is dry snip of the loose ends. This picture shows two block tie to a yard.

-

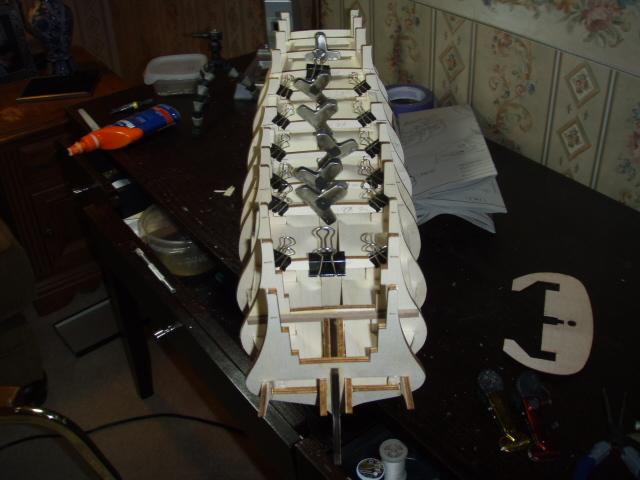

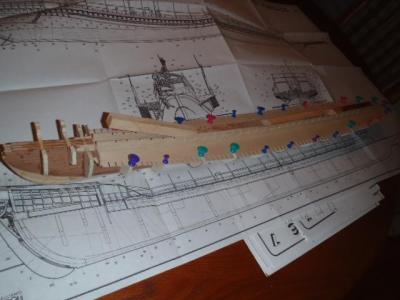

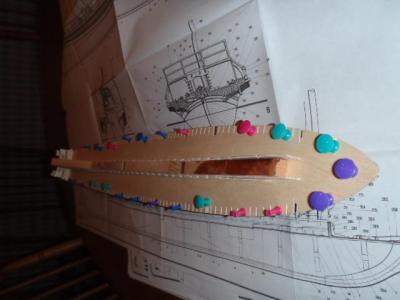

I tapered the frames. The directions said to file the first four and the last three. I took some pictures, but you couldn’t tell they were tapered. The directions were specific on the planking. I’m following them as close as possible. I included two pictures. Notice the little pieces of planking pinned to bulkhead-six. The picture/directions suggested to use this technique to assure proper blank layout. The San Felipe had porticos (balconies) on two levels the wrapped around the stern. The decks for these porticos had to be added as the planking was attached.

-

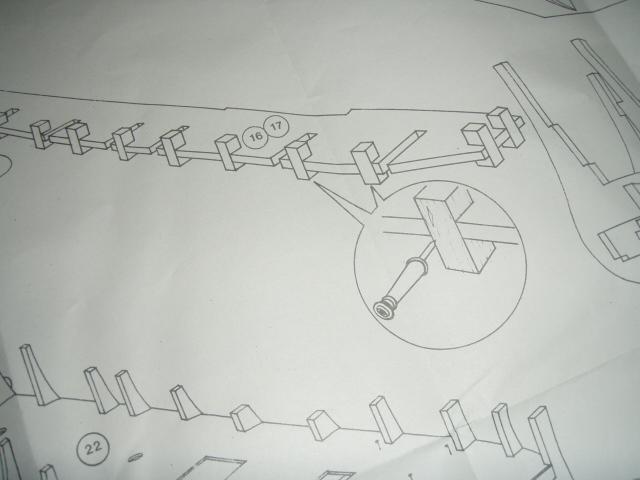

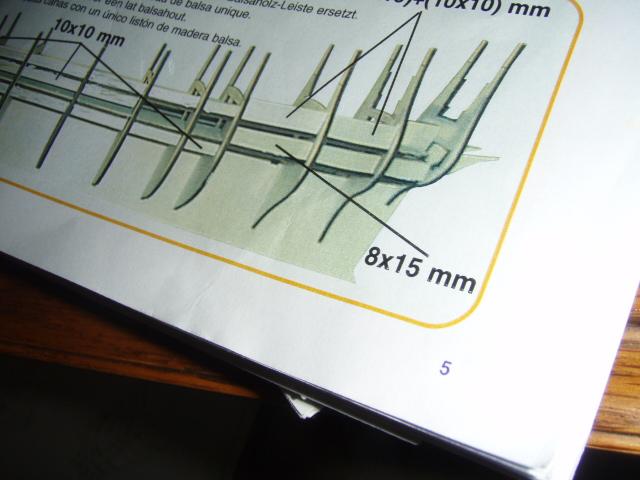

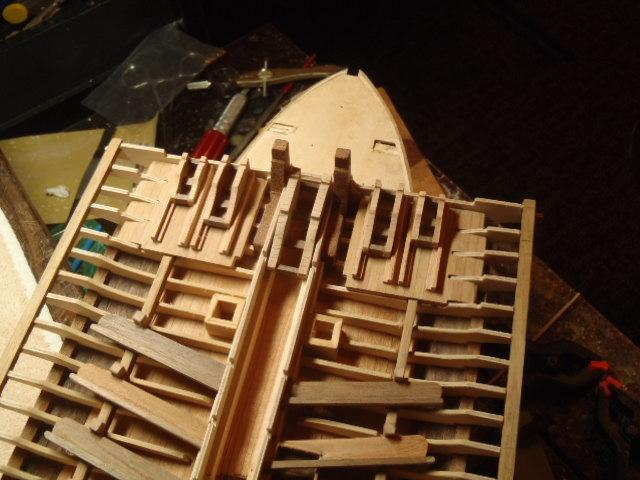

I am really pleased with the way the frame went together. There were no adjustments needed. The frame and stiffeners are designed in such a way that it would be nearly impossible for the bulkheads not to be square with the false keel. I have nothing but praise for Mantua/Panart for the design of the kit. The directions are a different matter. The instruction/picture book does not have the same directions as the large sheet. For instance: the instruction/picture book has the dummy cannon blocks mounted horizontally along the stiffeners, where as the large sheet has the dummy cannon blocks mounted vertically across the stiffeners. And sometimes the instruction/picture book doesn’t agree with itself. From the instruction/picture book: Step 19 shows frame 1b in place, and later in step 28 it shows the placement of deck 22a, but frame 1b must be mounted on top of deck 22a. All this makes the build that much more interesting. It appears that the kit I bought is a newer version of San Felipe. I emailed Mantua; here’s there reply referring to 747: if you have the latest model, you can see from the new color picture instruction, you have to follow them, considering the large plan an help but not a building indication. Please let us know the number of the last picture of the manual. On internet we have put the last updated version. regards MM So, I looked at Mantuahelp.com, and the online directions are also a mix of the old and newer version of instructions. I’ve read many times here on Model Ship World: Read the directions over and over and make a plan. Even with the wacky directions, I am still very pleased with the kit. Contents scattered across the floor. Direction from the large sheets showing the cannon blocks mounted vertically. Direction from instruction/picture book showing cannon blocks mounted horizontally. Frame and stiffeners with dummy cannon blocks mounted horizontally. Dummy cannon blocks are painted black. Starting the first layer of planking.

-

I decided it would be better to attach the keel and stems before finishing the raised deck, so the deck came off. I didn't have any clamps with jaws long enough so I used two pieces of wood with clamps on the outer edges.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

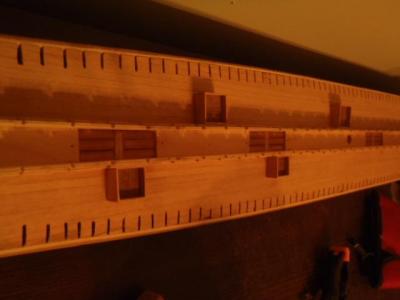

I took a little time and covered up some of the plywood. Here you can clearly see the edge of the plywood. I added a strip of wood on each side. Before the strip was attached it had to be notched on the bottom edge for each footboard. After the strip was attached, a notched had to be cut on the top edge for each counter footboard.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

At the bow a deck is built over the five cannons. The kit supplied plywood. I did not use the plywood except for a pattern to make sure I built the deck to the correct dimensions. I also used pictures of Gerard Delacroix's La Fleur de Lis to see how the frame was constructed. All of the beams and posts are cut from cherry. This is cherry left over from building the Oliver Cromwell. Everything is dry fitted at this point.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

This ship had five cannons mounted at the bow. A large cannon in the center. Two medium cannons on each side of the large center cannon. Two smaller cannons on the outside. Each cannon was mounted on a slide.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Near the front and rear of the ship--where the hull narrows--the overdeck sticks out well past the hull. Reinforcements were added under the overdeck. The supplied parts for this were precut but of poor quality. This is the supplied part. I had some cherry left. Here is the supplied part and the part cut from cherry I used a spacer to keep each parallel.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Next are the benches. . . .Benches? The rowers actually stood on these. There was a foot board on one edge and a counter foot board on the other edge. There is a clip of La Fler delis on YouTube that shows how the rollers stepped back and forth from bench to foot board. These are the benches. Gluing the foot board to the bench. I made a gig that held each bench at the correct angle The forward cannons will soon be attached to these platforms.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

At this point some cosmetic planks needed to be added. You can see the white strip of wood. This is due to the order of the build. The deck needed to be planked first so that the notches could be cut for the outrigers. Next was the first layer of hull planking. This is the light colored strip of wood you see in the picture above and below. Then the second layer of hull planking. The outrigers came next. Last the planks were attached under the overdeck. And this left the white strip. Pieces of decking are cut and glued between each outrigger. I had a few regrets with this build. One regret was not replacing the outrigger plywood with real wood. I had plenty of cherry to do this. Later in the build I found some paint that matched the color of the plywood so that the plywood is not obvious. Also from this point in the build I replaced any plywood supplied parts with cherry. At this stage the decking below the center cannon was added. Next come the foot boards, which looks like benches. The foot board attached to a beam that runs the length of the deck.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

A beam was added to the underside of the overdeck. This beam is the starting point for planking. The planks ran from this beam to the hull. These last three pictures show the planks on the underside of the overdeck. Notice that the keel and stems are no longer attached. After fitting these pieces they were removed until later to keep from damaging them.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Thanks, Frank, for the welcome back. It is nice to be back at it. Just four picture for this post. This first picture shows half the port side finished. This picture shows the last few outriggers on the port side going in. And you can see what the outriggers look like. The frame work for the overdeck is nearly complete.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

The next step was building all the hatch coamings. A wave of any significance would wash over the low deck of this type of ship, so the hatch coamings had to be tall enough to keep the water from pouring into the lower deck. Hatch coamings attached to the deck. Next was the overdeck. To support the overdeck, 80 frame pieces attached to the main deck on each side and stuck out past the main deck. For lack of a better name, I'll call these pieces outriggers. Here is a picture of the outriggers after they were shaped. The outriggers are sitting on the plan sheet. Each piece was cut from supplied plywood and had the top and bottom profile already cut. I only needed to cut the long strips of plywood into shorter pieces and then shape the ends that attached to the deck and the end that attached to the outer support beam. I made copies of the drawings, cut out the pattern, glued the pattern to plywood, and then shaped each outrigger. Each piece had a different shape. This task was not too hard. I used a desk sander to do most of the shaping and a file to achieve the final shape. And when attaching the outriggers to the deck I needed to do some more shaping. Corel's directions stressed the importance of making sure the outer support beam followed the curve of the main deck. I attached the fore and aft outriggers and three outriggers in the middle I used office clips to hold the outer support beam to the outrigger. One side is finished. The outriggers needed more shaping so the piece would fit snugly against the deck and the outer end of the outrigger followed the curve of the outer beam. Looking up. I mentioned above 80 outriggers on each side. I have not been able to find the drawings that came with the kit. My number of 80 came from counting the outriggers in the picture below. I counted three times and came up with three different counts. You are more than welcome to correct my count.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

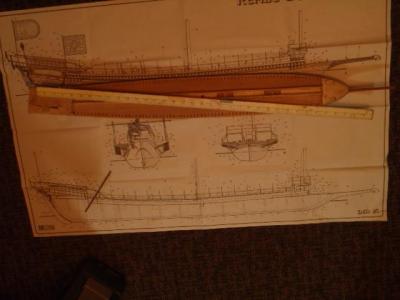

The second layer of planking is finished, and it took a lot of sanding to get the hull smooth. You can see there is a gap for the keel to fit into--actually--let me pull up a picture from the first post. This picture below shows the three layers of the false keel and how the middle layer of the false keel is inset so the "real" keel can slide between the outer two layers of the false keel. This added a lot of strength to keel. The kit directions gave two options for the keel. You could either assemble the false keel together with the "real" keel, or plank the hull first and then fit the keel. Which is what I did. In order to have no gap between the keel and the planking, I made sure the planking ran well into the gap where the keel would fit. I used a long file to shape the edge of the planking. The gap in the three layers of the false keel kept the file moving straight and kept it centered. I took my time with this. I didn't want to file the slot too wide. This is a picture of the finished hull sitting on one sheet of the drawings. I put a yard stick (almost a meter long) in this picture to show the length of the hull. This picture and the last picture show the cheeks at the rear. These gave me a heck of a time. And this is not their final state.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

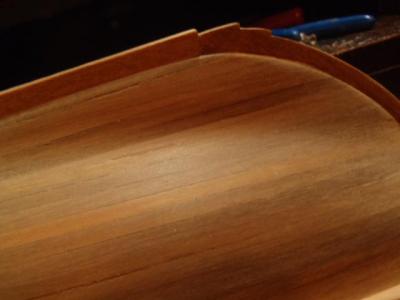

After sanding the first layer really well, I started attaching the second layer. Again, the only real problem was the cheeks at the rear. But as the second planking reached the bottom--near where the keel would attach--I noticed the shape of the hull was not correct. If I continued with the second layer the hull would not curve into the keel correctly. I had to remove about five inches of the bottom two strips at the aft so I could sand a little more from the bulkheads and the false keel. The next three picture show what it looked like after reshaping and re-attaching some more bass wood. They also show a steeler plank that needed to be added It was ugly at this point. You can see in the picture above and below where I removed two planks and added a strip of bass wood. The last two pictures show push pins holding the second layer in place.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

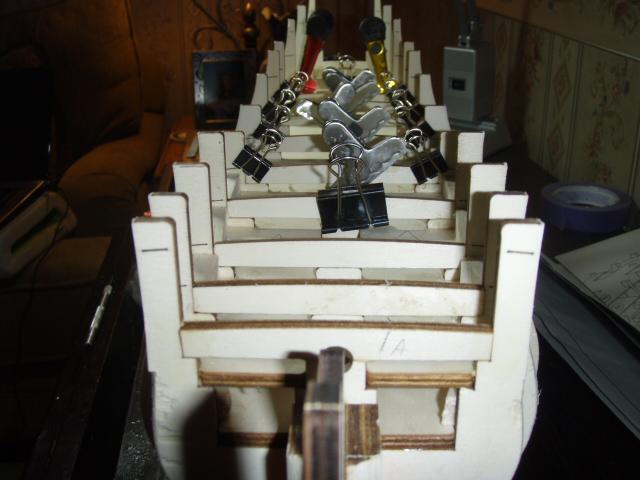

After adjusting the bulkheads so that the deck ran smoothly, I started with the first planking layer on the hull. The strips were long enough to ran the entire length, but I had trouble with the glue drying too much before I could attach the entire strip. To keep from cutting the strips shorter, I applied glue to a little over half the strip and tacked the strip with push pins. As I worked my way from front to back I kept applying more glue to the strip. The first strip started flush with the top of the deck. Besides the push pins I used blue tape to hold the planking strip tight against the deck. In the next two pictures you can see how the blue tape is holding the top plank against the deck. For the next few runs of planking I used the spring clips to hold each strip tight against the strip above. Not only did this hold the strip tightly together, it kept the edges flush with each other. After five runs of planking, the width was too much for the clips, so I went back to using tape. The silver clips are helping to hold the the edges of the strip flush with each other This is what it looked like after some sanding. Except for the cheeks at the rear end--which required a severe bend--the first layer of bass wood gave very little trouble.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Thanks, Wacko Joe, very much for the offer. I have found all the pictures. At the time I was in the habit of saving pictures on my computer at work. The problem I am finding is not remembering why I took some of the pictures and not knowing what to say about the pictures. All is good. I find that I am having a good time looking back at the pictures and making a new build log. Dan, that is what I thought but jumped in anyway.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

This is another problem I had with the bulkheads. You can see in this picture the the deck is not running smoothly. I had to separate the deck from the bulkhead and file the top of the bulkhead down. After re-attaching the deck to the bulkhead I had to add some material to the bottom edge of the bulk head. This is a strip of basswood I curled with a curling iron. I think this is what it looked like after the glue dried, but before I sanded it down to sit fare with the other bulkheads. I haven't been able to find the directions that came with the kit, and I don't remember the names to all the parts of this ship.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Even with the keel made from three layers of plywood, the frame still had a nice curve. The false deck for the main deck was one piece and took care of the curve. I had to break this bulkhead off to remove some wood off the top face so the deck would run smooth. I cut some pine blocks and slipped them between these vertical pieces to keep them square and parallel. After the false deck was covered with the decking, notches needed to be cut for the outriggers. The false deck had the slots pre-cut. I only needed to cut the thin decking with a knife and then finish up the notches with a file. This is what the deck looked like after some of the notches were cut.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

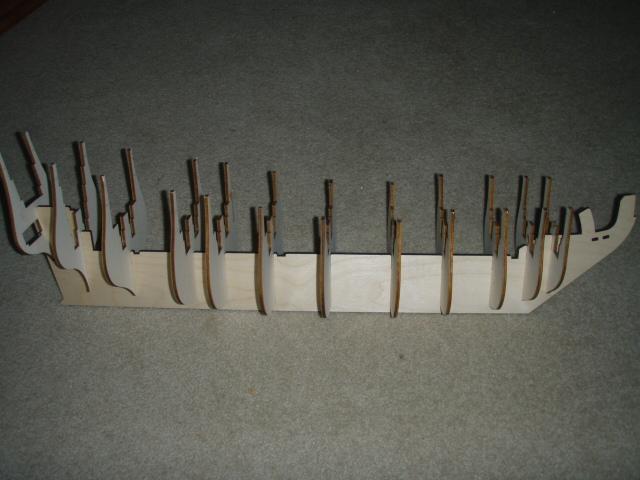

The first thing that confused me was the scale. As you can see the box says 1:24, but all the literature states 1:75. The box was heavy and well packed. Here is the contents. The keel was three layers thick. The frame went together well. I think I had trouble with only a few of the bulkheads fitting square. I had to unglue one or two of the bulkheads and do a little filing. The bulkheads were used to keep the three layers of the keel aligned during gluing. After the frame was assembled the bulk heads and keel was fared. More tomorrow. Edit: As you can tell I am having trouble posting pictures. I guess I need to read up on how to do this correctly.

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

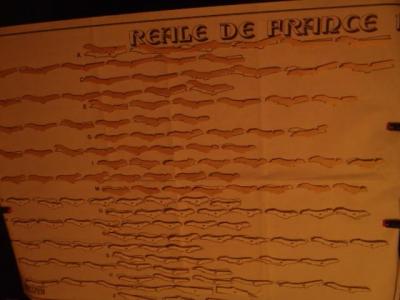

This is what it will look like. It seems I don't have the pictures from when I started working on Reale de France stored on this computer, only the last few after I finished her. I'll have to transfer the pictures to the computer I am using now. And here's to starting fresh and new

- 115 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.