-

Posts

78 -

Joined

-

Last visited

About Guillermo Eduardo Madico

- Birthday November 17

Profile Information

-

Gender

Male

-

Location

5 Chrysler Rd. Natick MA USA

Recent Profile Visitors

-

Saburo reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

Saburo reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

DaveBaxt reacted to a post in a topic:

Acrylic paint tips and techniques

DaveBaxt reacted to a post in a topic:

Acrylic paint tips and techniques

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Jeff 1/48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Jeff 1/48

-

Guillermo Eduardo Madico started following NAIAD 1797 by Bitao - 1:60 , Le Soleil Royal by Nek0 - 1/72 - Marc Yeu , La Palme by Tobias - 1:36 - POF and 7 others

-

Hello Chuck, Those were great modification; both the reduction in size and moving after the top part. Have you consider moving the bottom part/post a little to keep that diagonal line? Same as the top part but in the opposite direction (forward instead of after). The candle will need to stand by it self to stay center. I think the thicker candle also improved the look. In the drawing of the lantern parts, the top part appears rotated 60 degrees to the rest of the lantern (the arista of the top part does not align with the arista of the lantern. I really like the way it is drawn. Although the way you placed the top is the way it appears in contemporary models with the arista aligned, I will follow your drawing in my build. my 25 cents, G

- 1,784 replies

-

- syren ship model

- winchelsea

-

(and 1 more)

Tagged with:

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by westwood - 1:48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by westwood - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Guillermo Madico - semi scratch build

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by Guillermo Madico - semi scratch build

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

scrubbyj427 reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

scrubbyj427 reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by Rustyj - FINISHED - 1:48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by Rustyj - FINISHED - 1:48

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 a 1/35 por Jorge Diaz O

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 a 1/35 por Jorge Diaz O

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by Rustyj - FINISHED - 1:48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by Rustyj - FINISHED - 1:48

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

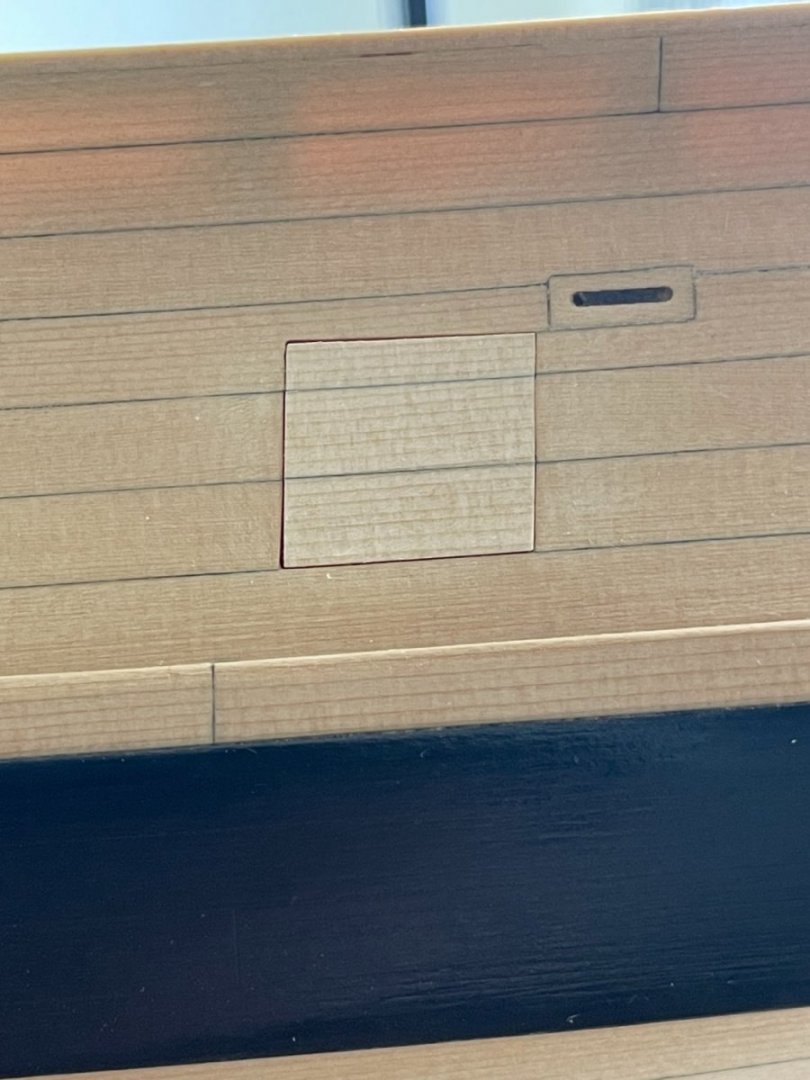

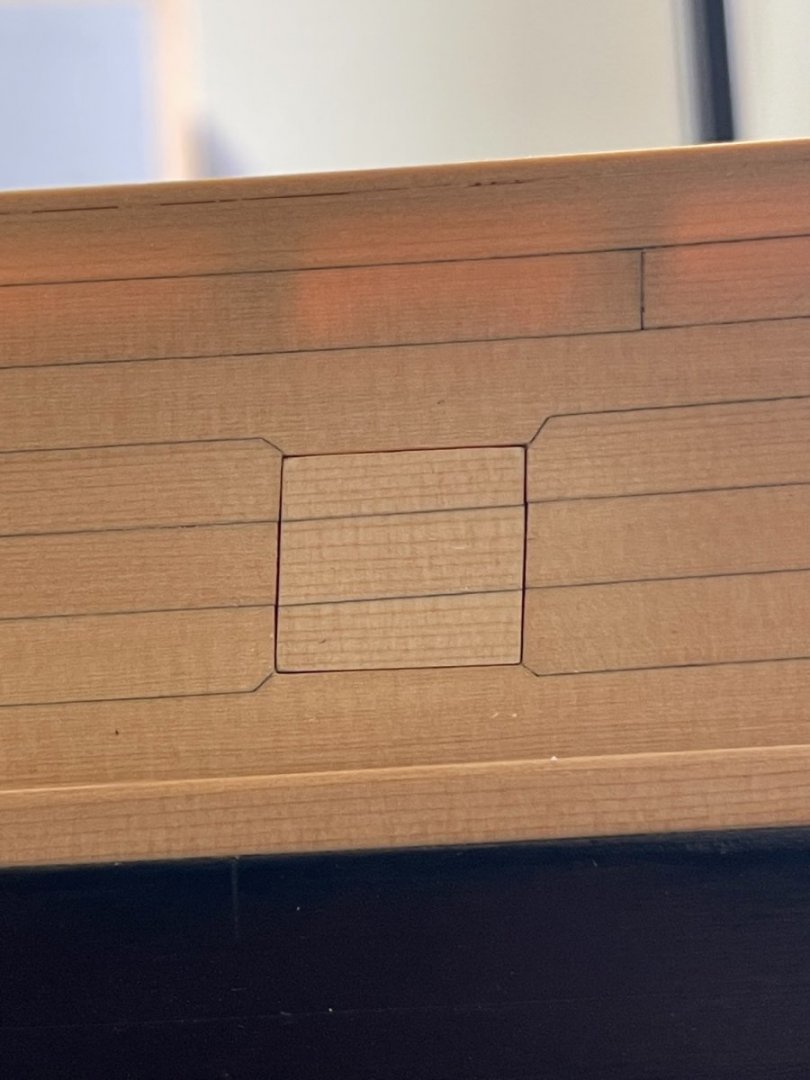

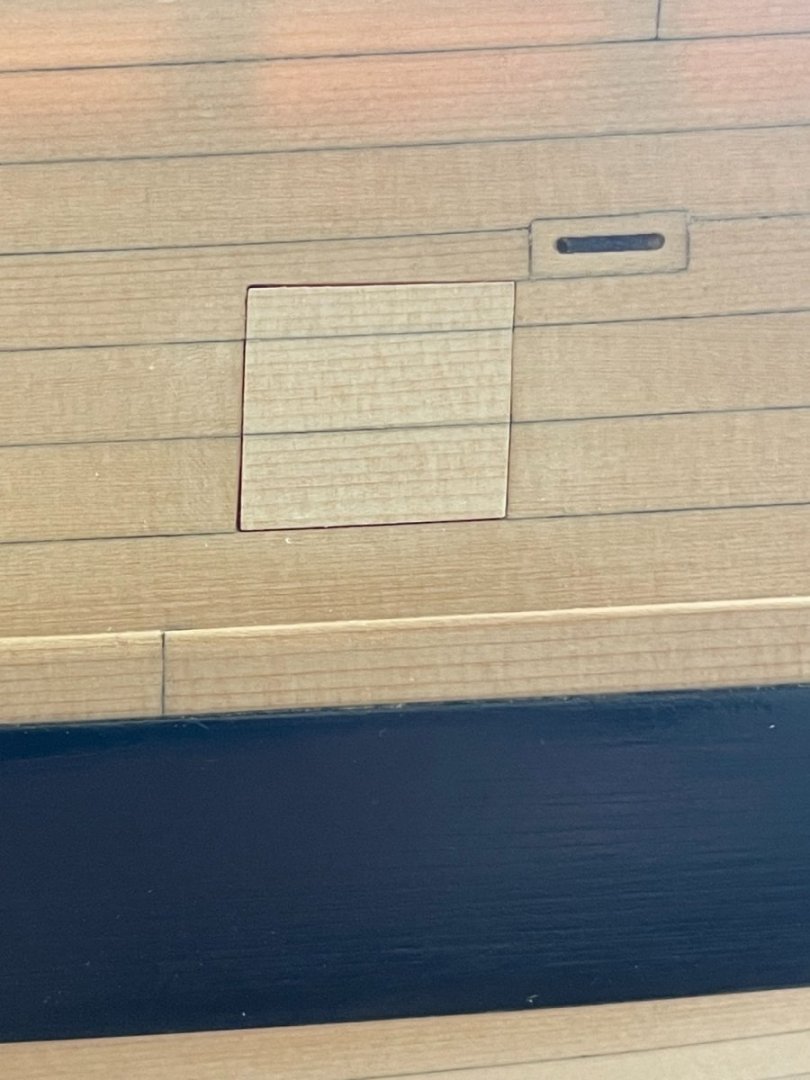

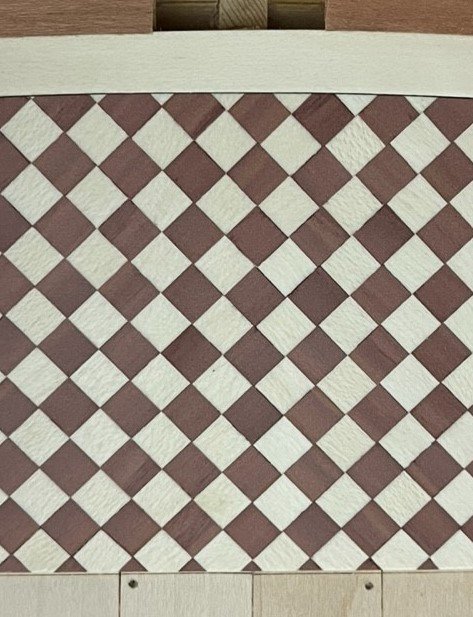

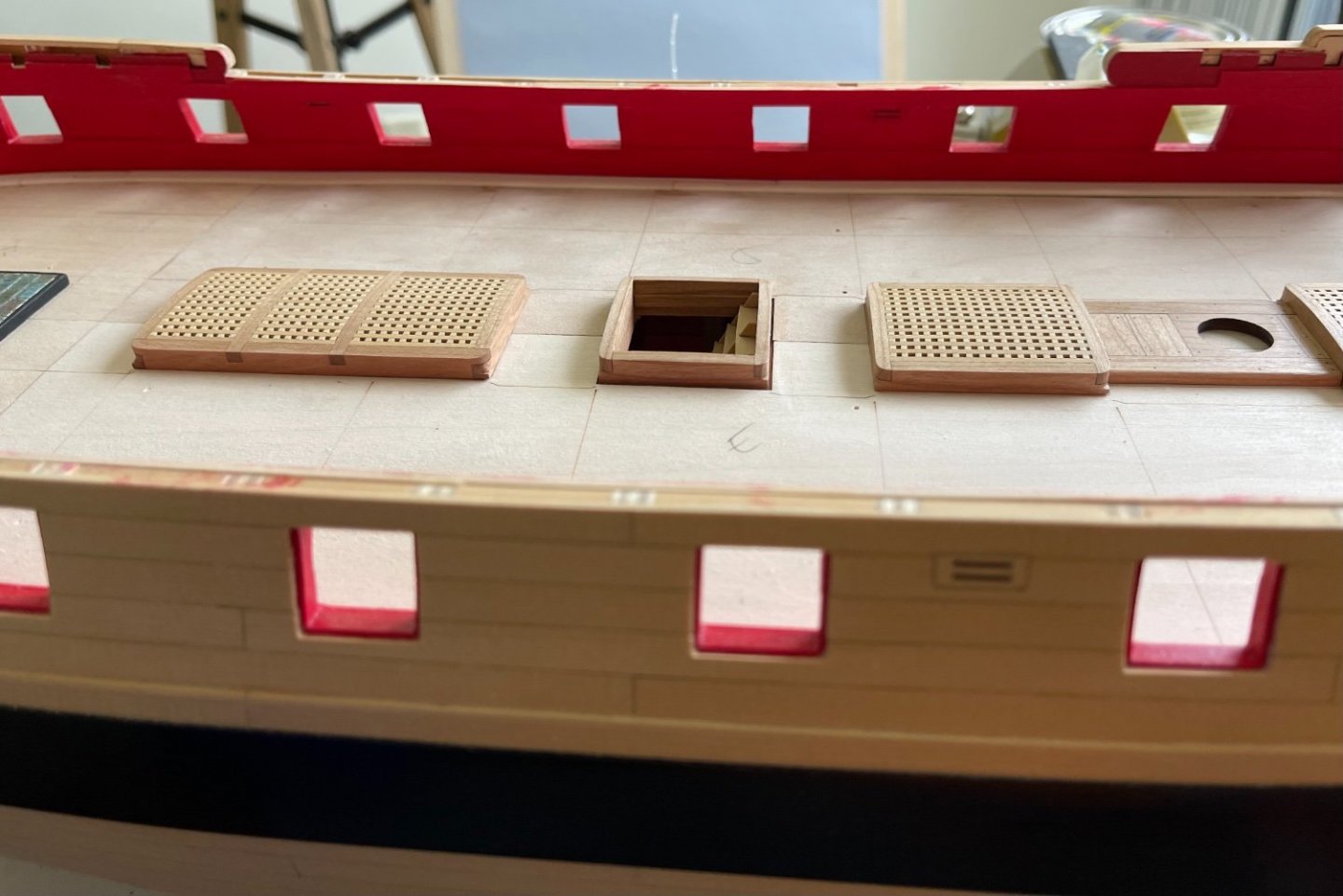

Thank you Vladimir and all for the likes. I finished the captain deck. I followed the method Chuck told us by gluing strips of wood first and cut them again ensuring the the cut is a perfect square. I made a template and glued the strips in a "V" pattern to keep the squares aligned. I use holly and red cedar. Next deck planking. Best, G

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

Guillermo Eduardo Madico reacted to a post in a topic:

1/48 Winchelsea by Dave S

Guillermo Eduardo Madico reacted to a post in a topic:

1/48 Winchelsea by Dave S

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by rafine 1/48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea by rafine 1/48

-

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - 1:48

Guillermo Eduardo Madico reacted to a post in a topic:

HMS Winchelsea 1764 by glbarlow - 1:48

-

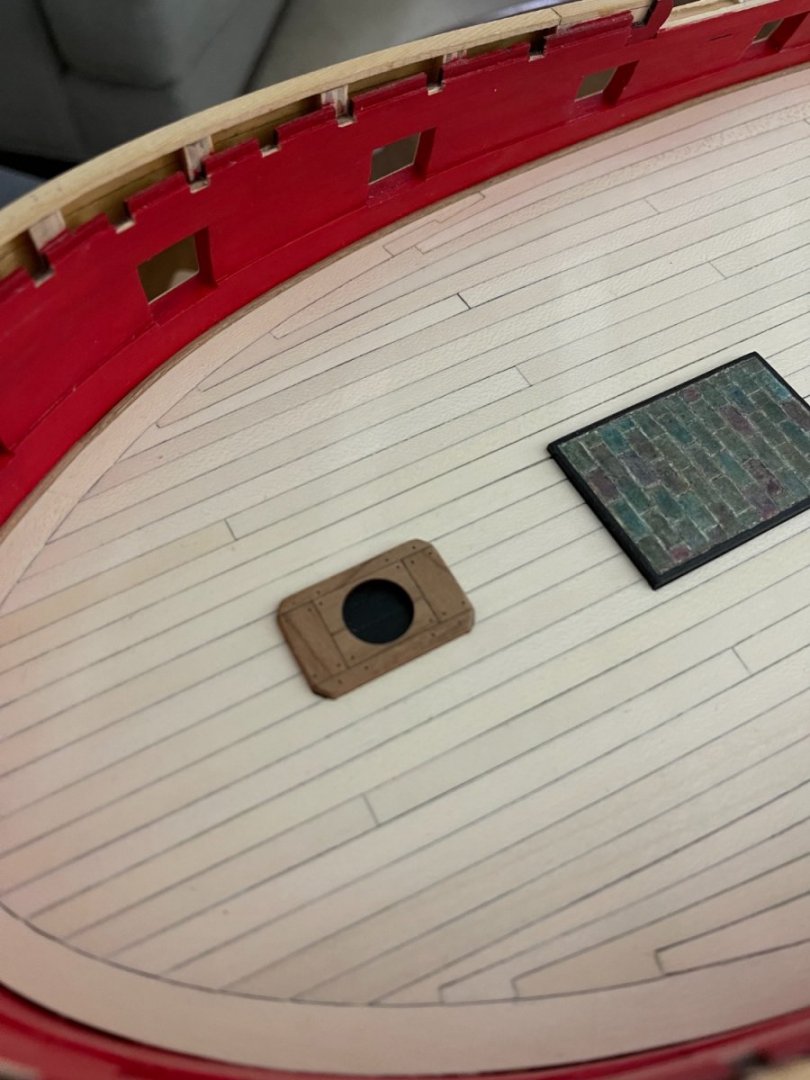

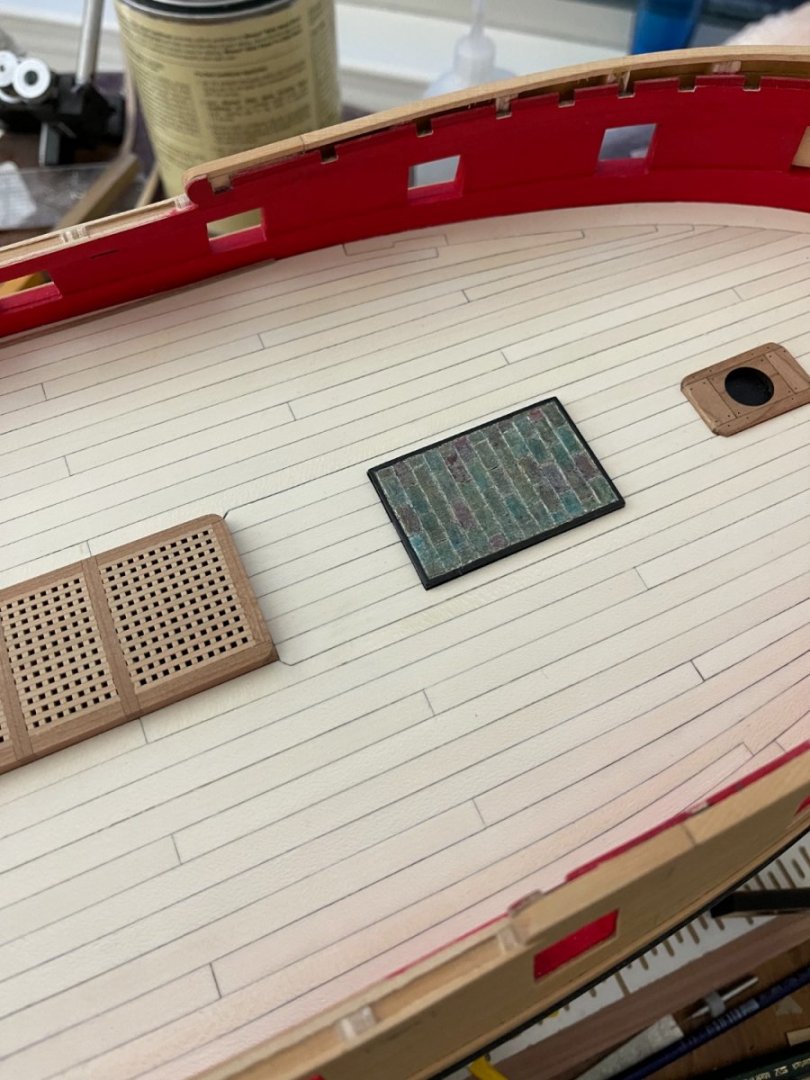

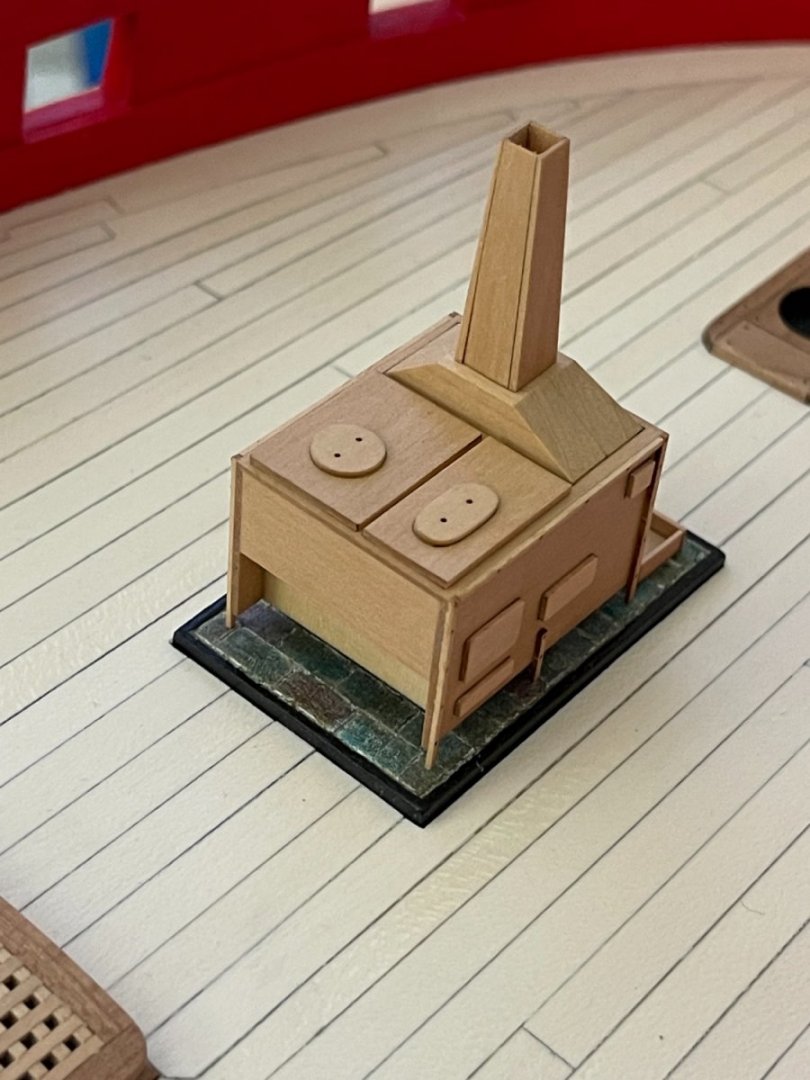

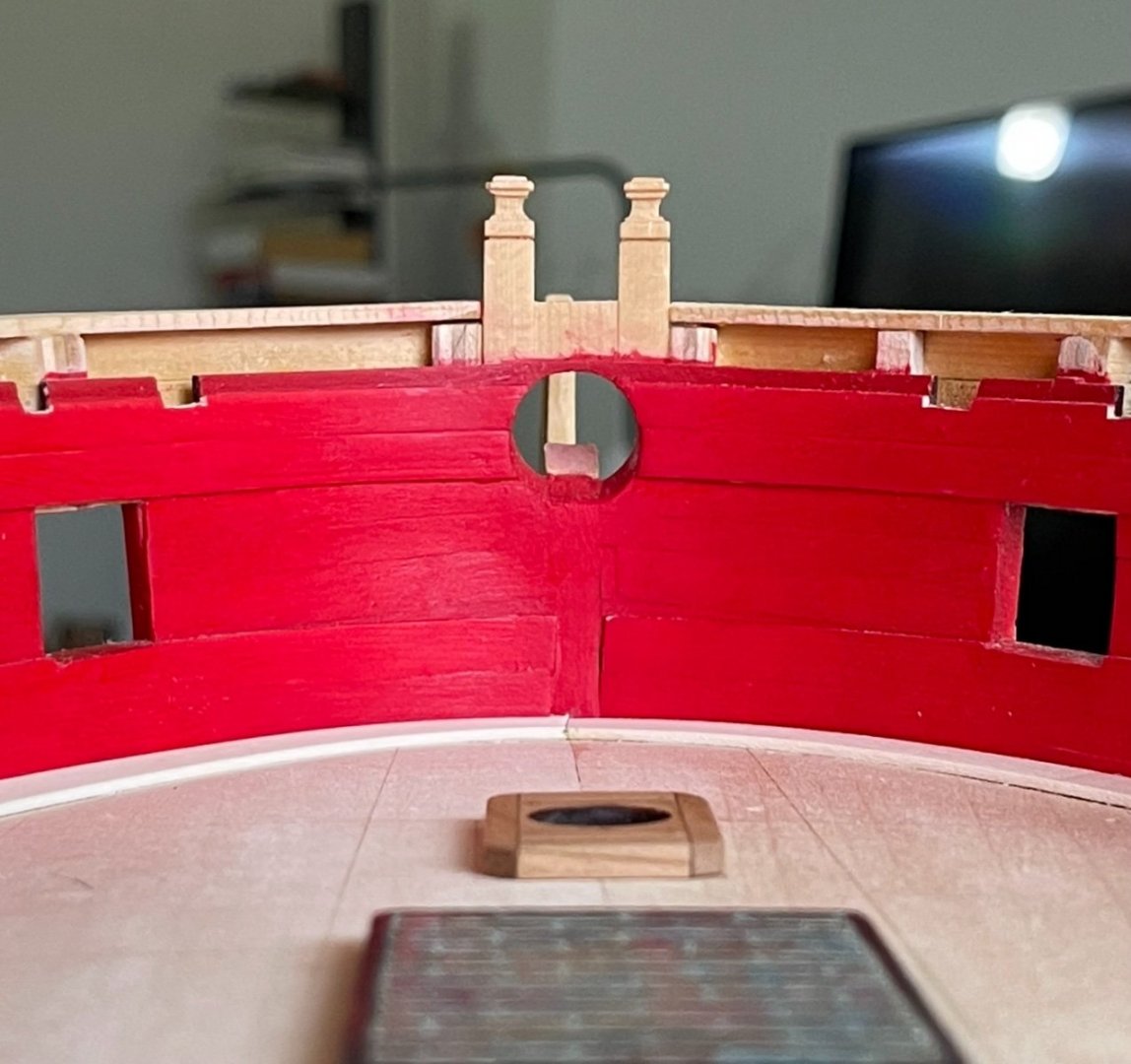

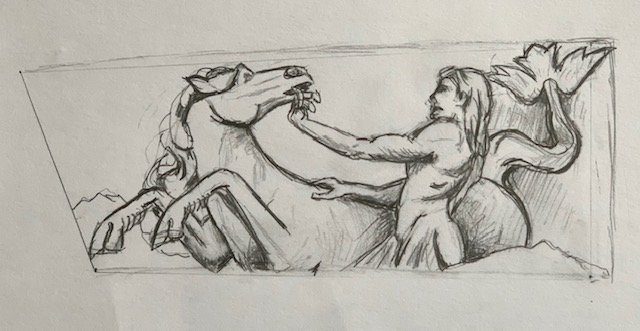

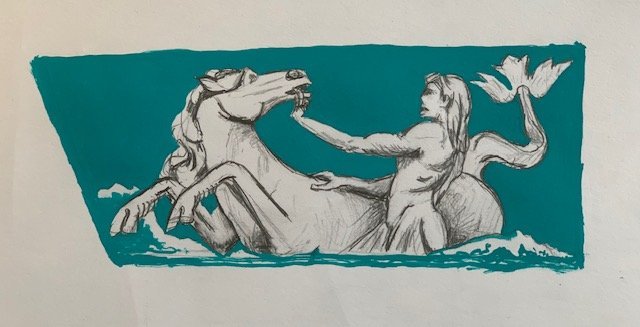

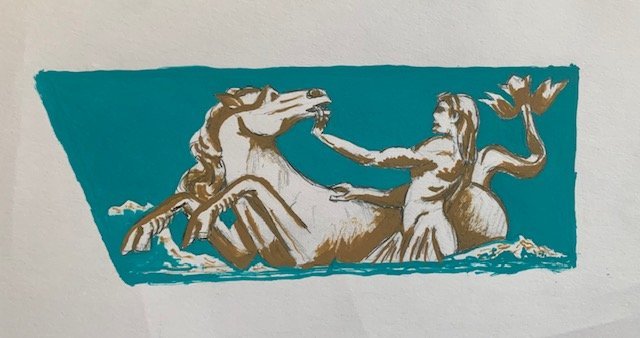

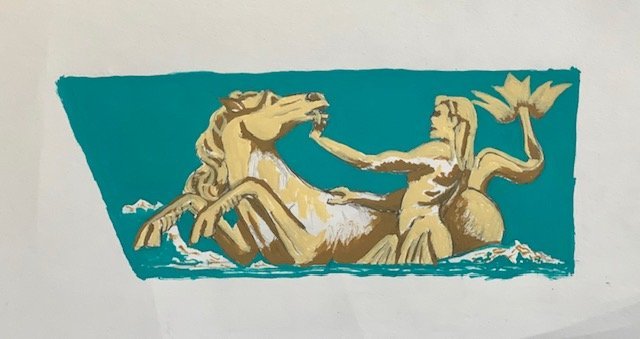

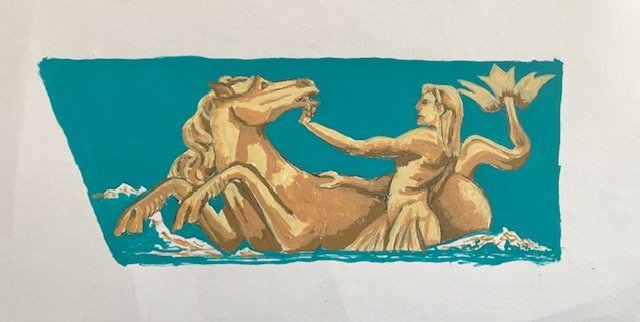

N Thank you JJ, My plan is to use wood for color. Thank you all for the likes. During the Holliday break I completed planking the bulwarks, added the spirketting, clamps, and the panels for te cabin. Before adding the false deck, I finished and placed the ladders. I used cherry for the counter planks, coamings, mast and capstan partners. The base plate for the stove was painted to simulate slate/blue-stone. The stone color was selected to add some of the green color of the freezes in the deck. After painting the bulwark red, I added the margin plank. I used holly and follow the plans for the scarf joins. Next, I will plank the deck with holly. The freezes will be completed after that. Best, G

-

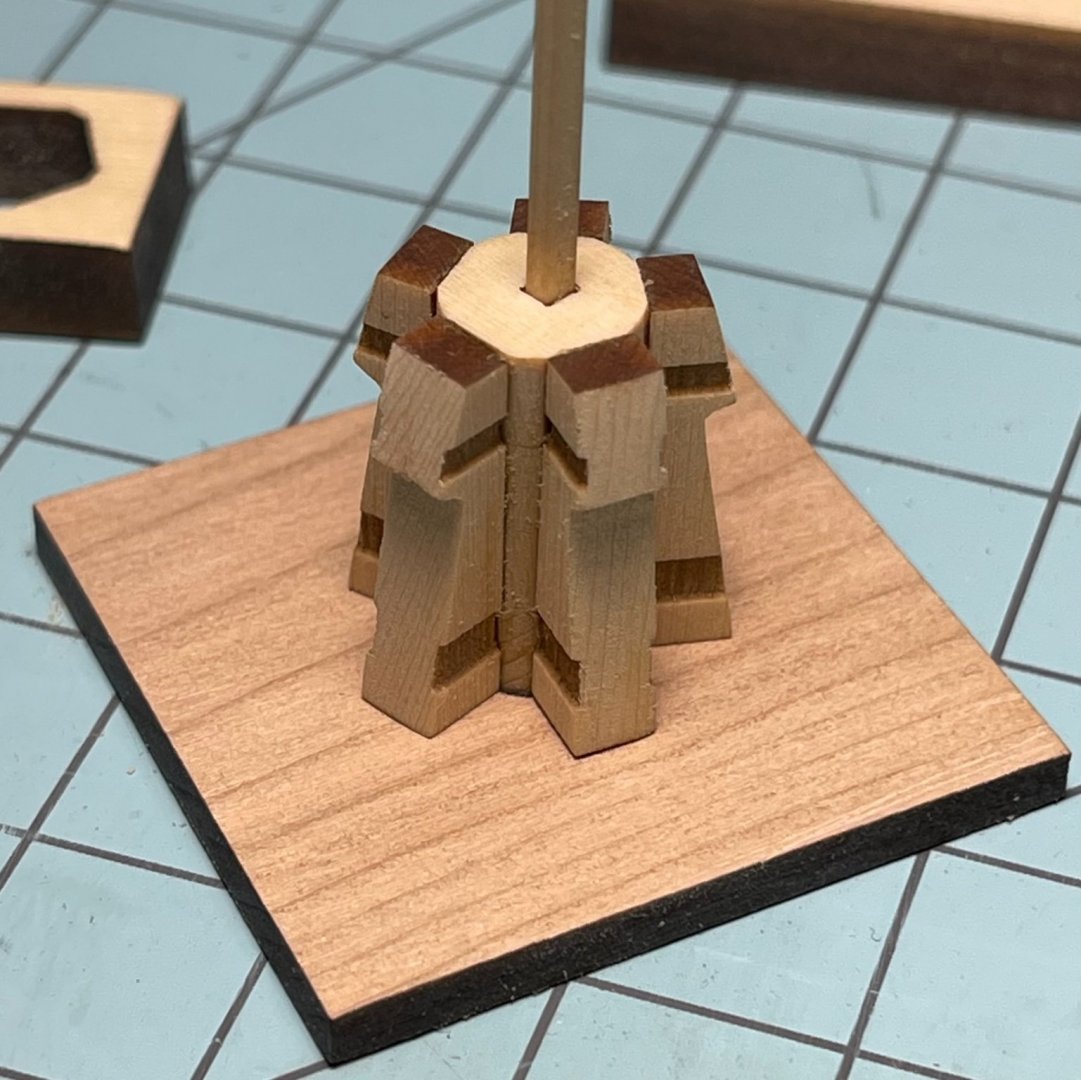

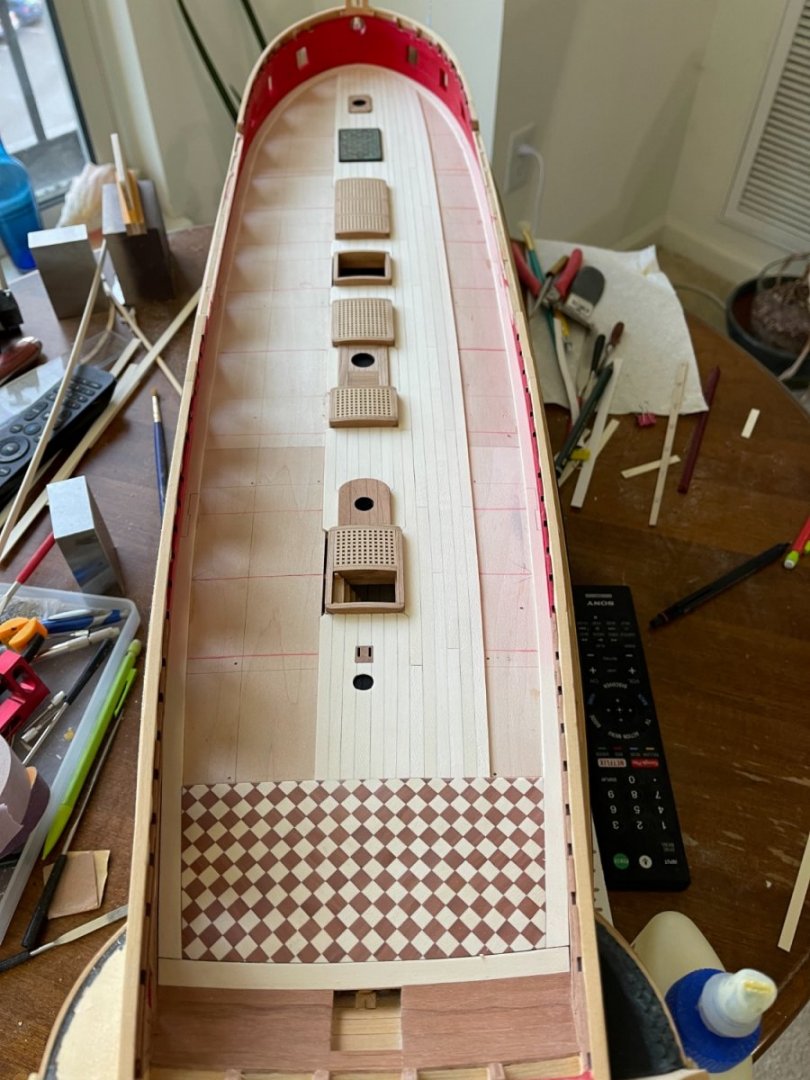

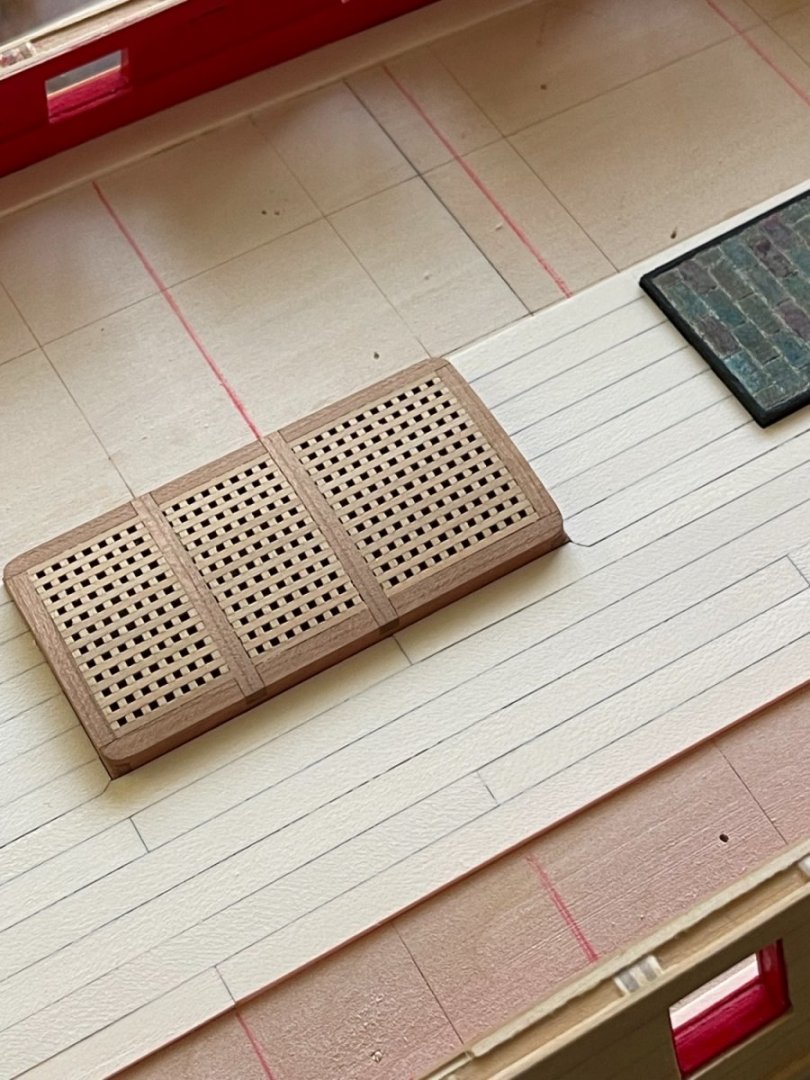

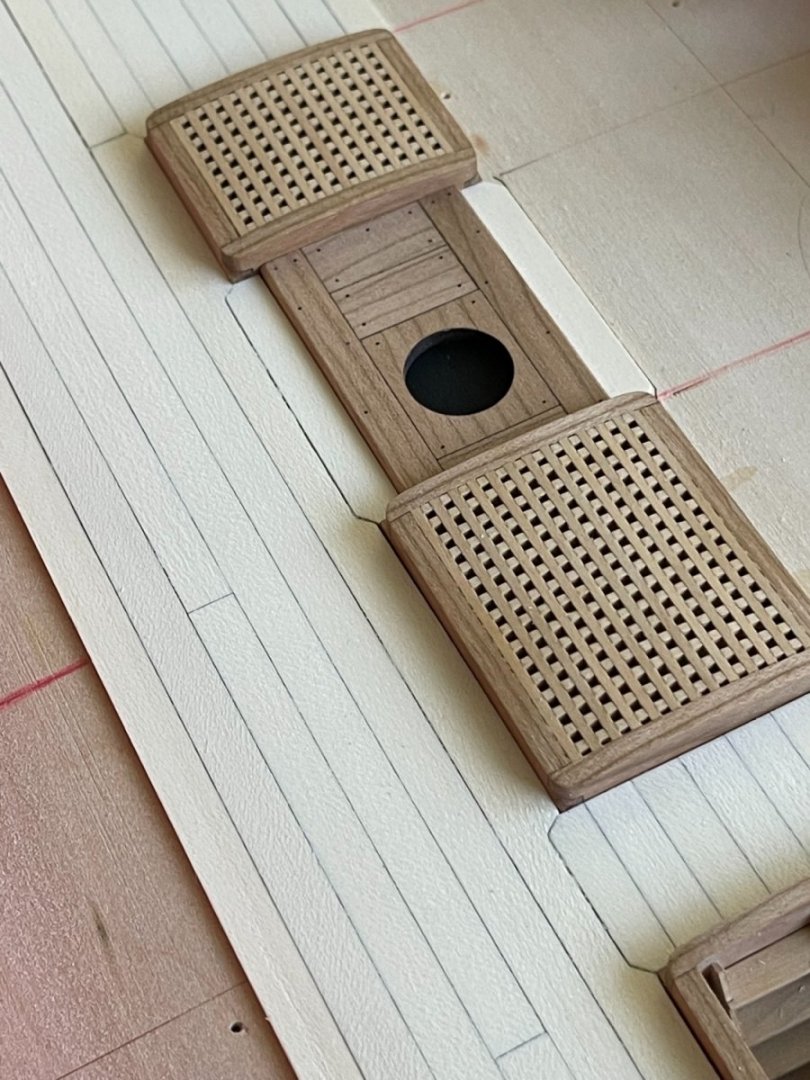

Thank you all for the likes, I decided to build inboard to give strength to all structures before completing the moldings and freezes. It will also give me more time to customize the freezes. I am intentionally mix and matching sedar and sherry wood kits from Chuck's chapter wood installments. The deck planks are holly. I build the sherry parts out of the model to ensure they were squared and placed back into the ship (they are not glued yet). Next, I will add the false deck. Best, G

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.aafc2ed32ce90d093a21655e0942e5f3.jpg)

.jpg.752a85ce3e999324606260baf81a7a5a.jpg)

2.jpg.37186ad2928953a8c8bb34e1f96bd259.jpg)

2.jpg.50ac0496330ebe2035ba8a8b9d50e039.jpg)