-

Posts

1,291 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtbediz

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I began preparing the masts with the main mast. Using my milling machine, I squared off the top and chamfered the corners, as indicated in the plan. I don't know how much work is involved in completing this task yet. I think too much -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you so much Jon. Great photos, taken from exactly the angles I was hoping for, they will be very helpful. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Jon. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hi Greg, I would be very grateful if you could share photos of the details on the channels. Thank you. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

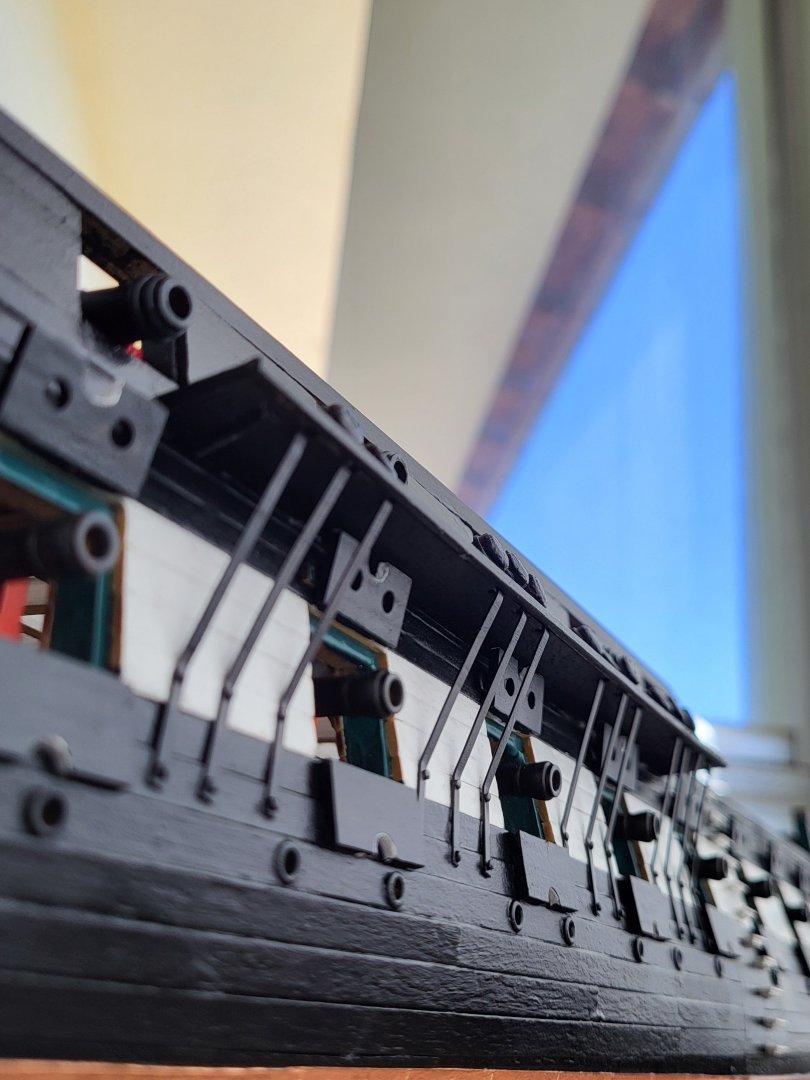

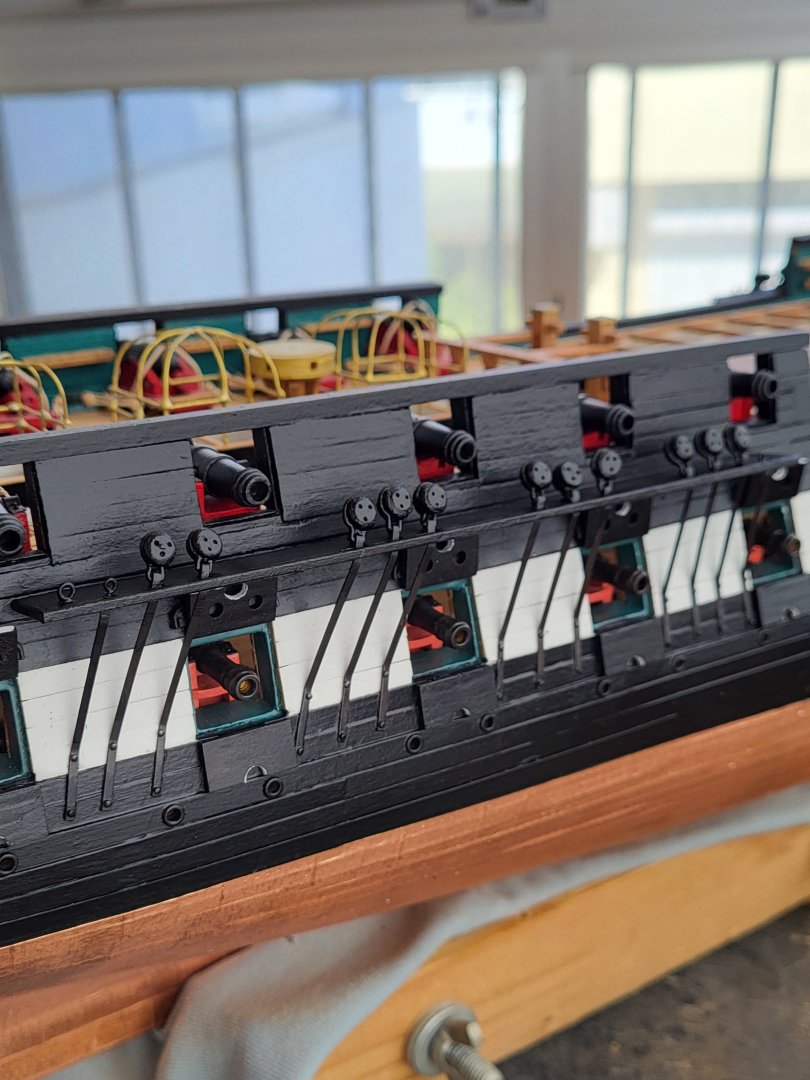

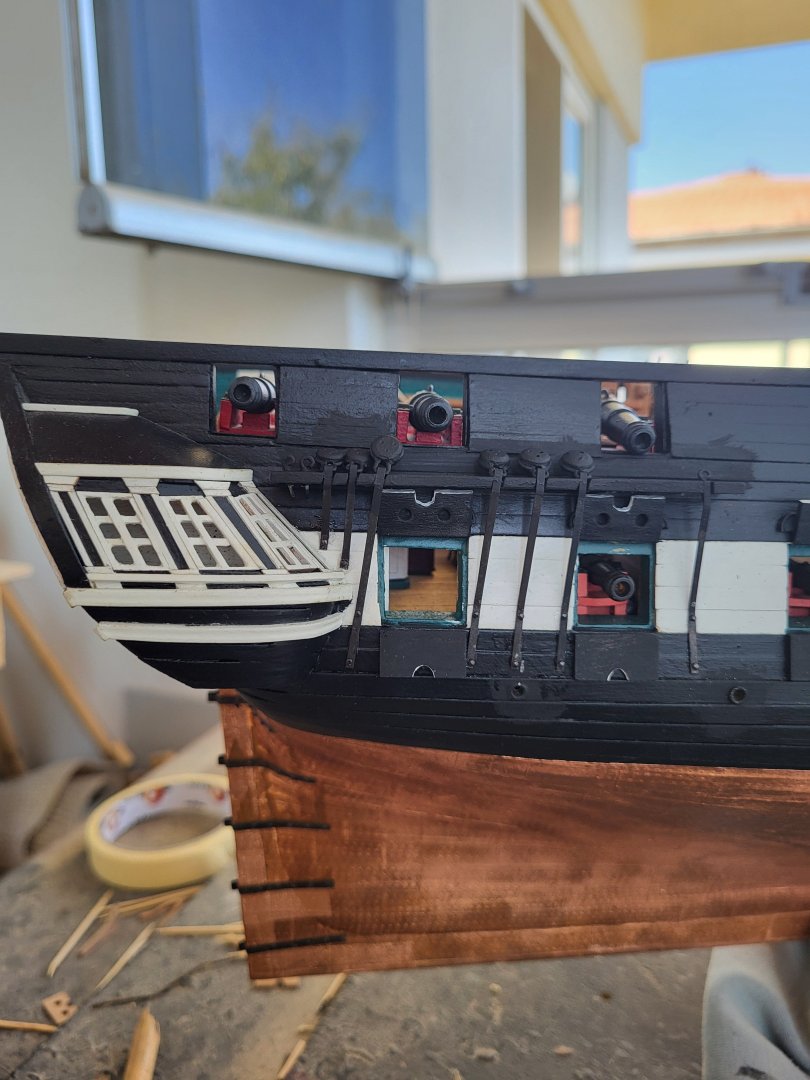

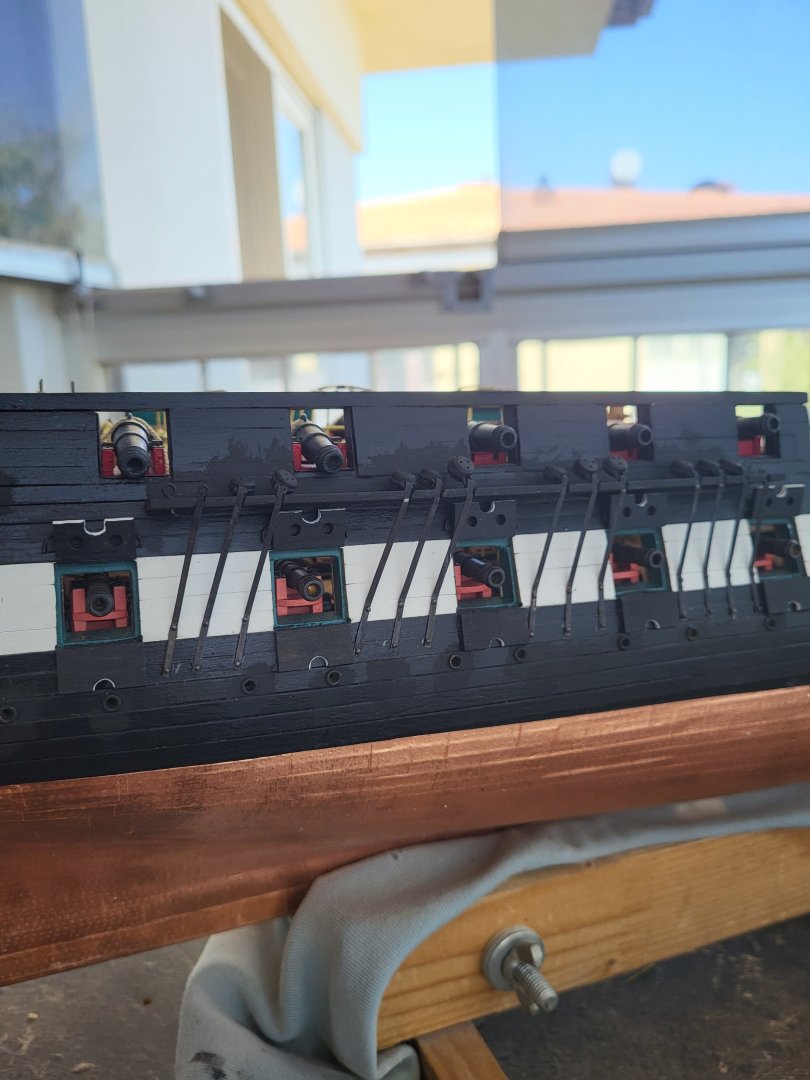

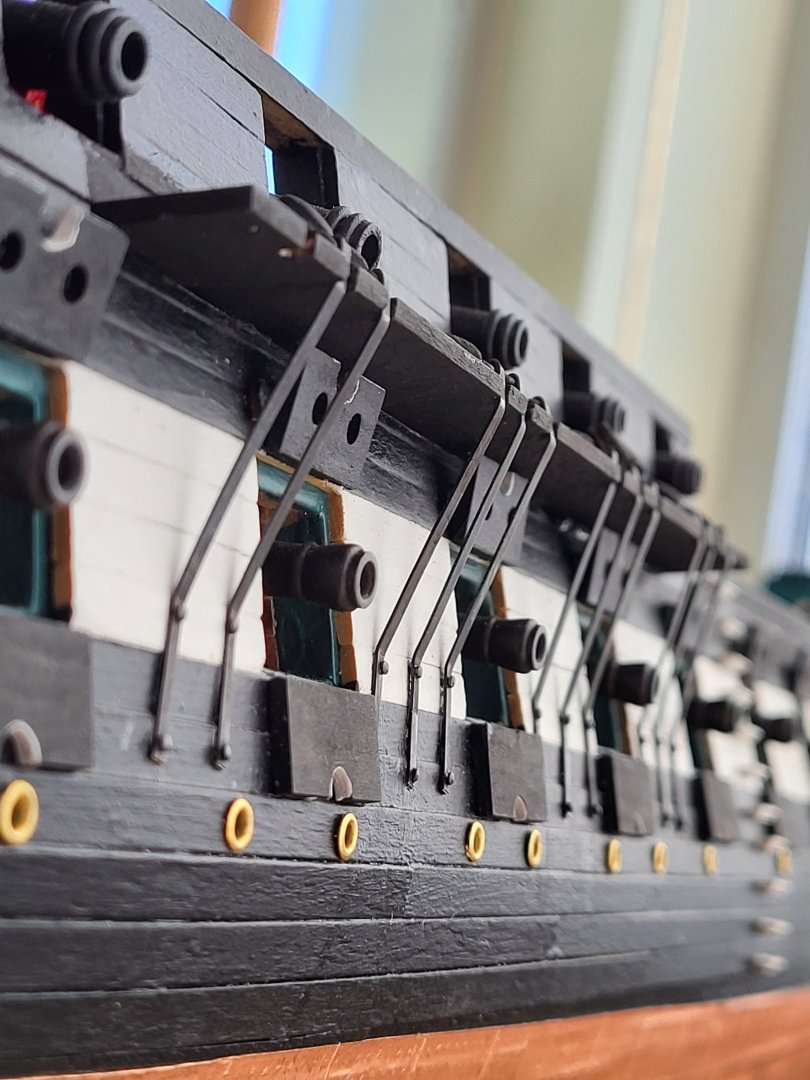

The fabrication and installation of the chain plates is complete. The entire job took 15 days. Unless I'm mistaken, a total of 64 chain plates were installed on the ship. It was a repetitive and somewhat tedious task, but it's finally finished. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

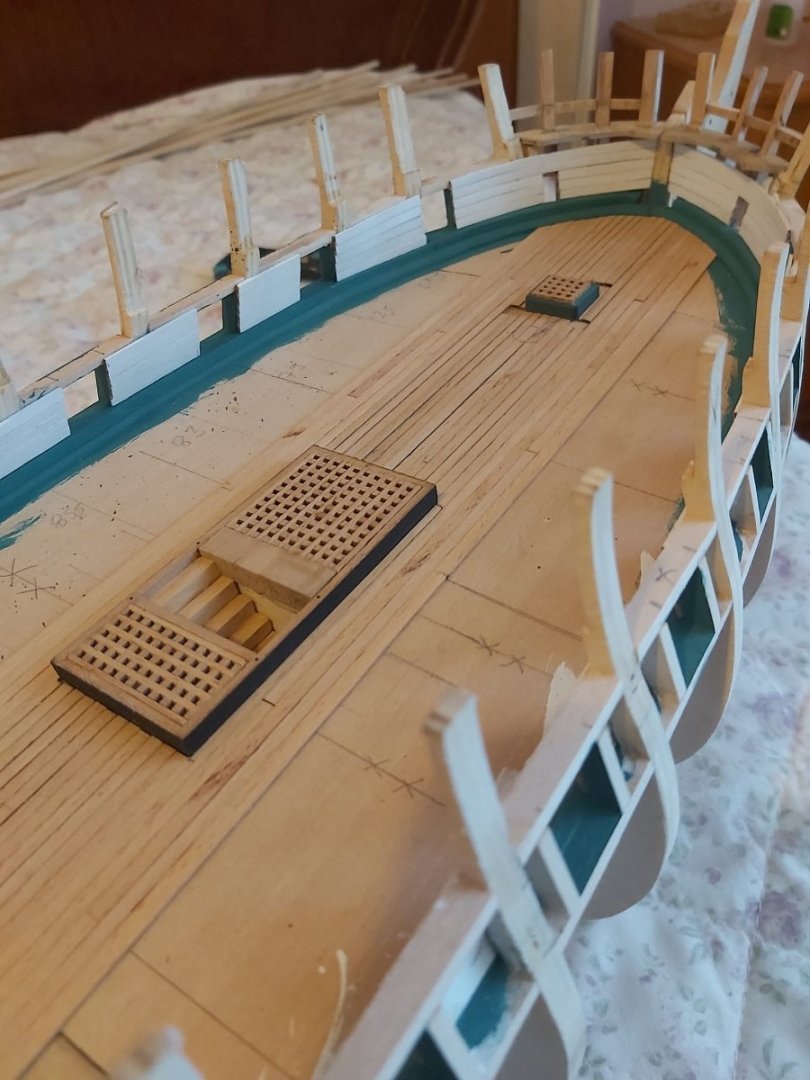

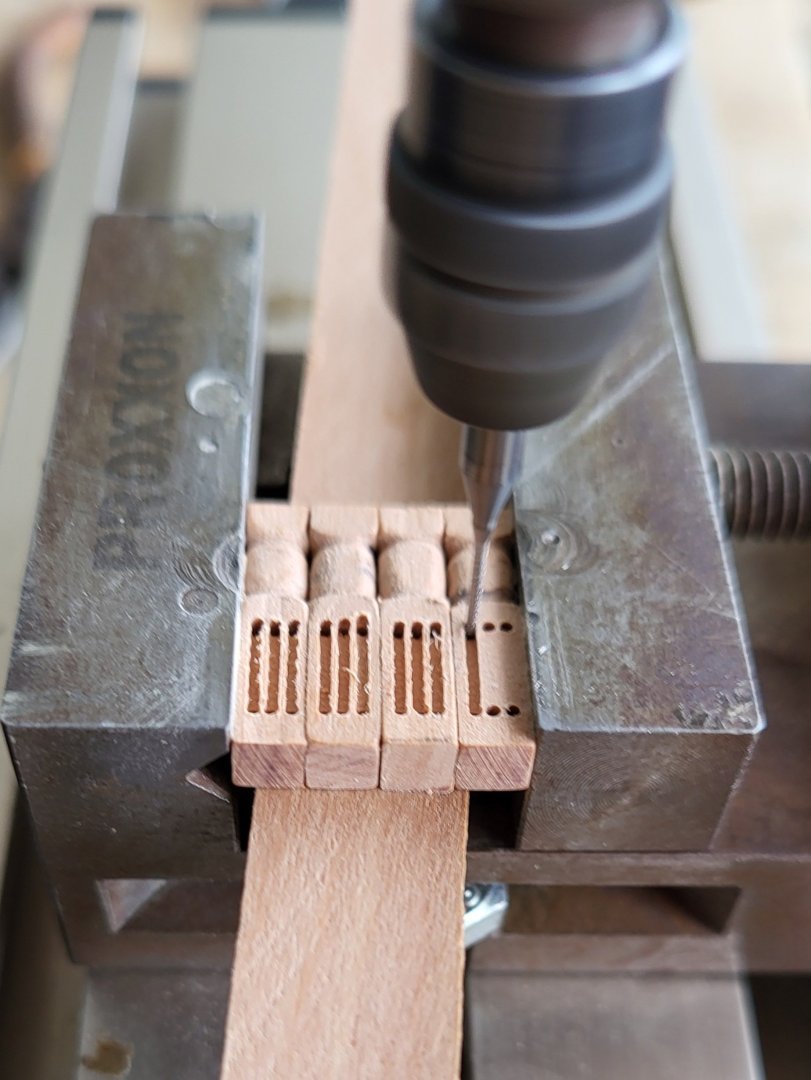

Peter is right, if you look at post #34 you will see that the grate on the bow has changed in size and shape. Actually, I am making a lot of things by looking at the images of the ship on the internet. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Sorry my friend, I didn't understand the question. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

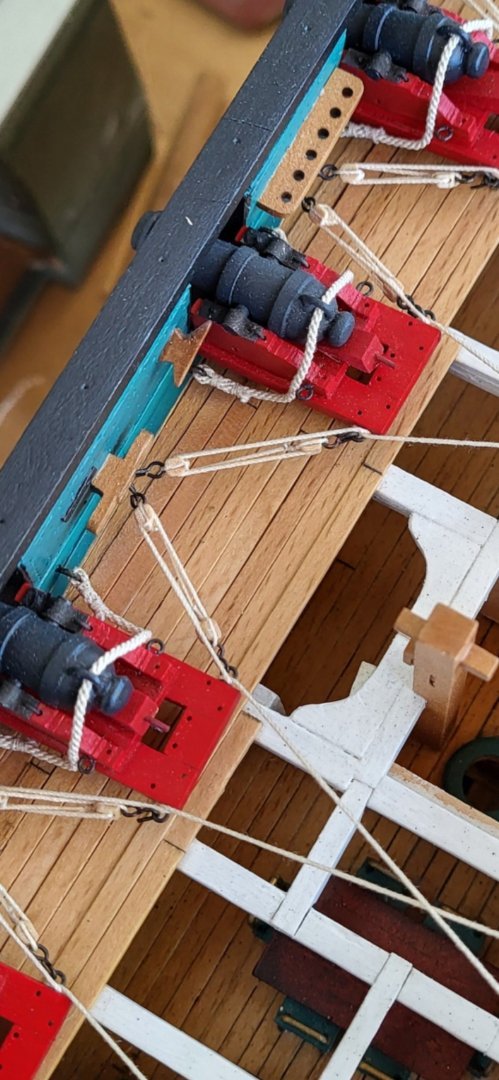

I've often considered sourcing small parts like blocks and deadeyes, which are used in large numbers in sailing ship models, from external suppliers. Sometimes I wonder if all the effort I put into making them myself is really worth it. The quality of the rigging ropes truly makes a significant difference in the overall appearance of sailing ship models. Since I couldn't find a supplier in my country that offered the quality I was looking for, I started making the ropes myself. I was pleased with the results, so I’ve continued doing it ever since. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hi Turcic, I made the eyebolts myself. I used 0.6mm brass wire and the inner diameter of the eyelets is 1mm. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Prepare the tackle outside as shown in the photo and tighten it with a pair of tweezers after attaching it in place. This will make it much easier. -

Here's what actually happened. When I first made the stancions, I tried using the three-jaw chuck on the lathe, but I couldn't get the square part to center properly, so I bought Proxxon's DB 250 lathe-compatible plastic four-jaw chuck and used it to make the stancions. I just realized I didn't show this in my build log. I see you have a four-jaw chuck, too, and can easily turn square parts. So, you won't need to make a shank.

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

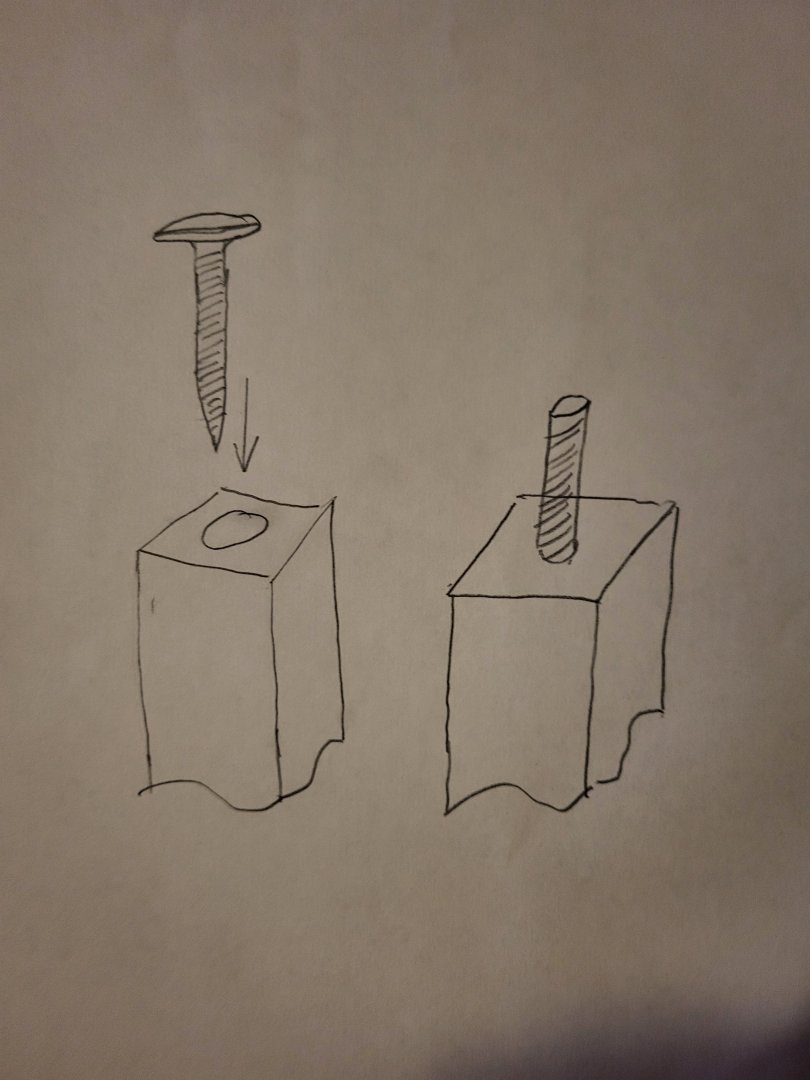

One more thing Peter. To mount a square workpiece in a three-jaw chuck, drill a hole at one end of the workpiece, insert a screw or stud of appropriate diameter, and cut its head to create a round shank. Then, clamp the shank into the chuck. There will be no loosening of the shank since the cutter will apply a force in the tightening direction to the screw while the workpiece is rotating. (Apologize for the terrible drawing. It was a bit rushed)

-

By the way, I sometimes use the milling machine as a lathe. I do this by clamping the workpiece in the chuck and the cutter in the vice. This way, I can move the workpiece (up and down) and the cutter as I please. In this case, the cutter does its job while the workpiece is rotating. Keep that in mind.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.