-

Posts

420 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Beckmann

-

You are Building a lovely model!! these elegant racing yachts are a dream. Regards Matthias

-

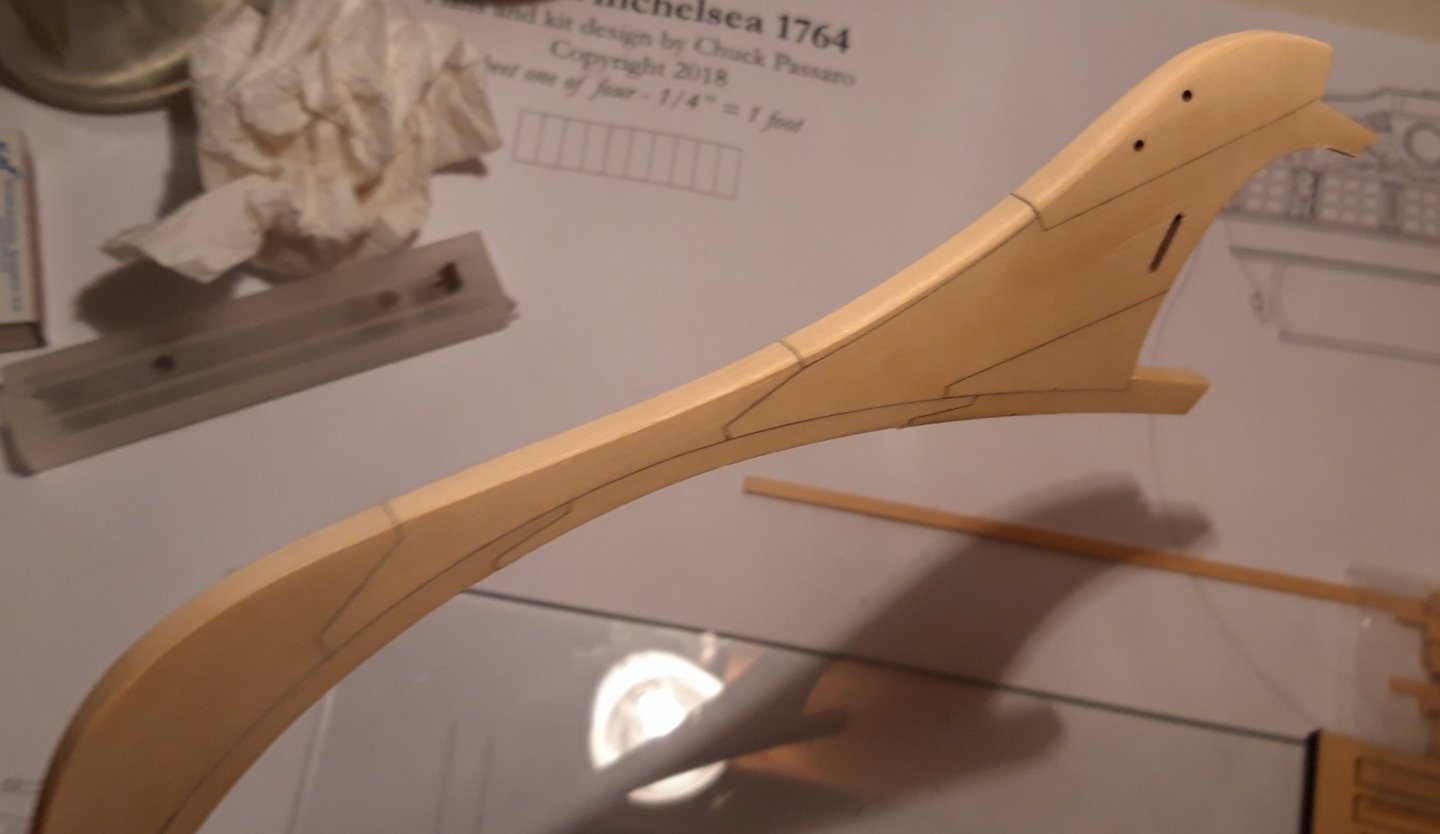

I have still another model (LEON / A. Underhill) wich is waiting to being rigged. But whenever I have to decide, whether to do the rigging of LEON, or to proceed with HMS Winchelsea, the latter ALWAYS wins. But luckily there is still a lot to do in chapter one, and all the planks have to be cut… So I will be fine for the next weeks. And if I really catch up to you, LEON will be lucky to get her main mast or something else. Matthias

-

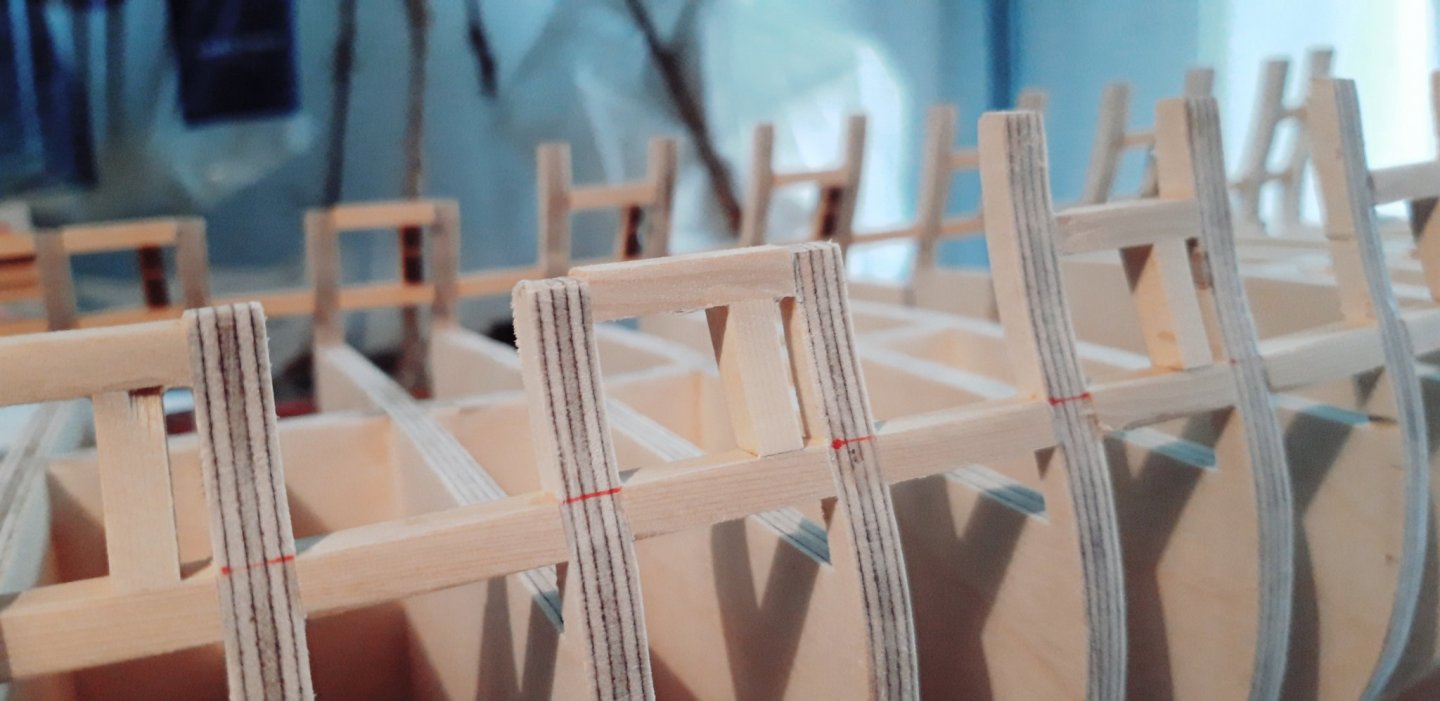

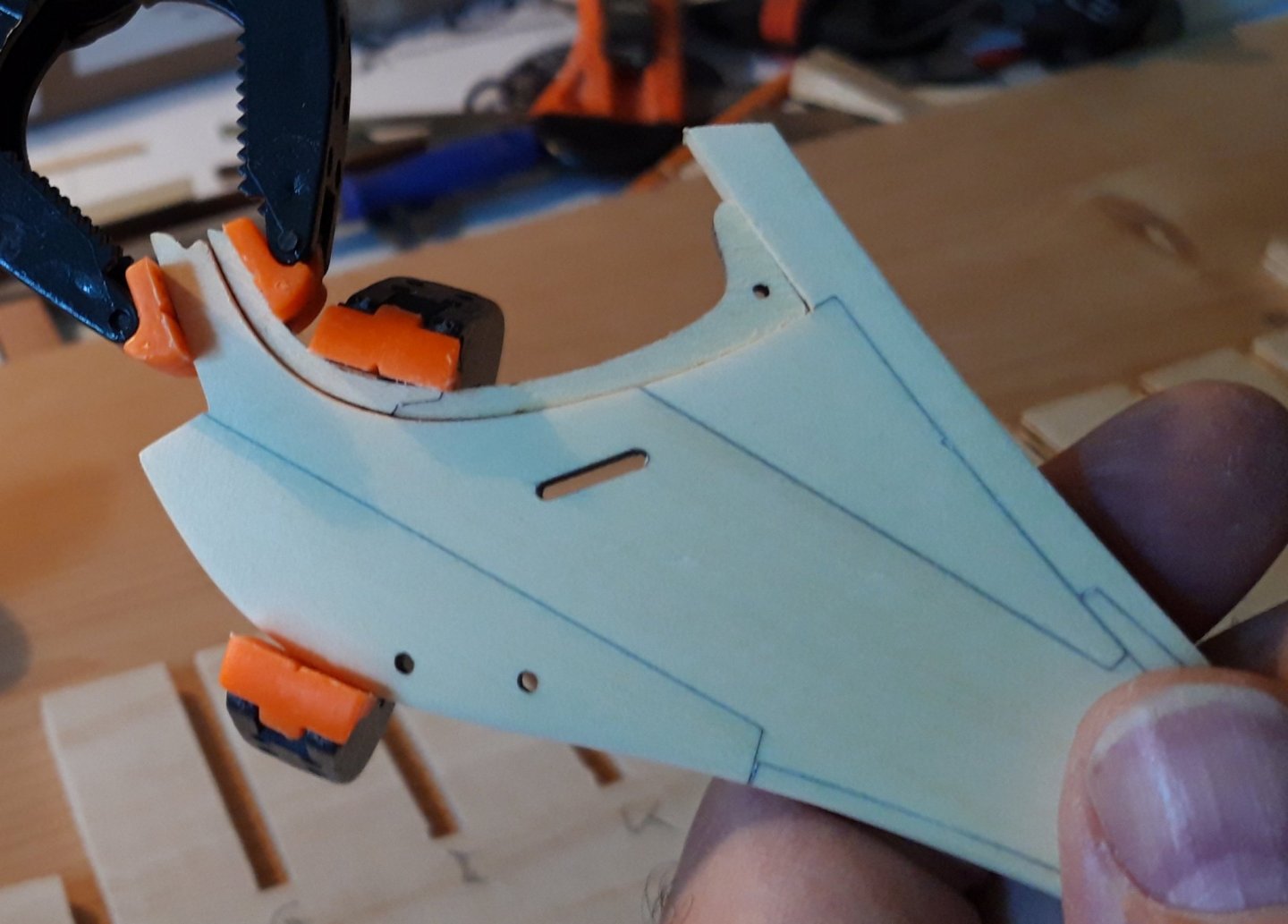

That looks perfect!!! Do you glue the planks just to the bulkheads or with each other as well? Matthias

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

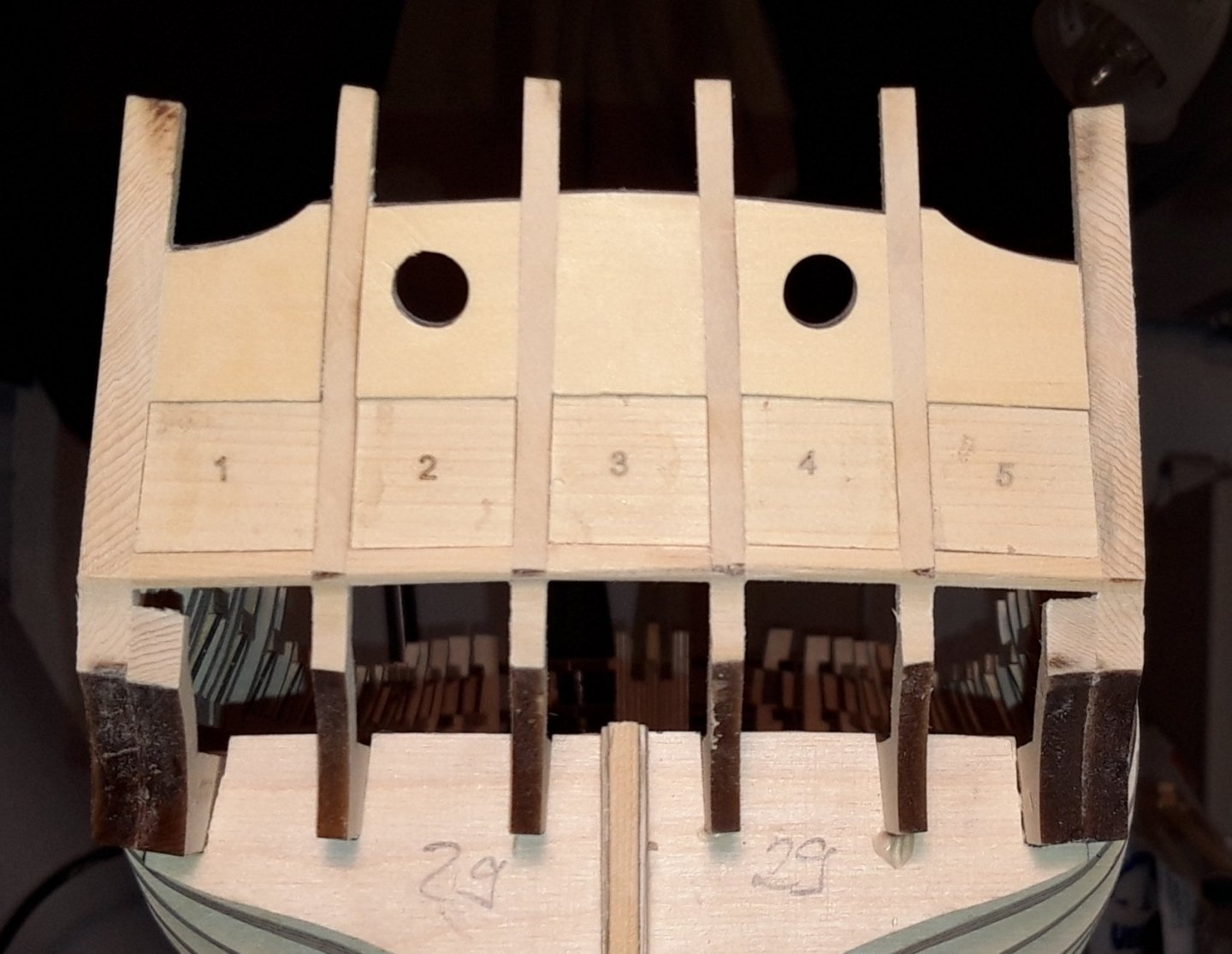

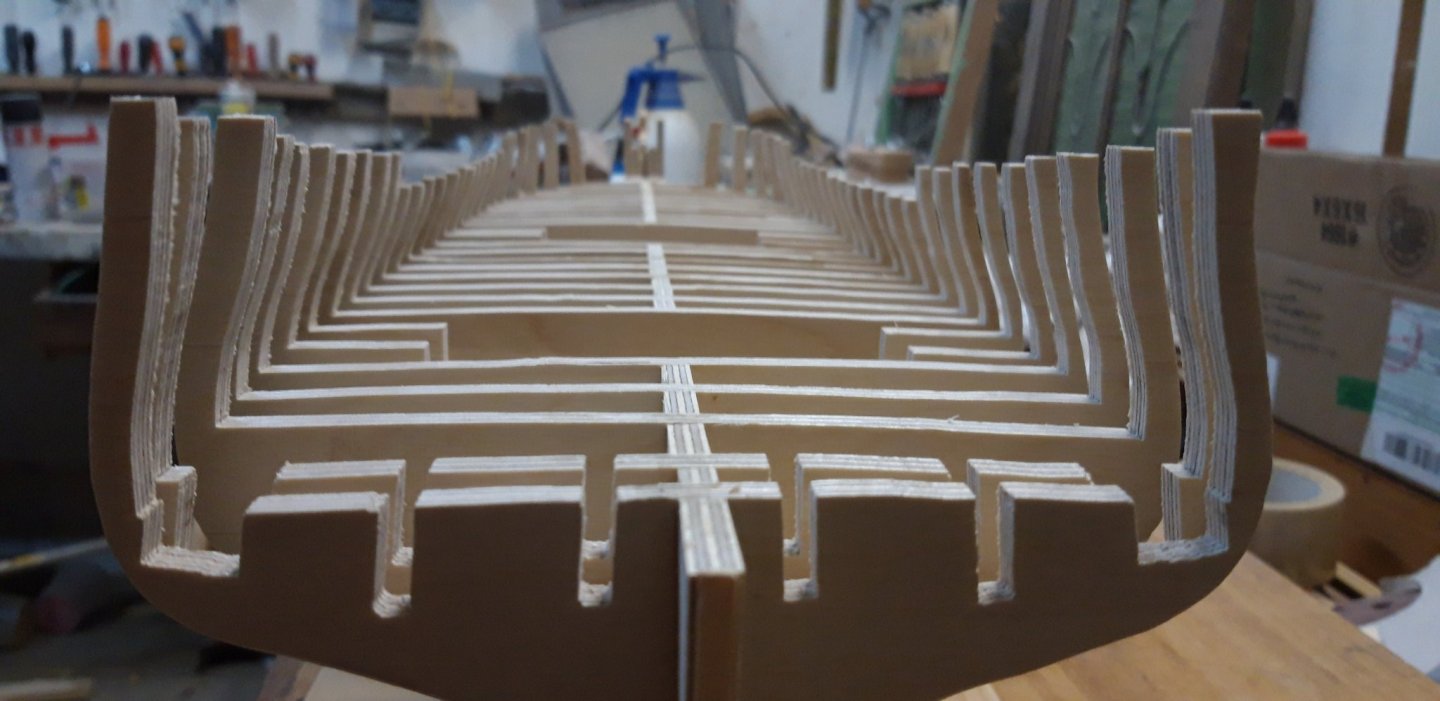

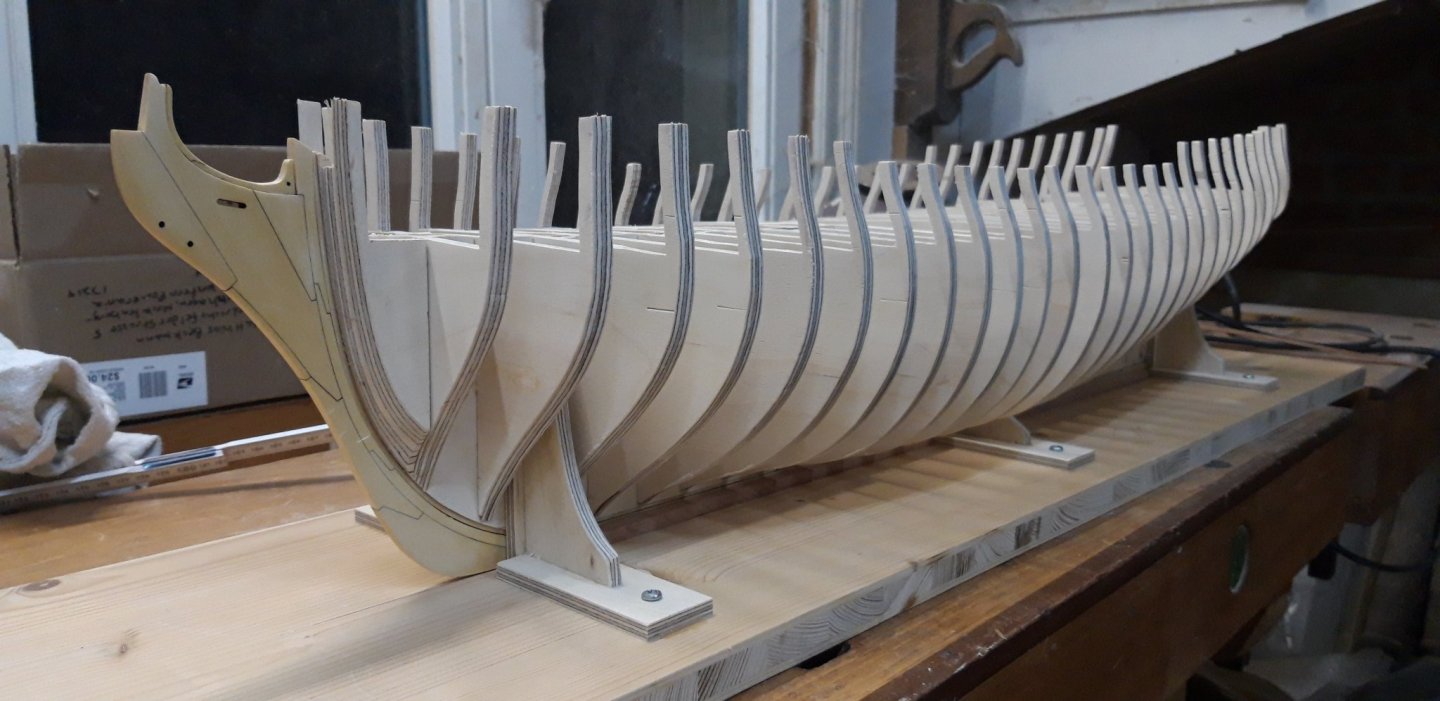

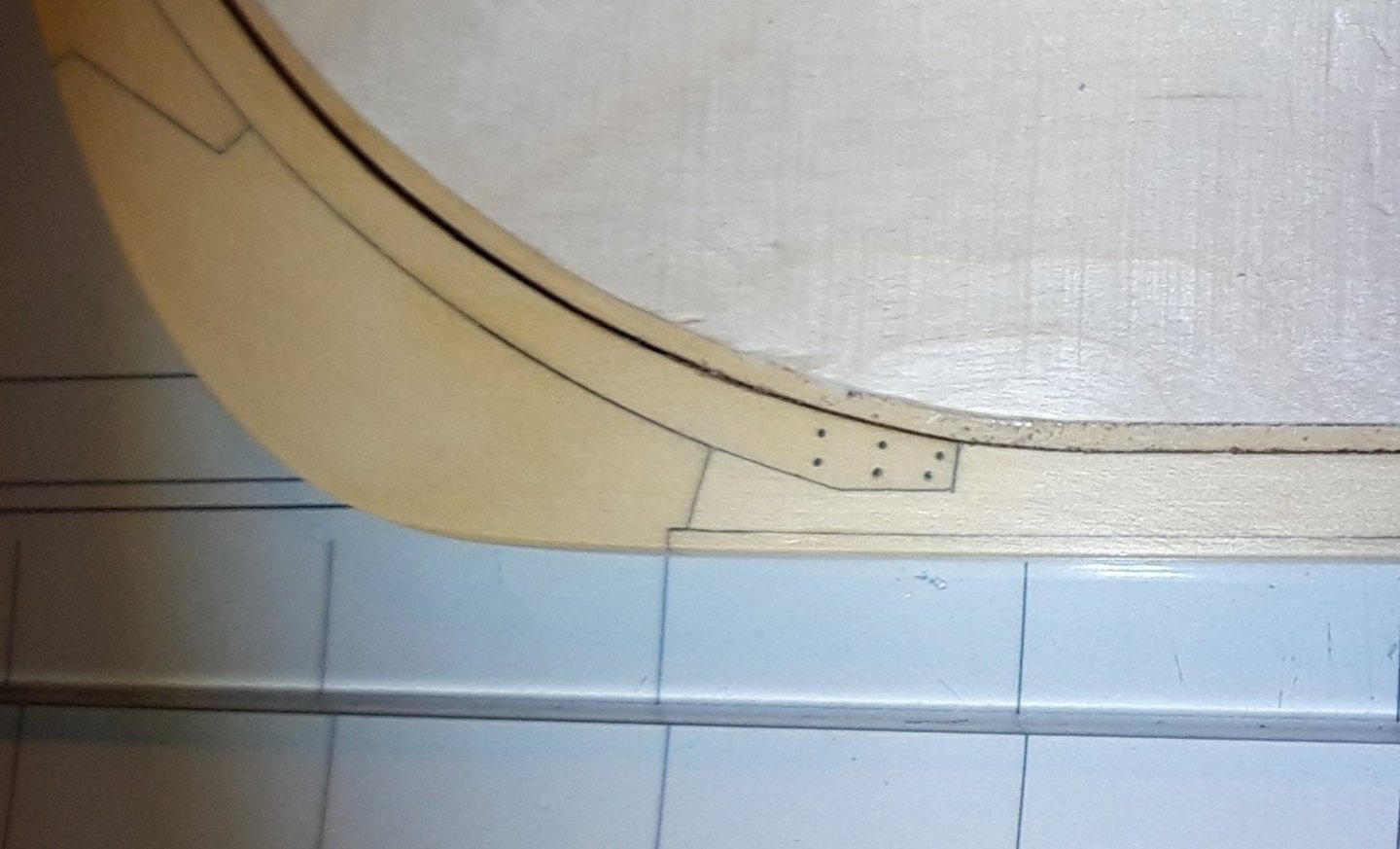

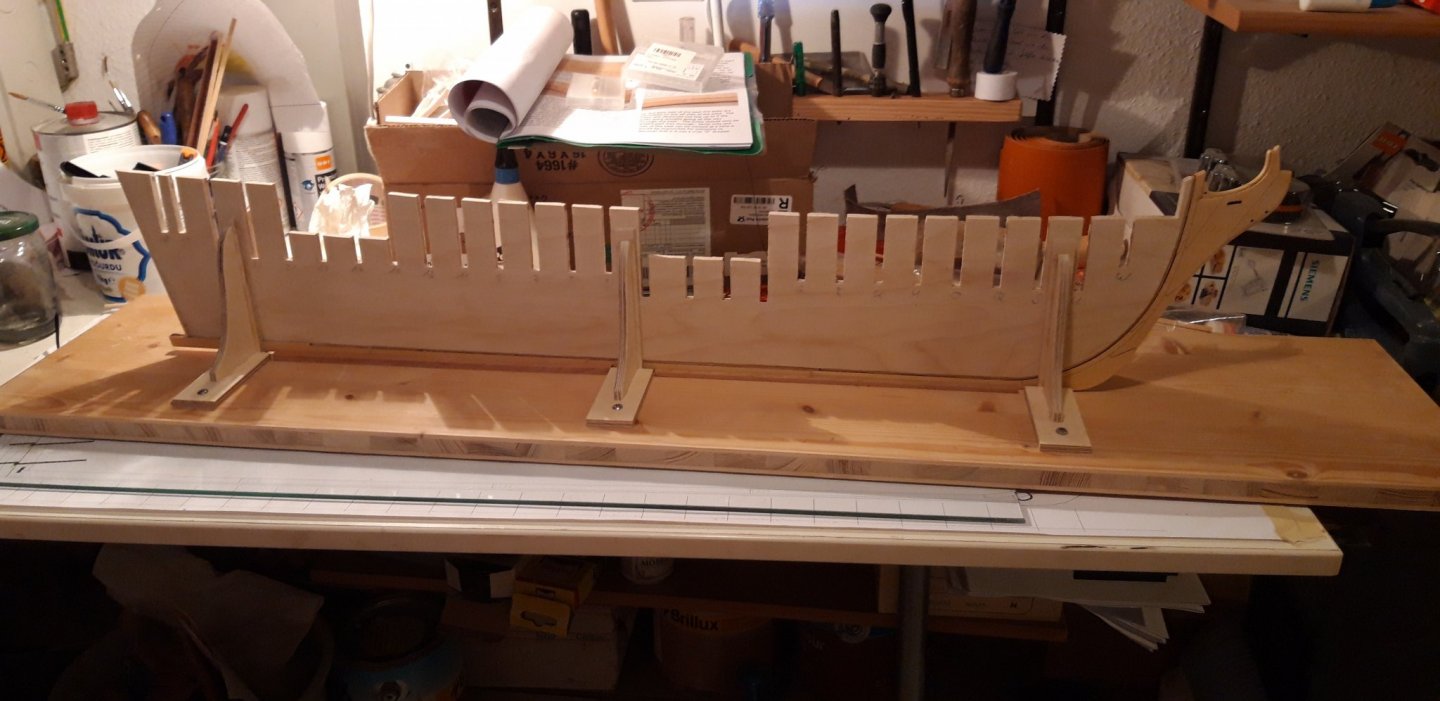

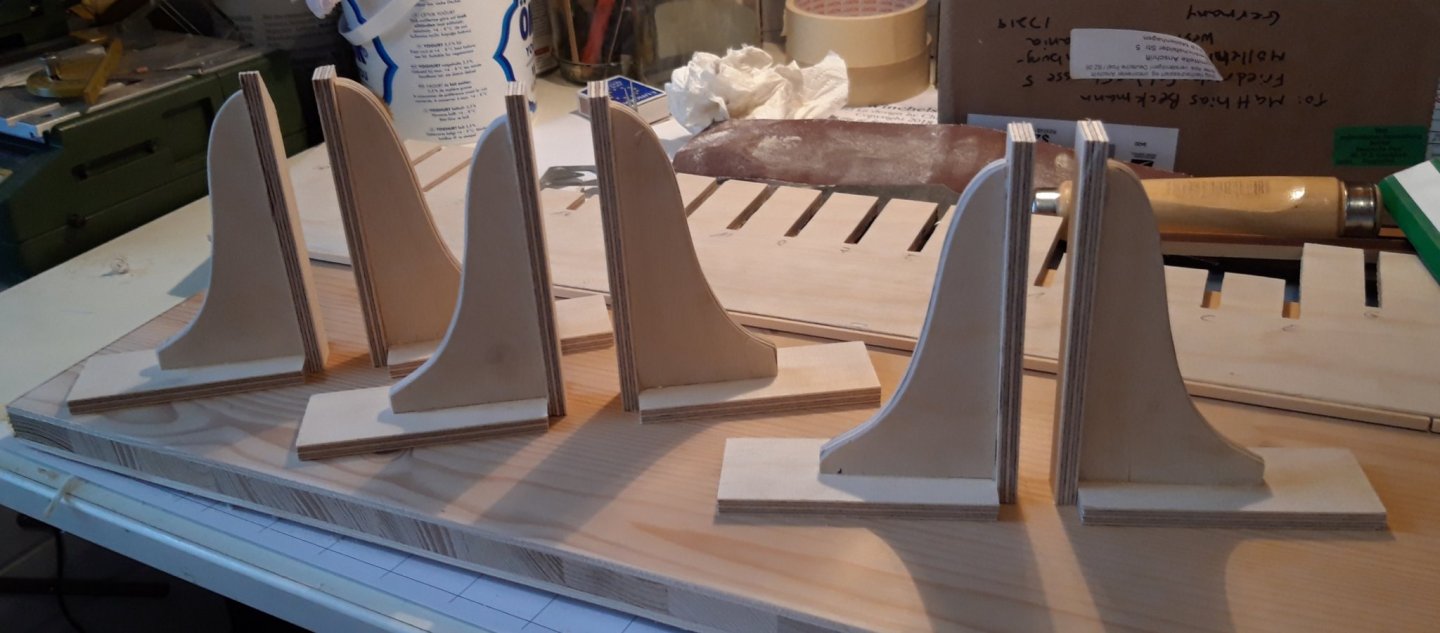

Today I did some sanding I think it looks a bit better now. I fixed most of the bulkhead-tips. I had to cut loose one bulkhead and center it properly. So for folk, who glue the bulkheads: Mark the center on top of the bulkheads so you can check better if it is really accurate centered. Otherwise the outer line of bulkheads dance in and out. Every Millimeter out of the center will cause problems if you now what I mean

-

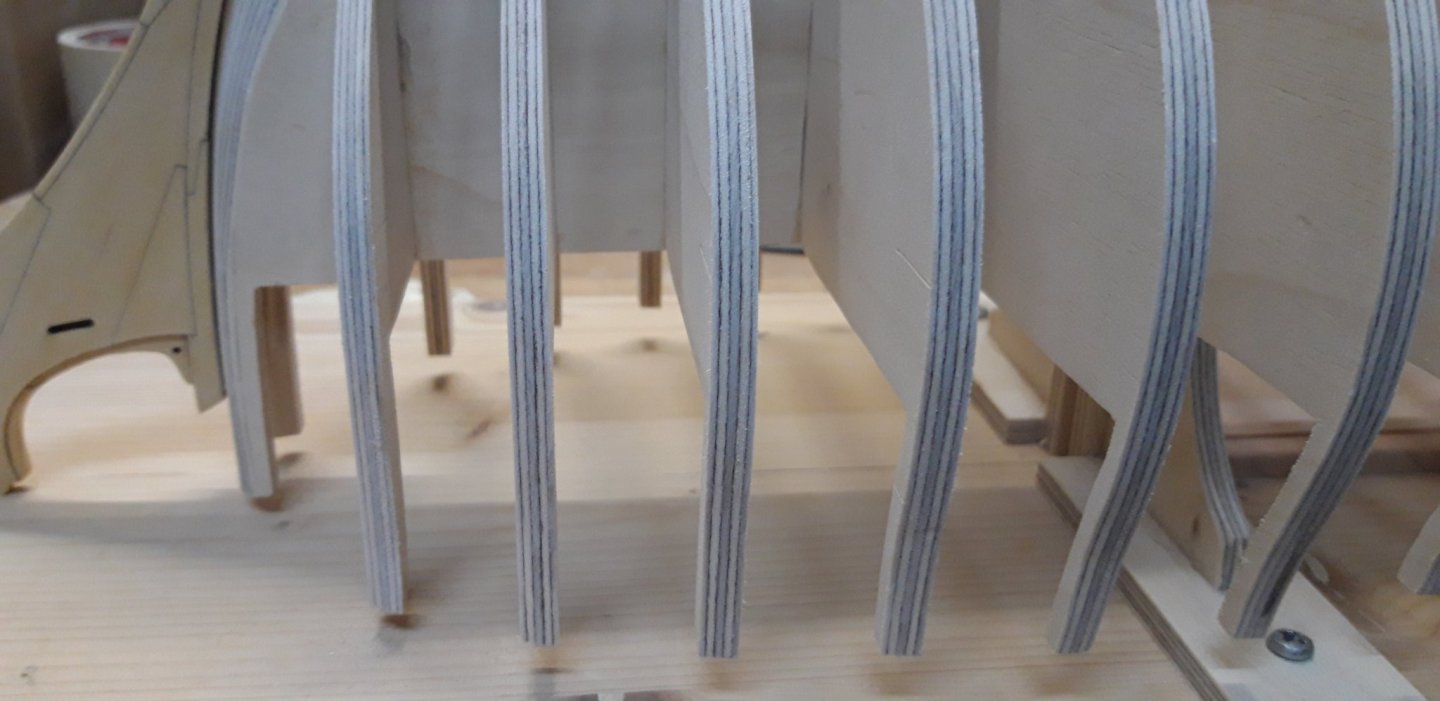

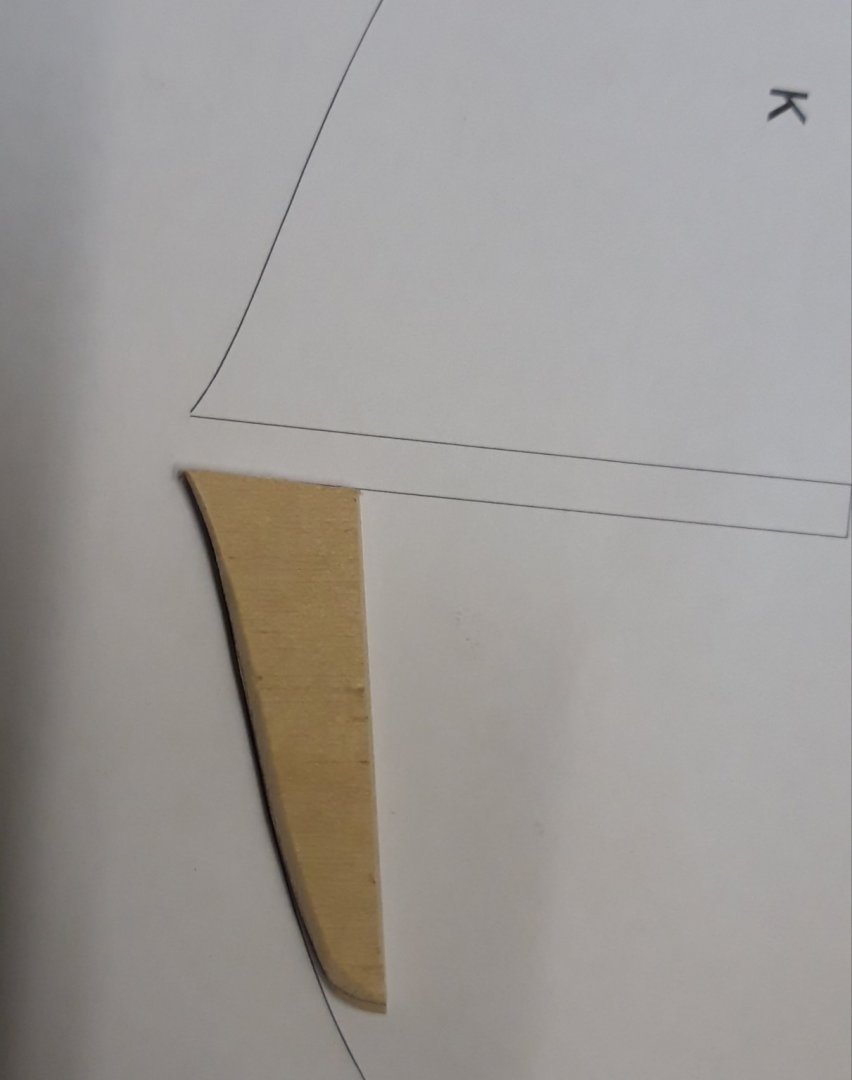

I printed the bulkheads again and tried to find out, what happened. There are two or three things that sum up. The biggest is my inaccuracy, when I cleaned up the bulkheads after cutting them out. I often sanded the tips of the bulkheads too much. That is 90% of the problem. The rest is about having not pushed it down into position enough.

-

I glued the bulkheads into position. That was the easy part. Then I startet sanding the bulkheads, that appears to be the challenging part. I am not totally happy with the result so far, I need to go over it again. One or two bulkheads jump a little bit back behind the line of the others. I have to see, wether I glue something in the gap or sand the others down.

-

I must admitt, without all the assistance you provide chuck, people like me would probably never start such a model projekt. If I come home after work I have about 1 hour time every second or third day to go into the Workshop and make some progress. You make it all very easy, so fulltime busy people still can have some model-building fun and make some progress late in the evening.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.