-

Posts

1,291 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtbediz

-

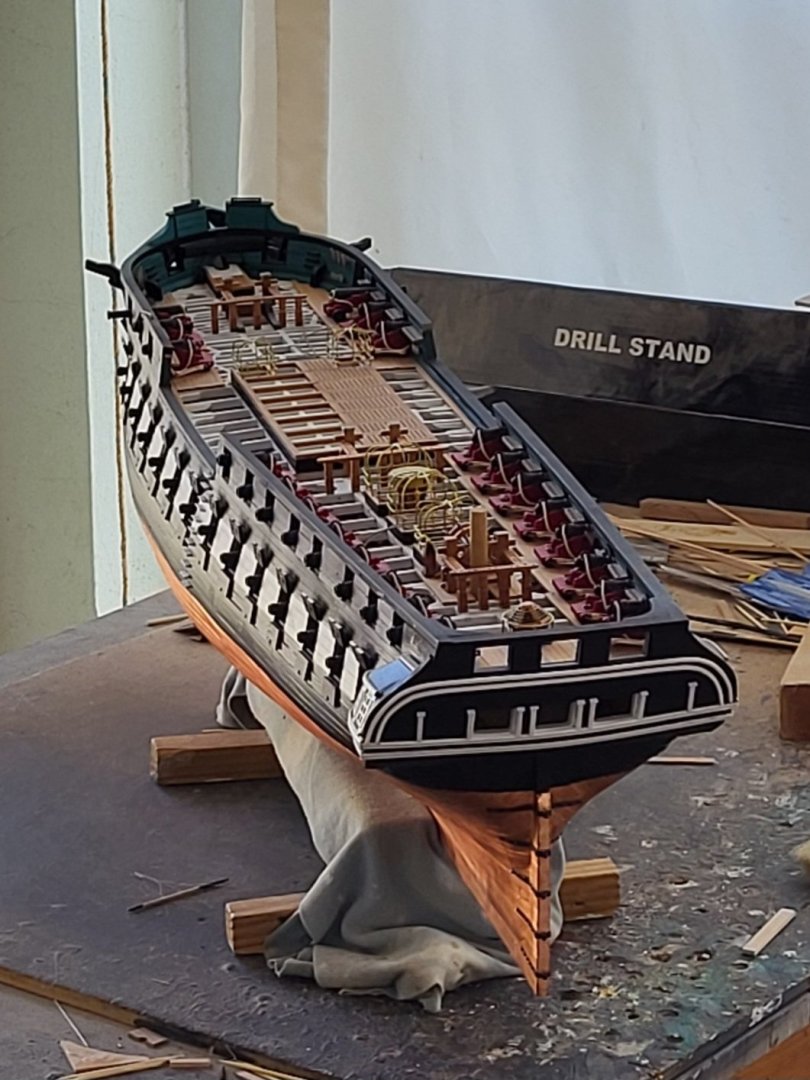

Welcome to the forum. The result you've achieved so far with limited hand tools on this challenging model is truly impressive. There are a few other modelers in this forum, including myself, who are building the same model and sharing insights. You might find inspiration by joining us and seeing how we tackle various challenges.

-

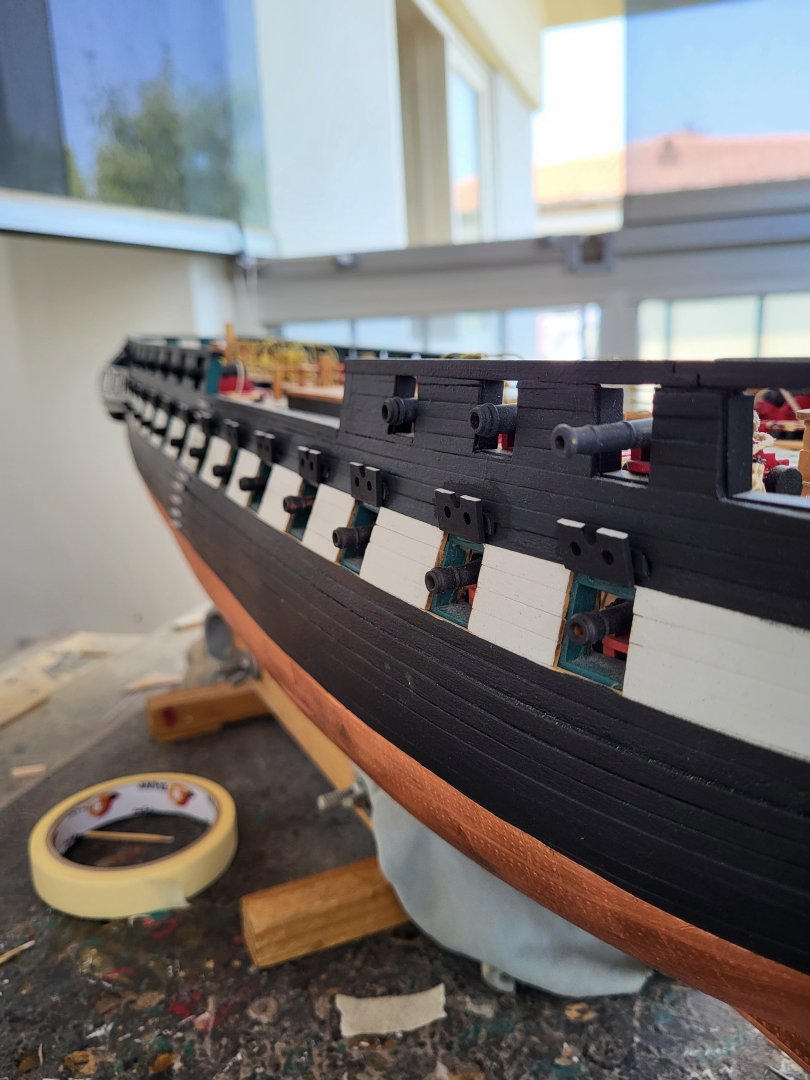

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

My mistake, sorry. When I said "I will remove them" I meant "I will remove the entire channels". Because I will cut the slots on the channels. These pins will also be there when the channels are permanently glued in place -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

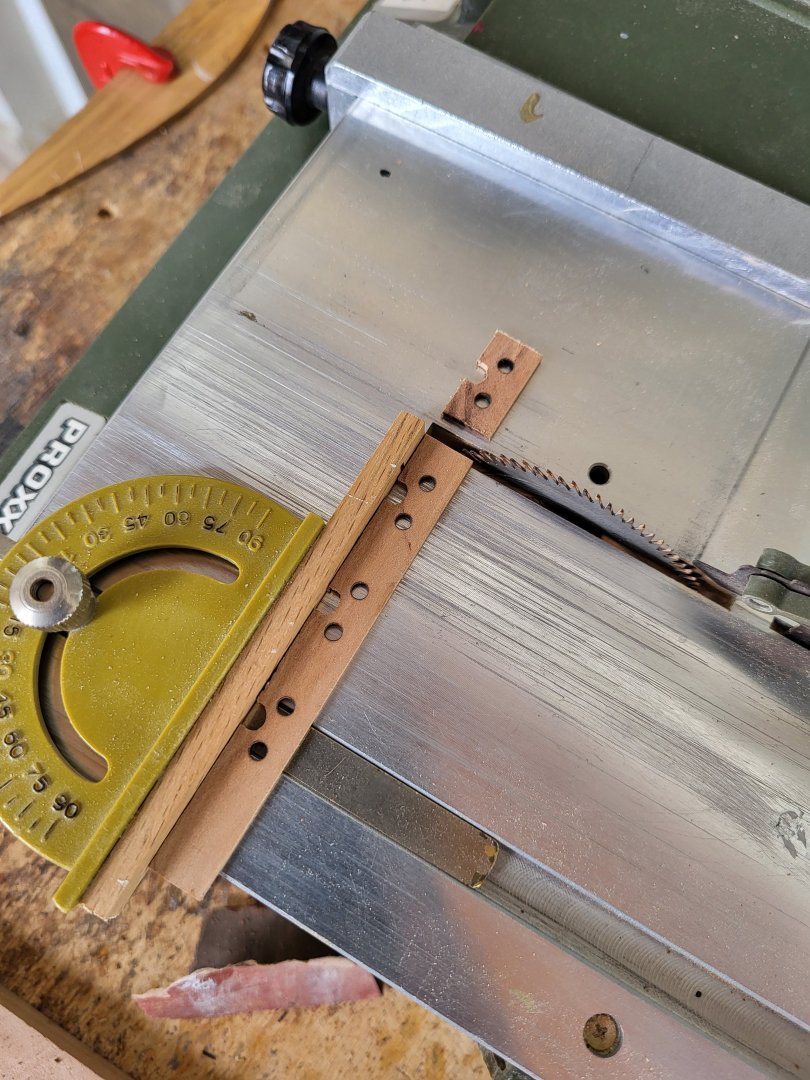

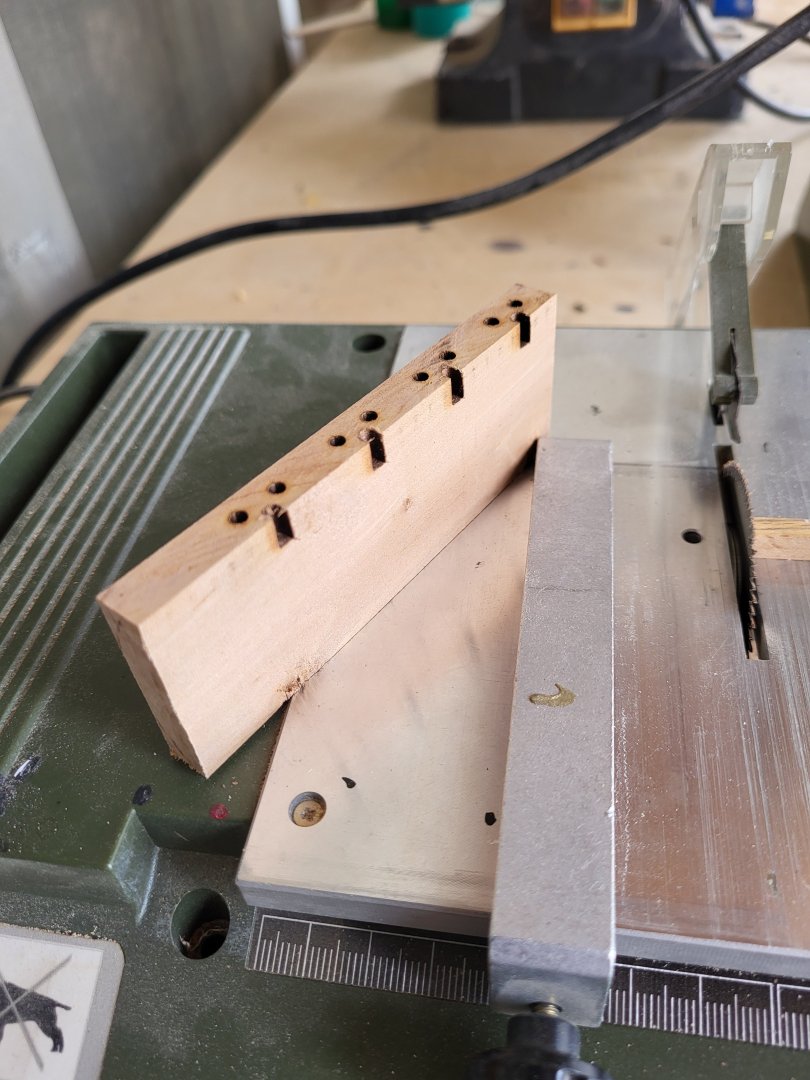

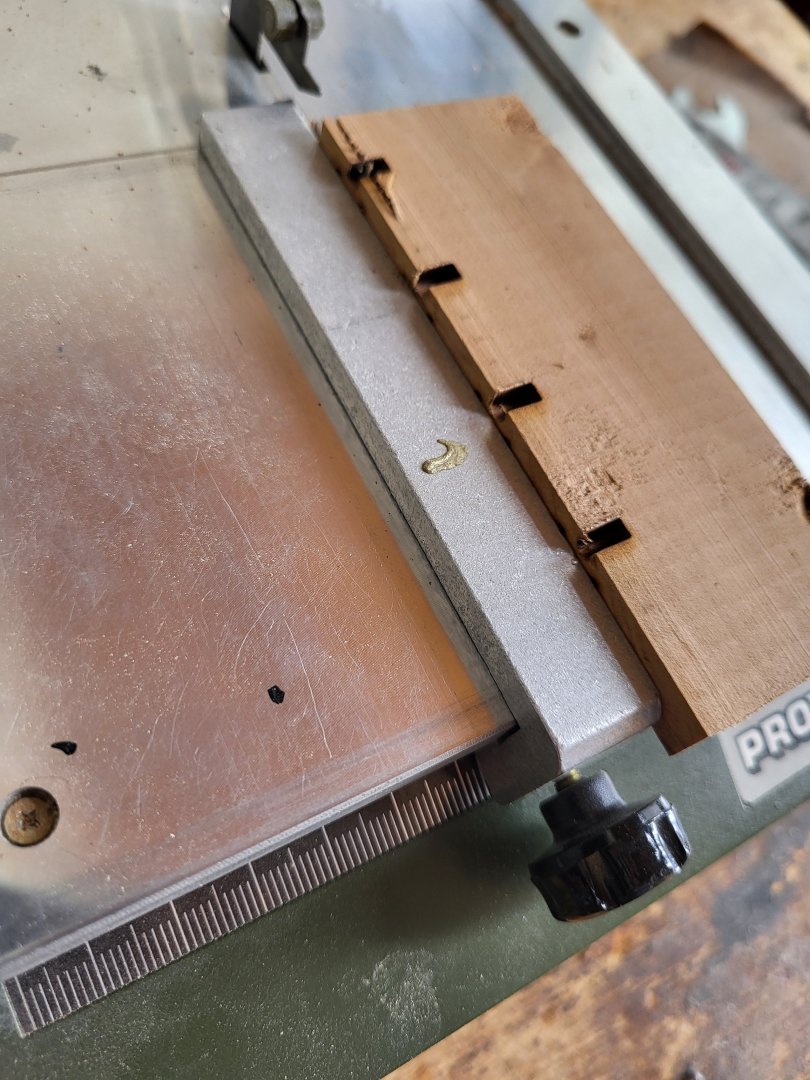

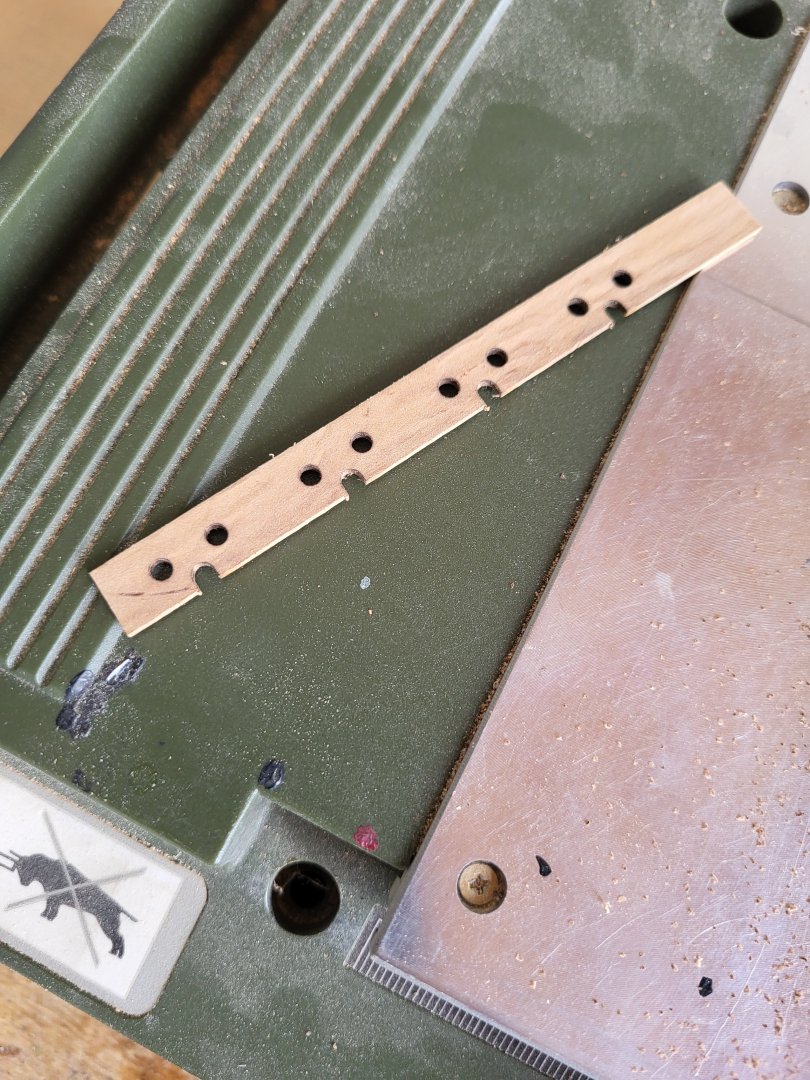

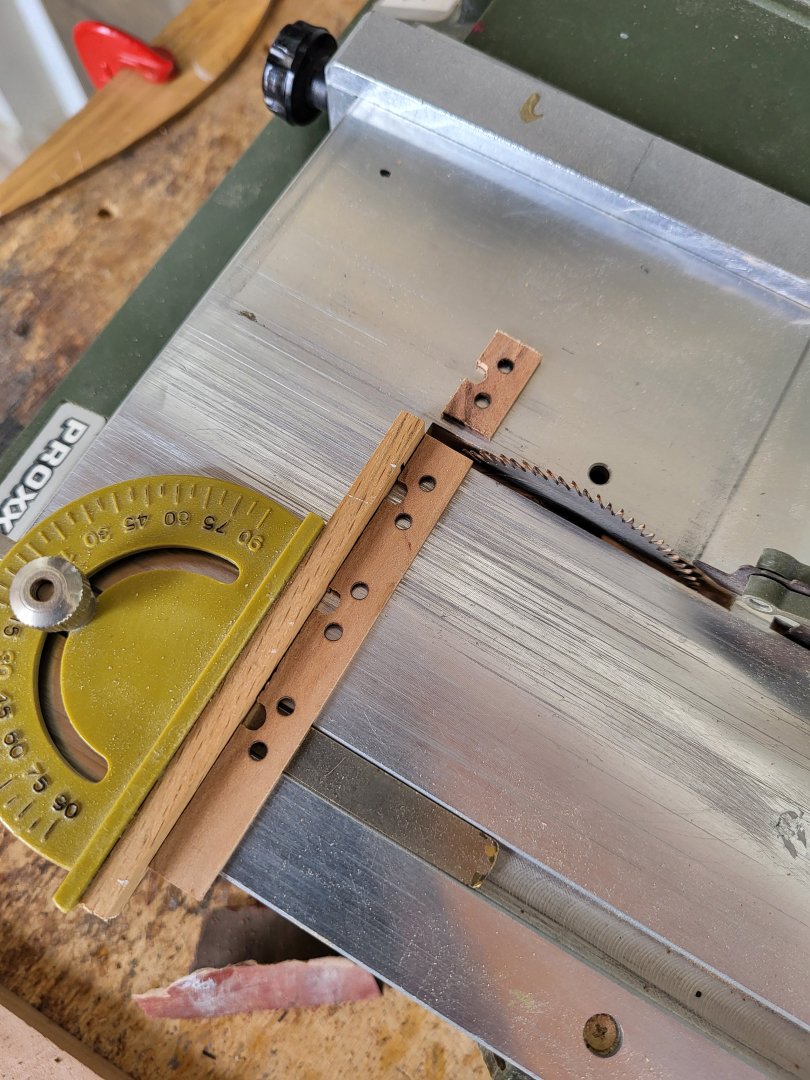

Based on the US Navy plans shared by Jon, I calculated the widths of the fore, main, and mizzen channels scaled to my model. These plans showed that all three channels have different widths. Accordingly, the fore channel is 16 mm wide, which is significantly wider than the main and mizzen channels. I don’t know the reason for this, but that’s how it is. I calculated the main channel to be 12 mm and the mizzen channel to be 11.2 mm. These measurements do not include the strip that will cover the chain plate slots. I cut the channels from 2.1 mm thick basswood sheet and temporarily attached them in place with pins. After marking the positions of the slots where the chain plates will be attached on the channels, I will remove them. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks for your efforts, Jon. The navy plans will be sufficient for me to calculate the correct dimensions. Thanks again. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Next Wednesday, I’ll be shutting down the shipyard again until September, Peter. I’m guessing you’ll catch up and surpass me easily. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Jon. I've reviewed the plans again, and yes, there are some details, but I couldn't find any information or drawings regarding the width and thickness of the channels, which is what I need. I’d be grateful if anyone who can see these dimensions could let me know. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hello friends. I couldn't see the channel drawings in the MS kit plan sheets. Do they really not exist or am I just not finding them? Thanks. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

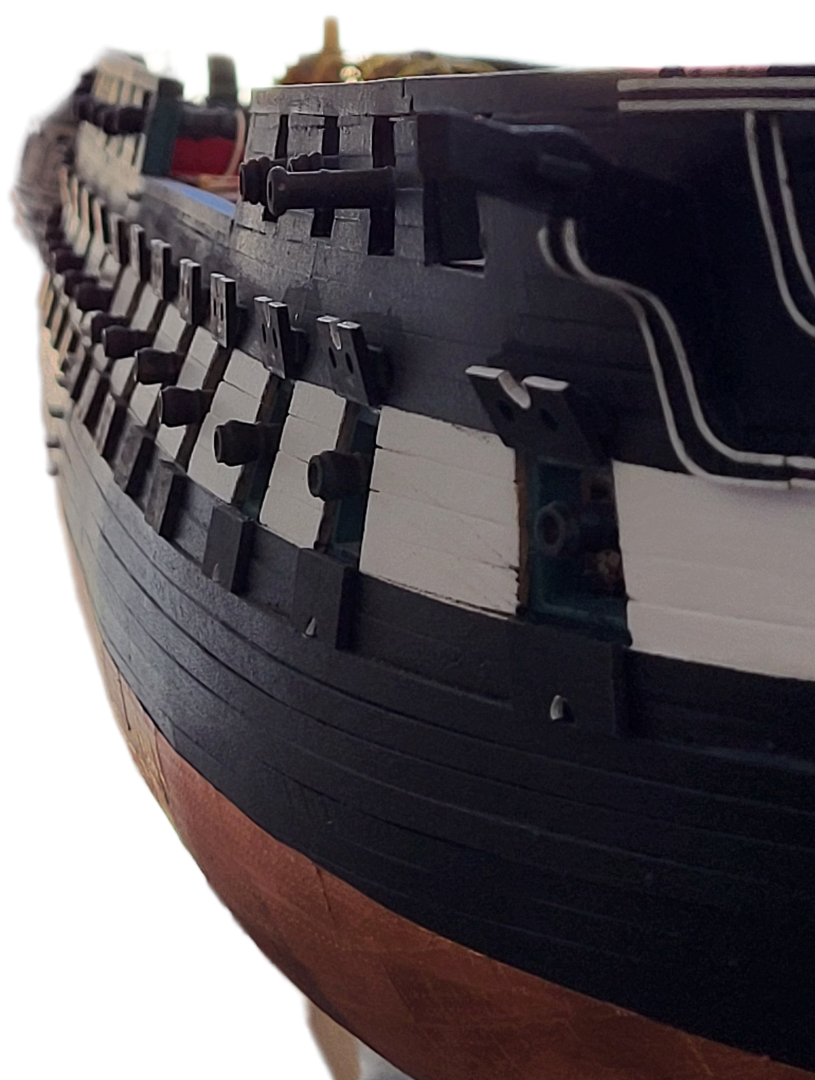

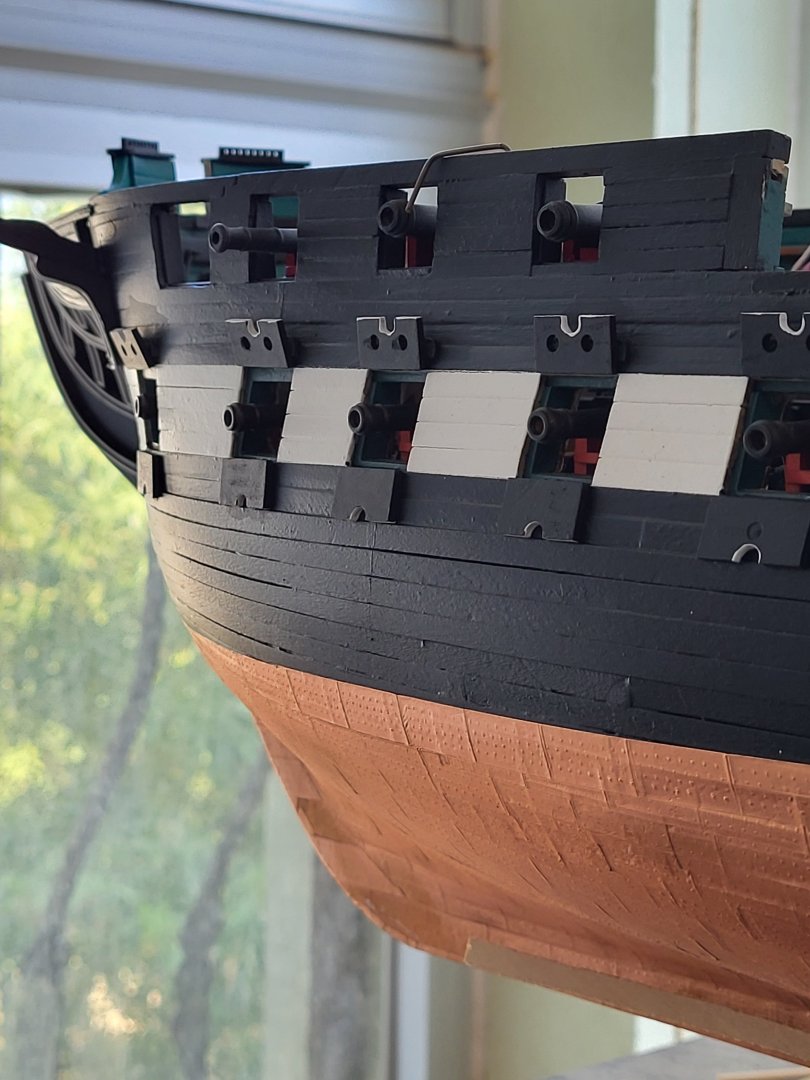

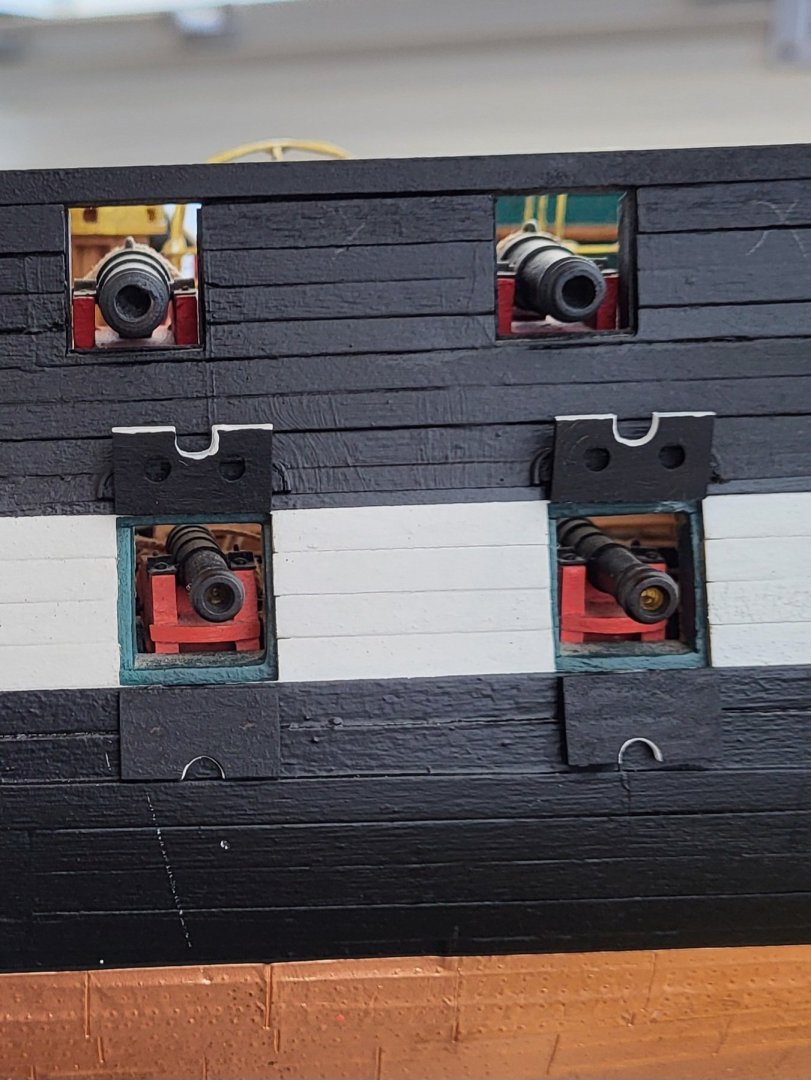

Yes, exactly that was the reason why I installed the curtains a little bit above the gun port. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

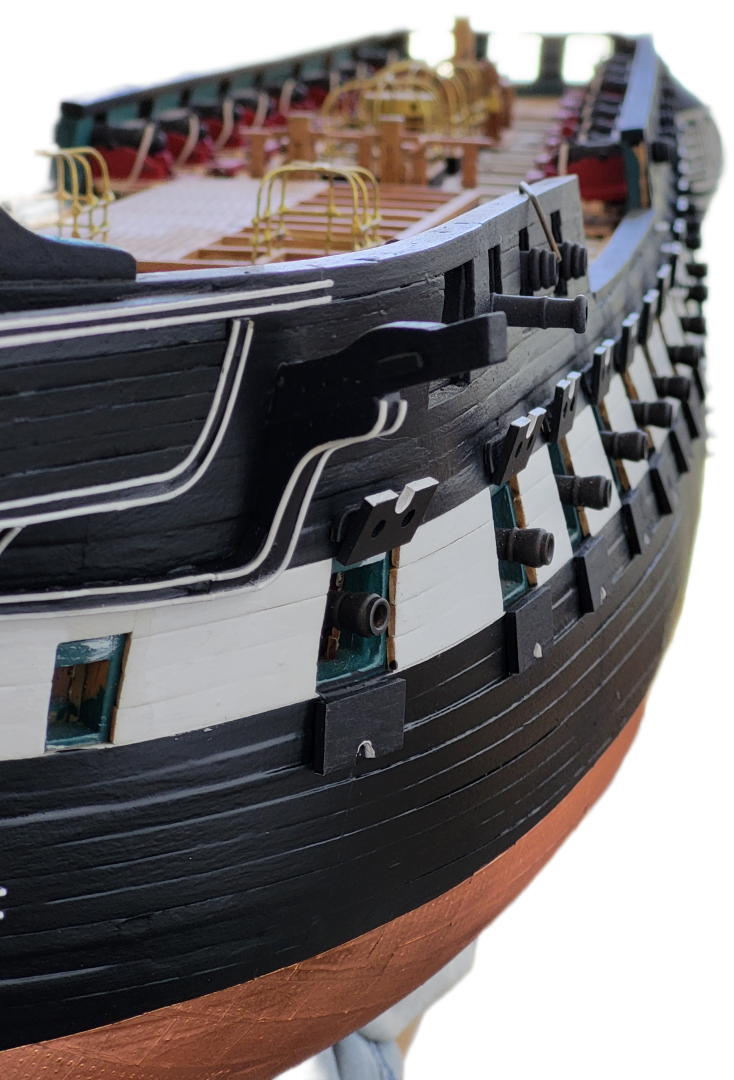

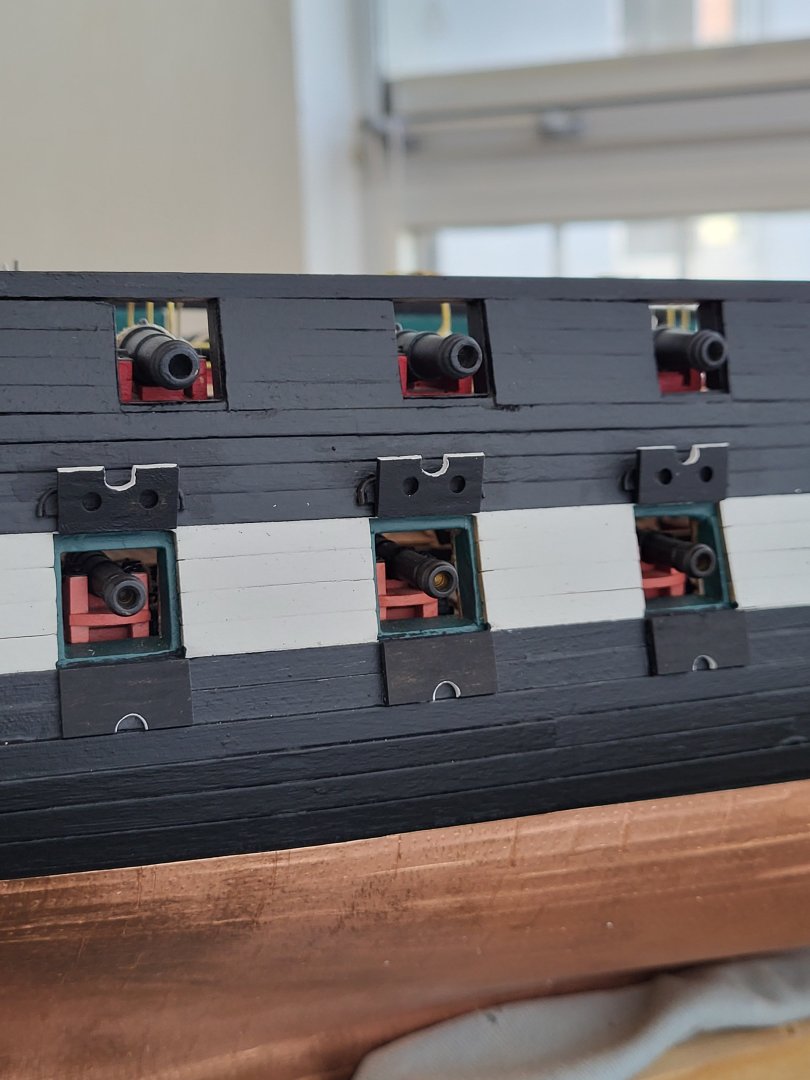

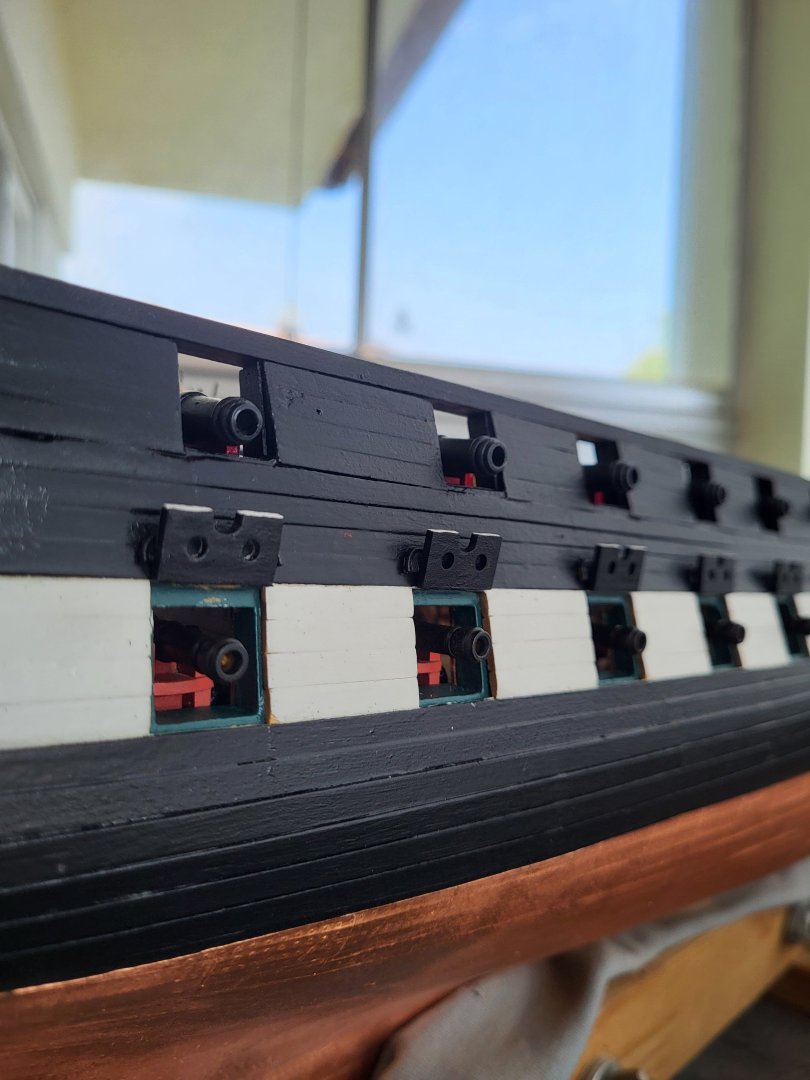

I'm back at the shipyard for a few days and took the opportunity to start making the gun port lids. I will leave the lids in the open position. I didn't add the lid hinges since they wouldn't be visible anyway. I glued the lids directly to the top of the ports. -

I think the photo I shared in my previous post, taken on the real ship, is being overlooked. In the photo, it is clearly seen that the hook is perpendicular to the eye. However, I apologize if I caused confusion on this matter. Of course, the model is Peter's and he is free to make it however he wants. Mine was just a suggestion.

-

Thanks for the explanation Peter, I liked your method. I am sharing my own method for the friends who follow. So it will be a second alternative for them. I pass the rope through the hole of the hook, wrap it around the block and tie a simple knot. I put a small drop of CA on the knot and cut the excess of the knot after it dries. Unless you look very carefully, it is almost impossible to see these knots on the model with the naked eye. This only takes me 1-2 minutes.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpeg.bc306c64021d0ca9ec82ad14c1c7c8de.jpeg)