W4LKR

Members-

Posts

33 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Prowler901 reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

Prowler901 reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

-

It's becoming apparent how much easier things would have been if I'd gone ahead and shimmed the bulkheads before starting to sand the bevels. At the time I didn't think I could identify which bulkheads would need shimming until after beveling, and maybe that was true, but in hindsight I think I'll be able to tell with my next build. Shimming an already beveled bulkhead is not easy! More on that later. Right now I'm bouncing back and forth between attempting to shim the bulkheads that need it and prepping the stern to receive the stern blocks. I've beveled and carved out the bulkhead that straddles the gap where rudder will go. When I run a test strake along these aft-most bulkheads it seems to create the right contour. I guess I won't know for sure until the stern blocks are installed and properly shaped. Several of the starboard bulkhead edges forward of O and N (pictured) have yet to be beveled. After taking this photo I realized the mistake I made. Bulkhead N, which straddles the gap above the rudder, wasn't supposed to be sanded back to be flush with the forward side of the gap. I don't know why I thought this was necessary. Looking back at the instructions and practicum there's no mention of doing what I did. In fact, the practicum shows the horn timbers installed between bulkheads N and O with no sanding to N like I've done. I think I've created another challenge for myself. Attaching the horn timbers will be more difficult with bulkhead N shaped the way I did it.

-

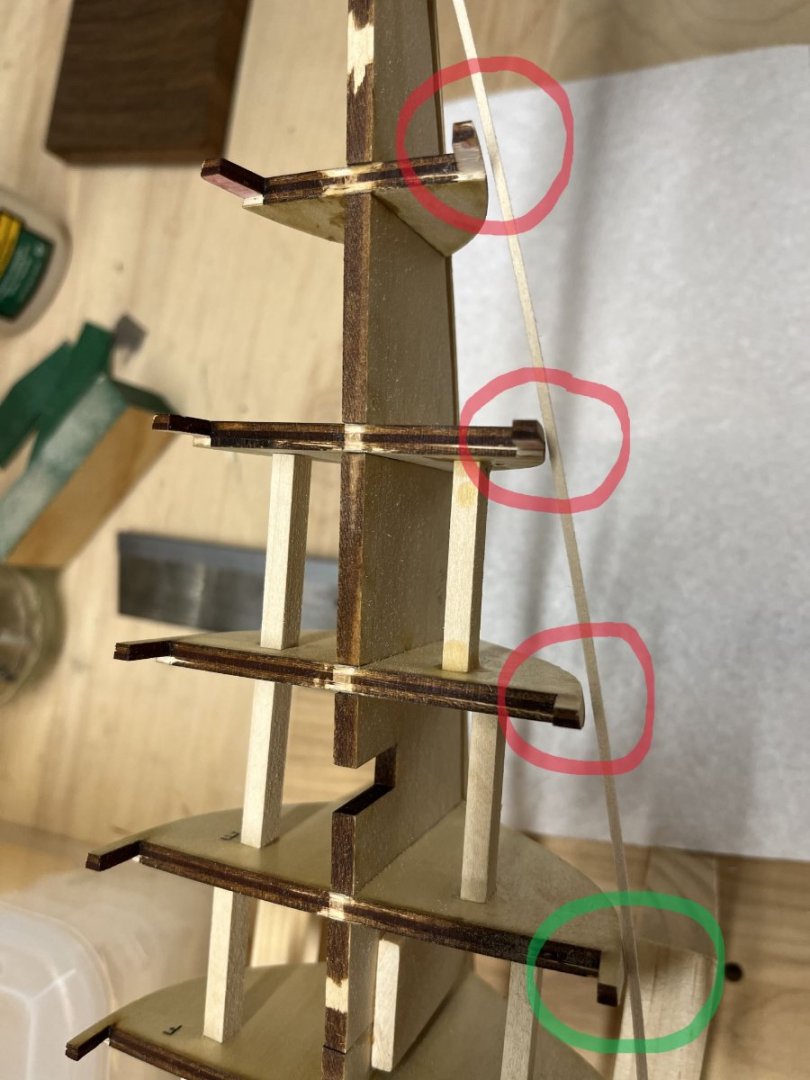

I'm long overdue thanking jwvolz, Yorky, Retired guy and CPDDET for the incredibly helpful feedback on the stanchions. The photos are so helpful. My plan at this stage is to remove the frame stanchions after installing the fake stanchions and bulwarks, but before installing the main rails. There are at least two or three different ways to skin this cat and get results that I would happy with, but doing it in that order feels the most doable to me personally. Seeing the photos on Suburban Ship Modeler swayed me I think. For the past week I've been sanding and faring the bulkheads with varying amounts of success. Overall it's going well I think. My homemade sanding block is about 3" long with an 80 grit strip stapled tightly around it. I'm changing out the strip regularly. This block can span a max of two bulkheads. Longer might be better but I'm taking it slow. I knew there would be a need to shim some bulkheads to fill gaps. One of these gaps is larger than I expected (circled below). I've definitely got some shimming to do before I'm anywhere near ready to start planking.

-

CPDDET reacted to a post in a topic:

Bluenose by CPDDET - Model Shipways - Scale 1:64 - First ship build

CPDDET reacted to a post in a topic:

Bluenose by CPDDET - Model Shipways - Scale 1:64 - First ship build

-

Those parts look great. By the way I own the same Rikon grinder. I've mostly used it for restoring traditional woodworking tools, putting bevels on chisels and plane irons, and buffing rusted parts. I've never had a problem with it. If you ever want a piece to have a somewhat burnished look, a wire wheel can do it.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Yorky reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

Yorky reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

-

I looked through RetiredGuy's build log of MSW Bluenose. Thank you for referring me to his build. It appears to be a top-notch job and is a source of inspiration. Looking at his stanchions though, I couldn't find any photo or mention of removing the bulwark extensions and installing stanchions in their places. Every photo in his log that shows a close-up of those areas shows the bulwark extensions still there. Later on he even paints them. To my eye his bulwark extensions and stanchions are indistinguishable from each other. This is probably a testament to his modeling abilities.

-

Thanks everyone for the advice about removing the bulwark extensions. I was concerned about them looking different than the others but I never considered removing them, especially after the bulwarks are in place. So what is the technique? Do you use some temporary attachment between the extensions and the bulwark so you can cut them free out from under it later?

-

Ron B reacted to a post in a topic:

Bluenose by CPDDET - Model Shipways - Scale 1:64 - First ship build

Ron B reacted to a post in a topic:

Bluenose by CPDDET - Model Shipways - Scale 1:64 - First ship build

-

Jond reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

Jond reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

-

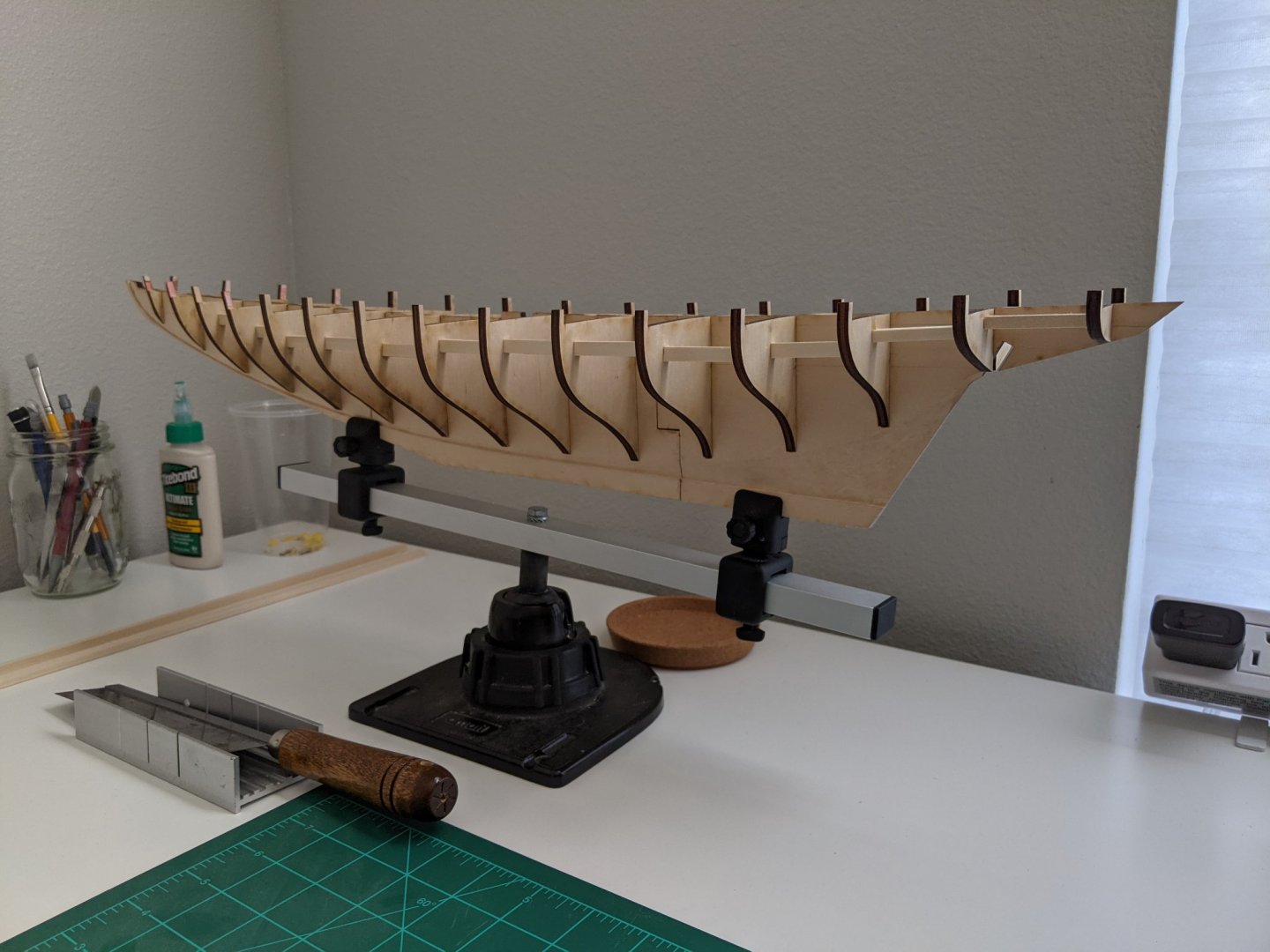

Batons have been added between all bulkheads except the forward-most two (A & B). I can tell how much stronger the entire model is after completing this step. It seems that one or two of the bulkheads have been pulled just slightly out of square with the keel. I'm making note of these little mishaps but not necessarily committing to fixing them in this build. I want to avoid making this mistake in the future but I'm uncertain how much trouble it will cause me going forward. Next up is continuing to trim back the bulwark stanchions. Bulkheads A thru D have already been cut back to be 1/8" thick from the 3/16" thick bulkhead material. I paused this work to install the batons. Once I finish the stanchions it will be time to address the bulkheads that don't reach the bearding line. After that, it will finally be time to begin sanding bevels into the bulkheads. I'd be lying if I said I wasn't still very intimidated by that process.

-

Thanks Yorky. Regarding #2, I've just finished installing the batons. I'll post some pics momentarily. It's good to know there's ample extra material in the kit. I may end up shimming the bulkheads with spare decking or planking materials, but before I go that far I'm going to attempt a wood putty fix. There's only three bulkheads that need it and I'm hopeful it will be less work. I think this makes four of us who are currently building Bluenose kits. I'm looking forward to following your build as well.

-

That's going to be a great setup. I'm looking forward to seeing what you're able to create with the milling machine. The metal parts in my kit are similarly rough. I have a 3D printer so I've considered sketching some replacements in CAD and printing them, then painting with a metallic enamel to simulate metal parts. But having the ability to make real metal replacement parts would be way better.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Duanelaker reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

Duanelaker reacted to a post in a topic:

Bluenose by W4LKR - Model Shipways

-

Thanks Ron, appreciate the encouragement! Congrats on starting your Bluenose! I look forward to following your progress and learning from your build. Another build I have followed is CPDDET's Bluenose. His kit had the exact same problem with the rear bulkheads not reaching the rabbet line. He fixed the issue by applying wood putty to extend just those bulkheads downward a fraction of an inch, then faired them as normal. I think I'm going to do the same rather than apply shim material to the entire bulkhead edge.

-

I'm considering getting the Amati Keel Klamper. For anyone who owns or has used one, is the base heavy enough that it stays put when light force is applied to the model? Or do you have to screw it down to the workbench to really get the most benefit?

-

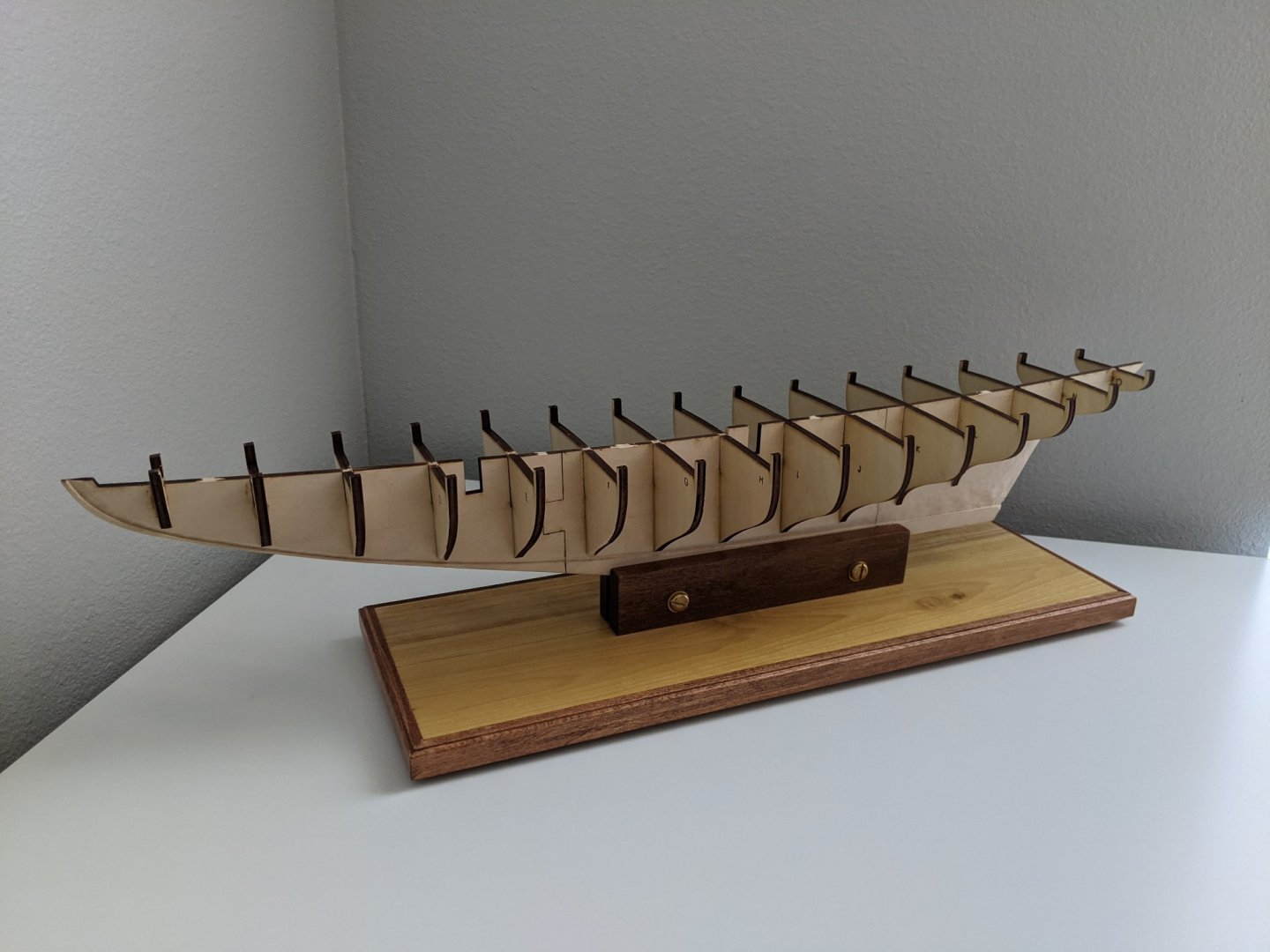

I'm a bit of a tool nut as well. For me there's a higher level of satisfaction when I'm able to make something using a tool that I also made. My homemade keel clamp is nicer to look at than it is to use I'm afraid. Well, for certain tasks I'm sure it will be fine, but right now I'm needing something that holds the keel at two points further apart so it doesn't flex as much. I'm afraid I'm going to crack something the way it's clamped right now. Oddly enough the Amati Keel Klamper is hard to find in stock. Maybe there's a boom of new modelers in 2020. Once all the jigsaw puzzles sold out, the people turned to models.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

I wanted to ask about your keel clamp. Early on in the project I noticed you were using a homemade clamp based on a mini tripod with ball head. That same thought went through my head a couple years ago but I ended up making a clamp without the ball head. I'm not real happy with how mine works so far. Then I noticed you switched to what looks like the Amati Keel Klamper in a few of the photos. What made you switch and how do you like it so far?

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

mtaylor reacted to a post in a topic:

Bulkhead beveling - lots of questions

mtaylor reacted to a post in a topic:

Bulkhead beveling - lots of questions

-

Robby The Brobot reacted to a post in a topic:

Bulkhead beveling - lots of questions

Robby The Brobot reacted to a post in a topic:

Bulkhead beveling - lots of questions

-

Canute reacted to a post in a topic:

Bulkhead beveling - lots of questions

Canute reacted to a post in a topic:

Bulkhead beveling - lots of questions

-

Canute reacted to a post in a topic:

Bulkhead beveling - lots of questions

Canute reacted to a post in a topic:

Bulkhead beveling - lots of questions

-

I was afraid I'd swap them accidentally so I did label them all. Fortunately with this kit each bulkhead was engraved with the letter. I took it another step by coloring in the engraved letters with ink. Since they are uniform thickness I don't think it matters which face of each bulkhead is forward vs aft. This photo shows how the profile of the rear bulkheads are markedly different than those forward. I'm pretty sure they are all in the right locations.

-

Thanks for the reminders about tapering. There is so much to getting this right. I appreciate the way you've explained it. Maybe I'm opening a can of worms but I'm going to ask anyway - is there any benefit to using CA vs wood glue? In my mind the wood glue gives you plenty of time to position the piece before it sets compared with CA, but they make some slow drying CA (relatively speaking). I'm thinking of the gels I've seen over the years that take up to a minute to set compared with the instant glues that set in 3 seconds or less. So far I've only used wood glue on this kit but I'm tempted to try a slower drying CA when affixing the planks to the bulkheads. The process you describe above sounds good to me. A dot of CA on the bulkhead, press and hold, wait a minute, move on to the next bulkhead.... Especially true with this kit as the hull is painted

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.