-

Posts

415 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Beckmann

-

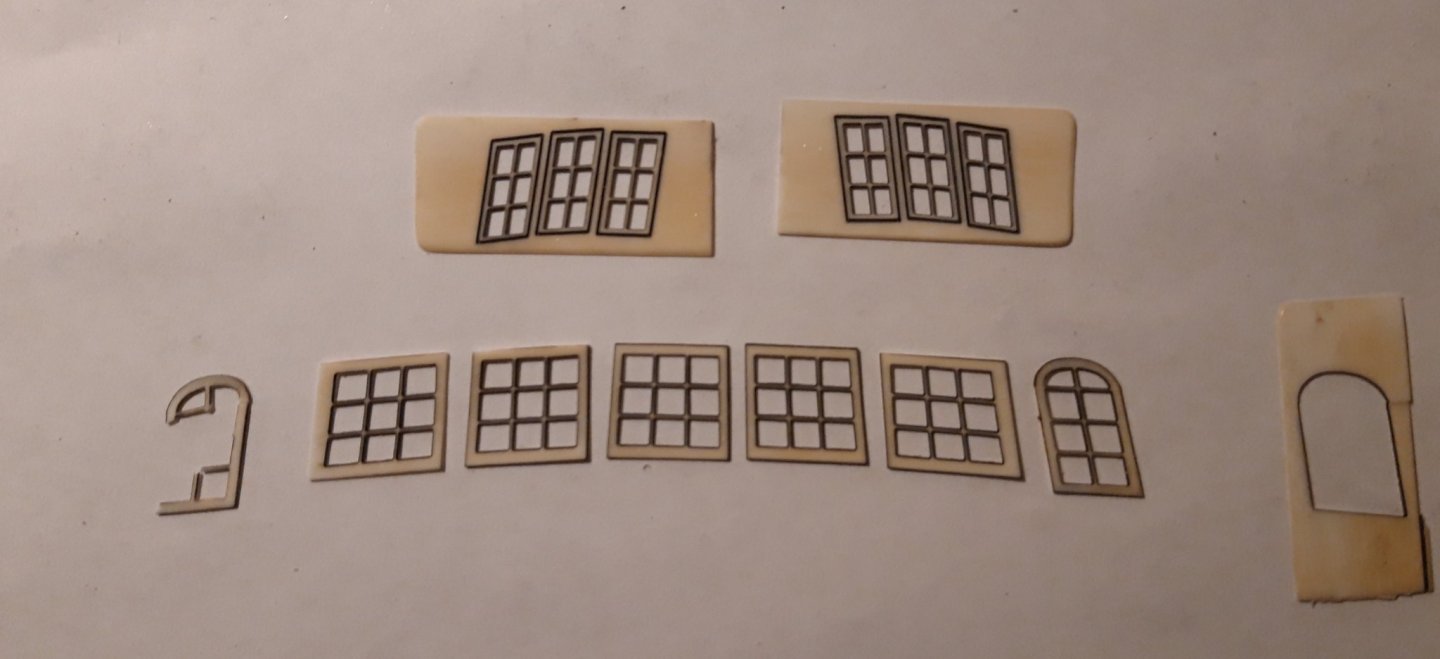

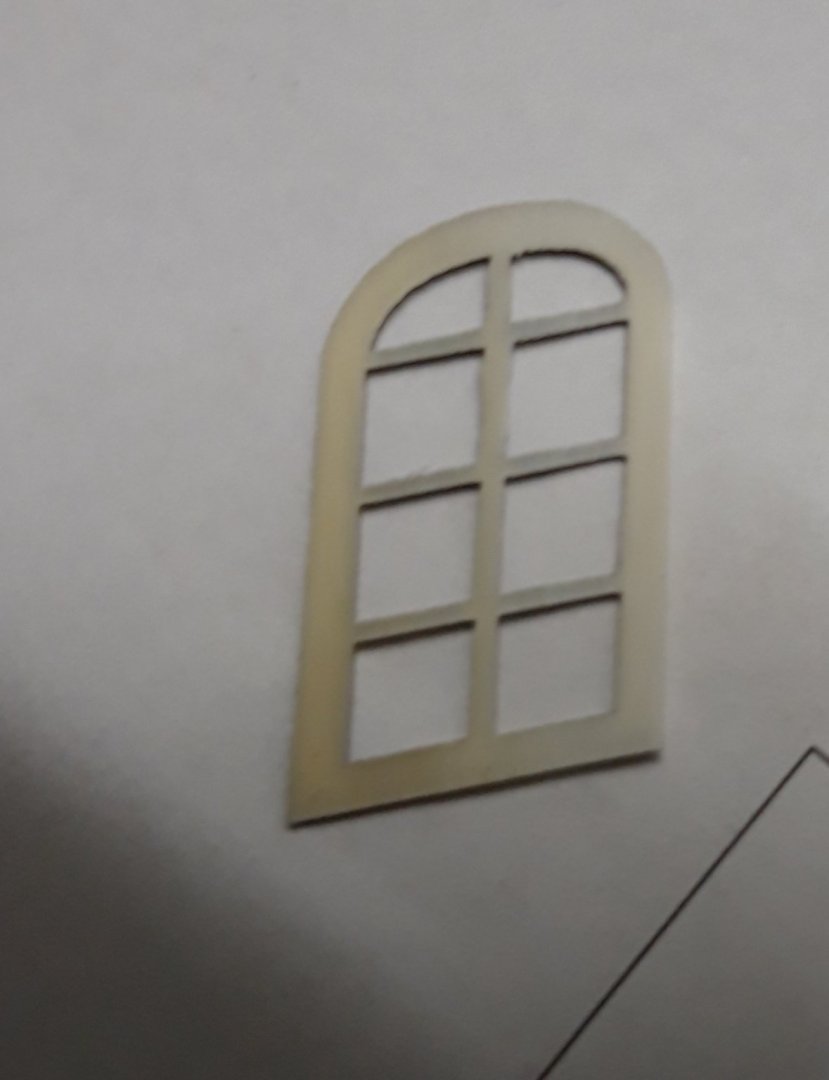

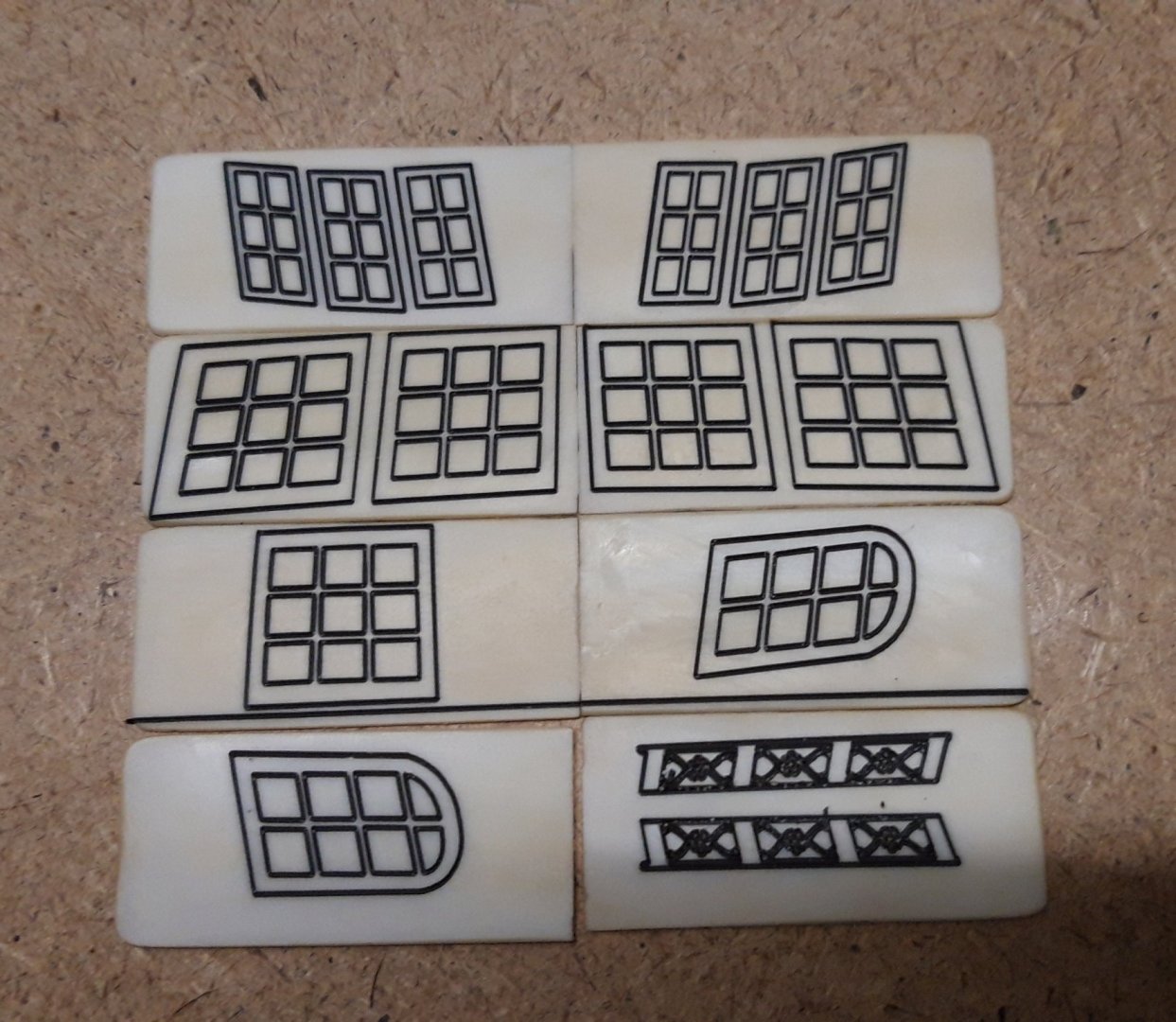

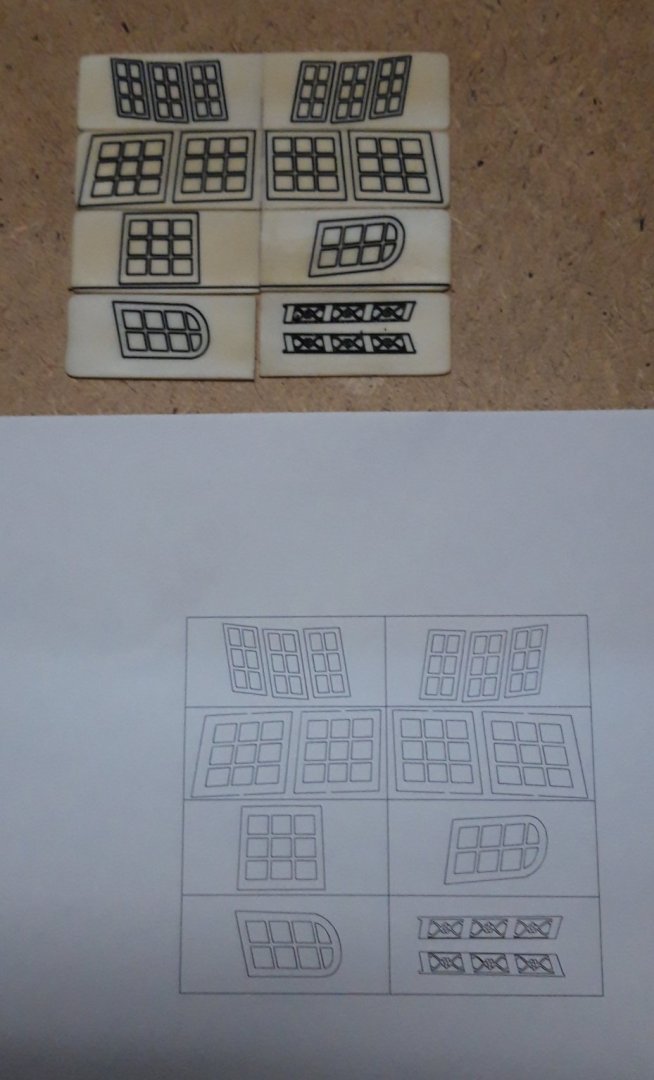

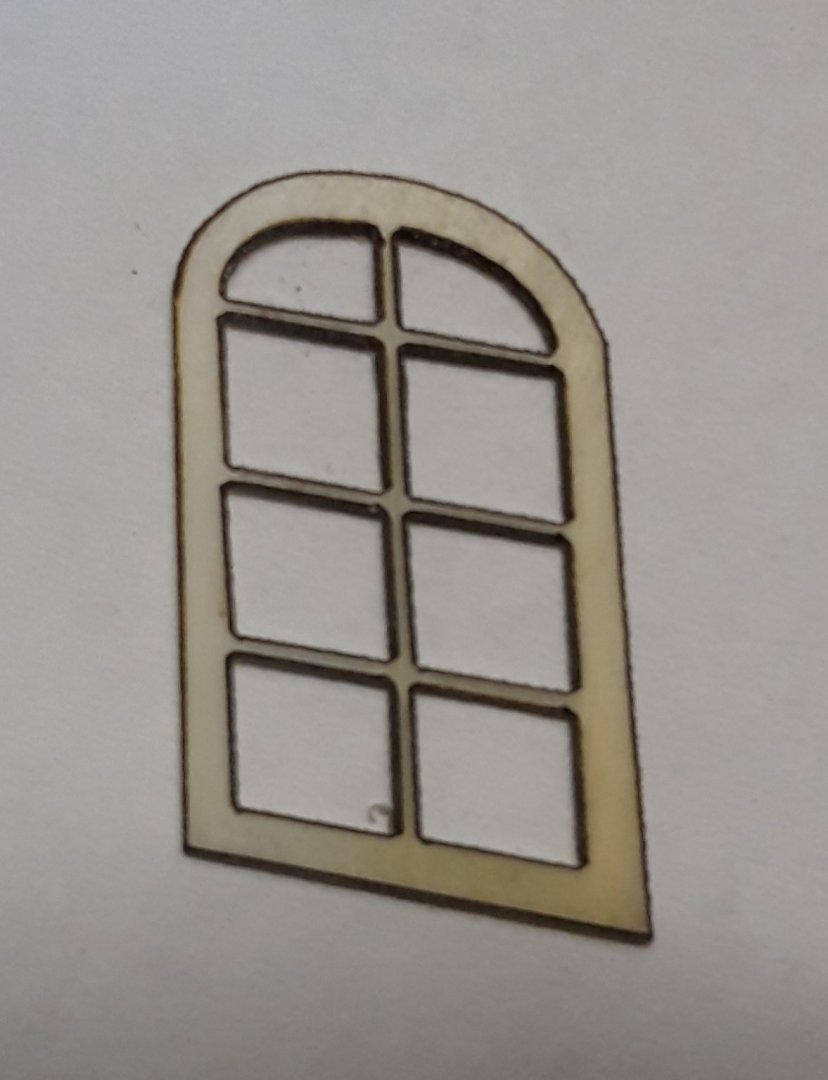

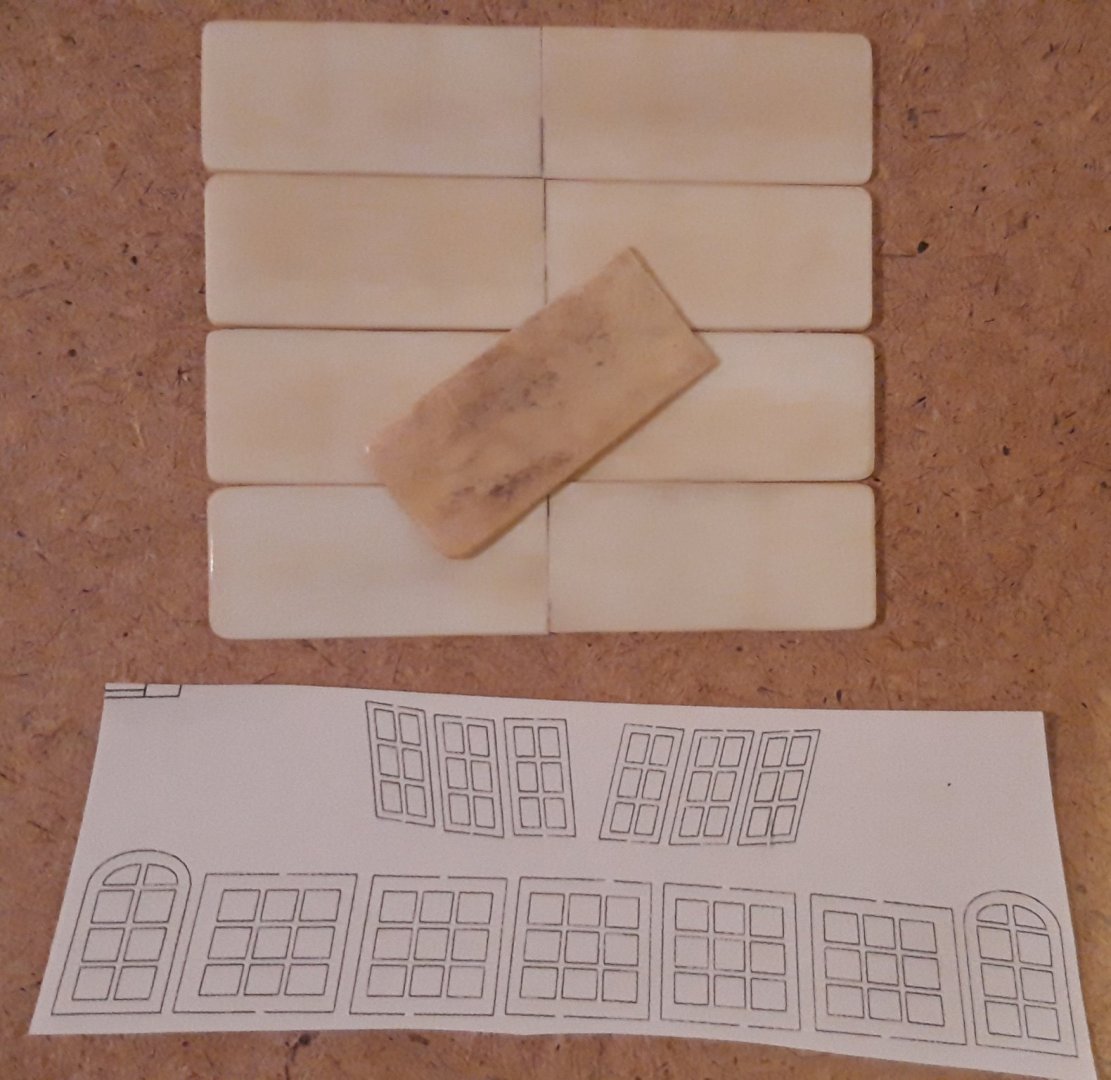

Here we go with my ivory experiment. As I said above, I use some old piano keys, wich are about 100 years old. I had to clean them, for they are very dirty. Then I made a CAD-drawing from the windows. An old woman! who runs a laser-cut-company nearby made the cutting for me. It was not easy, because eather the ivory gets yellow or it doesn't cut through the material. But she did a good Job and this is the result. What do you think? The upper side withe the laser char. the backside without the char. I am not shure, which one I prefer. The little fence for the quarter gallery broke into pieces when I cut it lose. It is just too delicate.

-

Hello Mike, your Winni Looks fantastic. Are you going to nail all the planks or not? Matthias

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

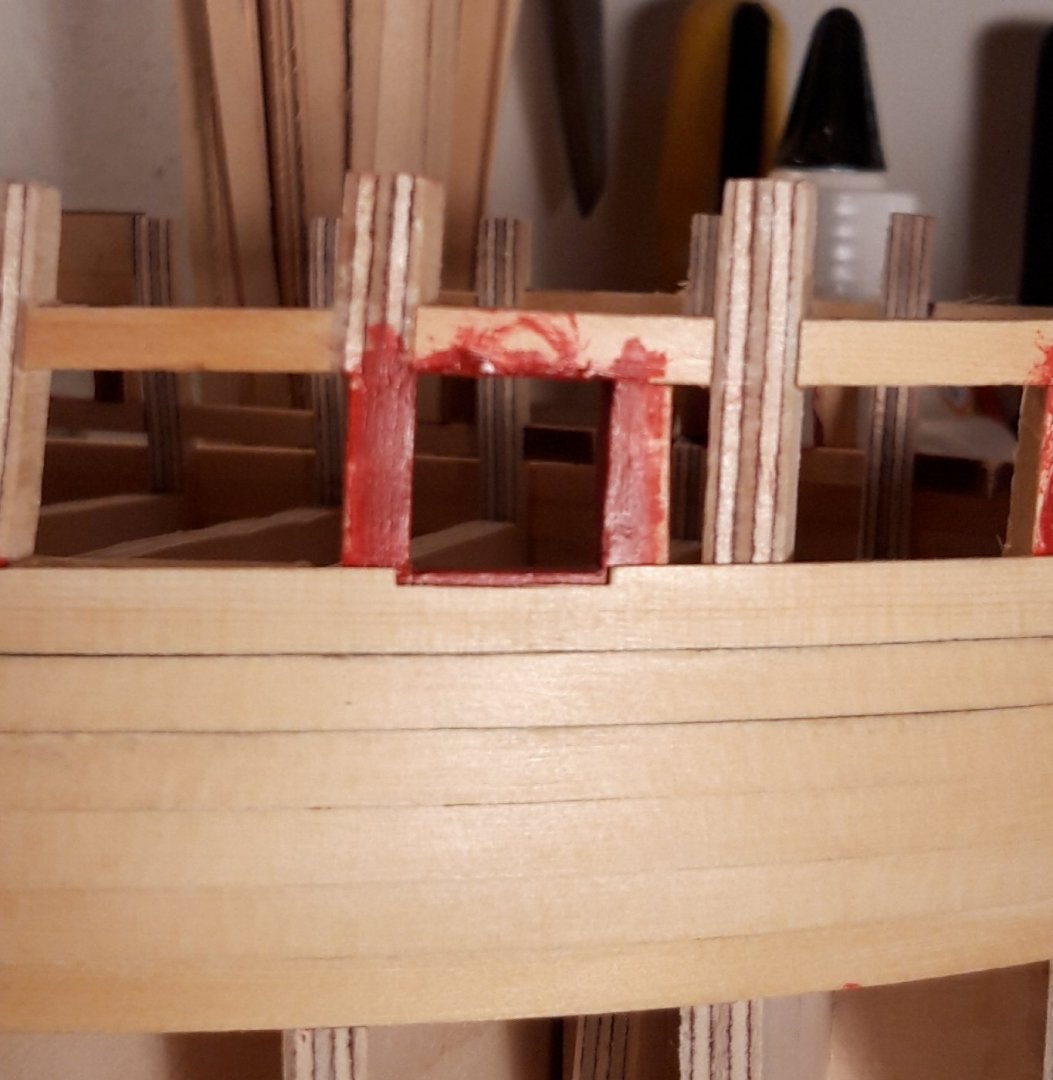

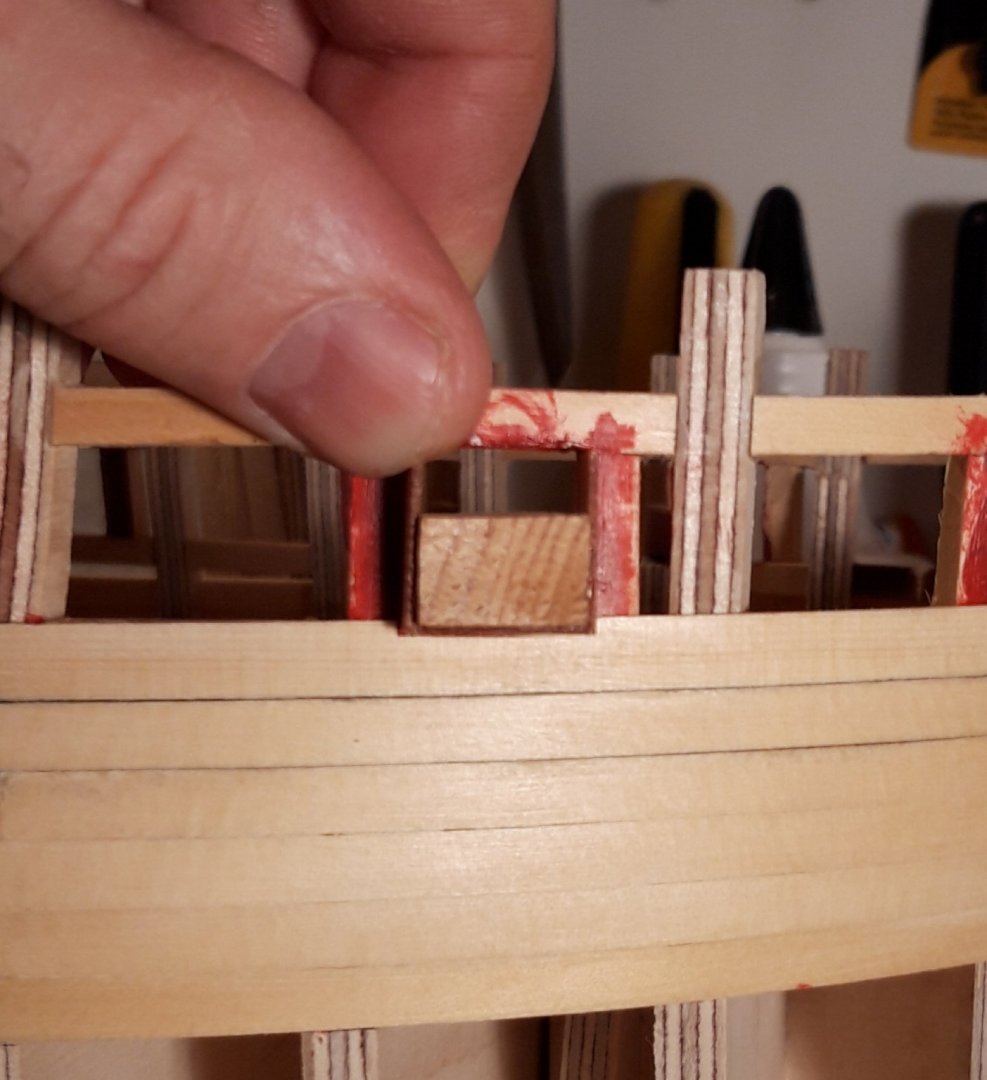

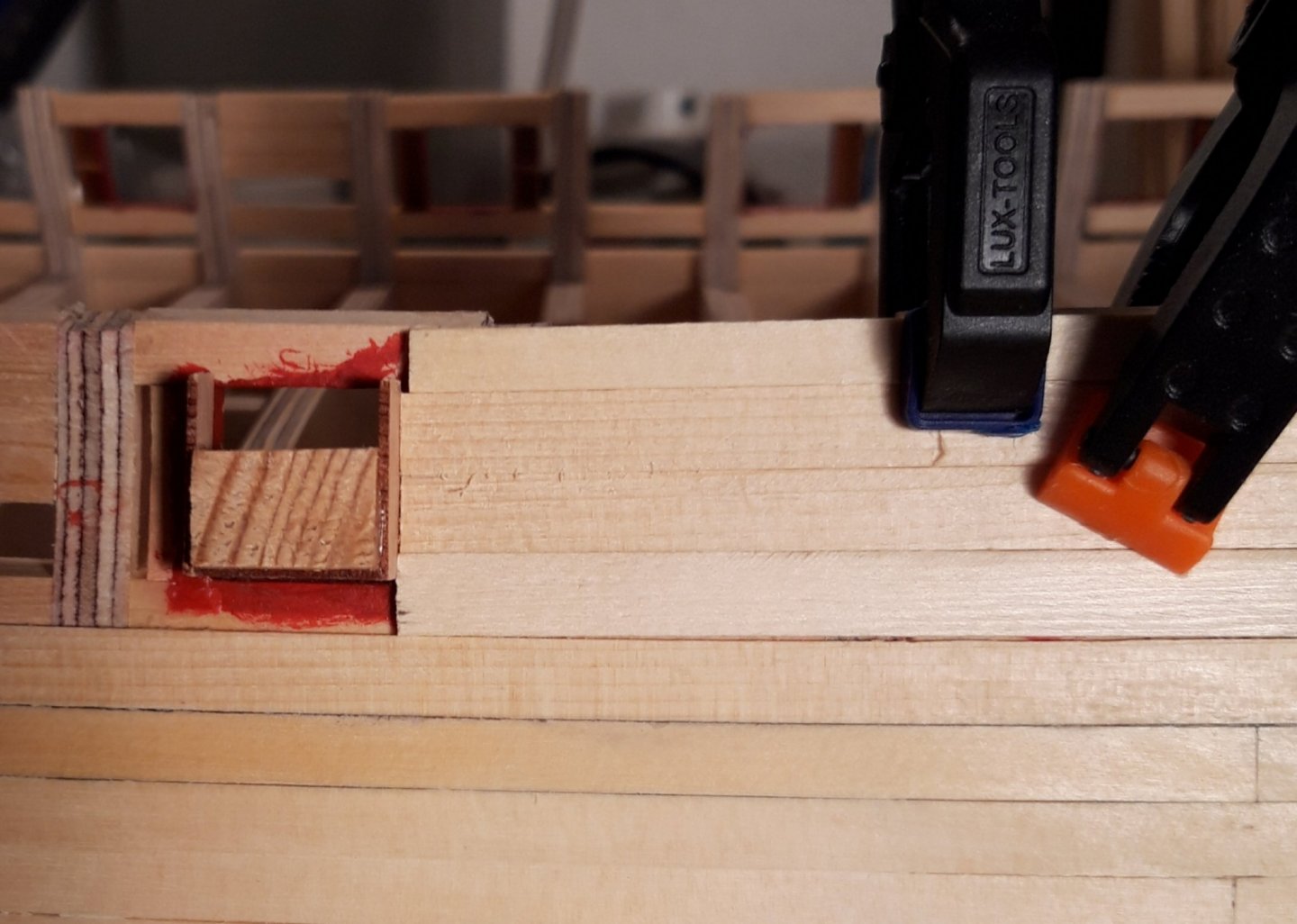

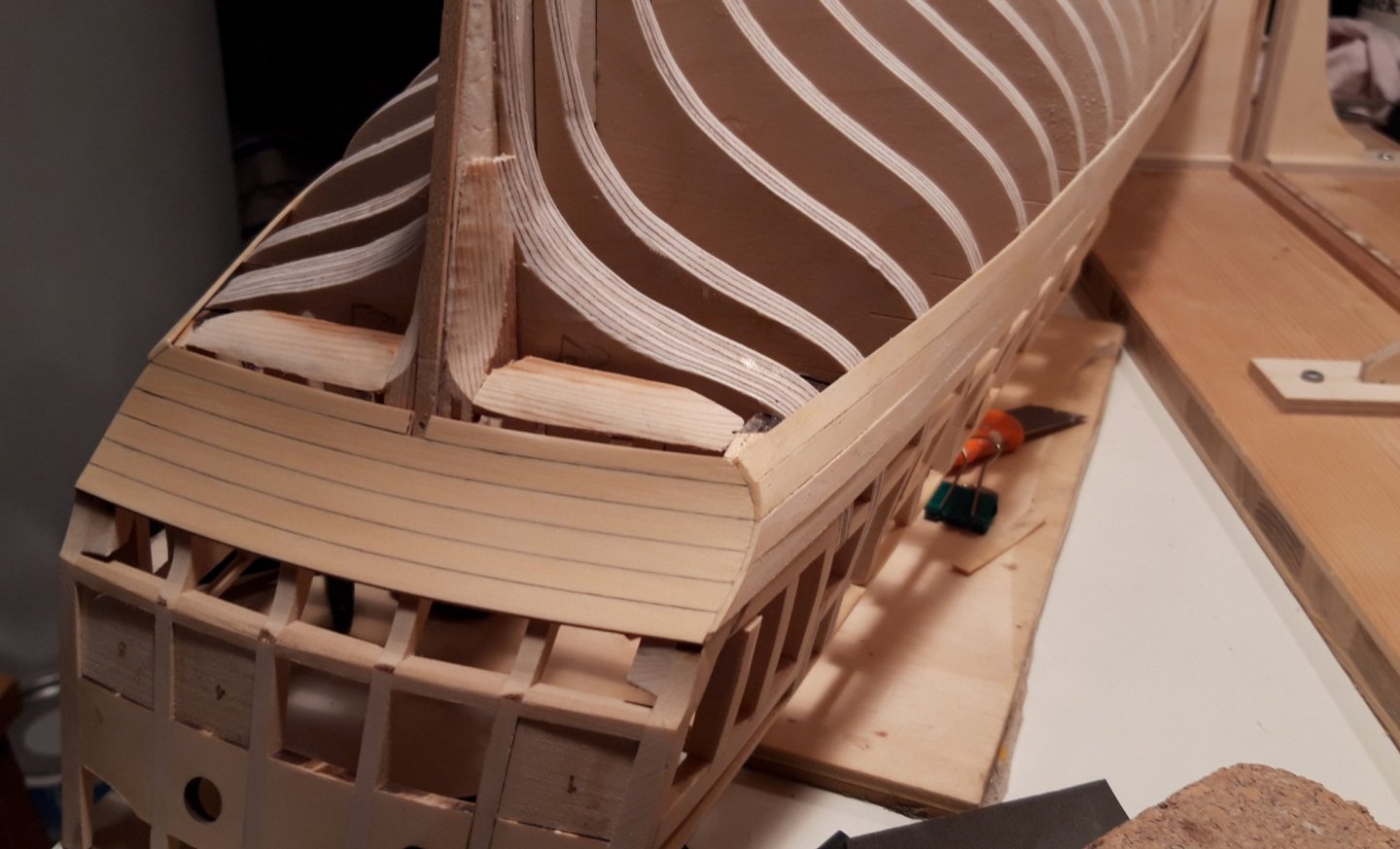

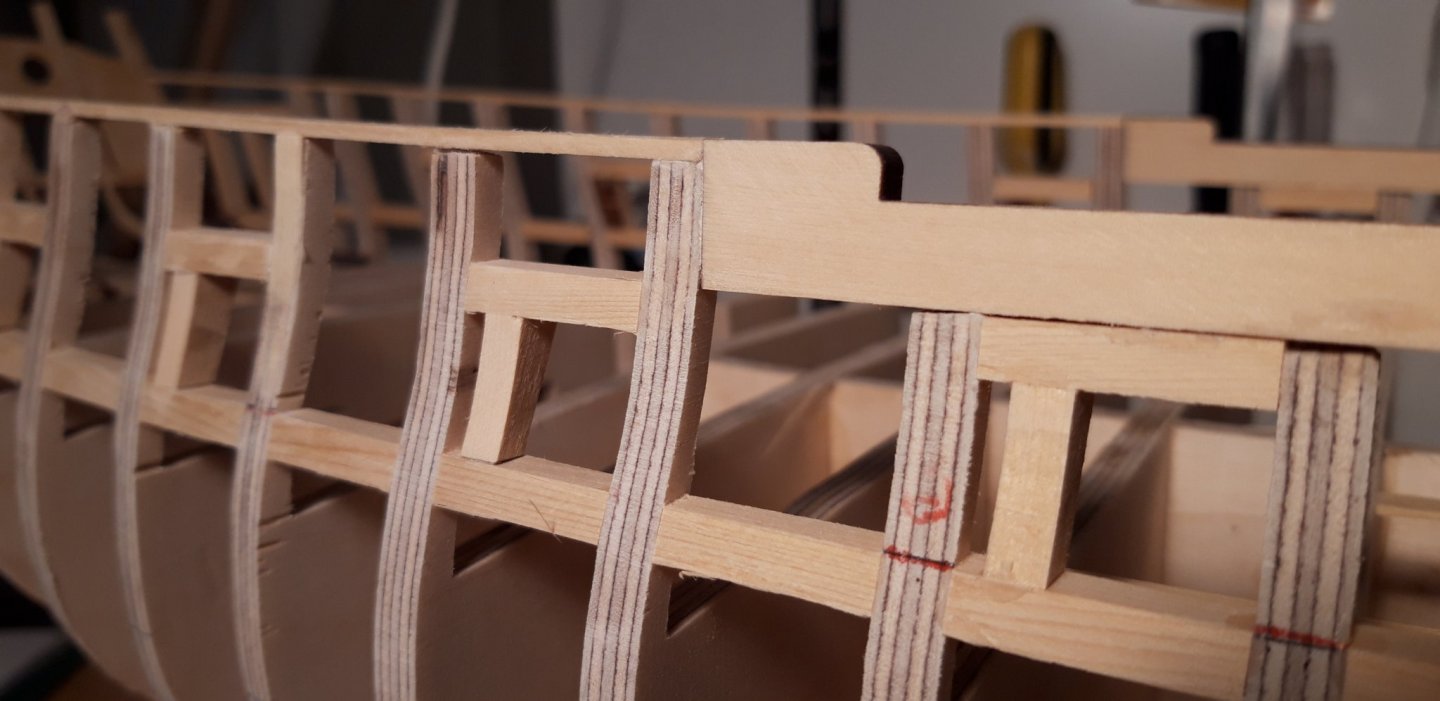

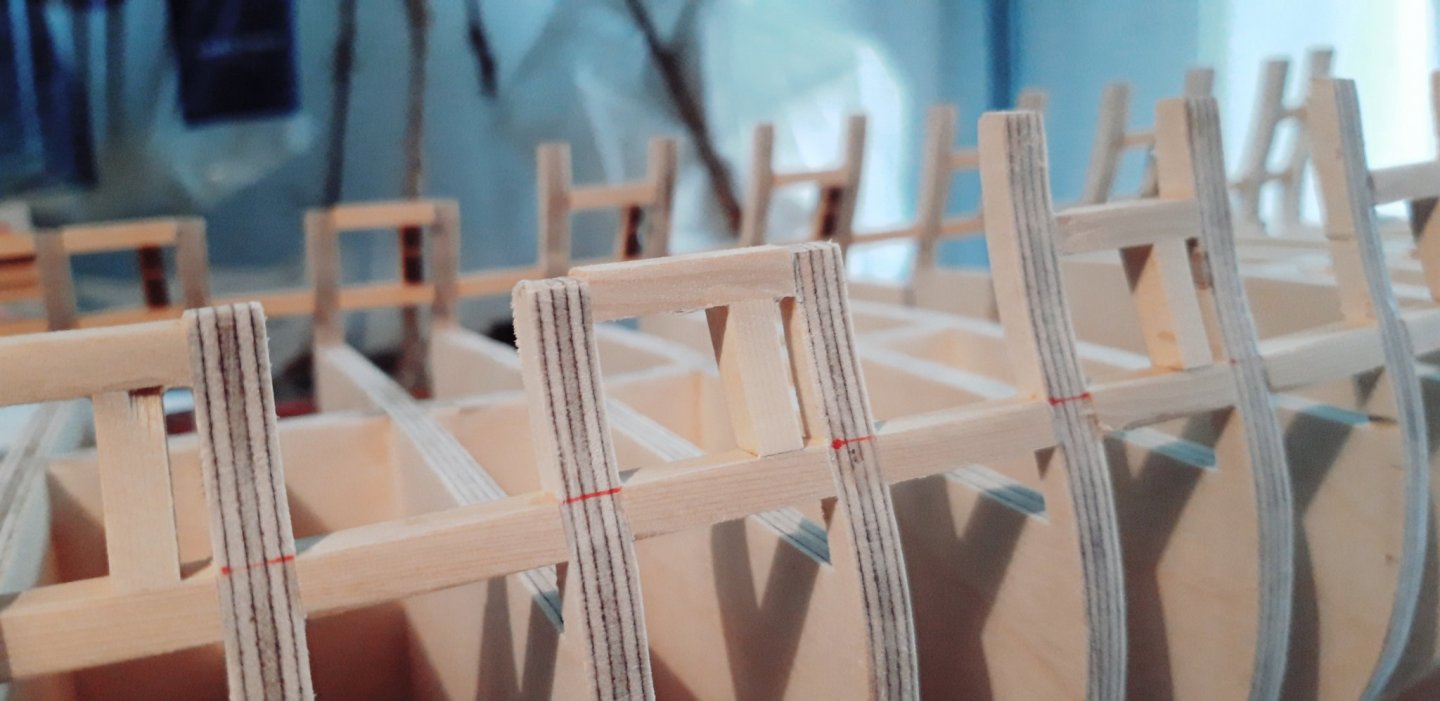

This weekend I did some planking. I sometimes doubt, whether I took the right strips. I used 7/32" x 3/64". I cut 23 of them. That will be enough for 4 planks in each side. But the 5th on top of them should be the same one or not? Taking 2,5 planks for one length, I used already 20 strips. The remaining 3 strips will not be enough for a 5th. row. With wich plank are the wales doubled up later on?

-

Hi, Your carvings look superbe. I admire your patience, I must admit, I used the resin casting ornaments. Yours look very good! It is definitely worth the efford. It will make a difference to the model. Matthias

- 103 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I dont know the exact english word. It is very dilute varnish. You usually apply it after sanding, before you start to paint the surface. It closes the pores of the wood if you know what I mean.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I think applying some primer from time to time helps to keep the surface free of dirt.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

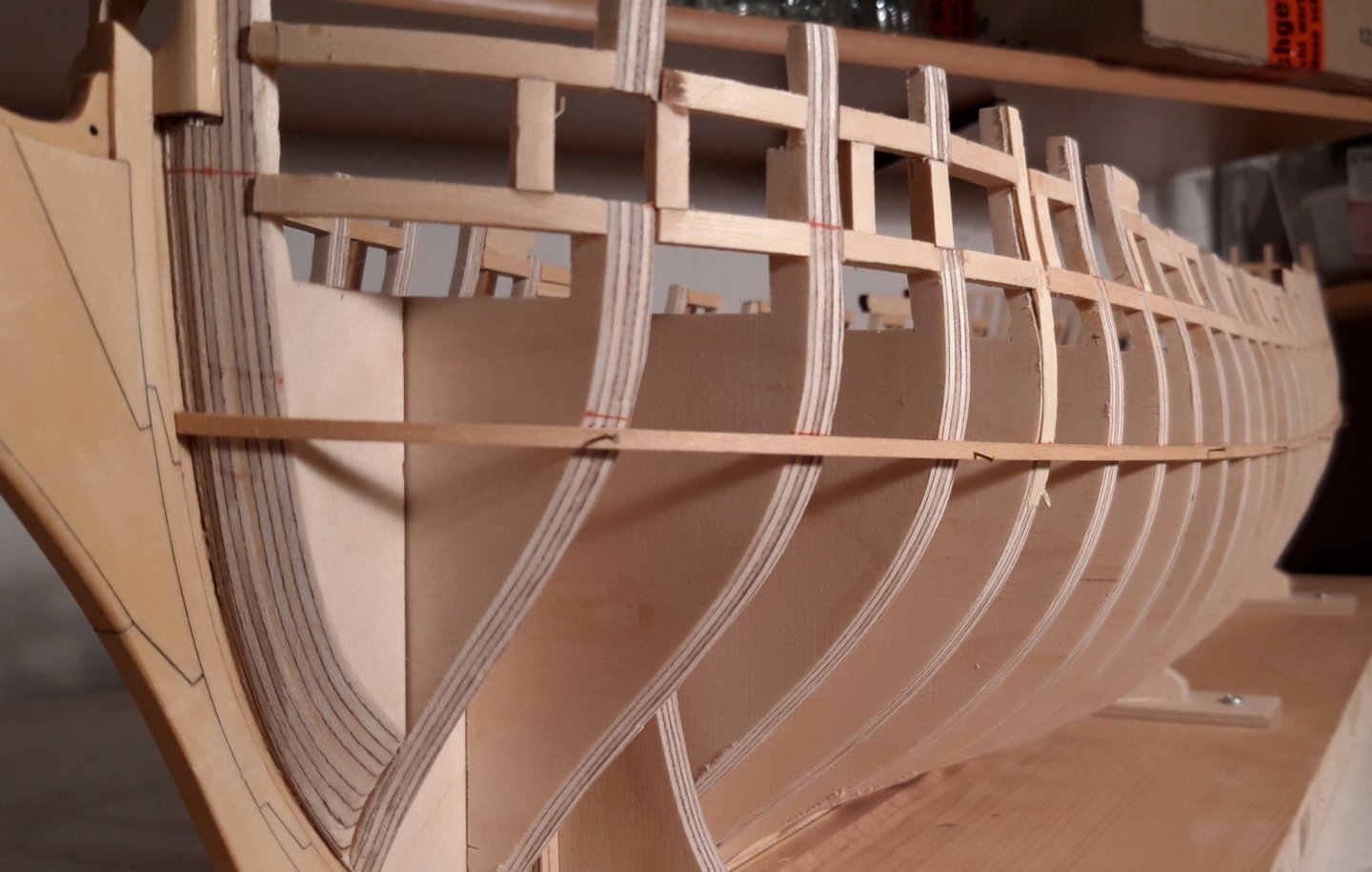

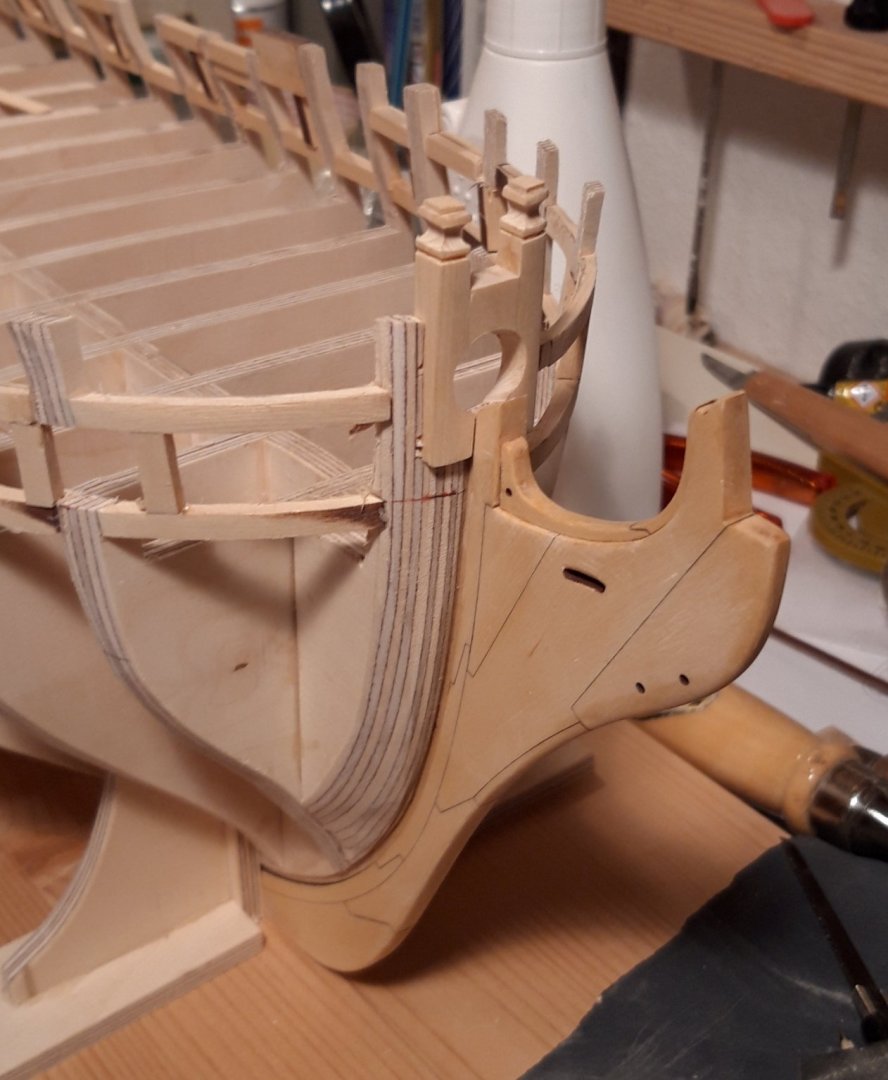

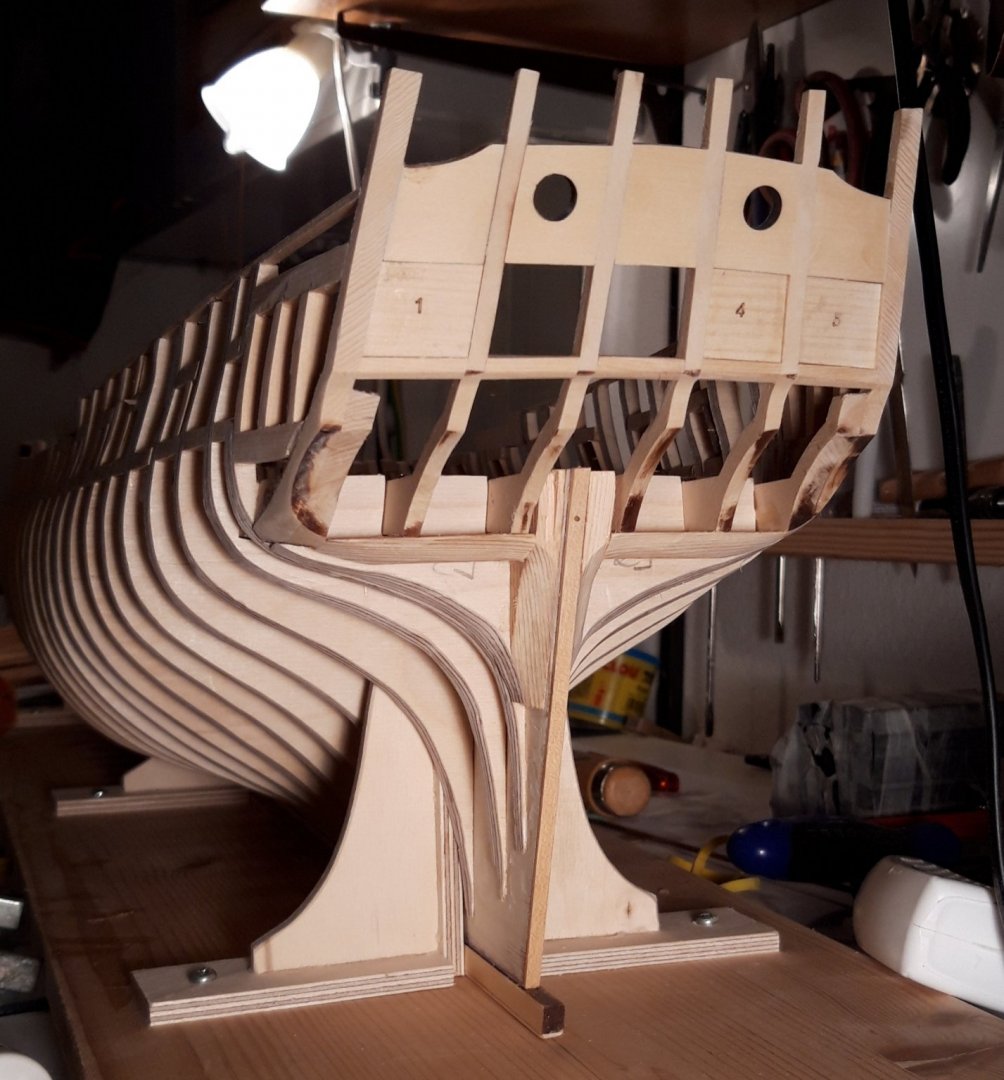

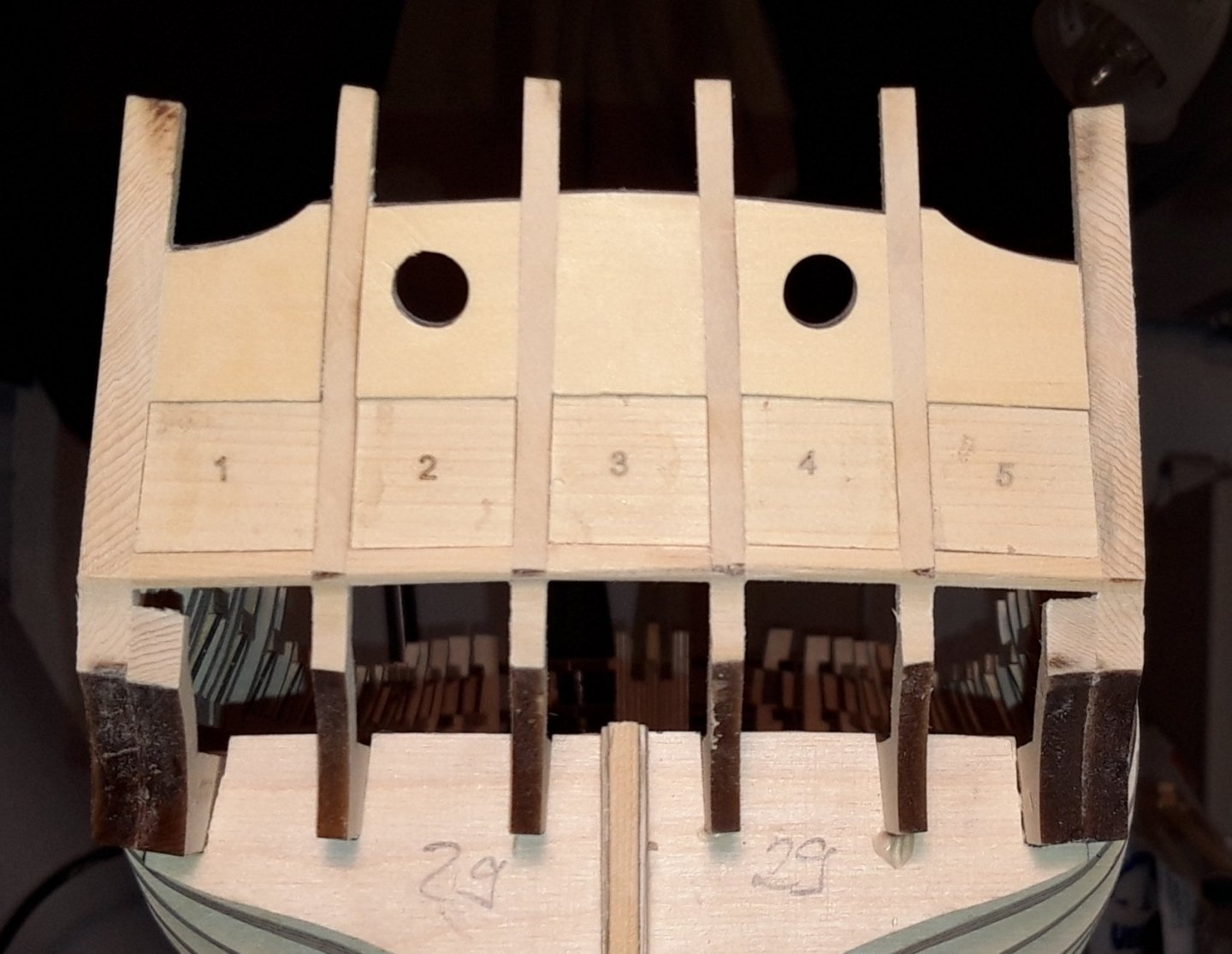

Rusty, I am very impressed, your Hull looks extremely clean and well faired. It is very inspiring to watch you building Winchelsea. Matthias

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You are Building a lovely model!! these elegant racing yachts are a dream. Regards Matthias

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.