cgiacoppo

-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by cgiacoppo

-

-

- Canute and GrandpaPhil

-

2

2

-

- Canute, robert952 and GrandpaPhil

-

3

3

-

- robert952, Canute and GrandpaPhil

-

3

3

-

- GrandpaPhil and Canute

-

2

2

-

Thank you Robert Chenoweth and Phil for your tips.

Well, we didn't like the way the last the last adjustment looked so we removed it. Unfortunately, I was a little over-vigorous with the sander and it distorted the top of the hull. My fault.

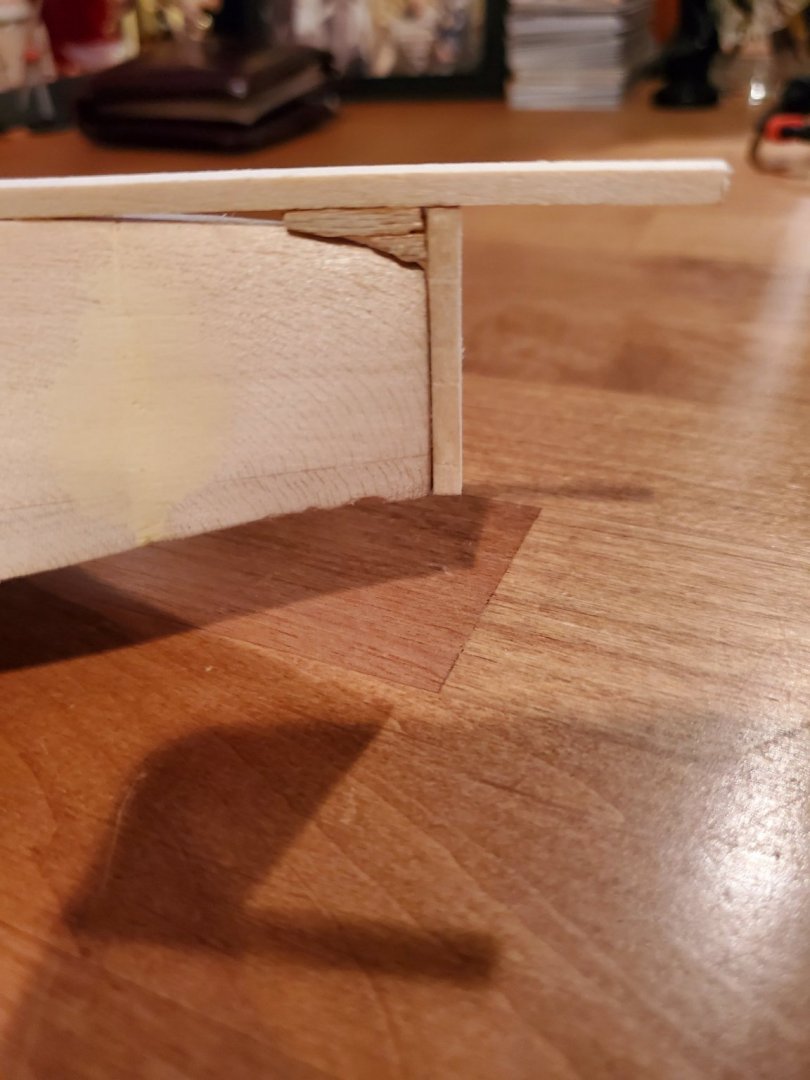

I repaired it with some wood strips. The hope is this will mostly be hidden when we paint.

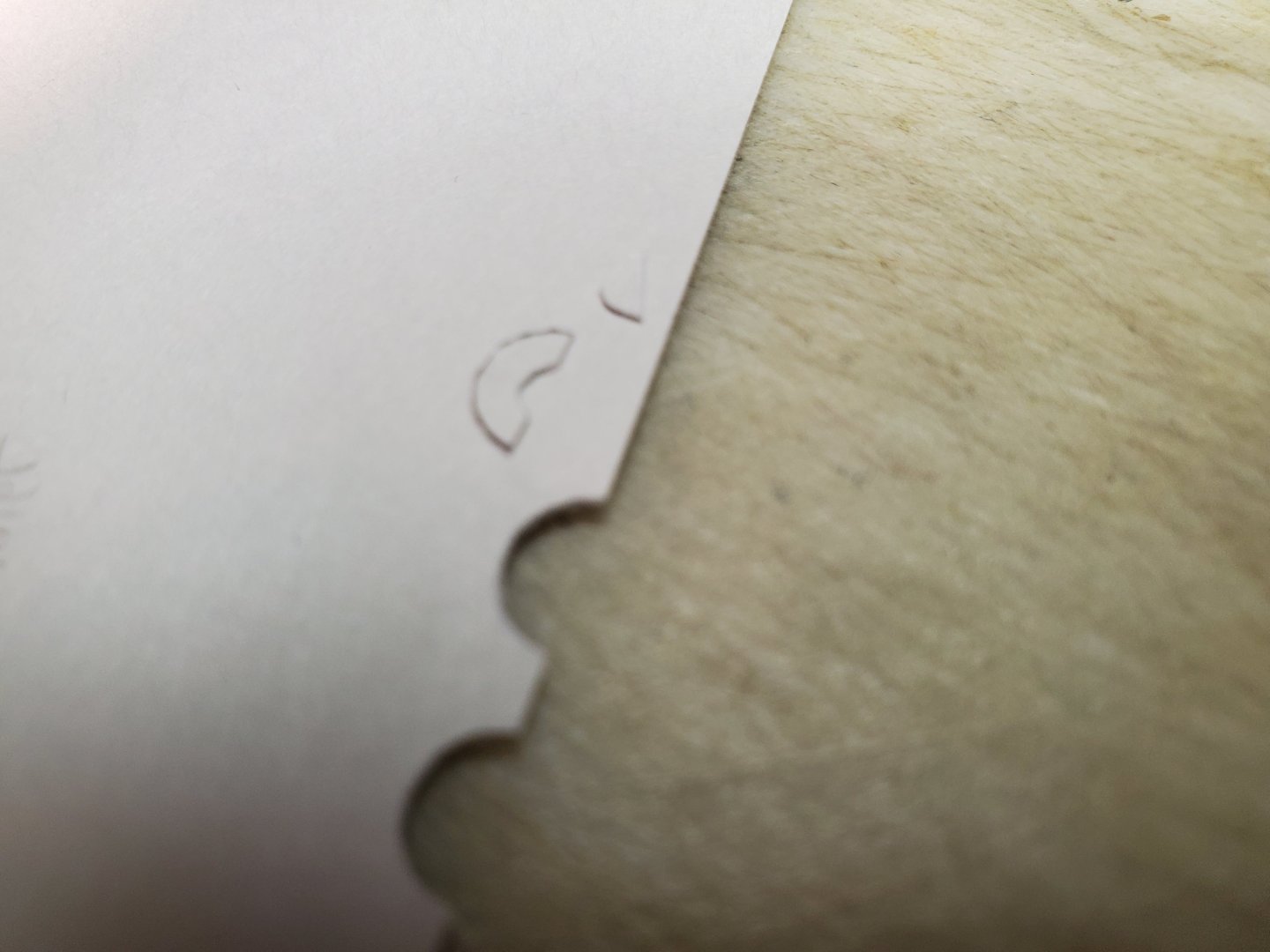

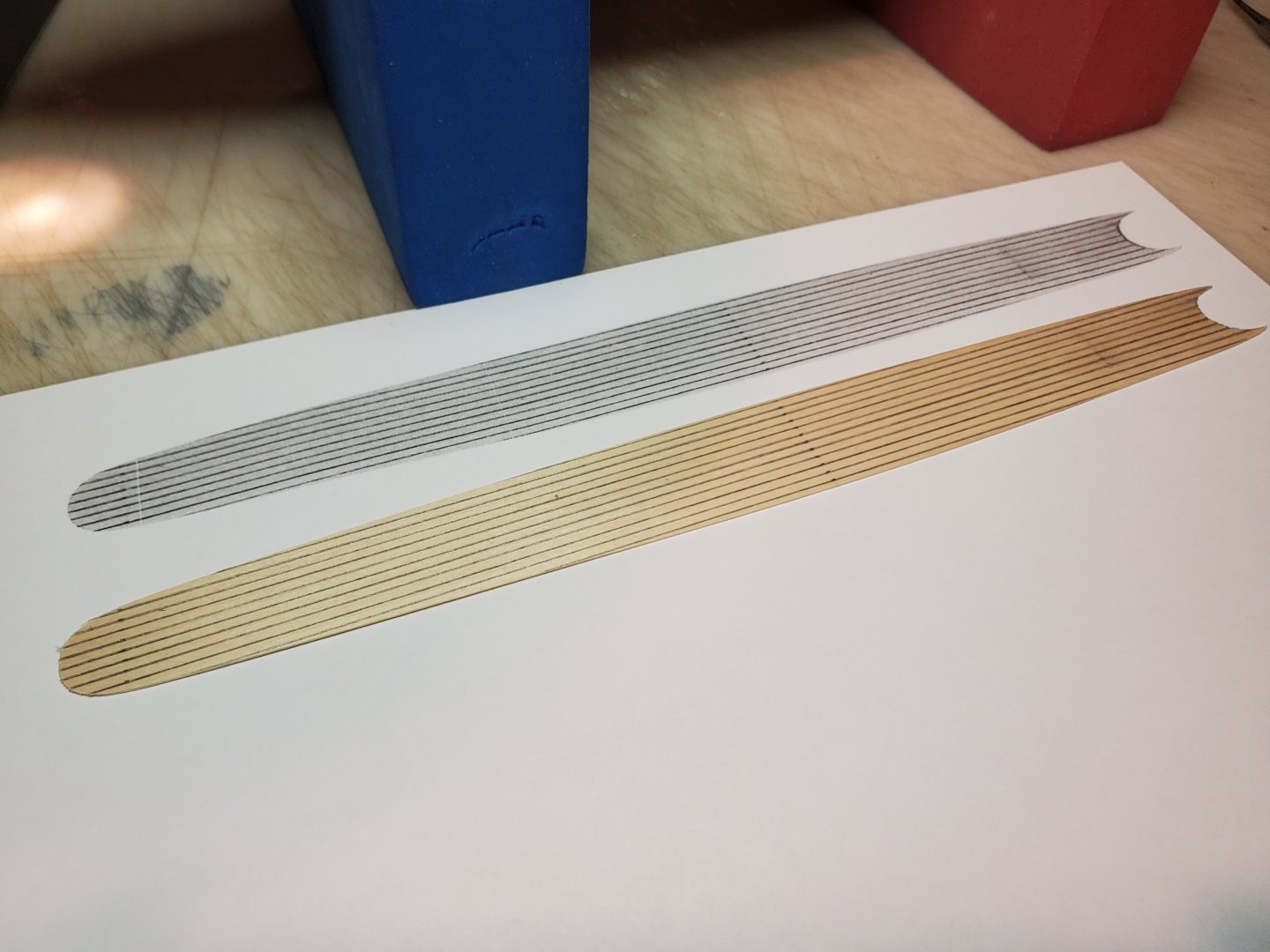

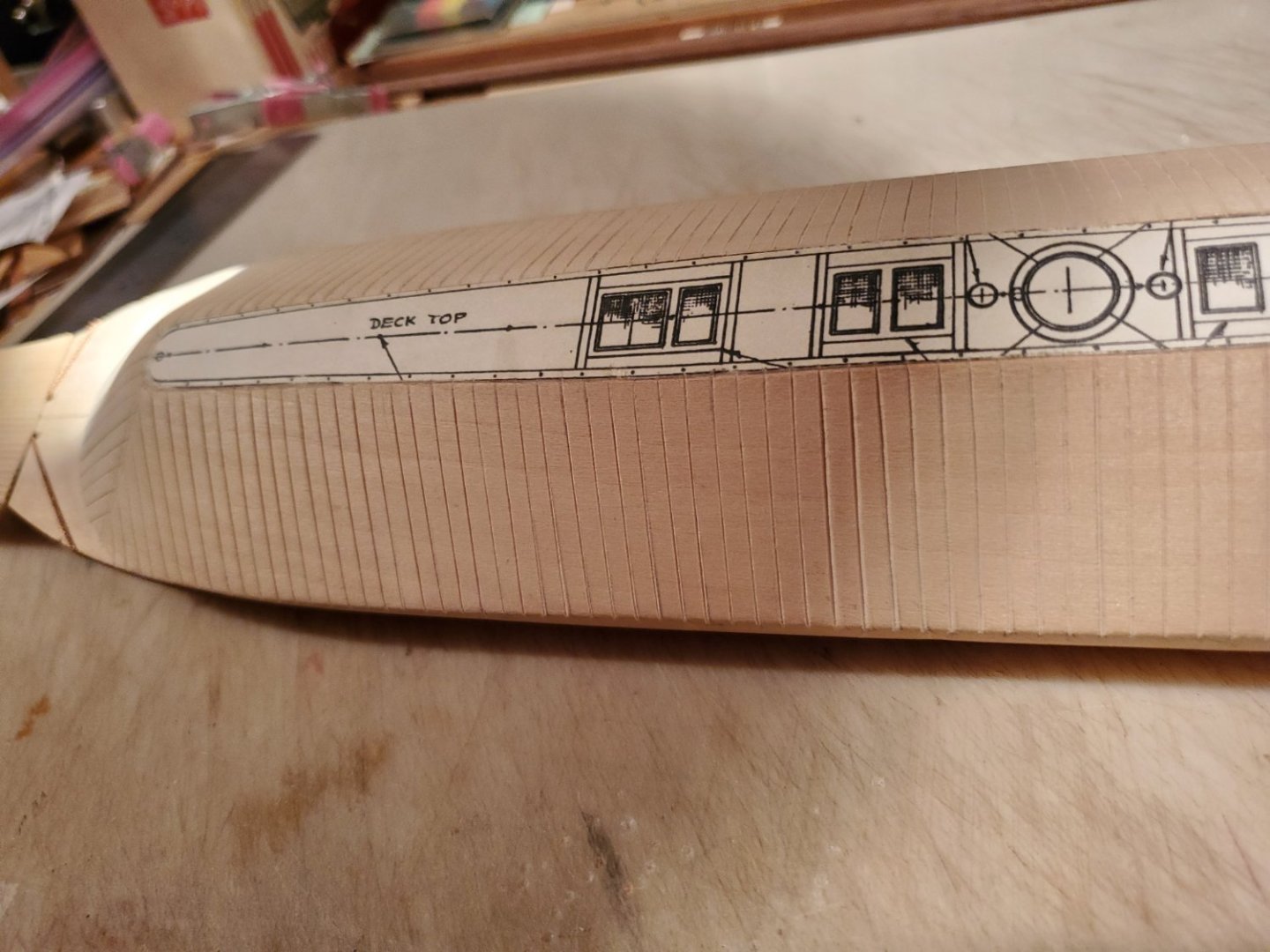

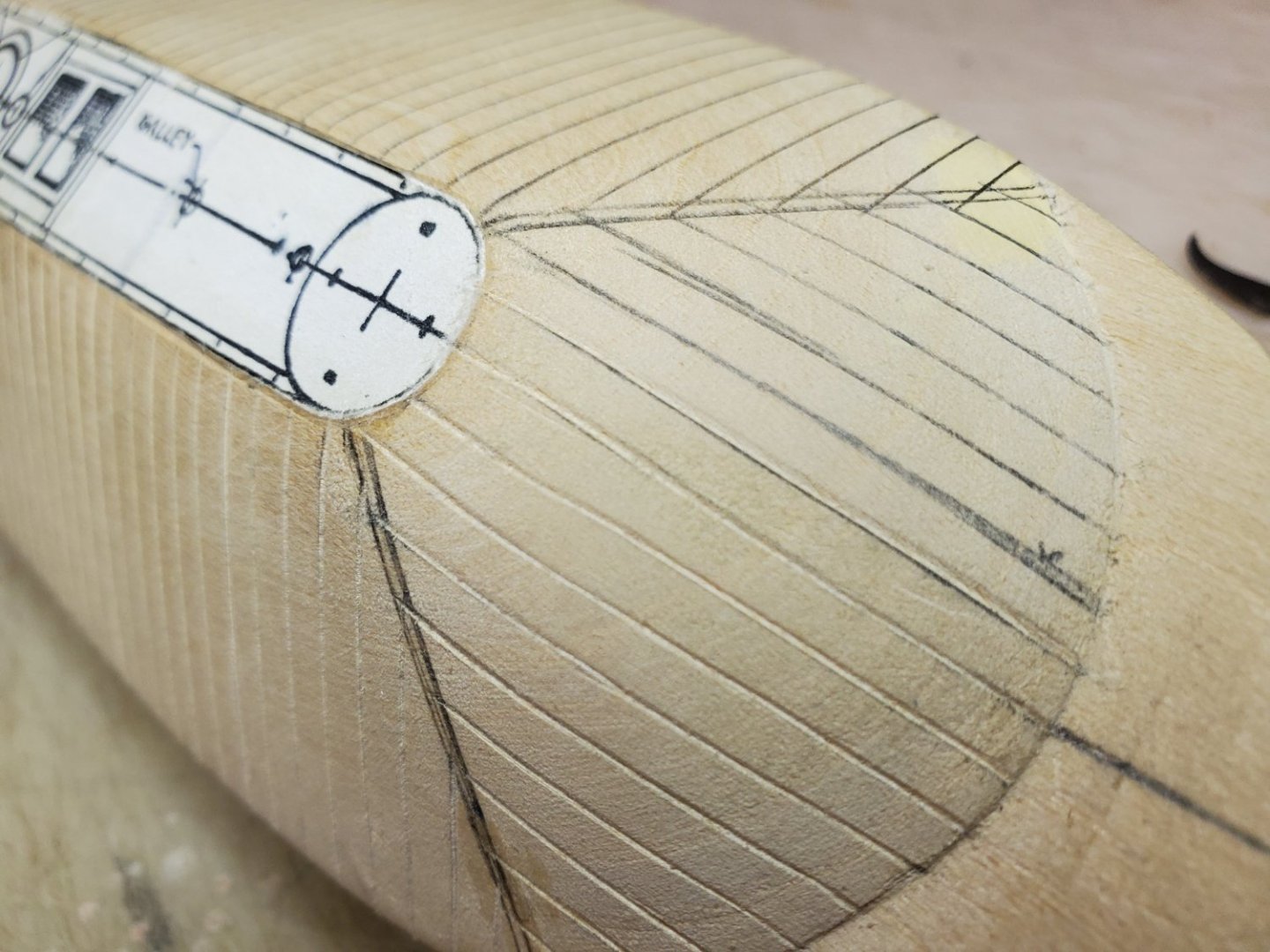

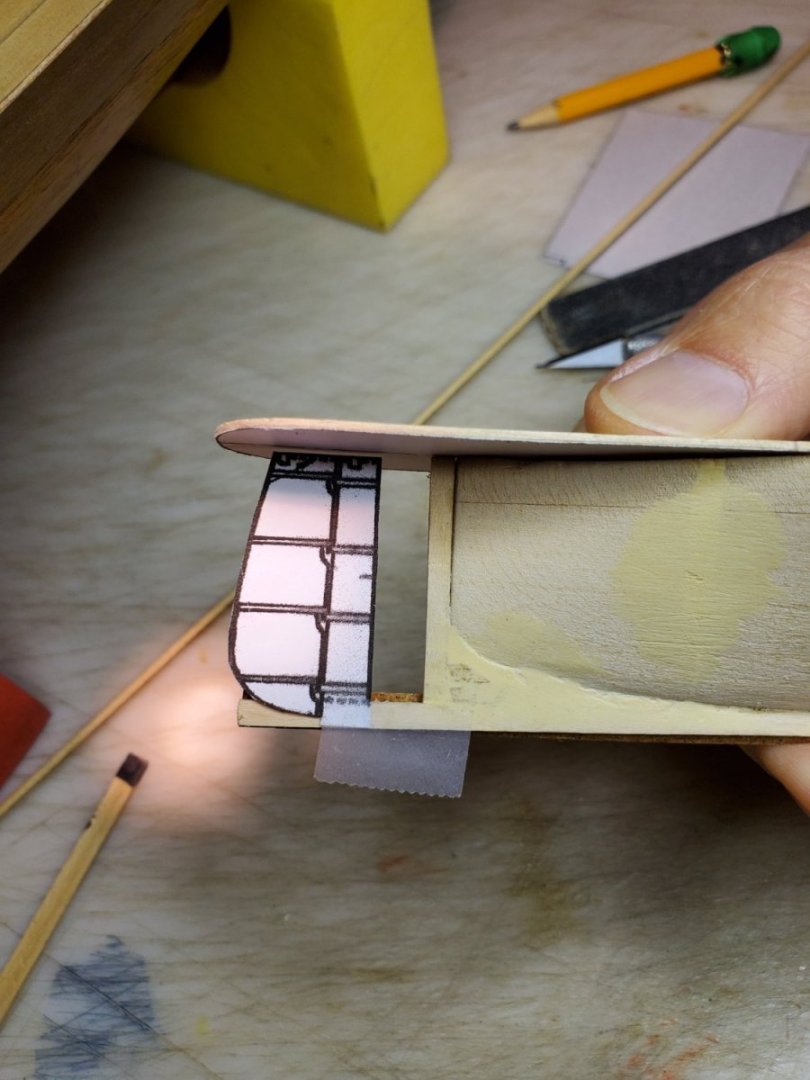

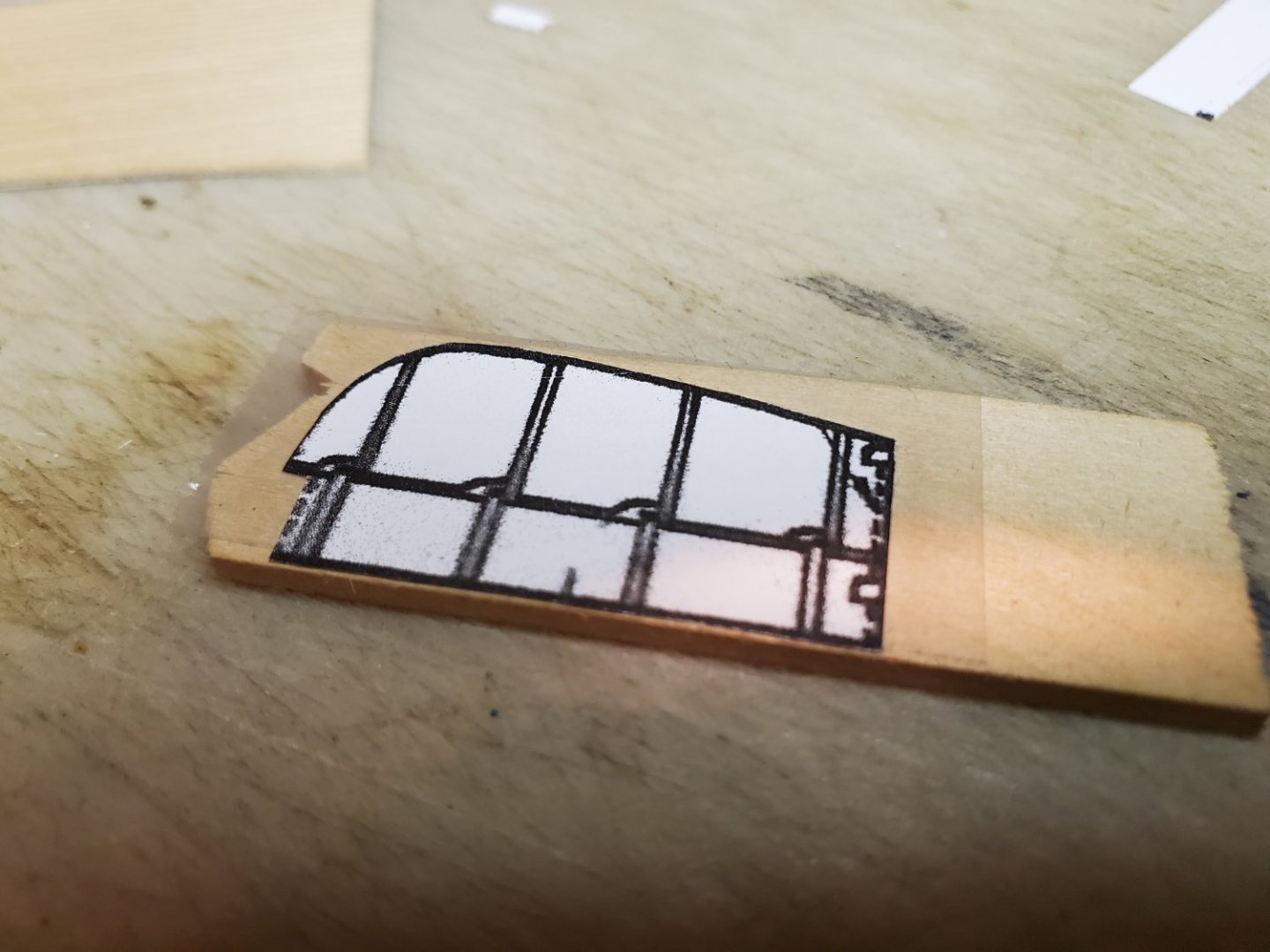

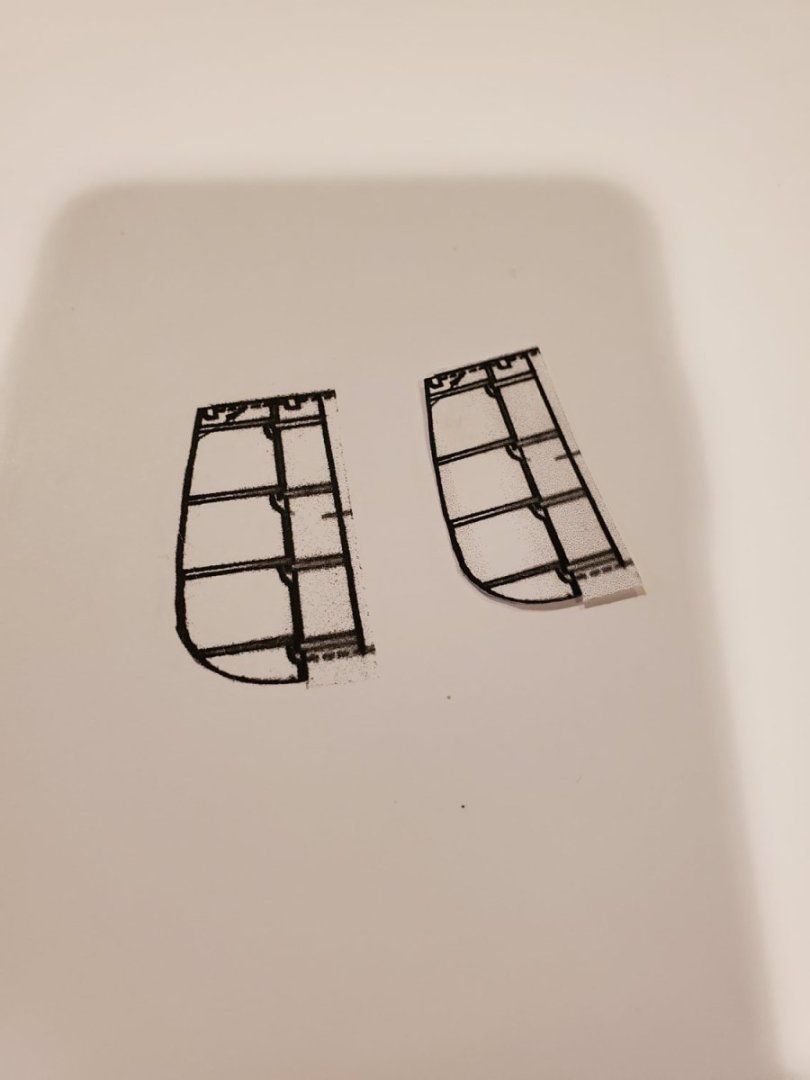

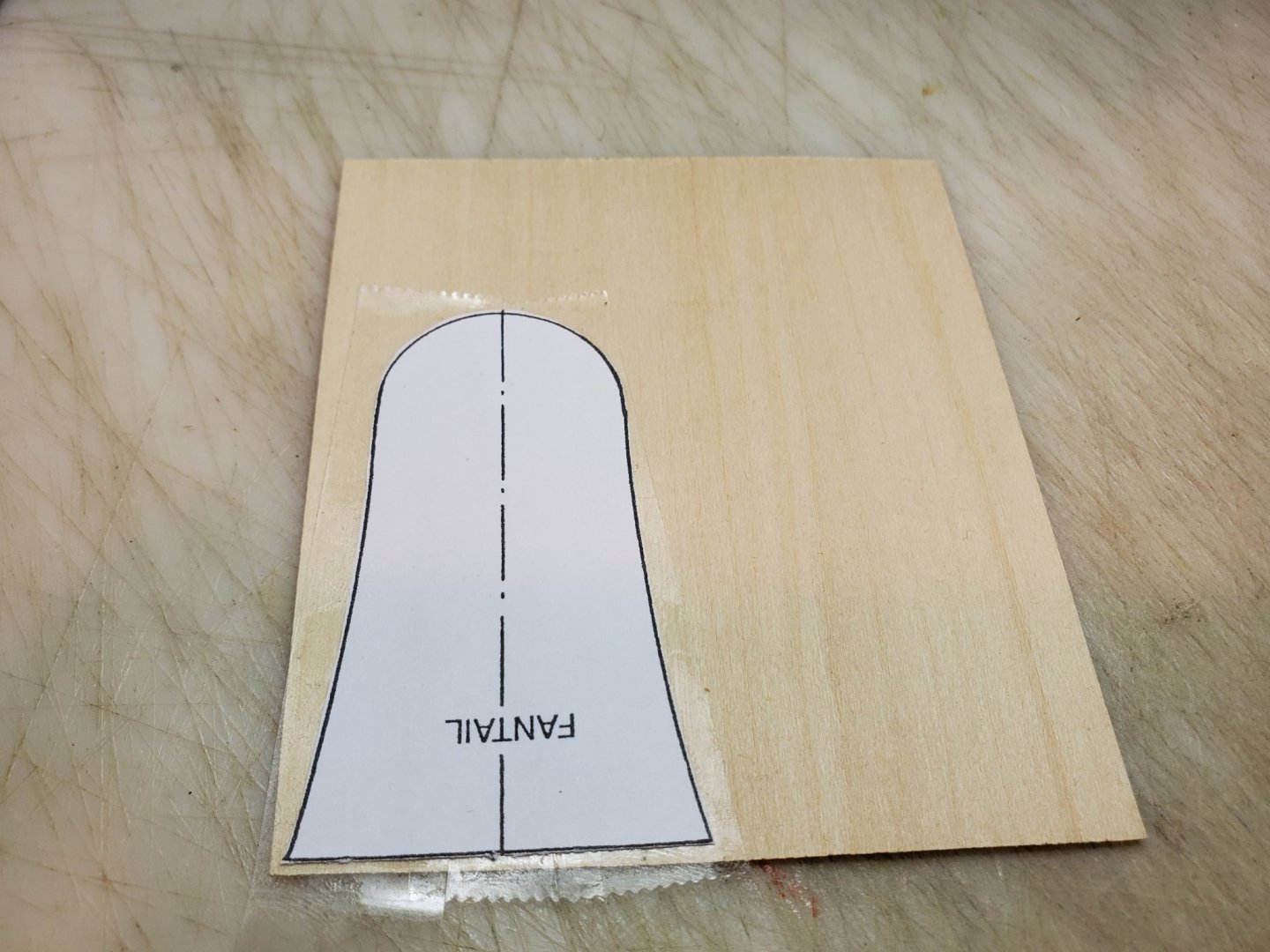

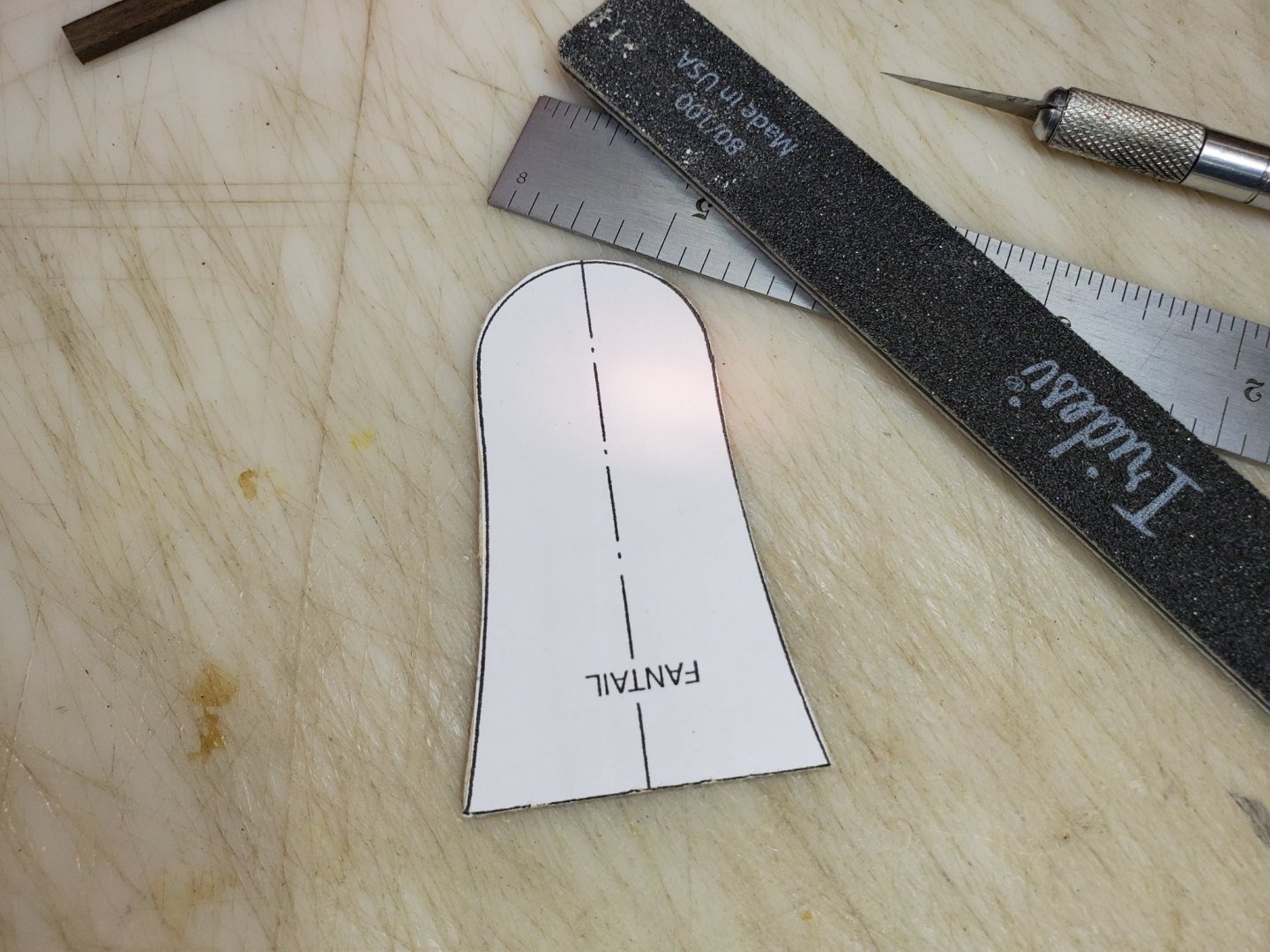

Next we decided to plank the top of the hull using a thinner piece of pre-scribed veneer. I purchased such a piece but decided the plank lines were too close to each other. So we flipped it over, marked new plank lines with a pencil to simulate caulking, and then scored those lines with the back of a putty knife.

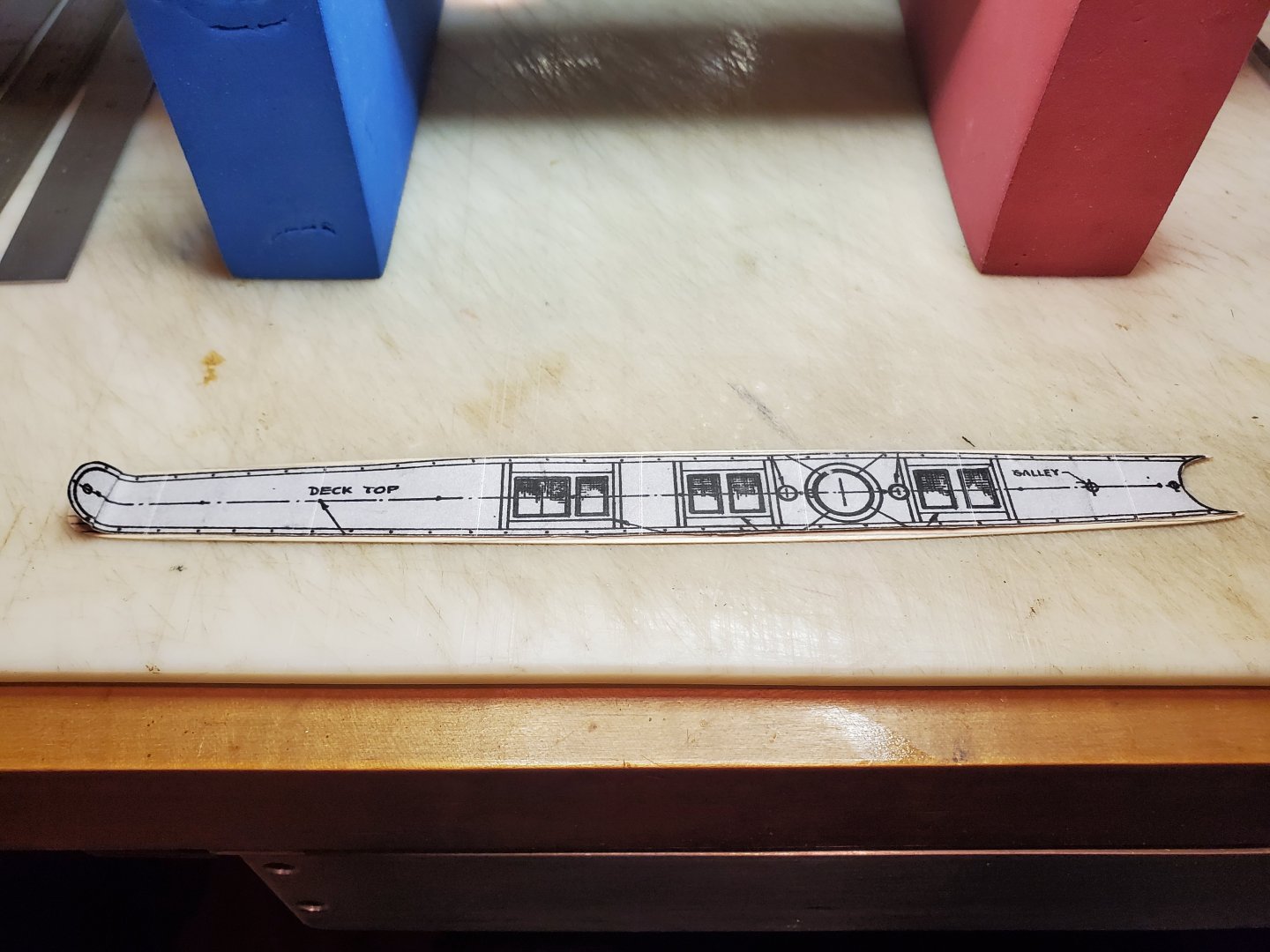

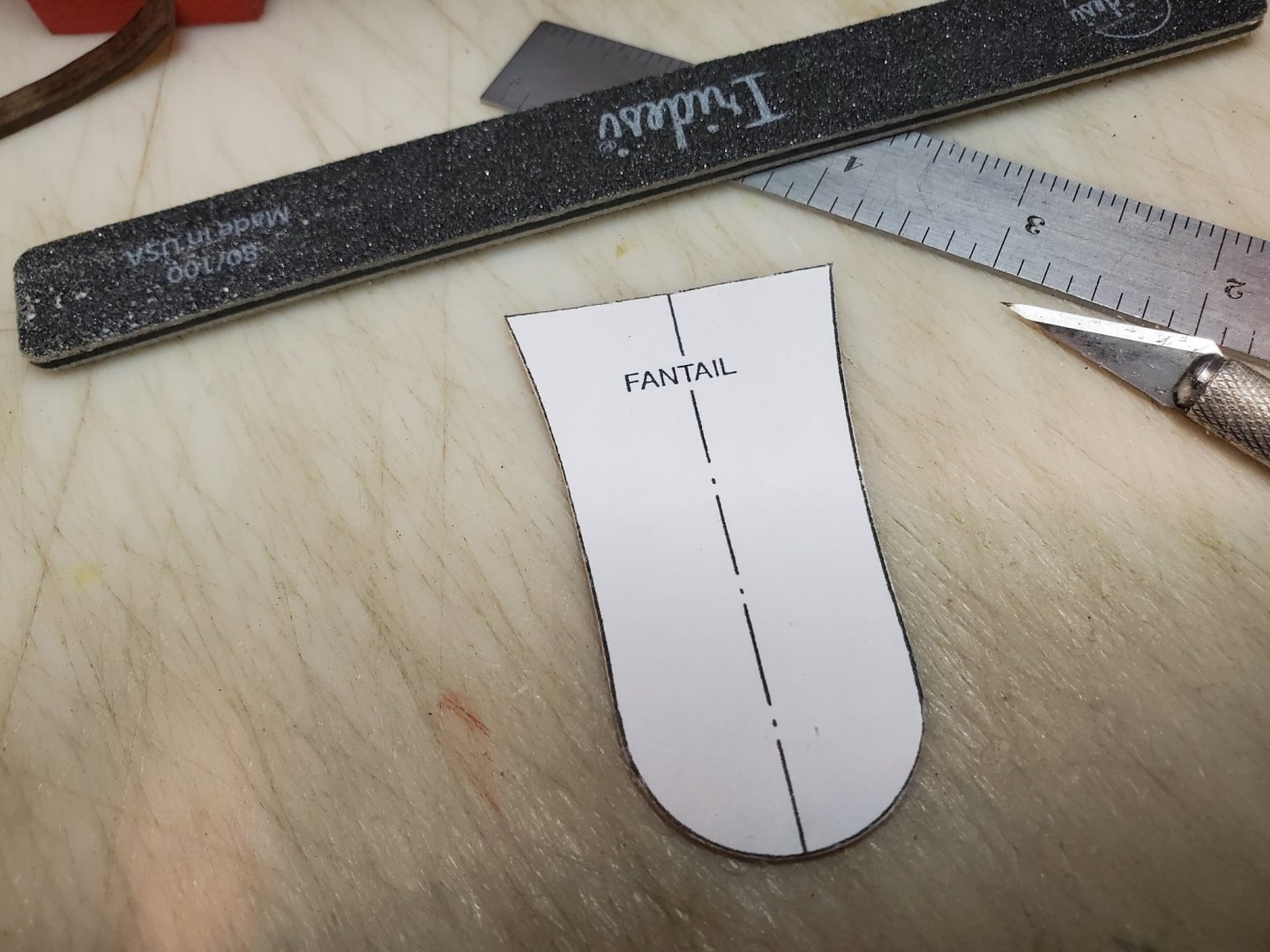

We taped a copy of the plan over it to get the shape and cut it out. We sanded the back to make the veneer as thin as possible.

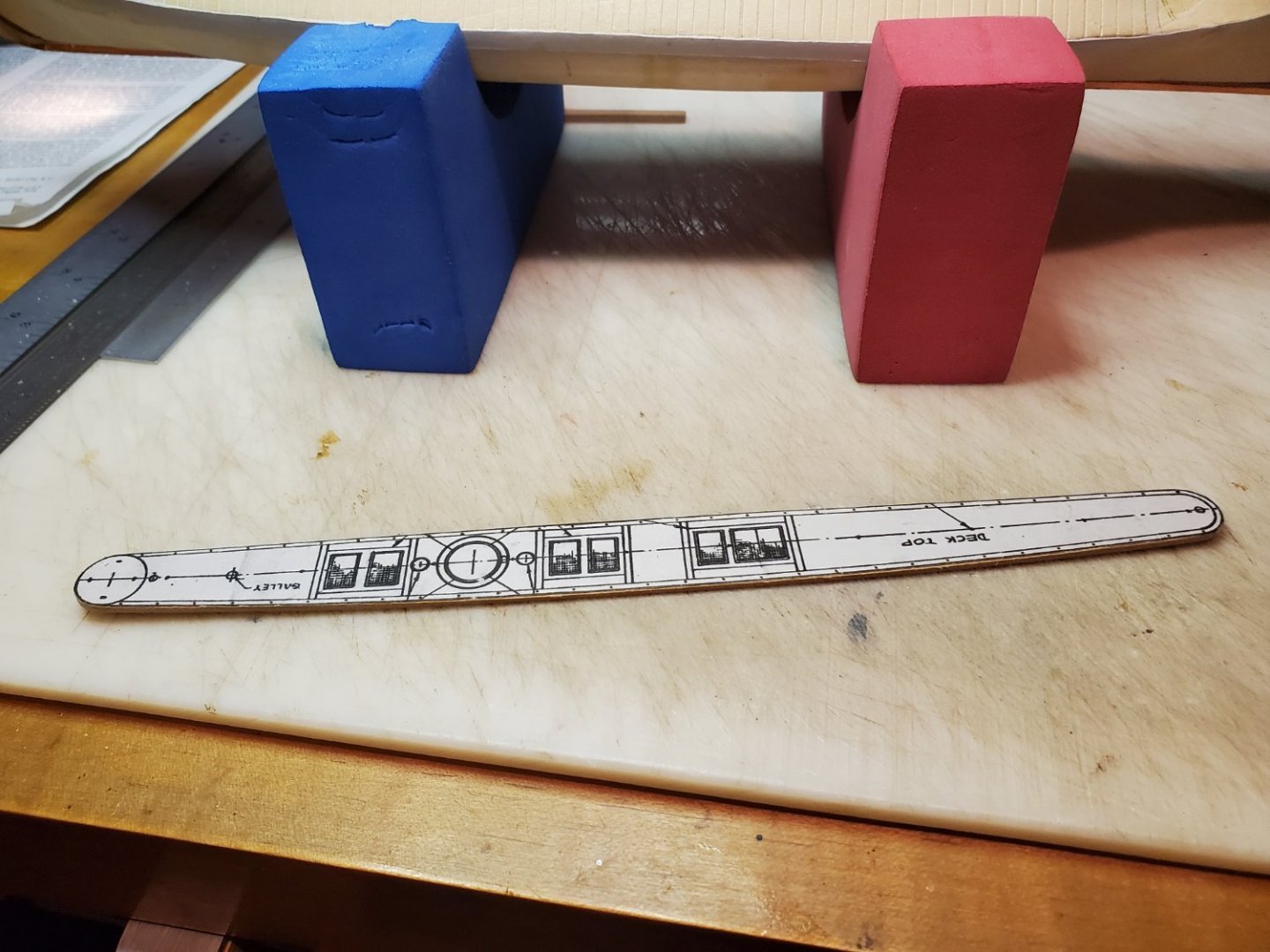

Set on the model before final sanding.

- robert952, Canute and GrandpaPhil

-

3

3

-

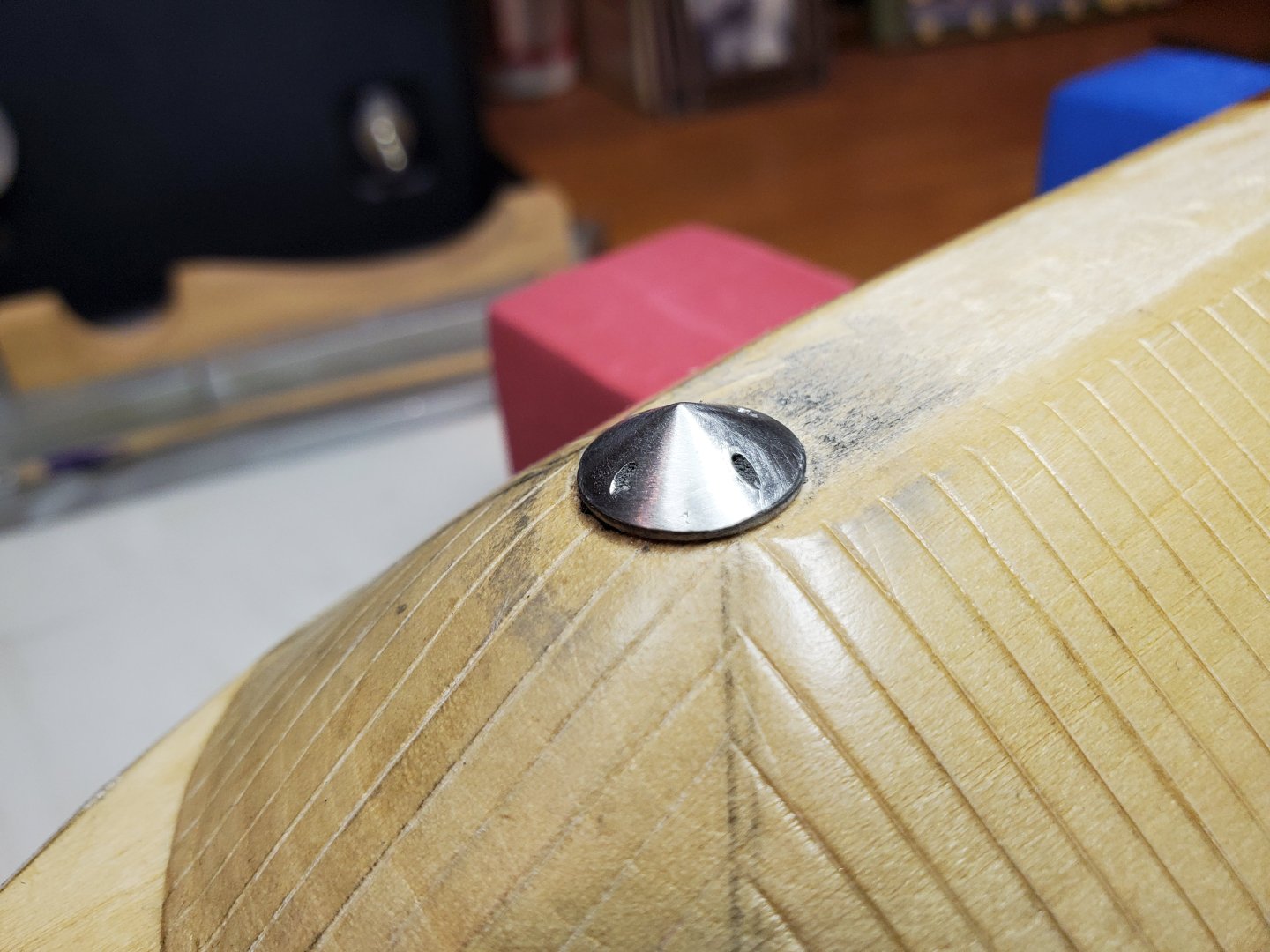

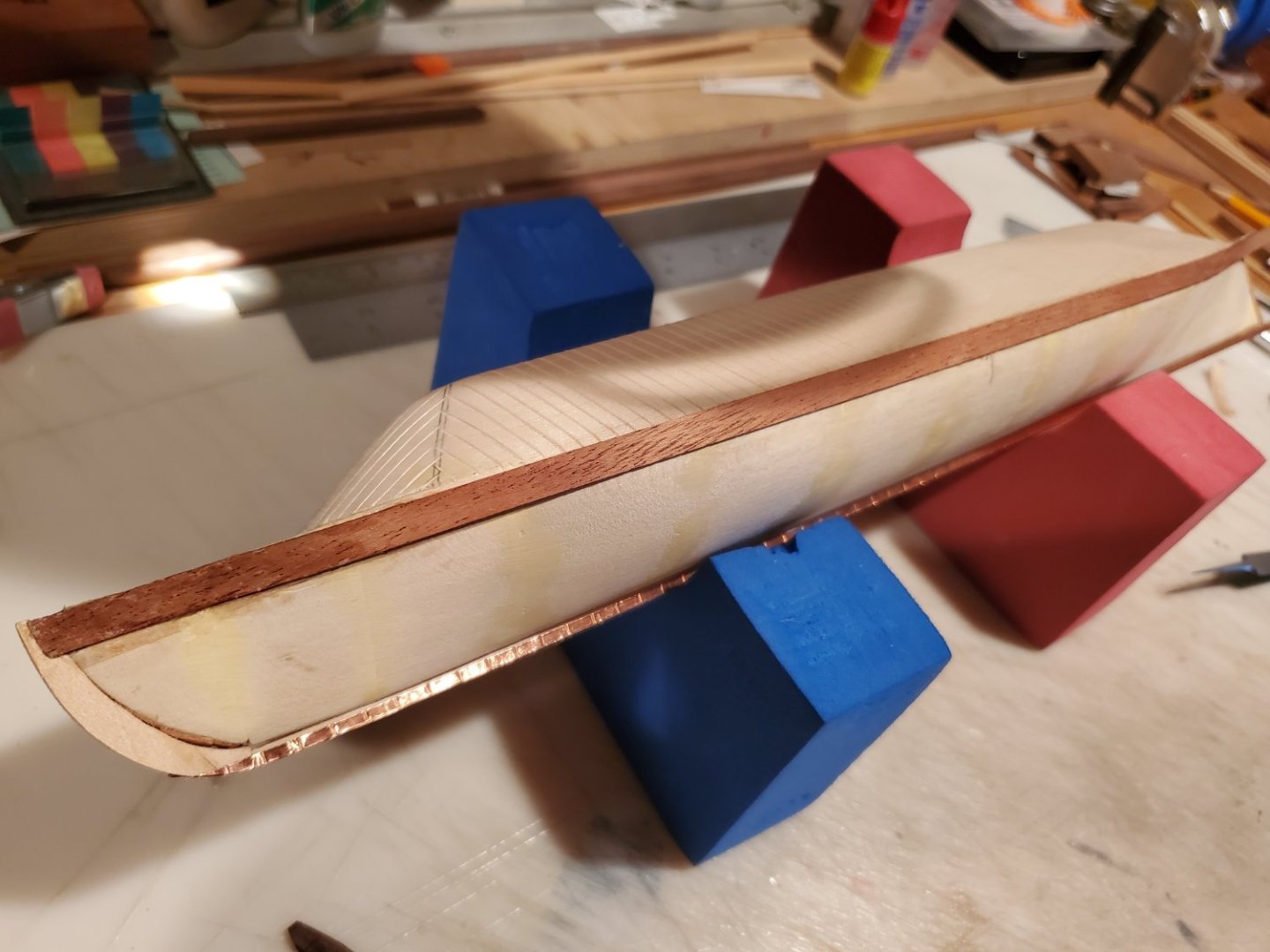

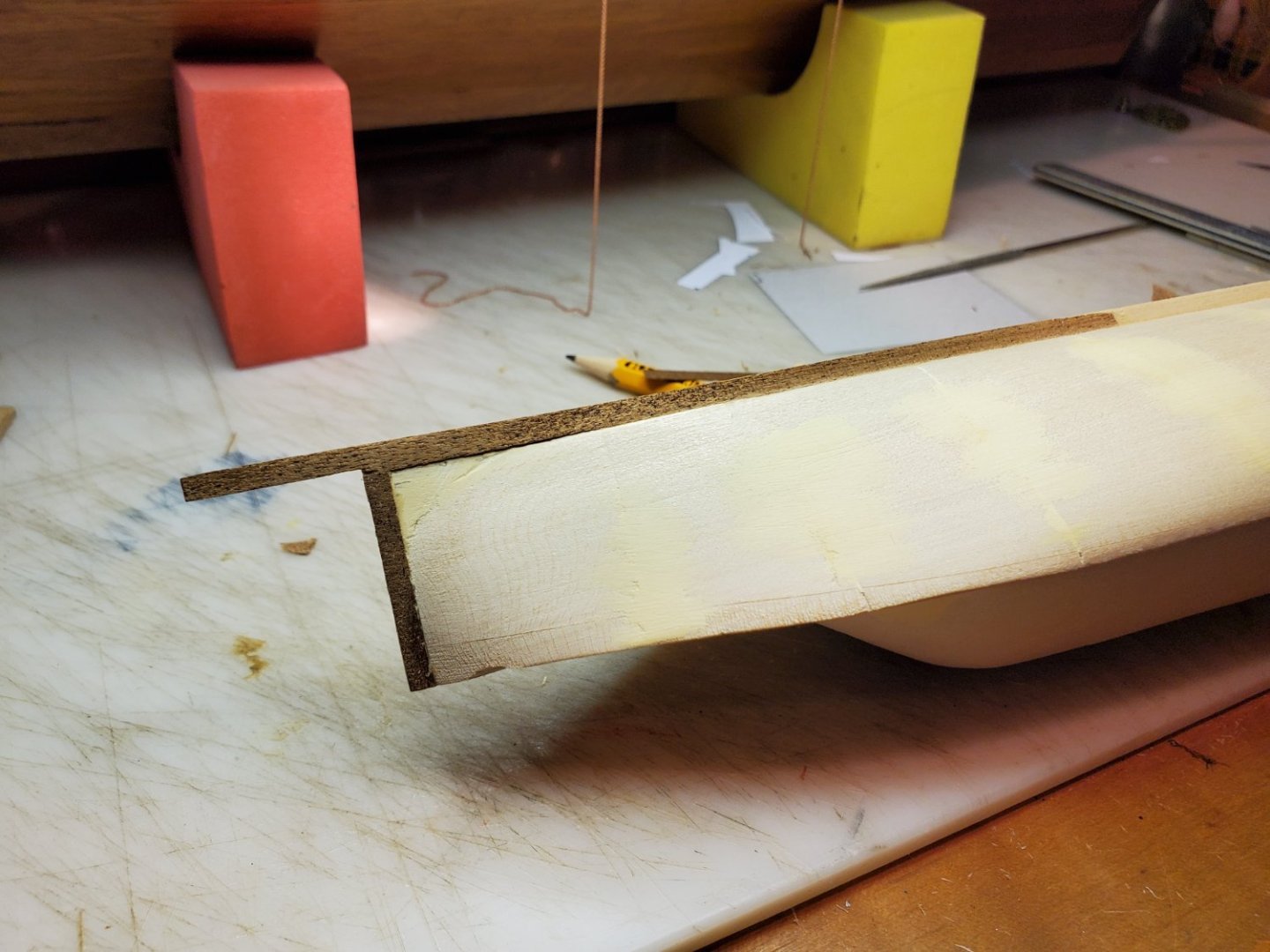

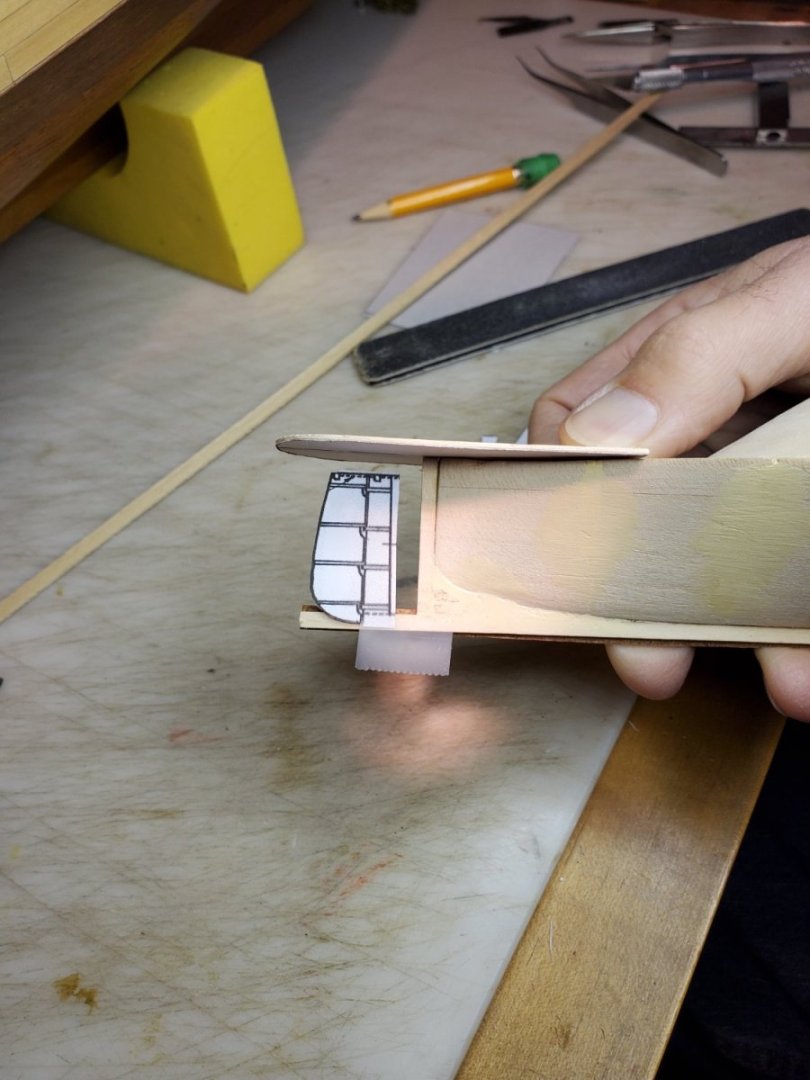

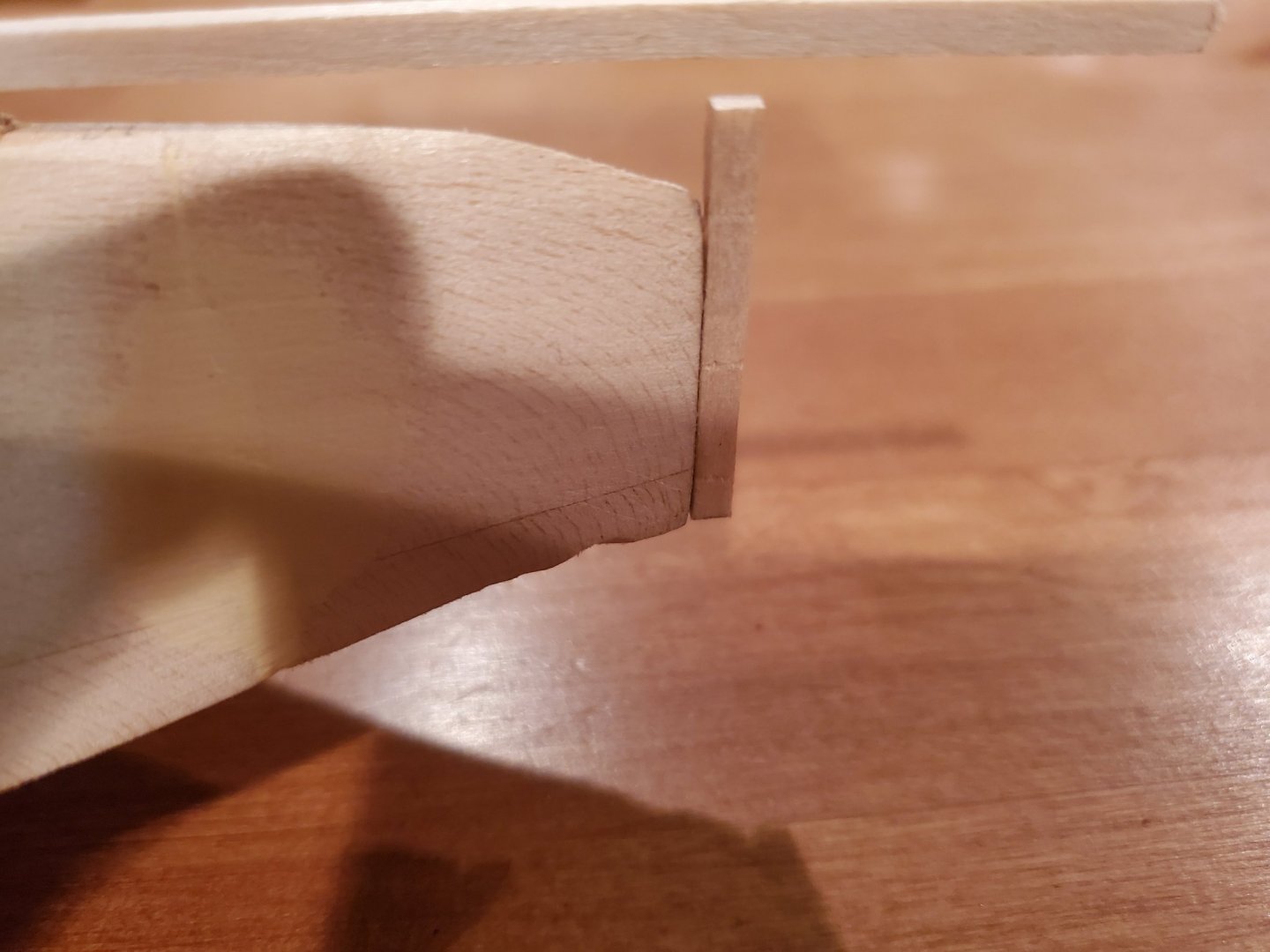

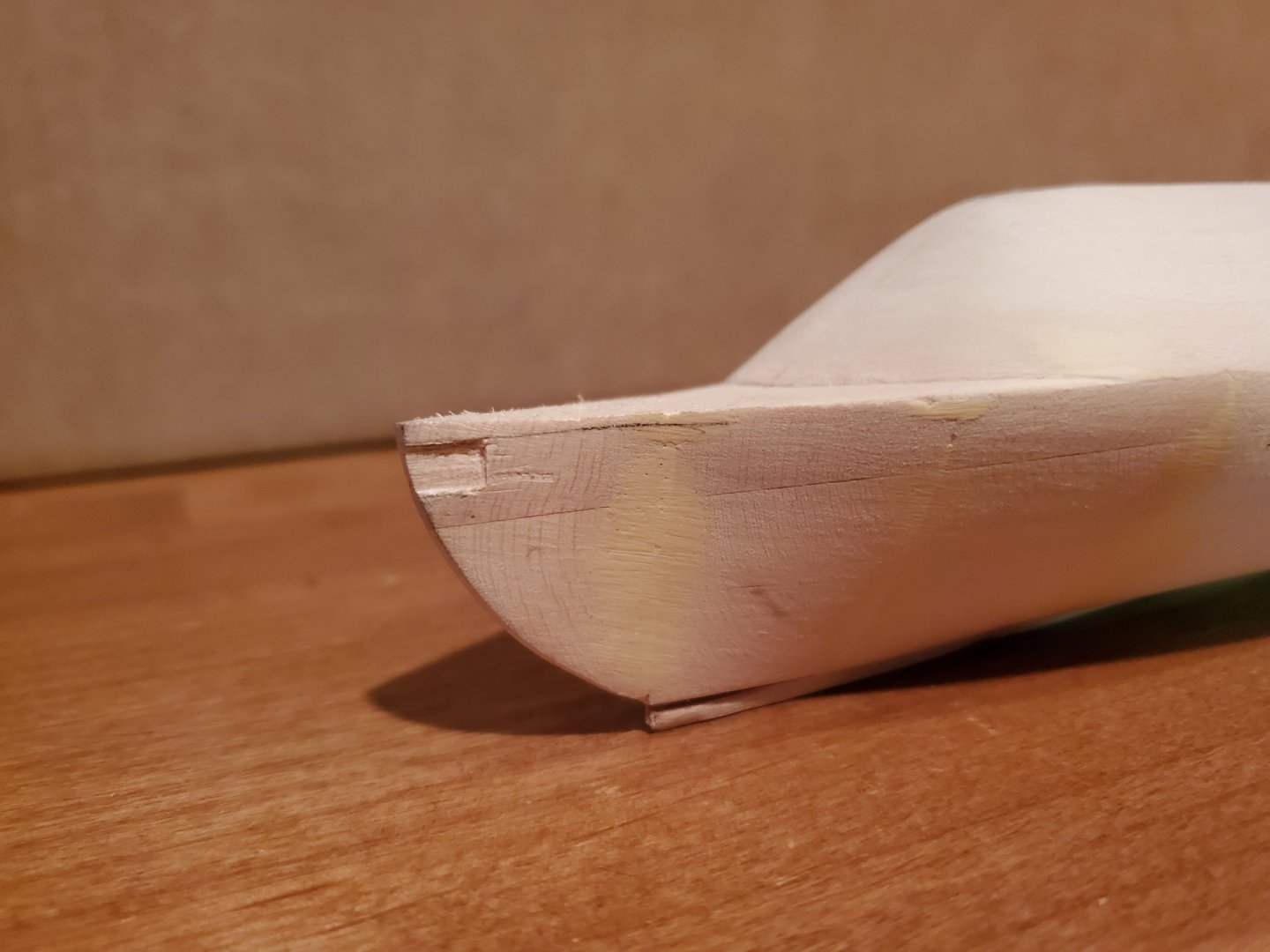

We cut out a thin piece of wood to serve as the top of the ship, in the hope of getting a sharp edge between the top and the sides. It has been glued and clamped in place.

Once the glue dries, we'll remove the clamps and see if any patch work is needed to create a clean, sharp transition from the sides to the top.- GrandpaPhil, Canute and Ryland Craze

-

3

3

-

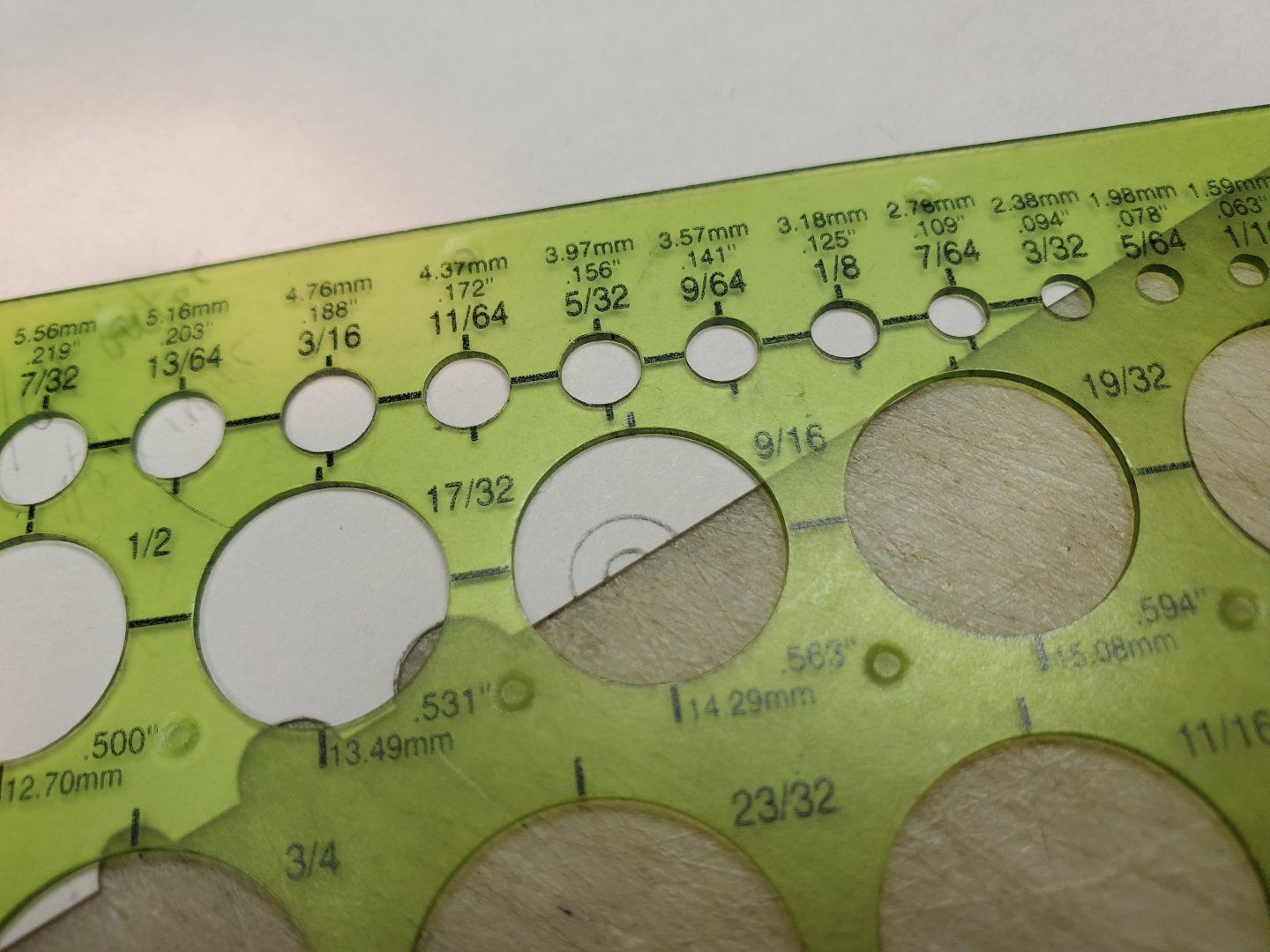

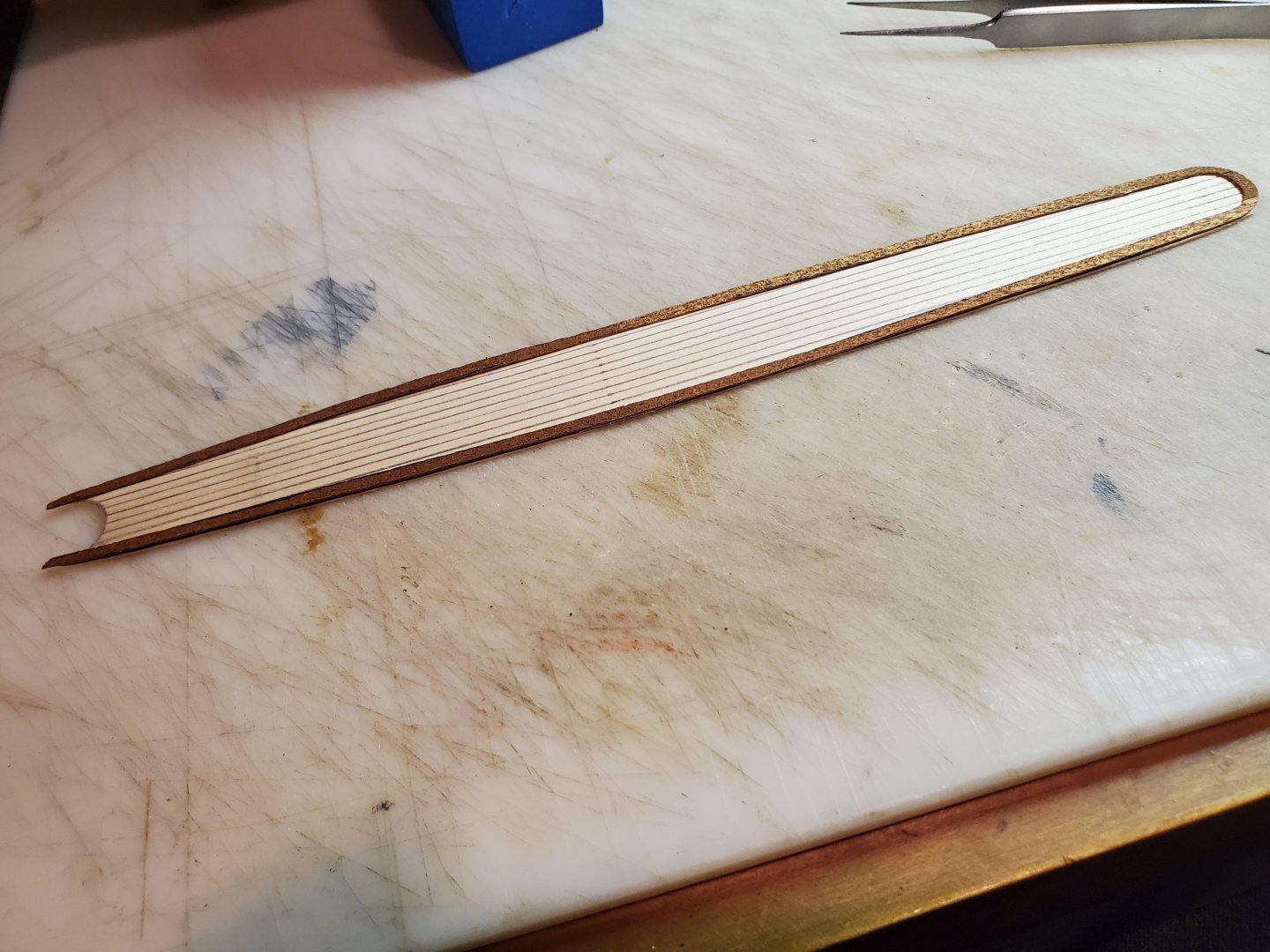

Notice the copper plating along the keel in the previous 2 images. This is difficult at this scale, requiring a 1/16" strip of copper foil. The smallest we could find was 3/16" so I am slicing them in half (not easy!). At this scale, we decided to leave out the nail pattern. This was a test strip and we were pleased with the result. We will continue this once further progress on the model is made.

- Ryland Craze, robert952 and Canute

-

3

3

-

- Canute, Ryland Craze and GrandpaPhil

-

3

3

-

- Canute, GrandpaPhil and Ryland Craze

-

3

3

-

- GrandpaPhil and Ryland Craze

-

2

2

-

- sjanicki, GrandpaPhil and Canute

-

3

3

-

- Canute and GrandpaPhil

-

2

2

-

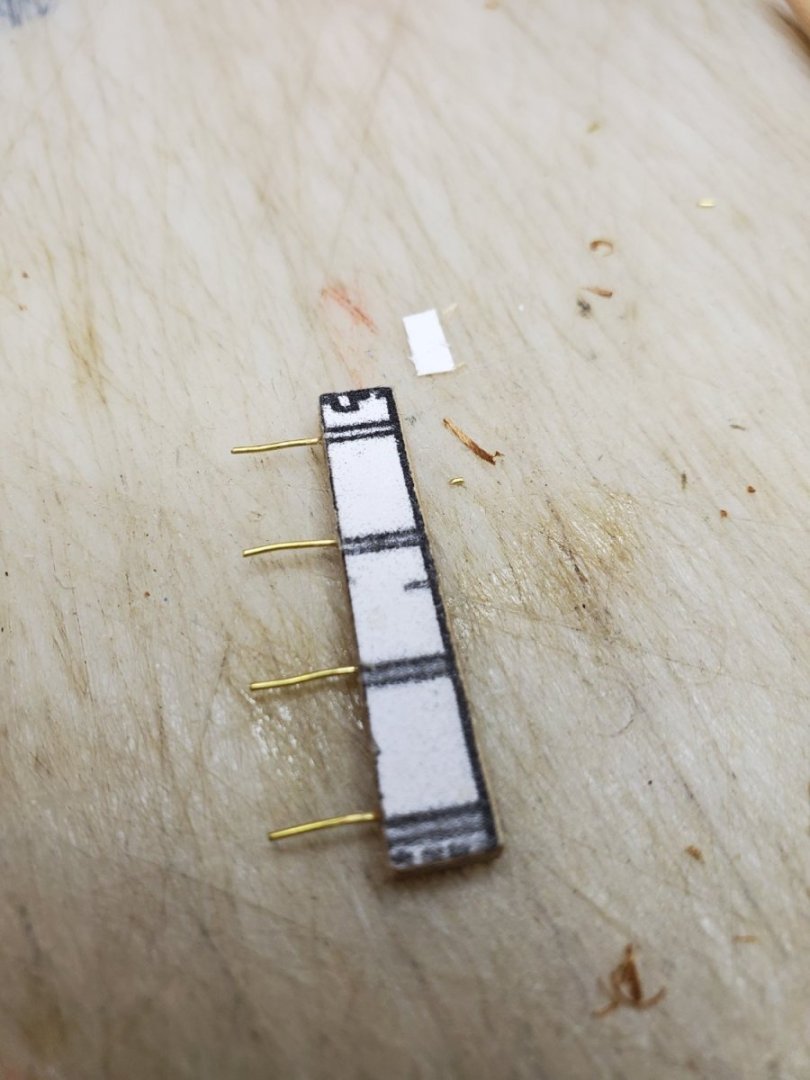

Pintles & gudgeons are not part of the kit. At 1/16 scale, we'll keep it simple. Hat tip to jre8655 and his post from 2013 - we will use a similar technique. Michael drilled holes with a #74 drill and glued in 4 pieces of brass wire. These will be used to connect the rudder to the post and should be concealed when complete.

-

- mtaylor, Ryland Craze, Canute and 1 other

-

4

4

-

- Canute, Ryland Craze, mtaylor and 1 other

-

4

4

-

-

After another long break Michael is returning to this model. During the break, he built the frame of the Chuck Passaro English Pinnace that he was given as a gift, and completed a model of USS Laffey DD-459, which took 1st place in the Junior division at the 40th annual NE Joint Clubs Ship Model Conference on April 29th in New London, CT. New pictures to this build log coming soon.

- Ryland Craze, mtaylor and Canute

-

3

3

-

- mtaylor, GrandpaPhil, Canute and 4 others

-

7

7

-

-

-

- Canute, GrandpaPhil and VTHokiEE

-

3

3

-

-

- gak1965, Ryland Craze, VTHokiEE and 4 others

-

7

7

-

- VTHokiEE, Nunnehi (Don), mtaylor and 4 others

-

7

7

CSS Virginia by cgiacoppo - BlueJacket Shipcrafters - Scale 1:192 - My son Michael's first wooden ship build

in - Kit build logs for subjects built from 1851 - 1900

Posted

It was difficult to get the chain back through the hole. I ended up tying a piece of thread to the chain and then the other end of the thread to a piece of thin wire that I was able to push through. Once the end of the wire emerged with the thread, I used the thread to pull the chain through.