texxn5

Members-

Posts

2,473 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by texxn5

-

Hhi Bruce, nice progress. These deck structures will be fun and test your creativity. Don't spare the details, just be careful and don't get too tall. Those are some nice tools you have, work pretty well don't they? lol. Your skylight looks good. I didn't have the luxury of decent tools when I made mine. Some of the brass rods got crooked and I couldn't get them straight without splitting the basswood. I didn't have a press so they were done by hand. Some good hardwood would have helped at this point. Good for you that your jig is working. Can't wait to see the end product. Keep up the good work. I have just completed building the masts, now ready to start Standing Rigging. I'll keep checking in to see your progress. Nice!

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

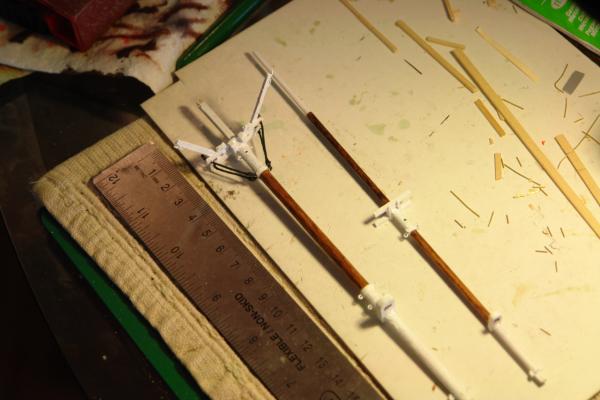

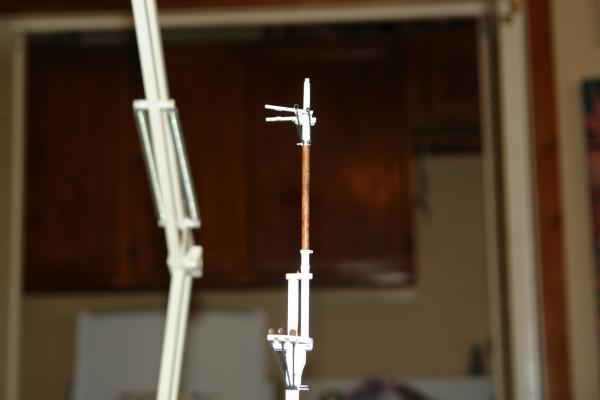

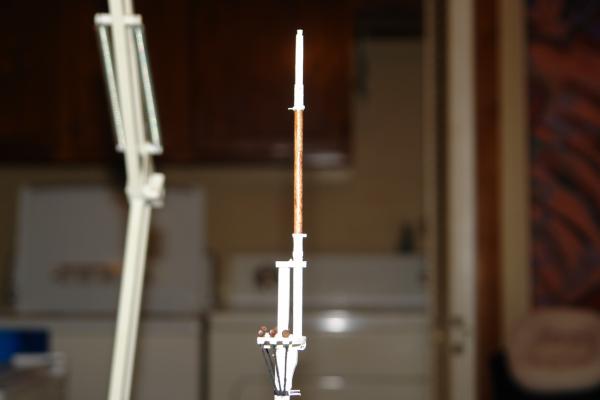

Today has been finish-up day. I finished building the Mainmast comonents, Topmast, Topgallant Mast and Main Royal, painted, served and dryfit everything together. The only thing left for them is to make the 2 Lookout Rings and paint the lower part of each mast Yellow Ochre - if I ever get my paint--10 days now and it's scheduled for delivery on Feb 4....kind of ridiculous, sure am glad I had plenty to do in between. So all the masts are done for the most part - next will be the Shrouds....hmmm got to learn how to serve for real now.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hello Lawrence, good to see you getting caught up. Thanks for the likes and kudo's. The outside pictures really did bring out the color scheme much better than the flash that might or might not work inside. I've had the Lathe for a while but the makeshift mill is kind of new. I had the drill press which is a MicroMark which ws made by Proxxon for them. I added the Compound Table, Precision Vice, and bought some Mills after I became a Proxxon Dealer. The Drill Press set up is not as precise as the MF 70 Mill, but will suffice for the type of work I have to do with it. Perhaps someday I'll upgrade to the real Mill. Having the Proxxon Store has allowed me to obtain a few things that otherwise I would have been unable to do. The extra income sure helps an old retired guy...

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hi Lester, thanks for the info. I'm very pleased with the overall appearance.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

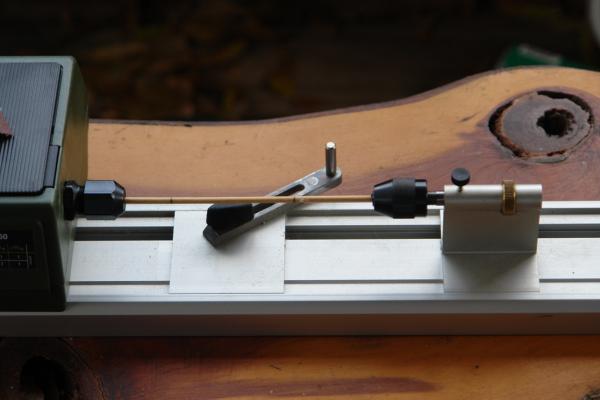

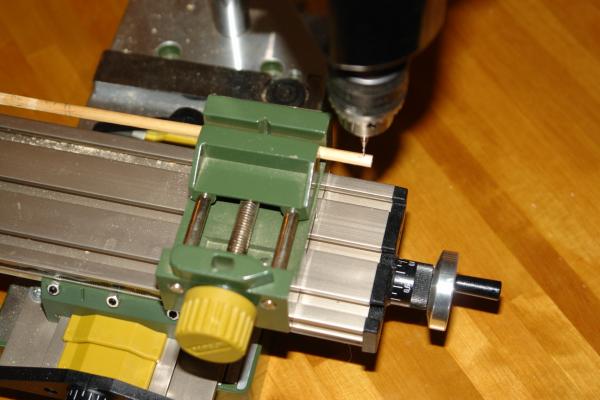

Hi Ed, I have PM'd you, I need some information. Thank you for the interest. The little lathe is rally nice to use. With the Collet set and the Variable chuck on the tailstock, you can really control the spin and like today, I was turning a 1/8" dowel down to about 1/16" in 2 stages and had 100% control of the turn and the variable speed allowed me to sand it instead of turning it with a chisel. I think I impressed myself that this did not break with the pressure. It is my favorite tool.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

These pictures show the versatility of the Lathe. Working with the short end of the stick so to say, and the extra length sticking through the center of the lathe.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Here's the DB 250 Lathe set up and the Mill for cutting in the fids, sheaves, and squaring the mast tops.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

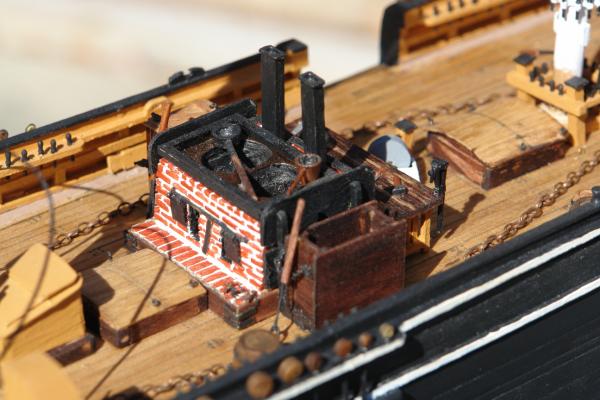

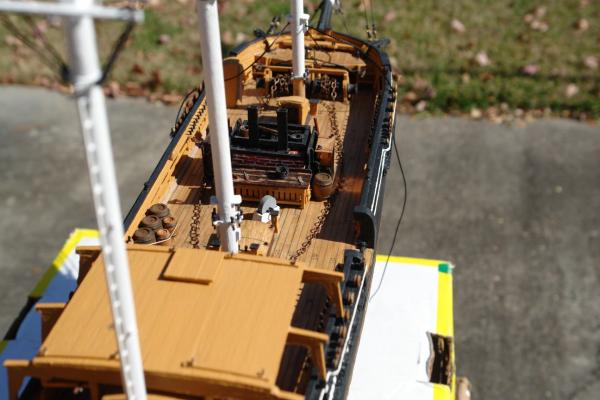

Today was such a beautiful day here (sorry for all you New Englanders and northern folks) 80 degrees and bright clear sunshine. This was an opportunity to photograph the Morgan outside, so I'm taking the opportunity to show her off a little. I also made the Mizzen Top Mast, finishing it and making the Main Topmast. I used my Proxxon DB 250 Lathe to turn the Mizzen and Main Top masts and Royal. This is done from one dowel so I set it up in the lathe and used sandpaper to reduce the diameters down to the proper size. One nice advantage of this lathe is that the longer dowels can go through the center of the motor freely. You could stick a 5' or longer piece through it and just turn the area you want.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

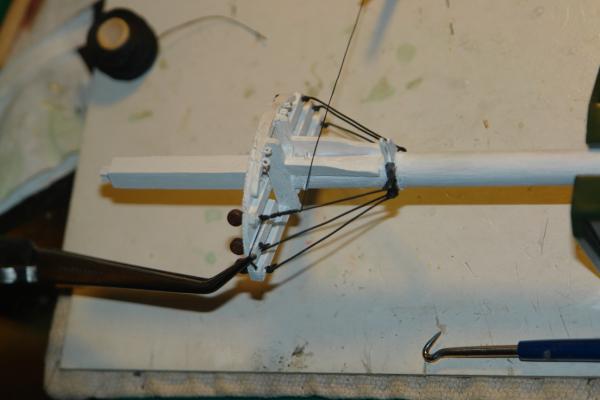

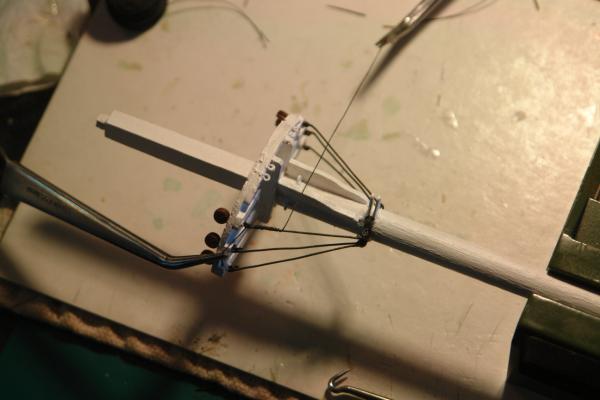

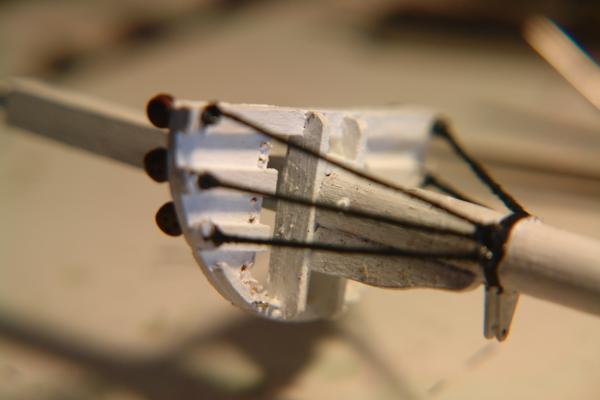

Thanks for the visits and the likes from everyone. Today was a continuation of stepping the rest of the Foremast. These are just dry fitted for now. I turned the Fore Topgallant and Royal mast today on my Proxxon DB 250 Lathe mostly using sandpaper rather than chisels to graduate the diameters of each. I then stained the natural areas, made the Futtock Shrouds for the Topmast Crosstree and served them, then made the Topgallant Crosstree painted and finished it. The Lookout Ring has not been installed yet. She's starting to get tall now and looking like a ship.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

jsgerson, I'll check them out today. Thank you for providing these. Sorry Jay, didn't mean to hijack your log, but appreciate the info.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

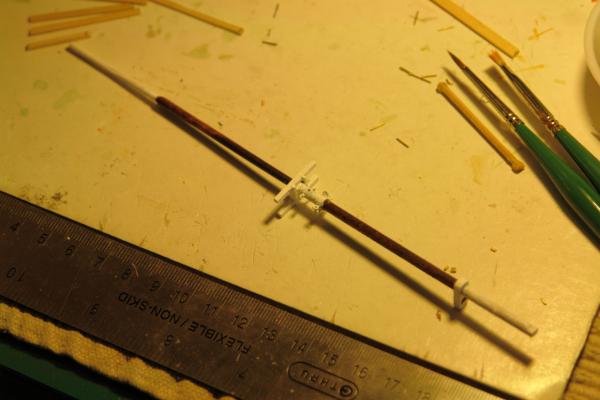

I think I'm going to continue building all the mast parts before moving on to the shrouds, that way as I keep moving up I'll be prepared to continue with the shrouds and not be held up by having to make mast parts. I'm not going to glue them together so that the shrouds will be able to be hung off easier, so I will just dry fit them. I stained the areas that need to be stained so that if I should get glue on anything it won't soak off into the wood and look "crappy" when staining it. So here is the Fore Top Mast. First I set up the mill to cut in the Fid, then moved on to make and stain the center section, then finishing all the trusses and sling band finishing with painting the rest of it.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hi Dave, good to see you visit. Ratboards - yep, ratboards. I'll be lashing 1/32" square boards to the shrouds for making ratboards. Ratlines will be the upper lines so I get to do both...fun fun fun in the old shipyard tonight...not really tonight, but soon. Found out today, my paint won't be shipped until tomorrow.....no comments, took only a week to ship so I probably won't get it until next week.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hi Jay, thanks for finding that utube. I do have that one, but was looking for some more specific details on creating shroud loops and serving to deadeyes, such as how to judge the lengths and means of securing deadeyes properly and uniformly. I have served very little and I have not ever served shrouds.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Jay, for some reason I thought it might have been one of your videos. good comment on serving...lol. I'll see what I can find, I knew that if you had one it would conatain all the details and be very thorough - a one stop shop kind of thing. Thanks for the input once again, John

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Hello Jay, good to see you back. Your model is looking fantastic....as if we would expect anything less from you. I have a question concerning serving. I'm sure that somewhere in your archive of information that you've covered this before, but I'm at a loss as to where it might be. Would you mind providing a link for this. I'm beginning to start the shrouds for my Morgan, and could always use instructions. I will be using Alexey Domanoff's serving machine. Thanks for all your posts and help that you educate us with, they are greatly appreciated. John

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Les, the bending is what I thought it was, but I must admit, the "baggy wrinkle" is new, even for an old salt! I'm familiar with most nautical terms, I just wanted to be sure. I'm ready to bend, however, I'm wondering if I need to hang the shrouds prior to bending so that there are no conflicts in angle or or lines and cross lines. Seems like the shrouds should be next???? Any advise?

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Well, this turned out easier than I thought. Good catch Lester, it wasn't bad to retro the serving lines to the fixed mast tops. Fortunately they weren't glued to the hull, so all I had to do was put them in my Proxxon Vice and roll them by hand on the bench. I was able to complete that in one day so I'm very happy.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Thanks Les, I'll be sure and pass it on. I'm not sure I'm understanding the term "bend" at this point. I think I do, but for clarity and especially for anyone looking in here, can you be specific?

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Thanks to all who hit the like button. I thought I was finished with the masts, however, I have learned that I was not. Thanks to my good friend Lester, who actually worked rigging the Morgan, I learned that the plans are incorrect and that the Futtock Shrouds are to be served. Had I known that prior to the installation they probably would have been easier to do on the Serving Machine rather than by hand. I wasn't sure I could retro them on to the model, however, to my surprise I could. So I began the laborious task of hand serving them. The Mainmast is done, and now for the Fore and Mizzen. I'm still waiting for paint - finally shipped today, so why not - actually I'm glad I did it as I really like how it looks. Thank you Lester.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.