-

Posts

914 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drobinson02199

-

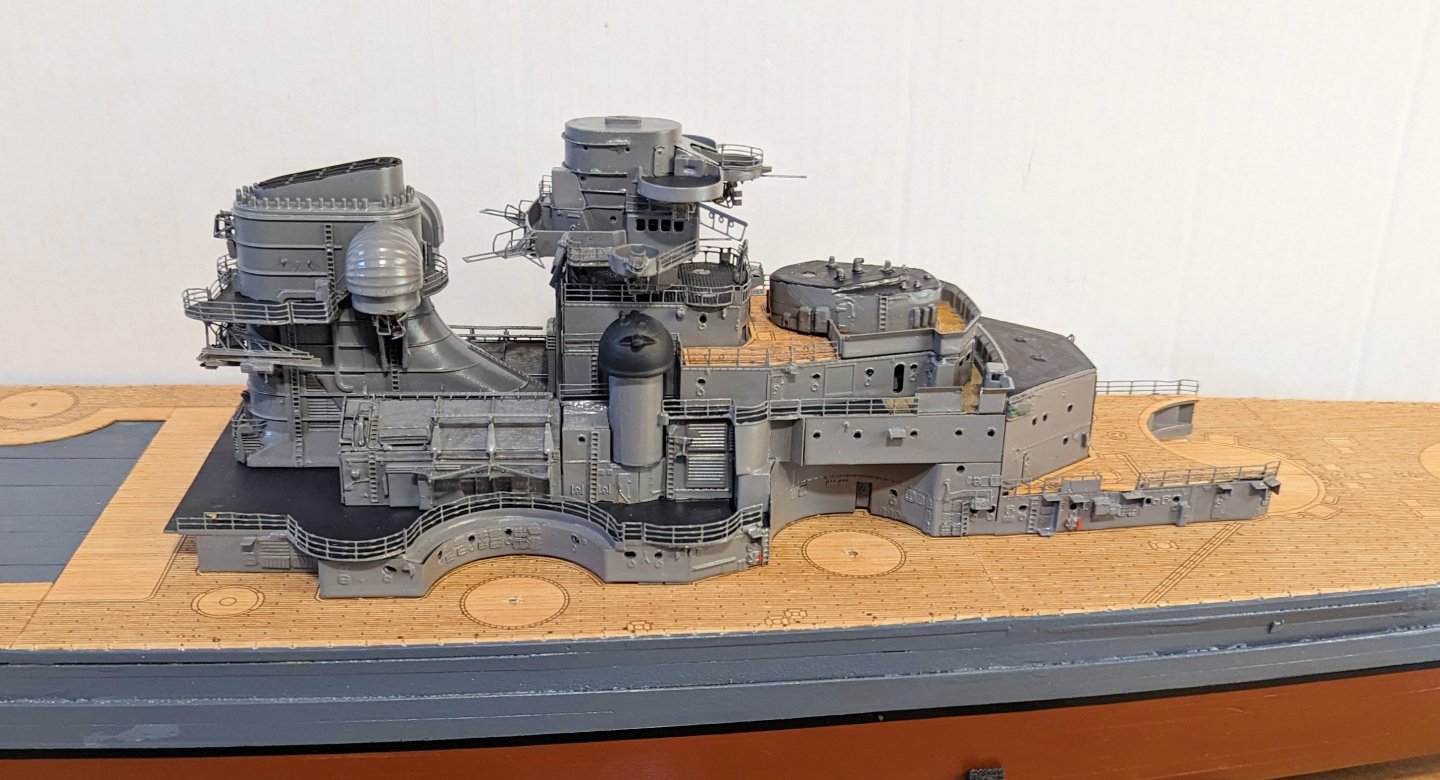

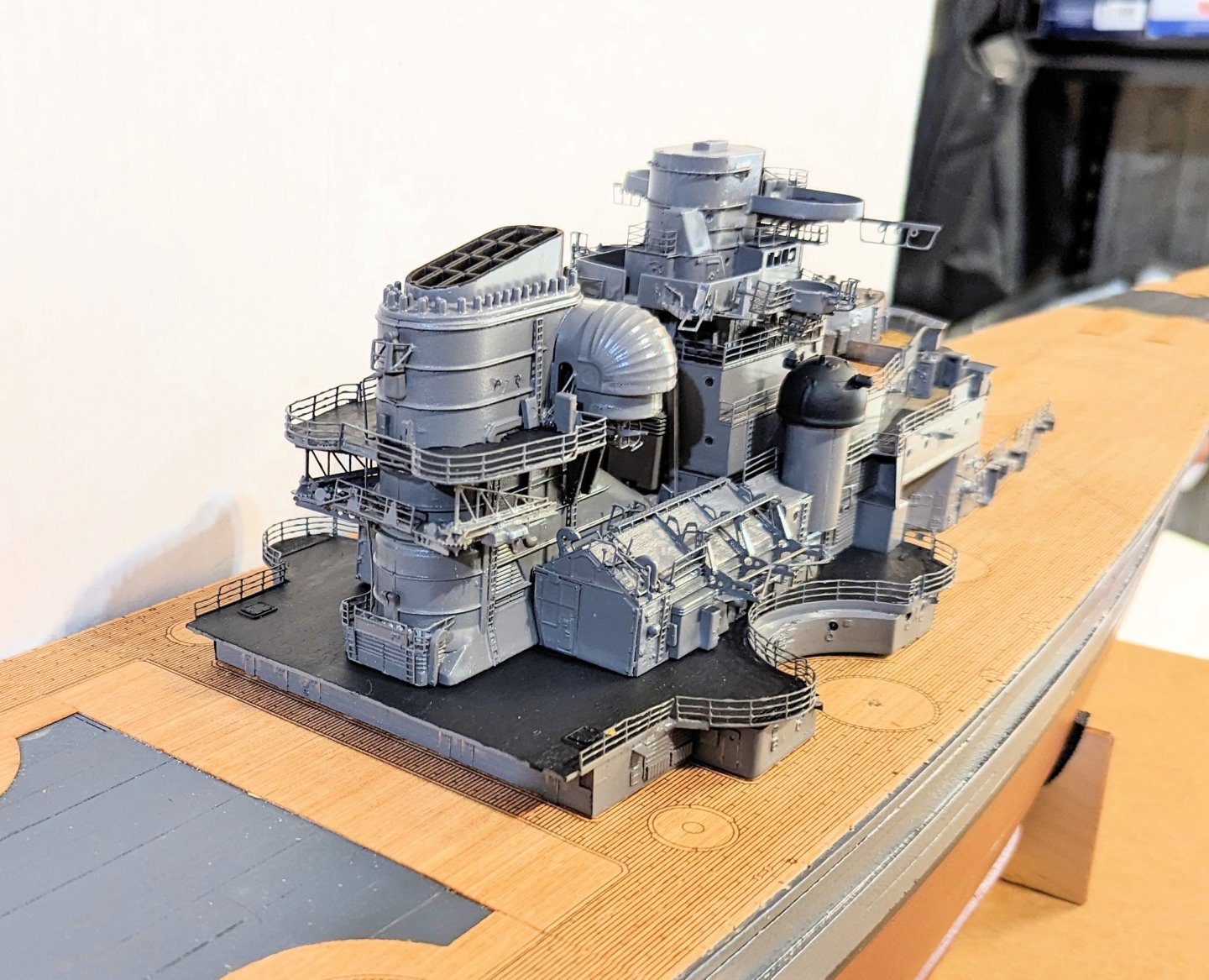

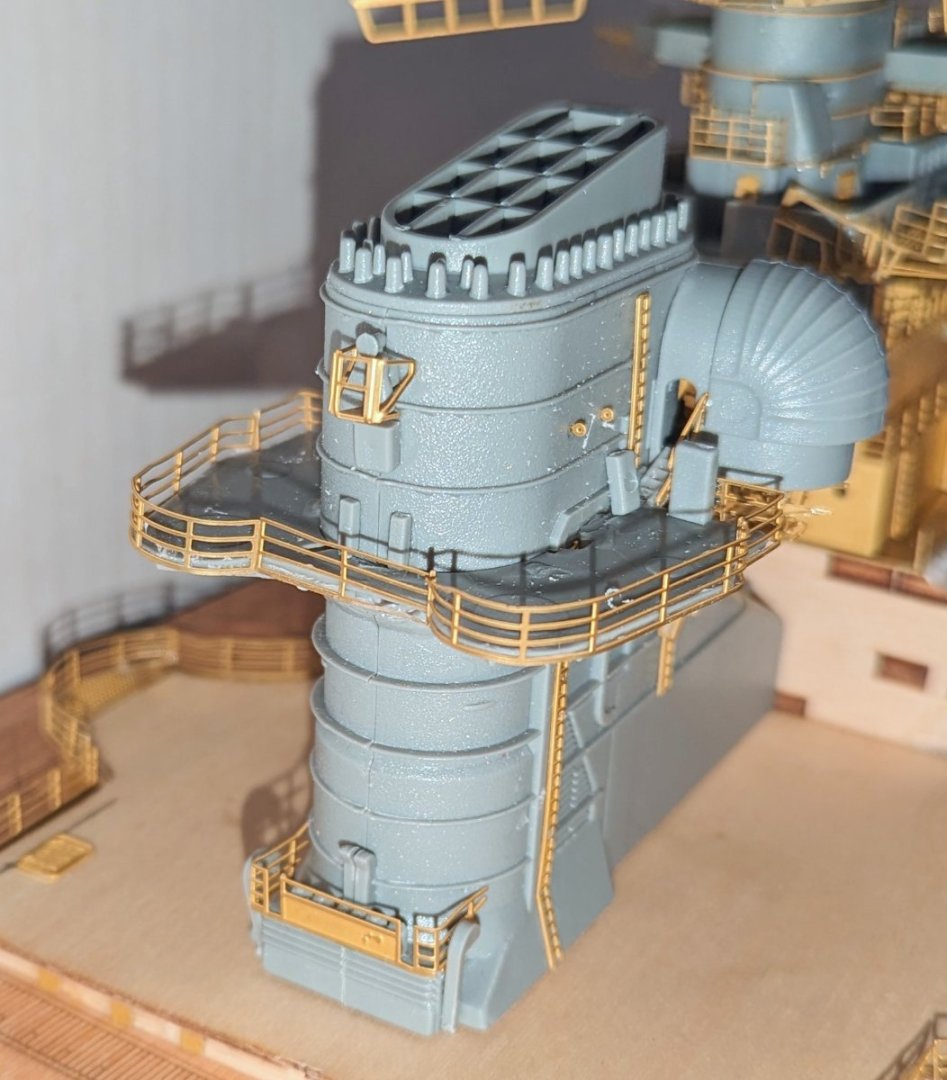

I've had a few pieces that needed painting, and since I put my spray booth away, I've been waiting for a good day to spray those pieces outside. That was today, so I've now finished the bow structure. New parts: mast, ladder next to mast, small catwalk, some braces, two turrets. I started the stern structure a few days ago, so that's underway. Regards, David

-

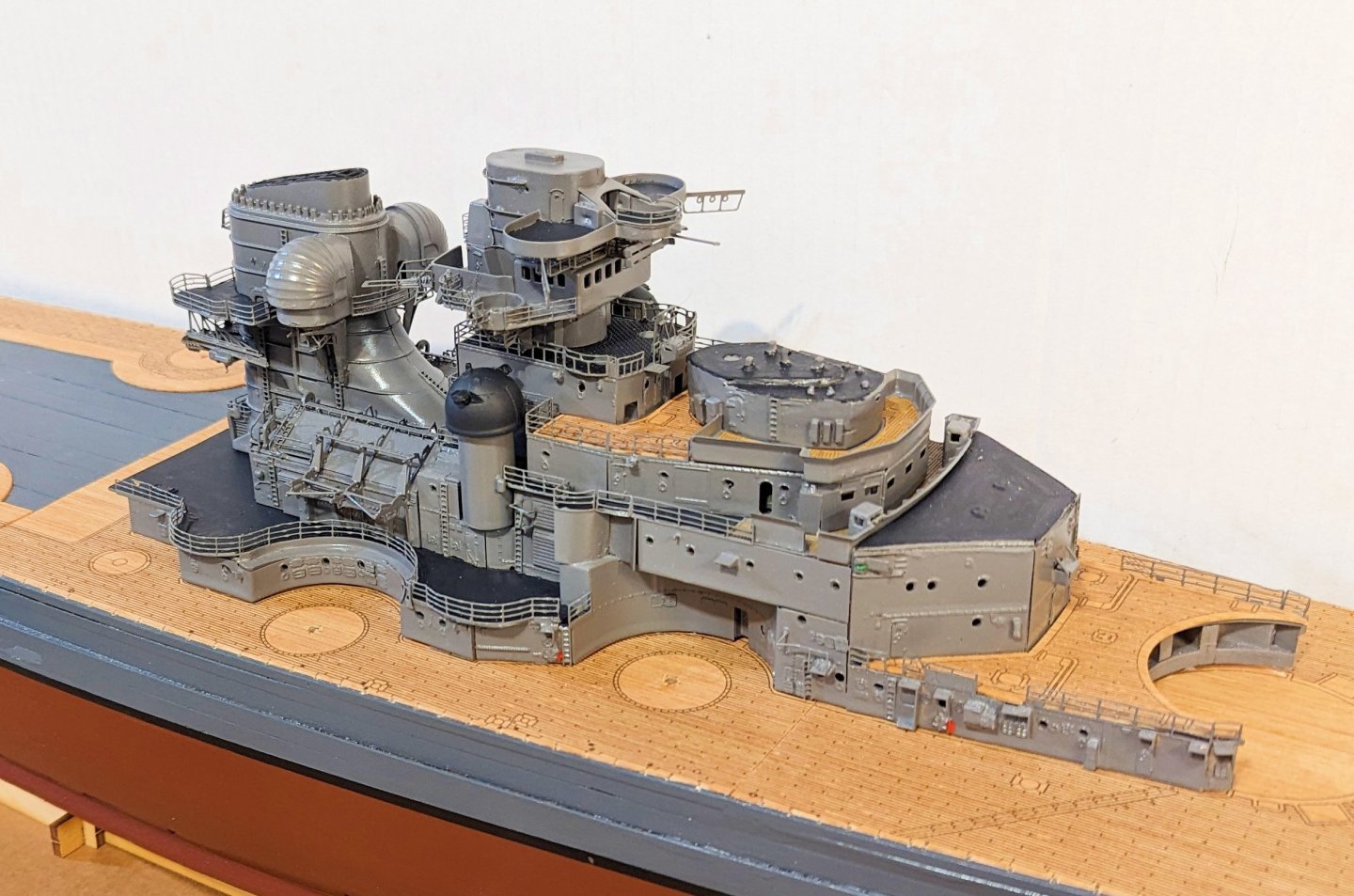

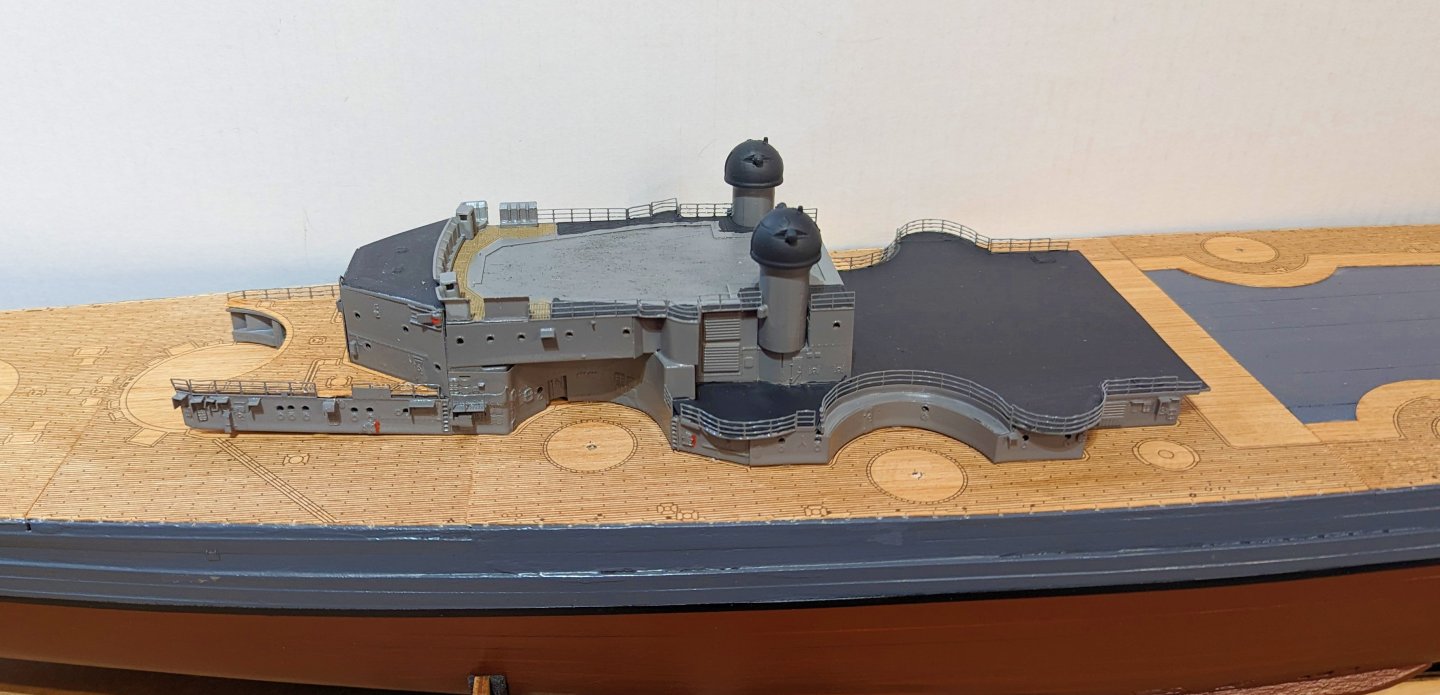

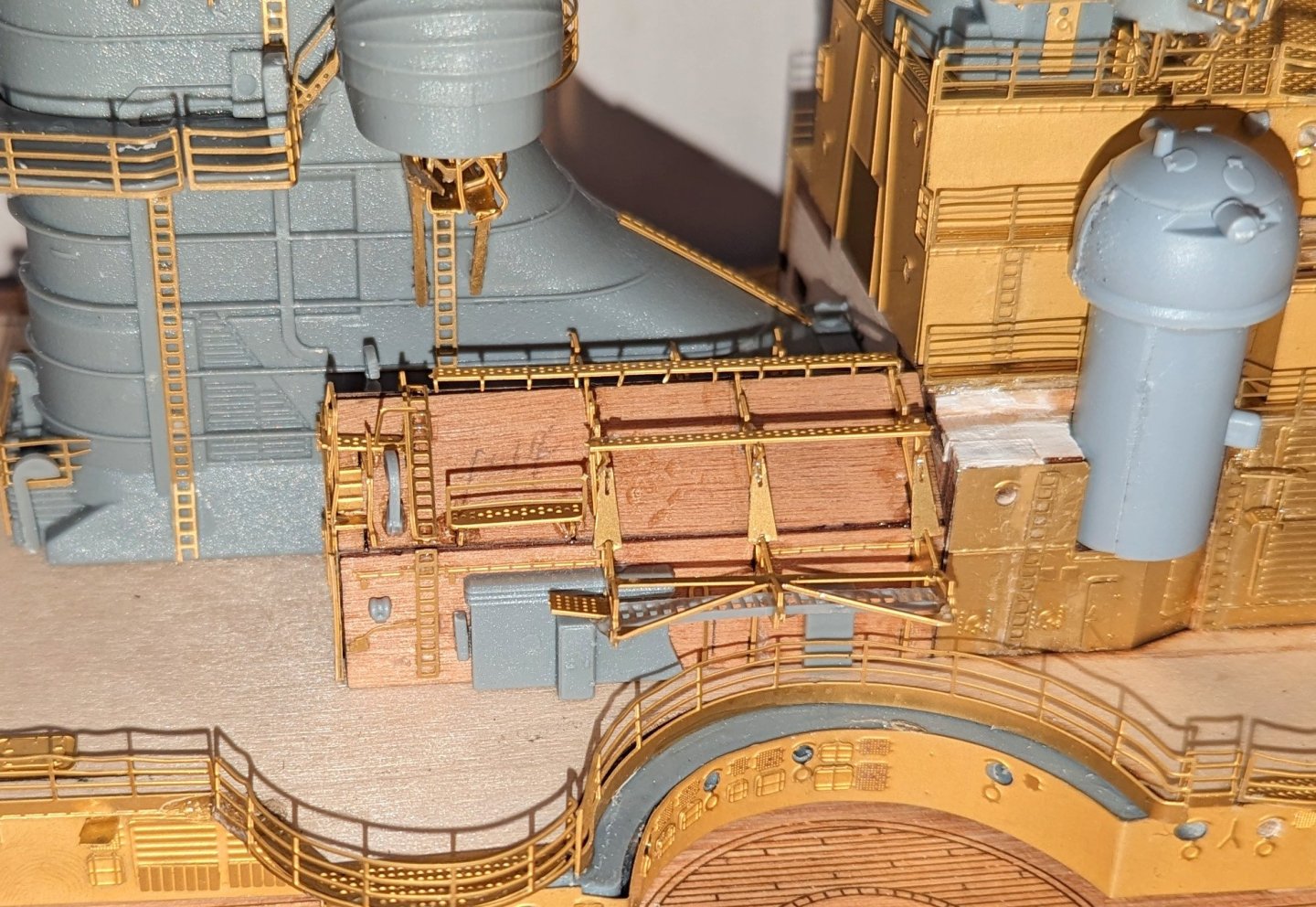

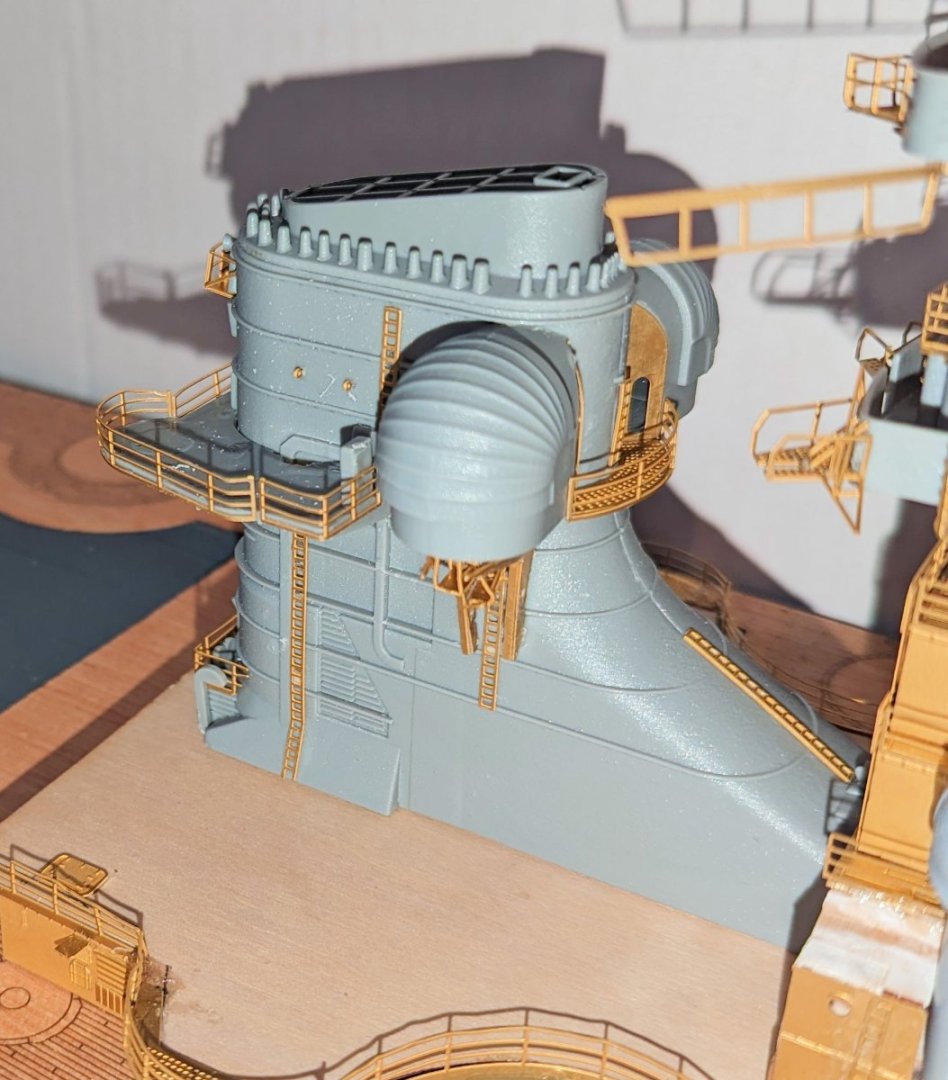

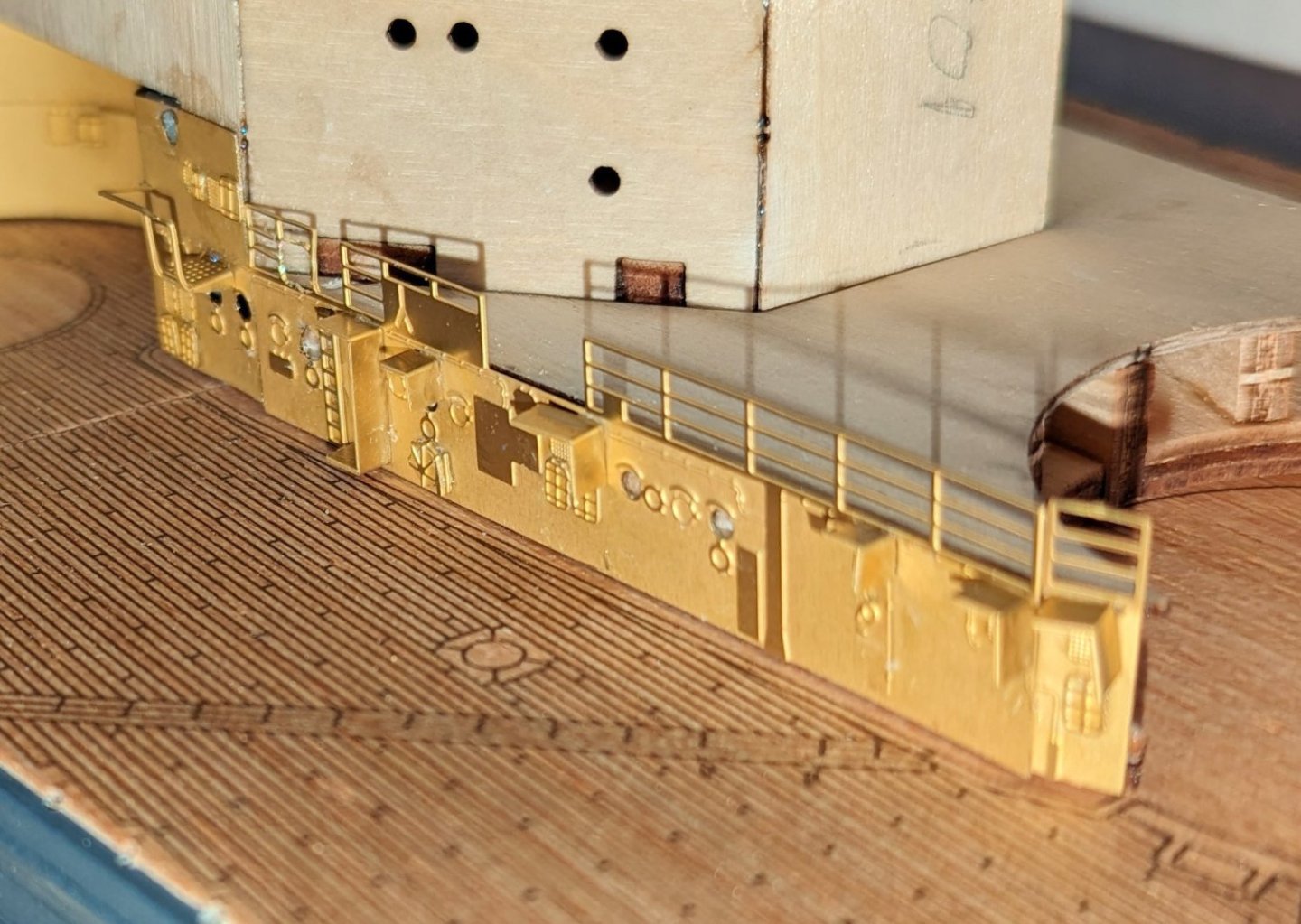

This is the starboard hangar in its position next to the funnel. An identical one goes on the port side, and I will build that now. Really nice detail here -- and of course all of this will be painted gray. A tip: there are notched slots in the roof to accept the brass pieces. I used a craft knife to widen them so they would more easily accept the fittings. Regards, David

-

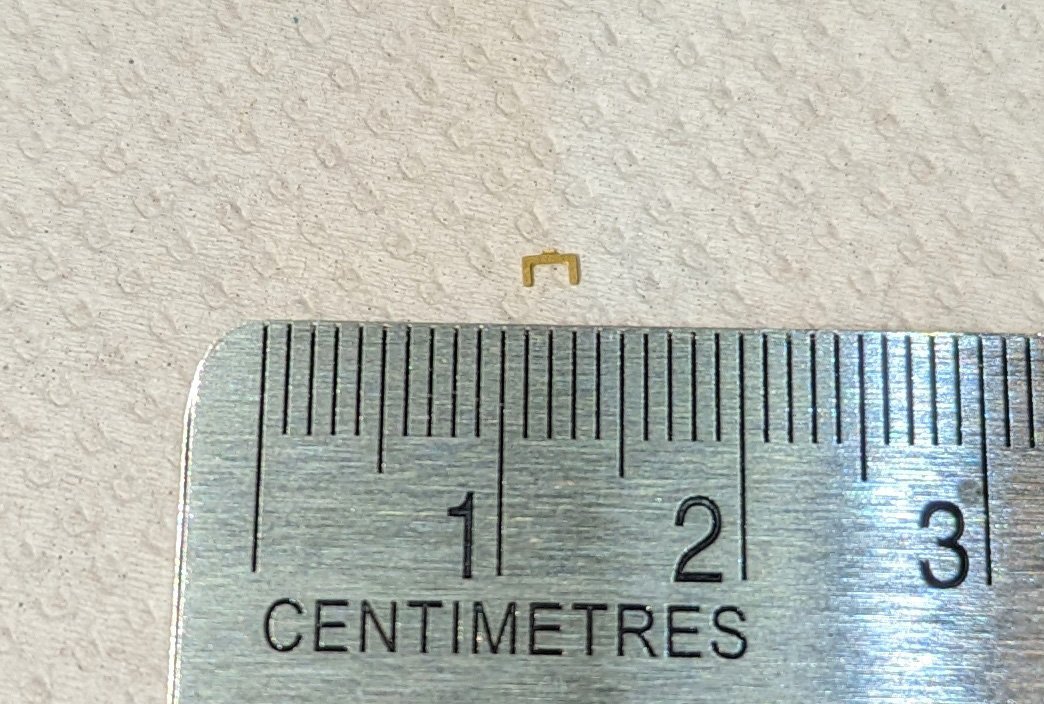

Thanks, Ian. I've found the most challenging part to be the tiny little brass and plastic pieces -- the smallest ones. I've lost a couple that slipped out of my tweezers onto the floor, where I couldn't find them, but they are so small that I have said "to hell with it, they will never be noticed" and moved on. 😁 Regards, David

-

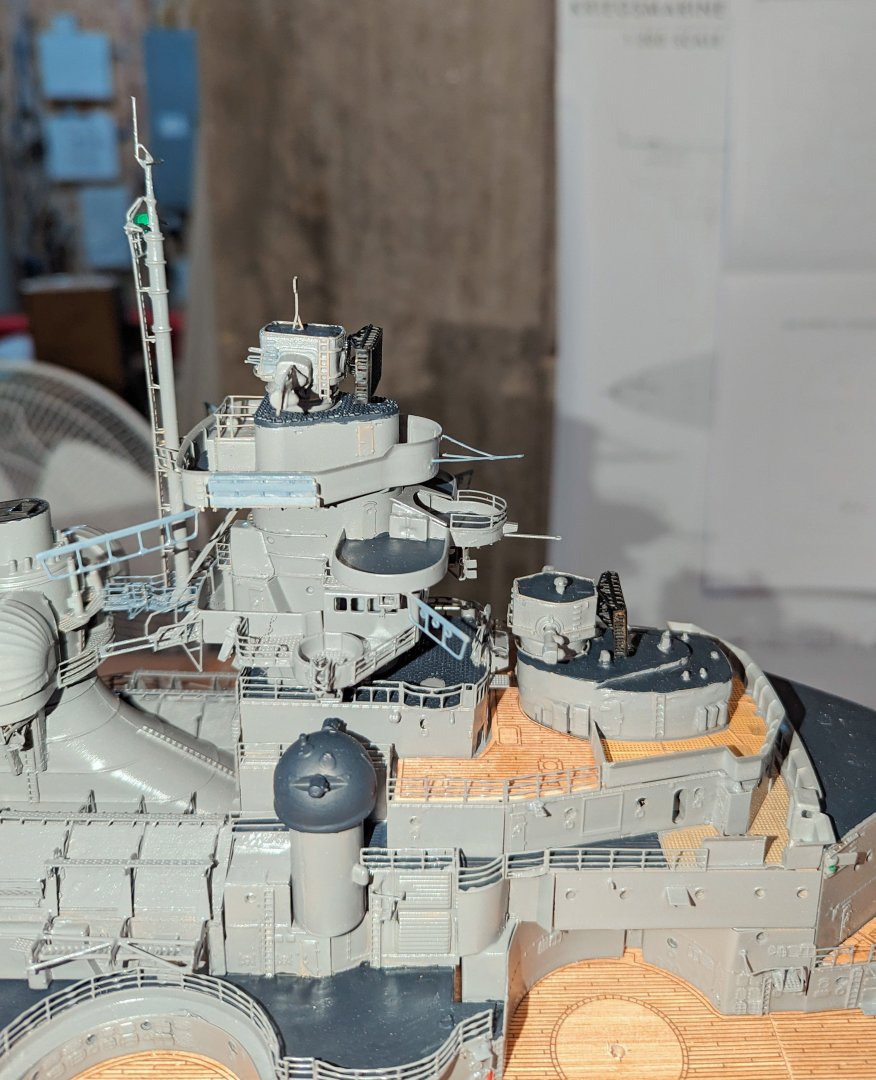

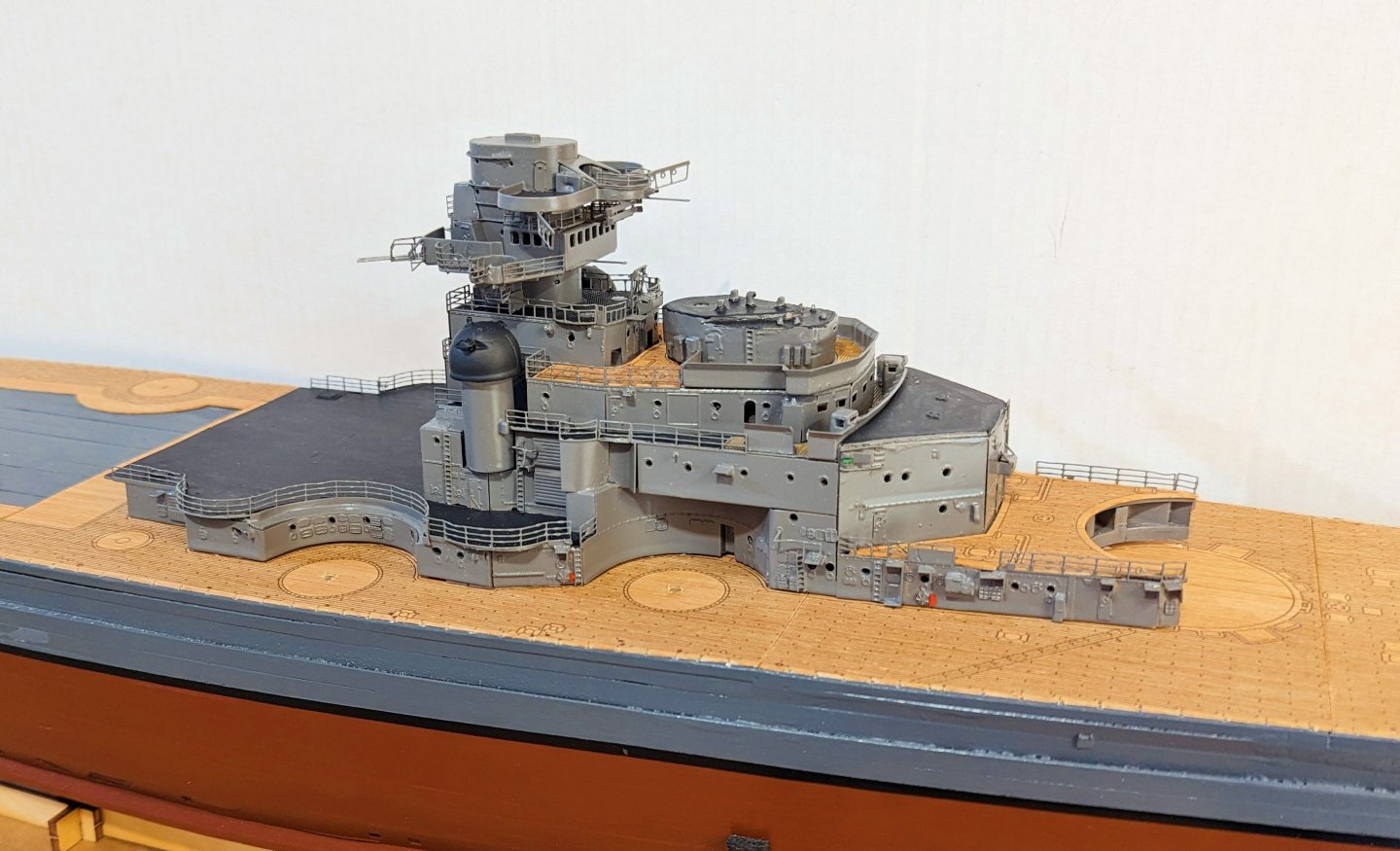

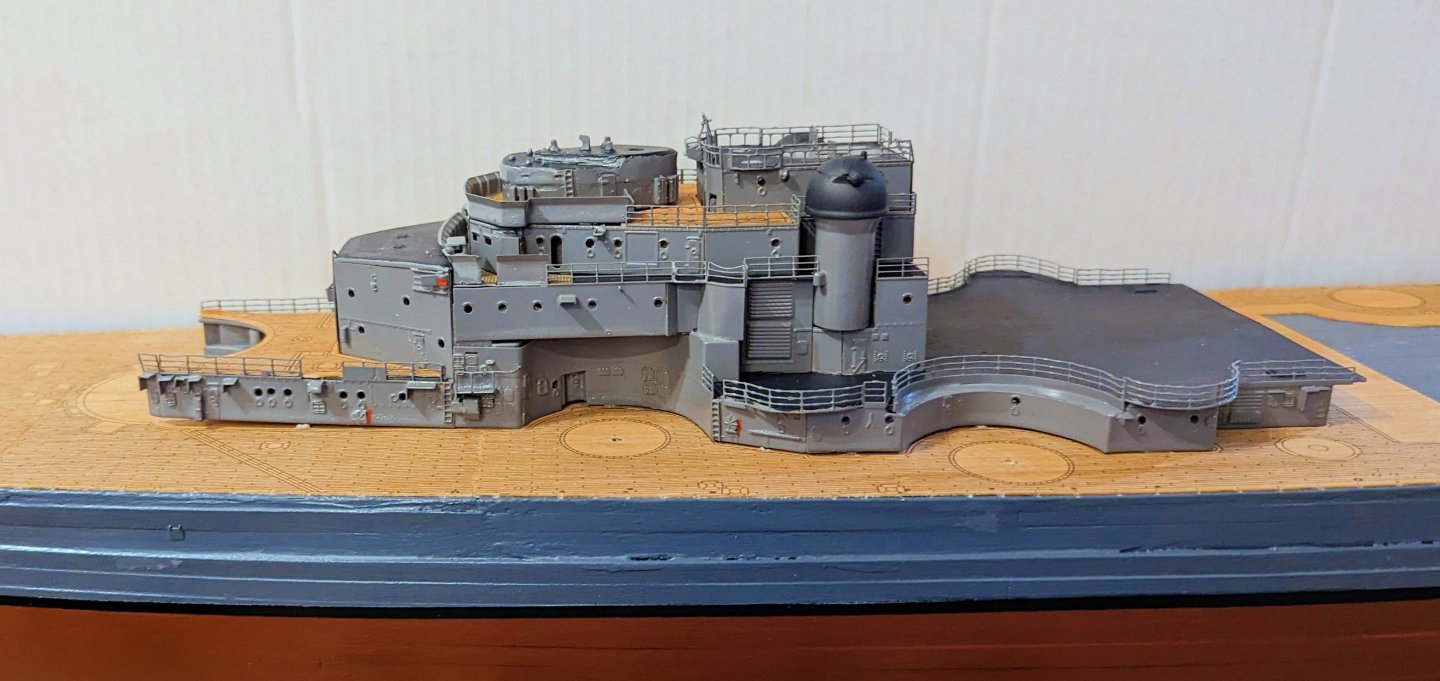

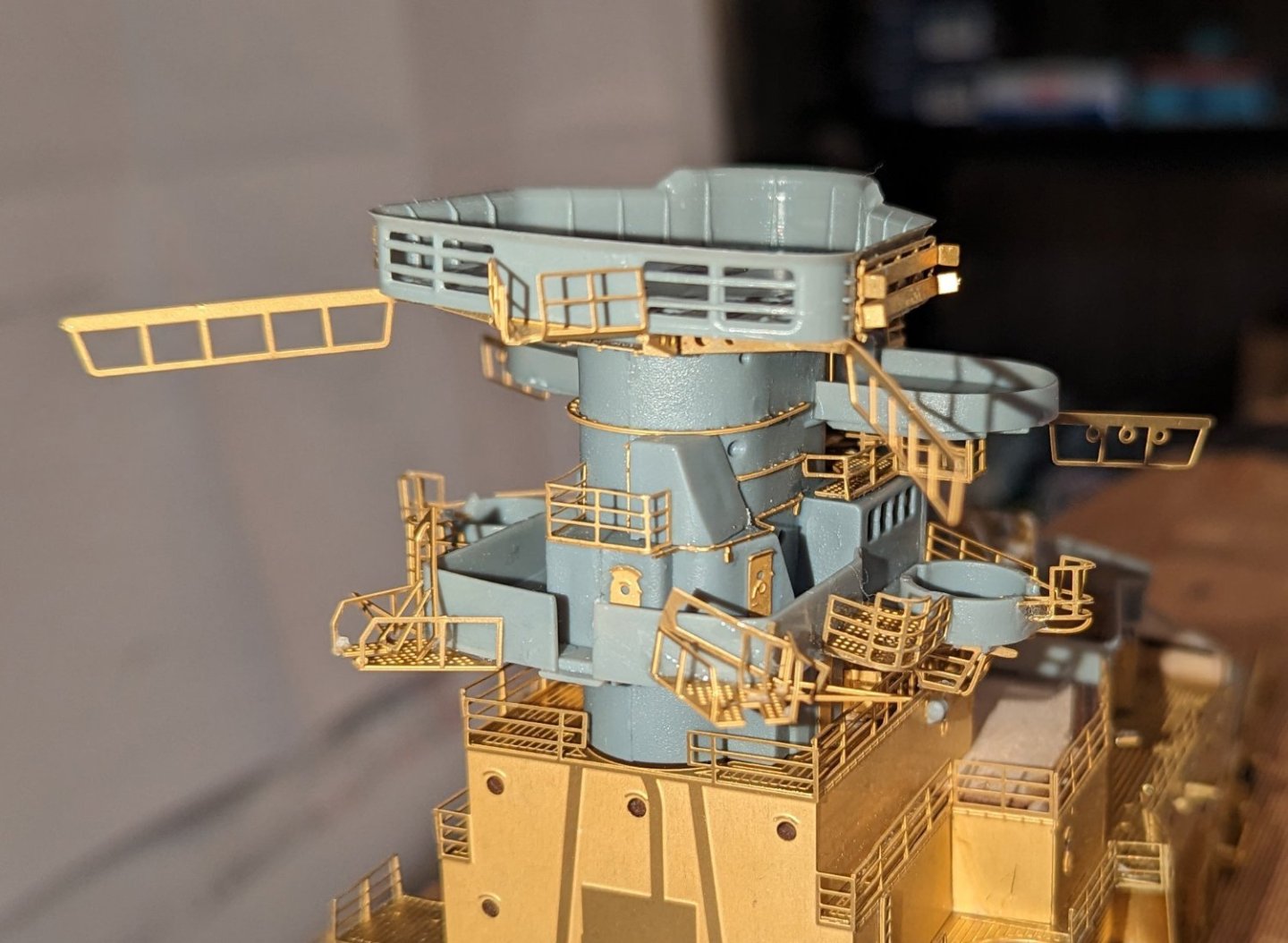

More stages of the bow superstructure. I've added some closeups showing the new detail. The turrets have been removed here and "parked" on a piece of tape. It might seem like I'm going fast, but I had held the previous stage for about 5 days waiting for some paint to arrive, and was working on this stage during that time. Regards, David

-

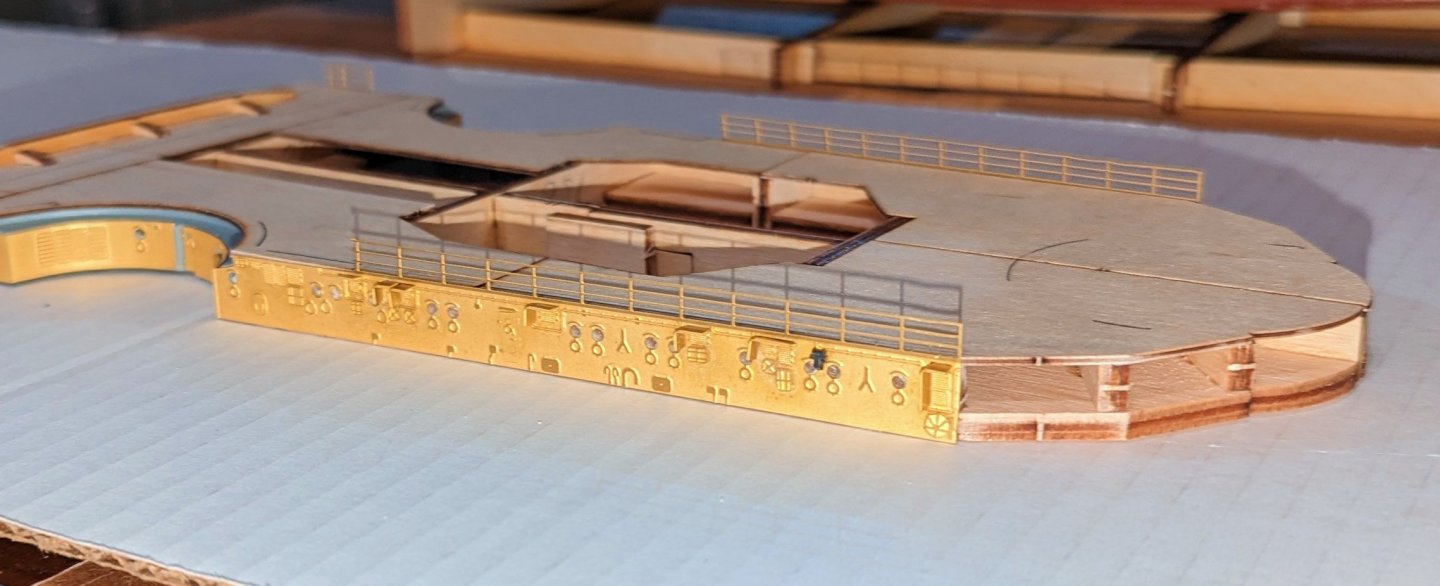

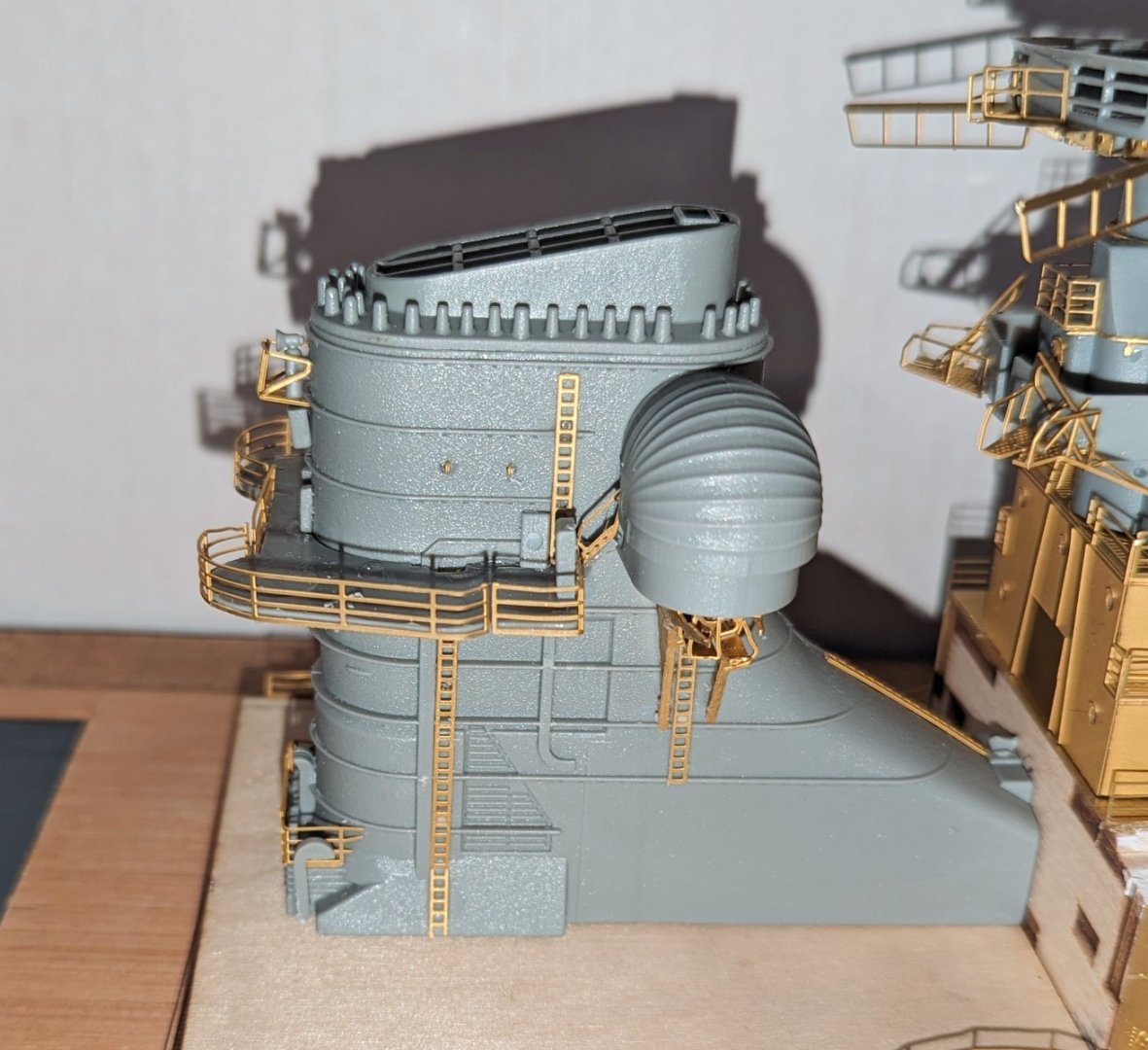

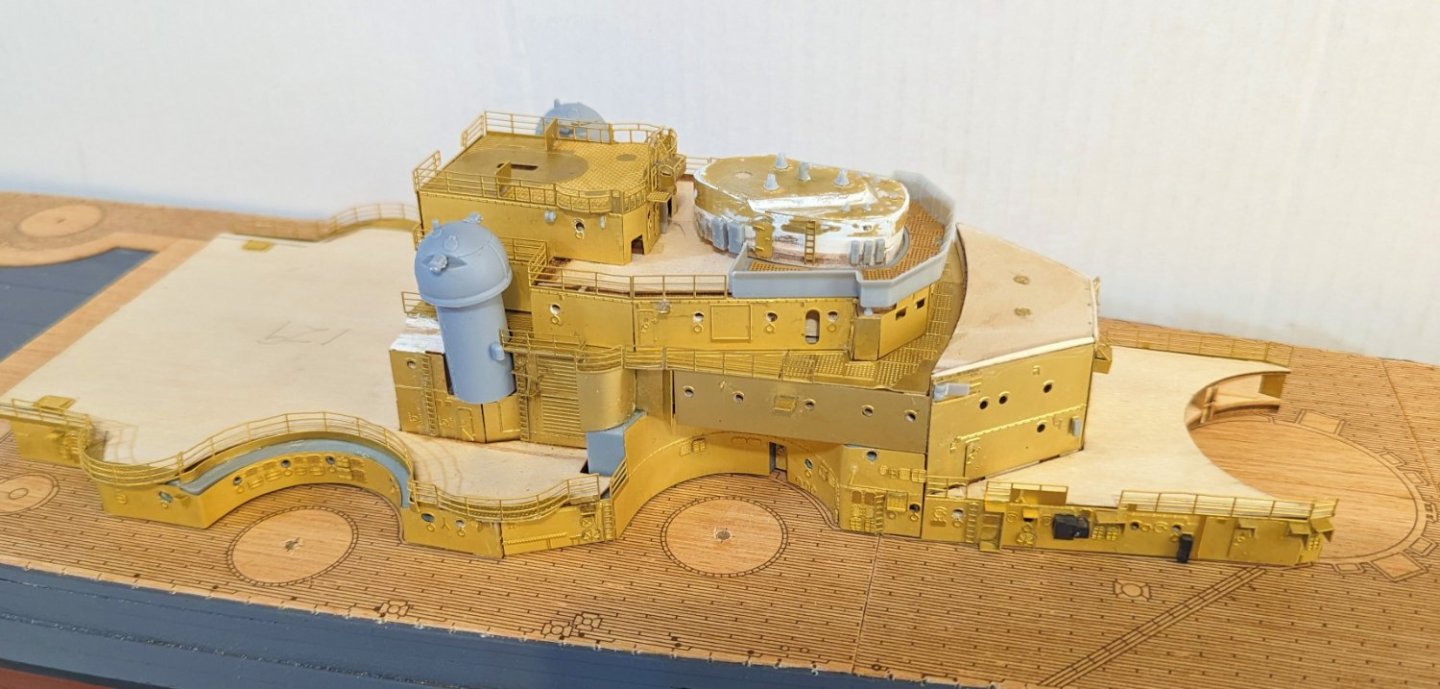

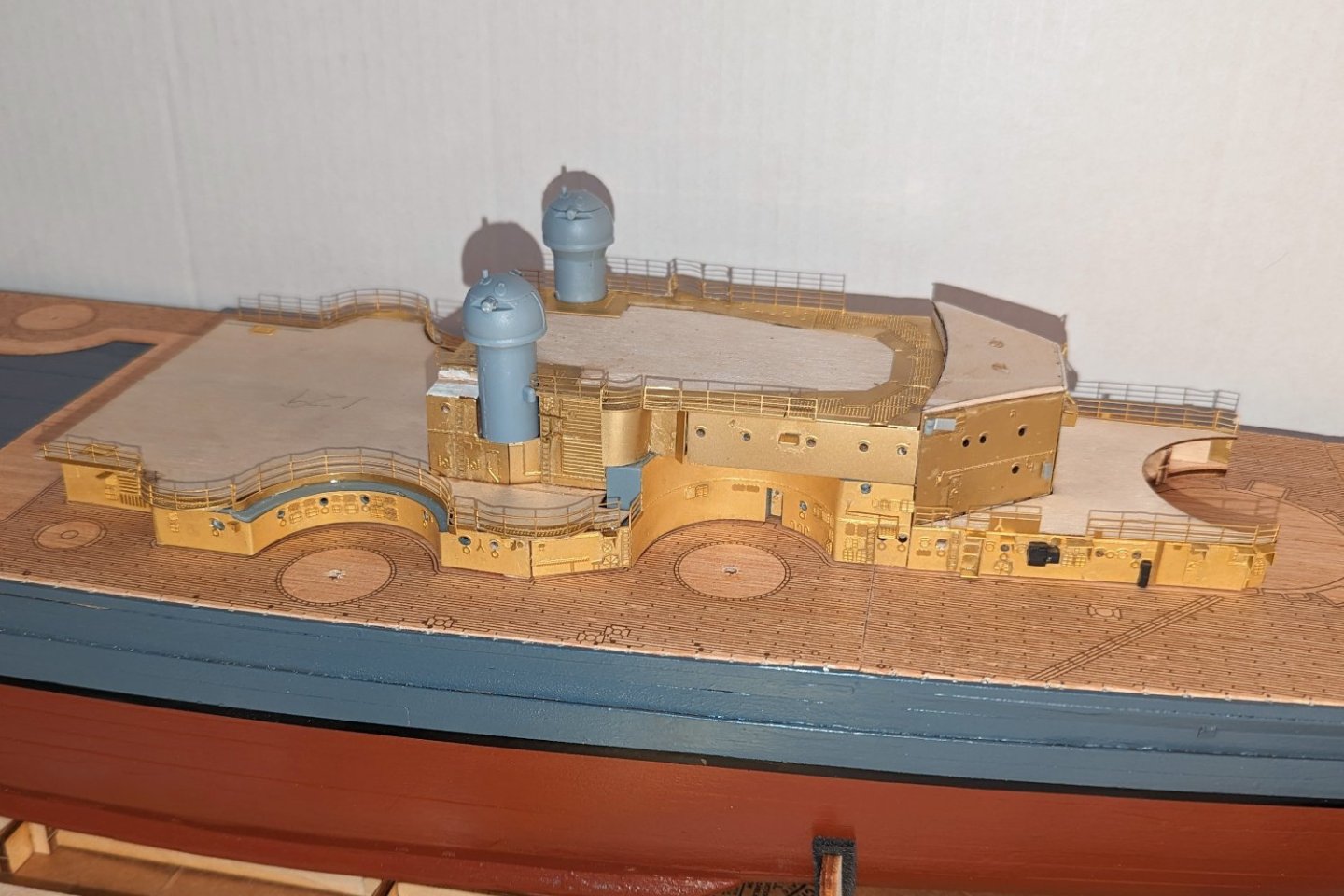

This ship shows an incredible level of detail, achieved by using brass etched sections on the sides that will ultimately be spray painted gray. This is the first level of the starboard side. There is detail etched into the surface of the base plates, and then you add very tiny pieces on top to create additional raised detail. Regards, David

-

Something I forgot to mention for any of you who might be using this build log as a reference for your own Bismarck build: The base frame for the structure in the picture above is initially built in two sections -- front and rear. Those are then joined by stringers on the sides of the beams that run fore and aft -- you can see the beam numbered 75 above, but the join is hidden now. You use the deck pattern to get the spacing of the fore and aft sections right before joining them with the stringers. But the picture in the manual is confusing -- it didn't seem right to me when I looked at my model. It was only after really close inspection and comparison (including using a magnifying glass on the picture) that I realized that the actual pattern I have is different -- slightly -- from the one pictured in the manual. So I then used common sense to do the alignment. Point of this is that you could make a really serious mistake if you just look at the picture and align the way it shows. Regards, David

-

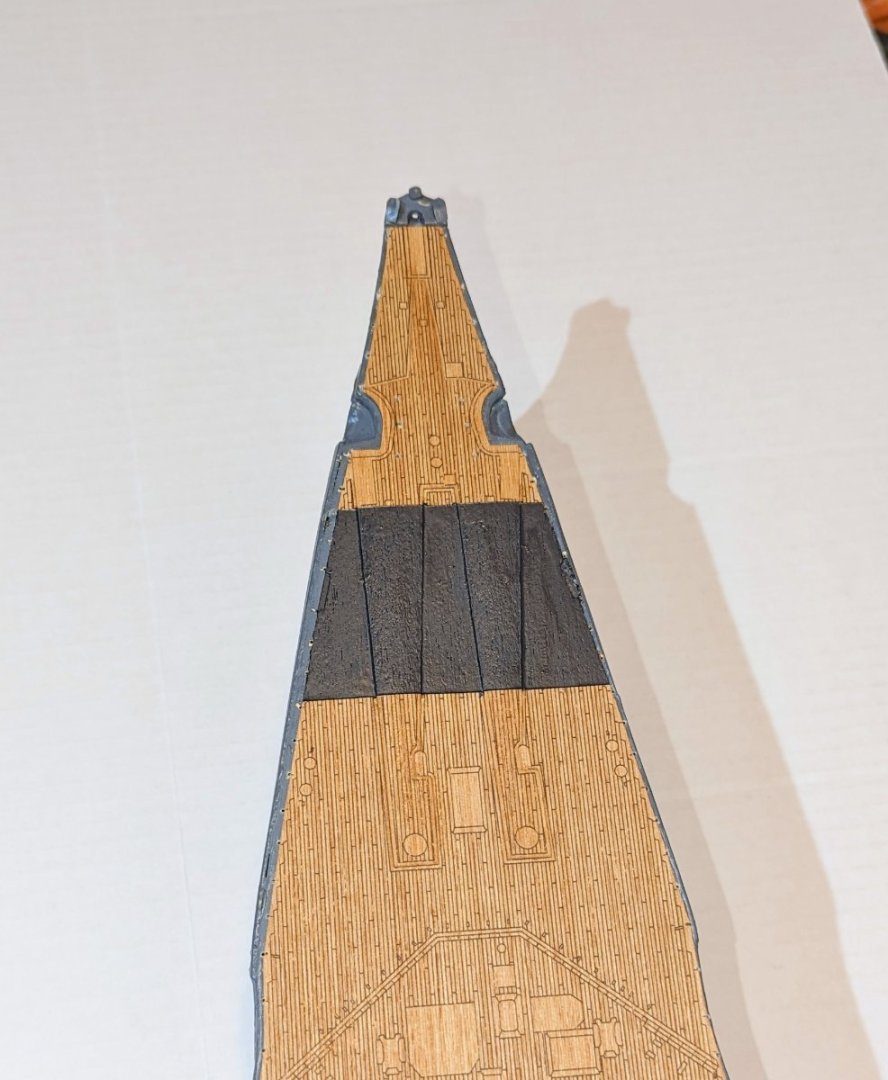

Stanchions (which will go on later) require about 200 tiny holes to be drilled around the edge of the deck. The way my decking fit, there was very little free room beyond it, so for many of the stanchions I'm gong to have to notch a small slot just a bit into the decking to accommodate the stanchion base. Regards, David

-

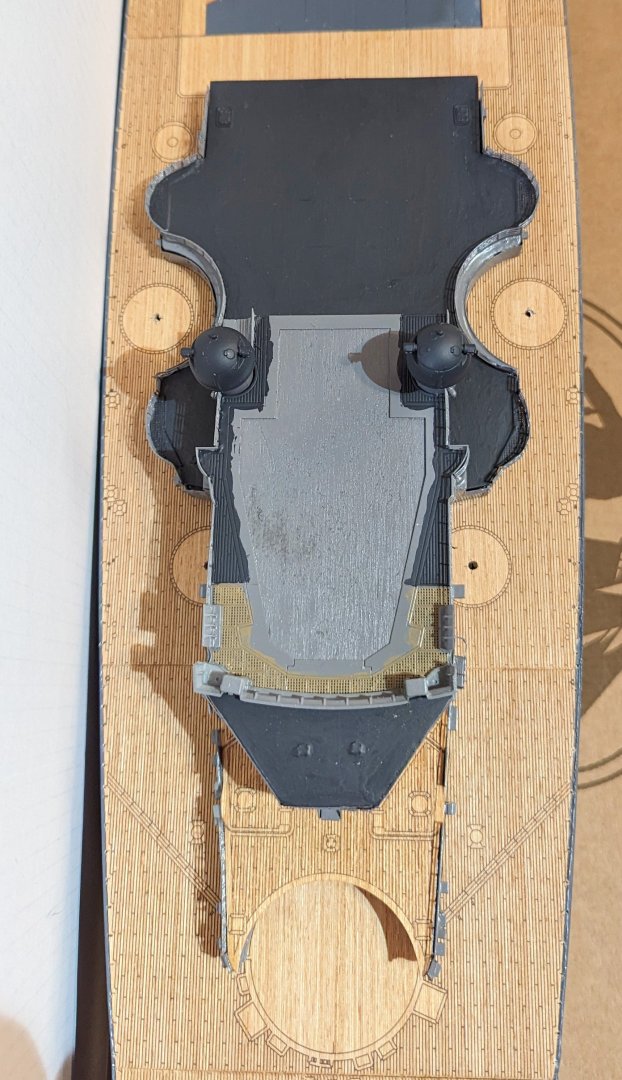

Back from my trip (and finally time zone readjusted), and I've gotten back to the Bismarck. First step from where I left off was to drill the holes under the hull for eventual mounting on a nicer stand than the one they supply with the ship. With that done, I applied the decking, which is thin printed wood sections. The way I did it was to line them all up, sand as required to get everything lined up, and then tape the sections down, checking alignment until I had the whole thing taped. Then I glued sections bow to stern, removing tape and lifting one side, gluing, and then doing the other side. With that done, I varnished the deck. I think varnishing it at this point is important because soon I need to paint two dark gray bands on it, and I want a smooth surface for masking. The unvarnished surfaces are kind of rough wood. Also, if there is any bleed under the mask, scraping it off will look much better if it's on top of varnish. Regards, David

-

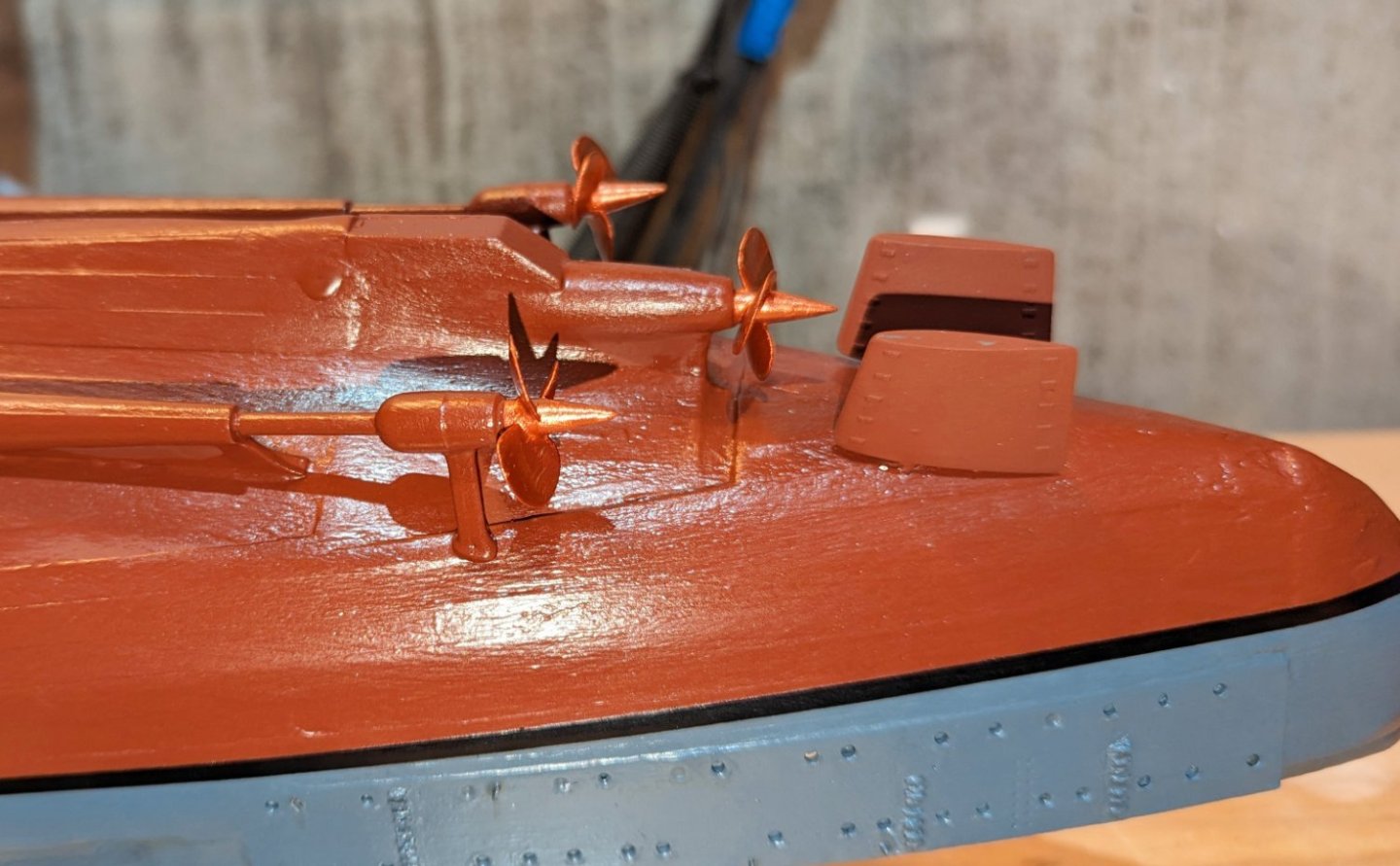

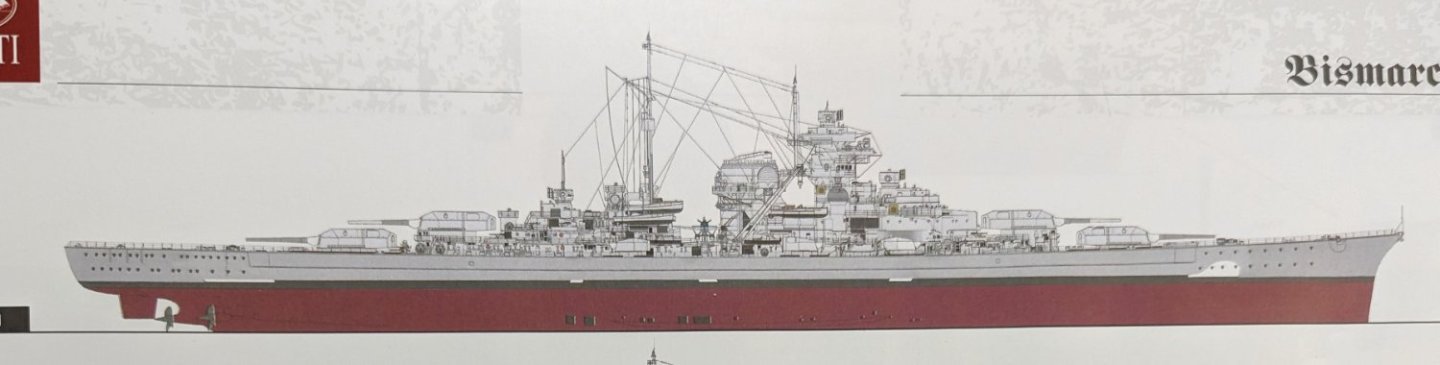

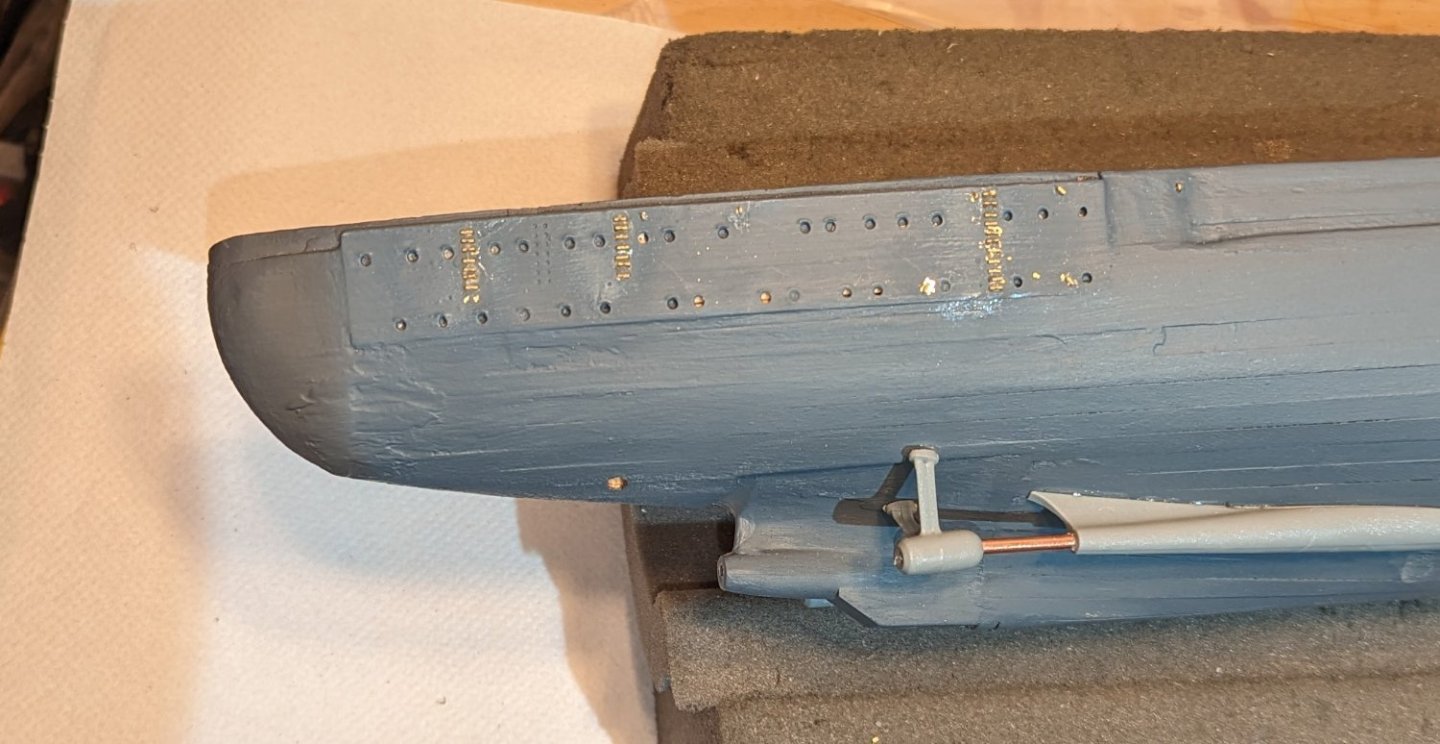

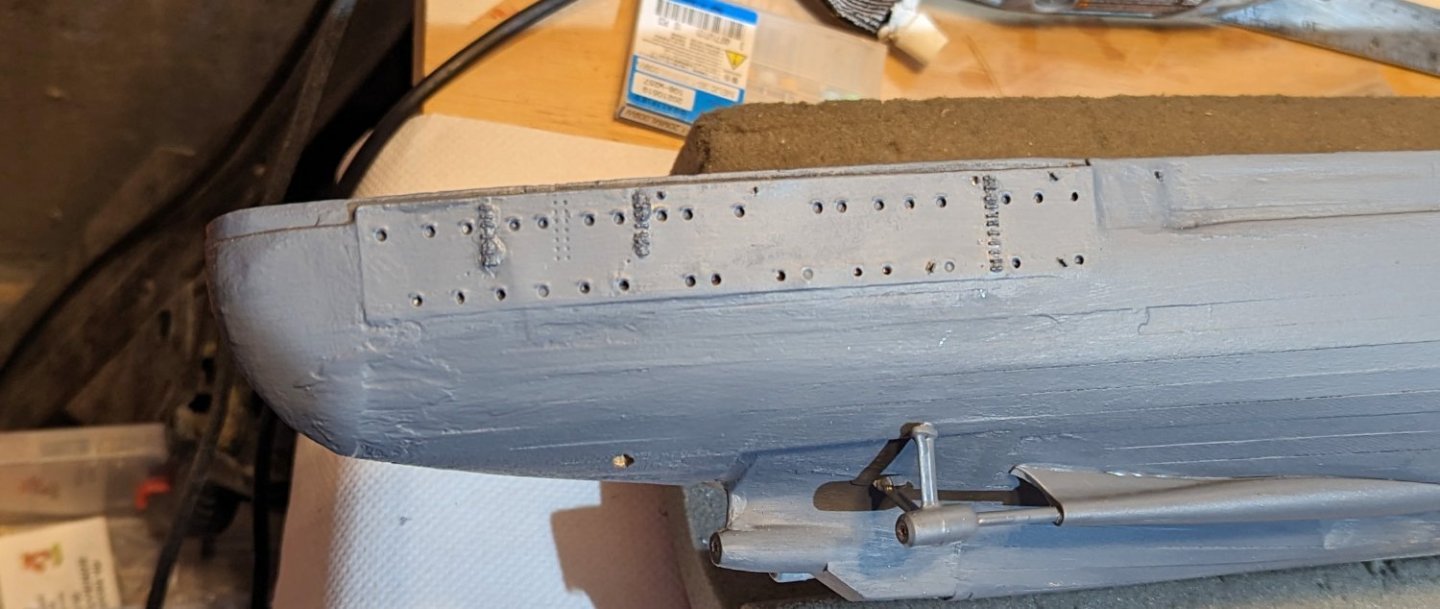

Finished painting the hull. The thin horizontal white patches you see are lighting. Also installed rudder and screws. The screws look the same color in this pic, but they are actually copper-colored. Now my dilemma: I have attached a picture from the manual showing the simplest of the three camouflage patterns. My issue is that I really don't like the way this looks. So after some deliberation, I'm going to skip the white coloring. I really respect those of you that pay close attention to historical accuracy, but I'm going to skip the white designs. This will be my last post until late February. Going on a long winter trip. Regards, David

-

So I flipped the model over and did the last ladder -- the one in the center. Tried a new approach, which is to spread out some glue and dip the ladder rung points in it and then insert, and then you can see the difference. I wish I had tried this earlier. So with this I'm now ready to paint the lower hull red-brown. Regards, David

-

Over to the other side and up the learning curve. On this side I did two things: (i) Drilled out the holes in advance, and (ii) Used my super bright LED headlamp so I could see the holes clearly as I was installing the rungs. Worked better. The first picture reflects all of the skipping of the drill bit on the metal surface. The second one, now painted, shows the "glue globs" between the rungs. So I took a needle file to it and cleaned it up (third picture) as best I could. As they say, "It is what it is." I only have enough rungs left to do three ladders on each side. My loss rate decreased but was still greater than zero. So now I'll go back to the other side and add the third ladder, and paint it. There are also some very small eyebolts and keybolts that have been added. Not sure if you can see them or not. Regards, David

-

I'm applying the ladders to the external hull at the stern. The way Amati has designed this is that you do it rung by rung, into pre-drilled holes in the brass plate at the stern. The issue is that the rungs are fiendishly small. So they are very difficult to grip with tweezers, and of course, they pop out of the tweezers. If that happens, they are almost impossible to find on the floor or even on the workbench. As part of my learning curve I've now put a white paper towel under the stern area, and if they pop out onto that you can see them. But I've lost 6 already, and so I'm down to 2 spares to cover the remaining ladders. What you see is the two ladders I've done on one side. As you can also see, there are holes for two more on this side for a total of four on a side. Counting what I have left, if I don't lose anything else, I could make it with two spares left. But not confident in that. So I'm going to flip the model and do these two ladders on the other side. That will leave four to go. I'll do two (one on each side), and then assess my technique and spares supply to see if I can do the last one. One thing that helps is to drill out the holes. Then put in the rung without glue, then drop on some glue. Slow going as you have to wait for the glue to dry, or use accelerator. So now I'll attack the same two ladders on the other side and see if I've learned anything, and I'll report about that. Regards, David

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.