-

Posts

1,020 -

Joined

-

Last visited

About drobinson02199

Recent Profile Visitors

-

yvesvidal reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

yvesvidal reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

egkb reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

king derelict reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

king derelict reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

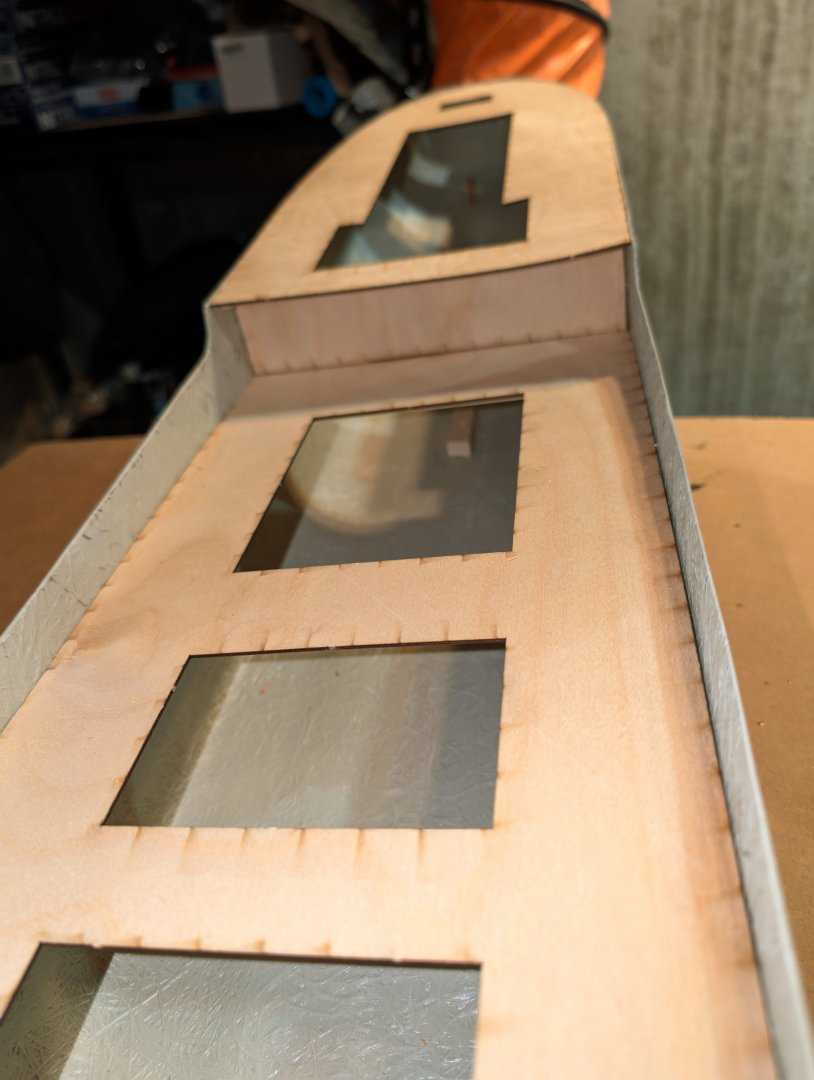

Combings fitted to the inside of the deck openings. In the manual, it says that this is for positioning the structures, and also to keep water out. But there isn't enough wood in the kit to finish the job! Since I don't care about water, I shorted two sides on the stern as you can see. Drilled all of the portholes and the mooring port openings, as well as the hawse holes in the bow for the anchors -- the latter have external fittings as shown. Regards, David

-

yvesvidal reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

yvesvidal reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

drobinson02199 reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

drobinson02199 reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

king derelict reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

king derelict reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

king derelict reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

king derelict reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

ccoyle reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

ccoyle reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

All of the decks are now in. It's something of an adventure given the limited instructions. The decks take some shaping to fit the hull. You also have to figure out where the stern bulkhead goes -- finally I measured on the main plan and converted its scale to the main ship's scale. The main deck went in last, and I positioned it (after shaping) and then installed fillets through the openings from bow sternward, measuring height from the top of the side bulkhead as I went along. I also added cross beams under the main deck to keep it from sagging in the middle. Regards, David

-

Started on the decks. This is the stern deck, which has to be installed flush with the hull edge, on the inside. It rests on "fillets", which you have to install, so getting those positioned well is key to that flush alignment. I will fill the gaps between the deck and hull edge wiht putty. Regards, David

-

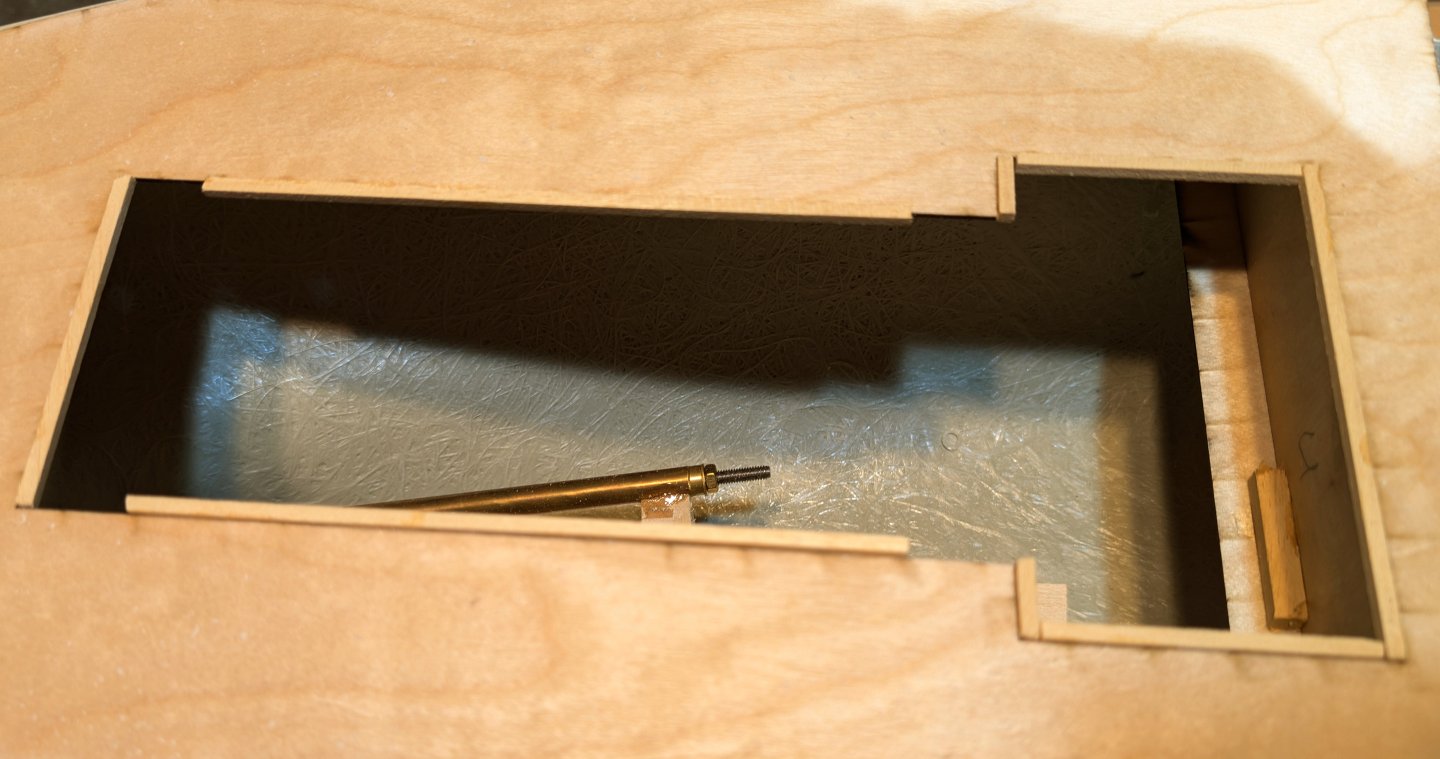

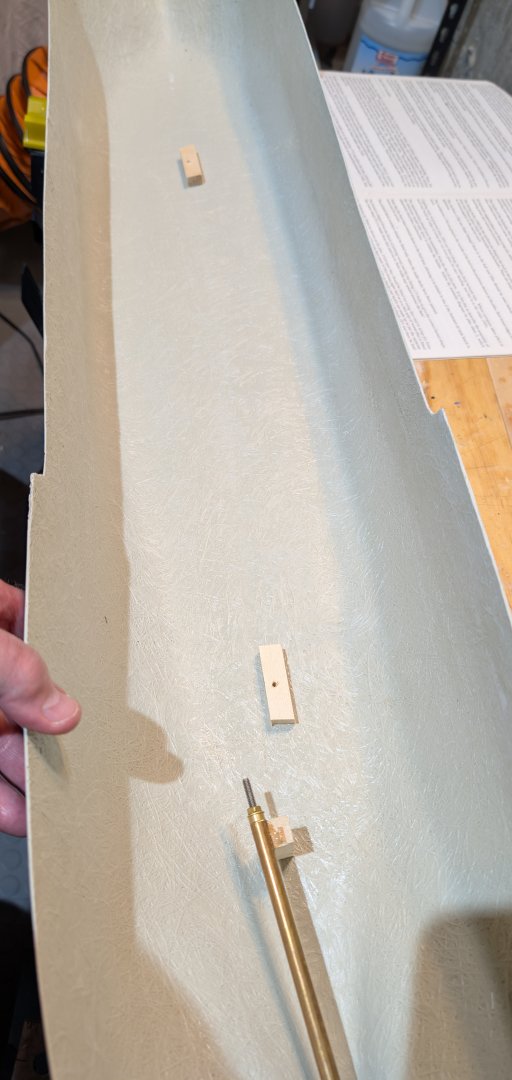

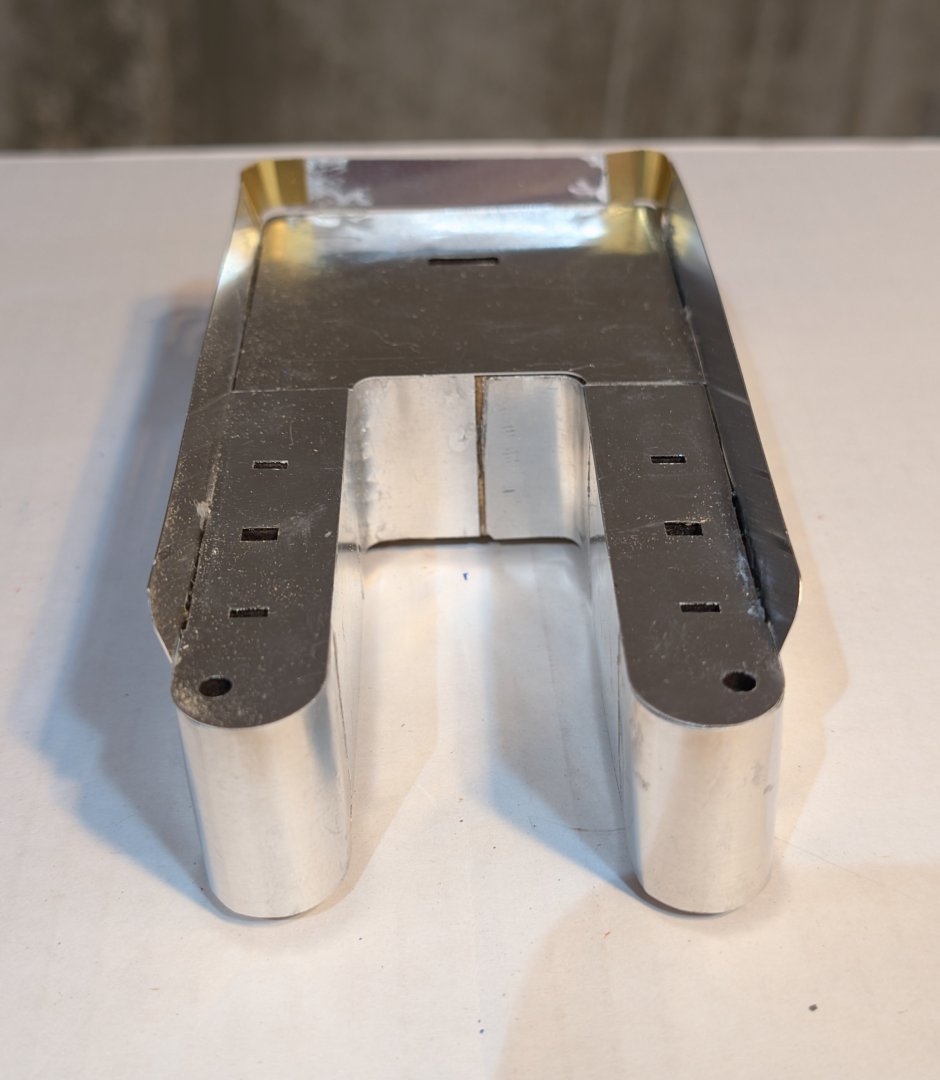

Because the decks will prohibit access to the interior of the hull, I needed to pre-drill the mounting holes. Because the hull is very thin (1mm), I installed wood blocks to give the mounting screws something to bite into. The holes have been pre-aligned with holes on the mounting board. I'll use screws and brass pedestals. The brass rod you see is the propeller shaft, which I've attached a post to for stability. Regards, David

-

Prop and rudder assembly done. I'm building this as a static model, so I didn't have to worry about some of the running hardware. One tip: if you follow the sequence of the instrucitons (as I did), you fix the lower rudder arm and then discover that the rudder doesn't fit (look at the picture and you can see that there is zero wiggle room). So I had to bang the rudder shaft down to flush at the bottom -- fortunately it does move inside the rudder if you use a hammer -- fit it, and then carefully bang back enough to create a shaft stub to grab the lower rudder housing arm without dislodging the arm.. A better approach would have been to dry fit the rudder arm, then position and drill the top hole in the hull for the rudder shaft, fit the rudder into the arm and the hull, and then reposition and fix the arm. The white stuff is some putty to fill the gaps between the arm and the hull. Regards, David

-

drobinson02199 reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

drobinson02199 reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

drobinson02199 reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

drobinson02199 reacted to a post in a topic:

Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

drobinson02199 started following Brannaren by drobinson02199 - Caldercraft - Scale 1:48

-

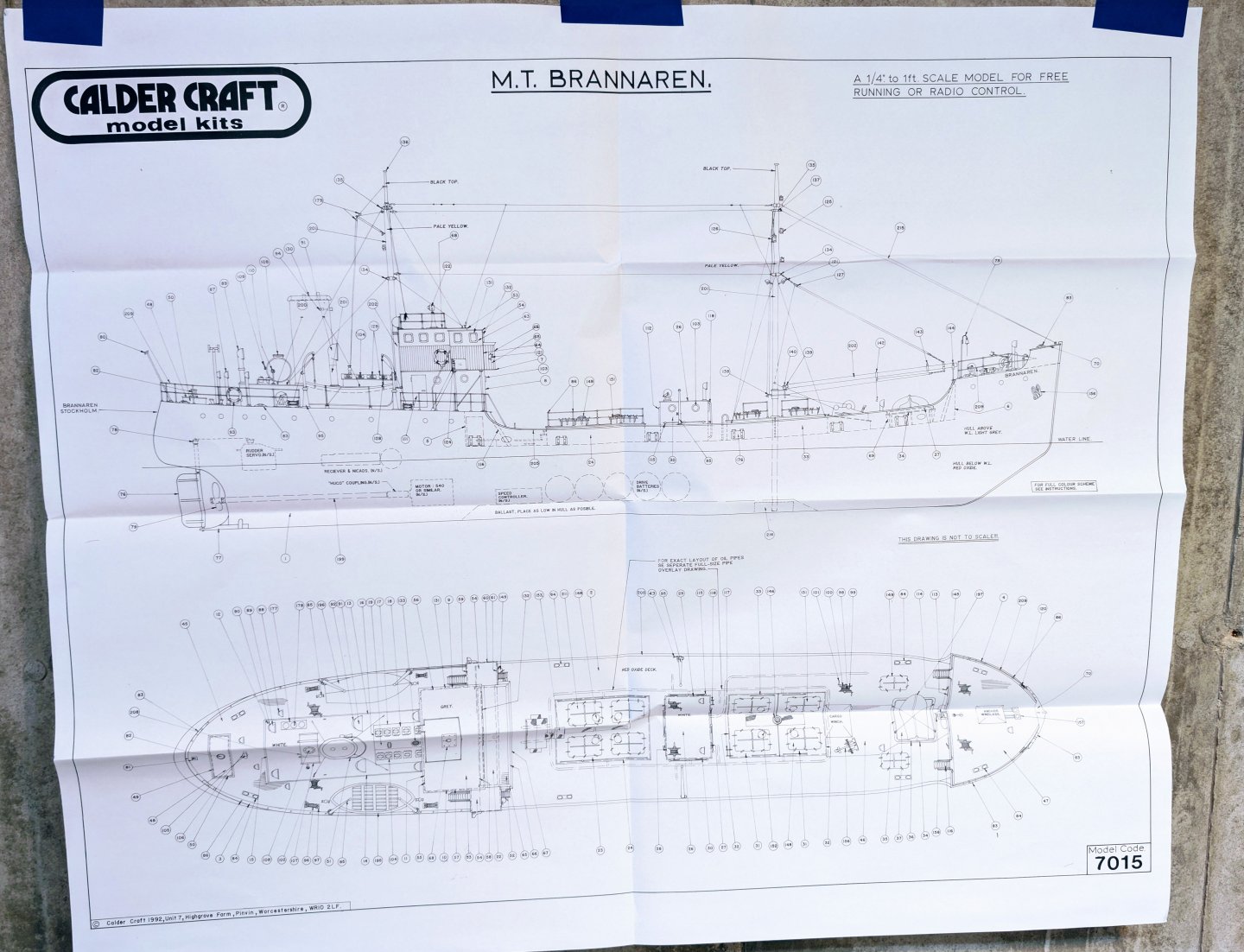

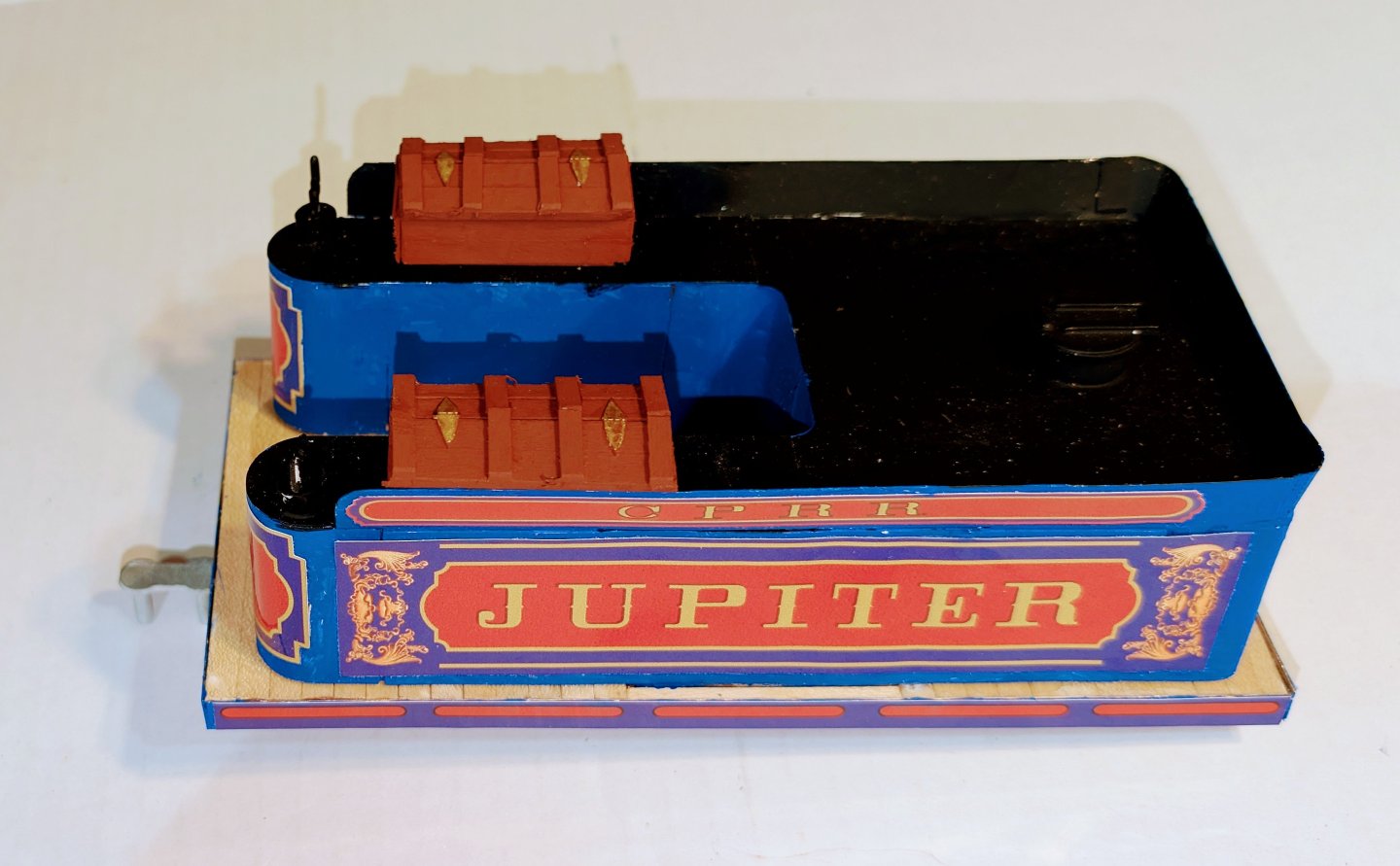

After a break from ship building with the Jupiter locomotive, I've returned to ships. But the HMS Victory really maxed me out on ratlines, so I was looking for something different, and wanted to build a cargo ship. The Caldercraft Brannaren looked like a good bet. Included here are the tranditional "what's in the box" pictures. The hull is pre-formed since Caldercraft intends this to be a RC model if desired -- but I'm going to build it as a static model for display. I pulled the manual and quickly realized that sparse is perhaps an inflated description of the written instructions. So I went looking in the box for a bunch of how to build diagrams -- but no dice. There are a few charts -- I've included an example of a master chart -- but for me at least there was a real gap in figuring things out from the instructions. I think Caldercraft's philosophy on this model is best summed up by the following excerpt from the manual: "Piece by piece descriptions of placement of the remainder of the fittings have been deliberately omitted, as it is thought that the drawings and photo pack adequately describe and show all placements of them." I read this and thought: great, where is the "photo pack". Not in the box. Did some preliminary web searching for pictures, but didn't find much beyond the single stock picture on the kit page at Caldercraft or Ages of Sail or others. Wrote Caldercraft about the "photo pack" but no reply. So I bore down on Google and searched really hard, and finally found a set of pics from several sources that will provide adequate guidance for construction, painting, etc.. I don't mean my tone above to indicate to any of you that this is one to steer clear of. Far from it: with the pictures I've found I'm now feeling confident and looking forward to the build. With that in mind, if anyone following this log decides to take on the Brannaren, I'd be more than happy to forward the pictures I found, as I think they are essential. I'm not going to post them here as I don't want to clutter up the log or confuse followers as to what I built and what others built. Regards, David

-

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

-

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

-

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

-

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

-

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

-

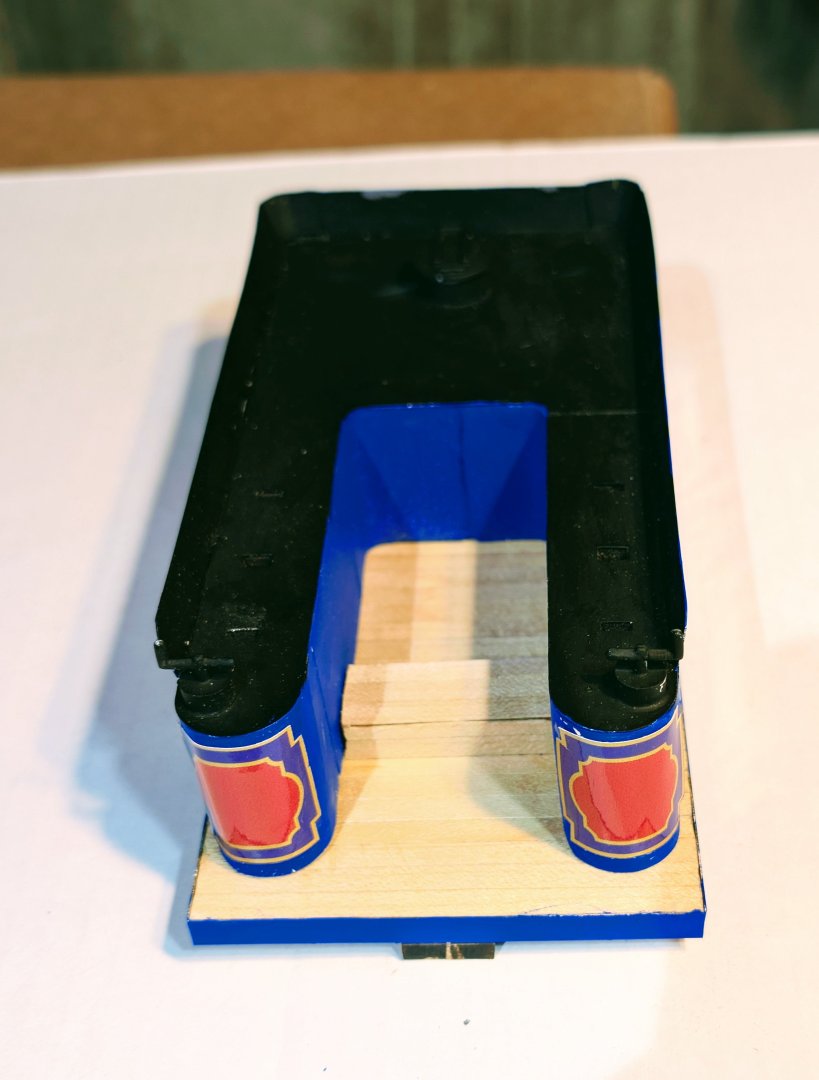

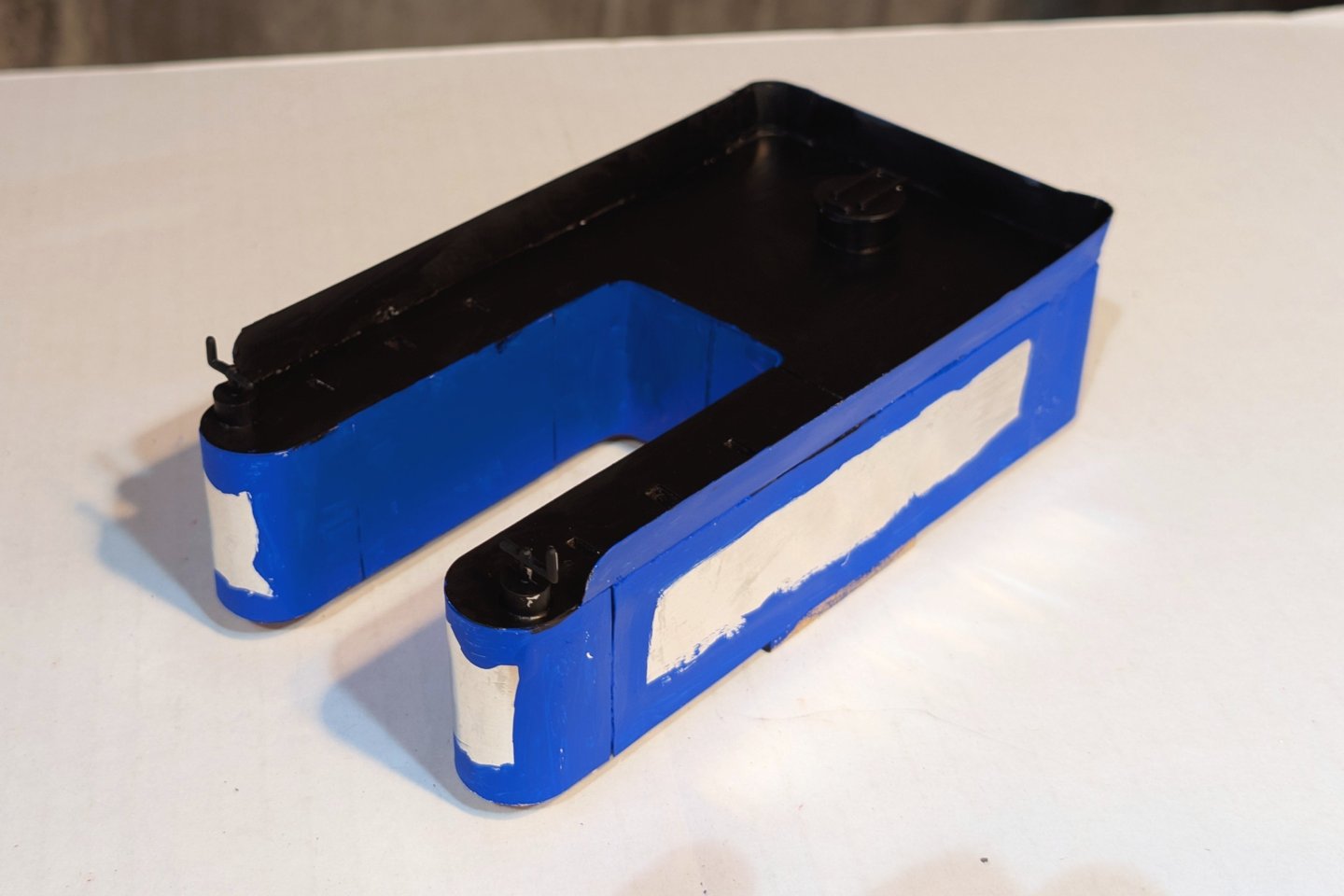

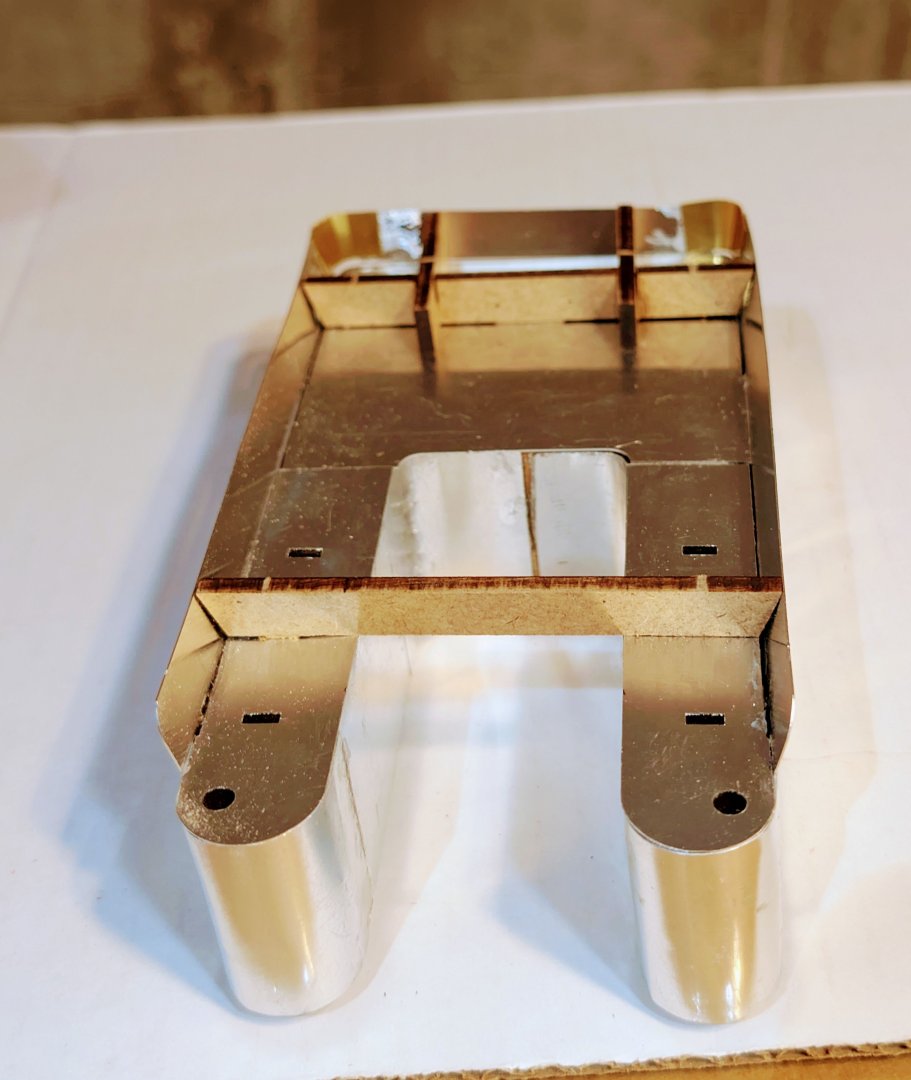

Planked the tender floor (I started to type "deck" out of habit, but this isn't a ship, is it? 😬). While the instructions say to plank the whole surface, if you do that you will have to carve out the different slots and holes. So I looked at where the tender body covers the floor and was able to hold off on planking across the holes and slots. You can see that in the picture below. Then some pics of the tender body with the floor mounted. Regards, David

-

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

drobinson02199 reacted to a post in a topic:

Jupiter Locomotive by drobinson02199 - FINISHED - OcCre - 1:32

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.