-

Posts

219 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Washington State

-

Interests

3D printing, CNC, and reading naval history

Recent Profile Visitors

-

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

Canute reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

thibaultron reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

Nirvana reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

Nirvana reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

yvesvidal reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

yvesvidal reacted to a post in a topic:

USS KATAHDIN by Haze Gray - 3D Printed - ram ship

-

well, according to wikipedia, the length of the Katahdin was 76.43 meters... My model of the Katahdin is one meter long 😃 I agree, it's very similar to a submarine - given that it's purpose was to ram ships below the water line having very low freeboard would give the Katahdin the a better chance at piercing the hull below the water line (if it could actually catch up to a ship to do so!)

-

Hi yvesvidal, the Katahdin model is 1/72 scale - it’s noticeably longer than one would expect . on the topic of files I’m just a bit shy to share them - but I could send the parts - it goes together rather quickly kid of like a matryoshka doll ! what I haven’t shown is how the access panel is removed.

-

Okay here's another one from the Spanish American war that that I find very interesting: The USS Katahdin did serve during the war - there's a good Wikipedia article about it https://en.wikipedia.org/wiki/USS_Katahdin_(1893) While it's pretty common to see a model of the Katahdin painted in white.... in actuality it was painted a green color so as to blend into the color of the water. I've already 3d printed out the hull and various other parts...

-

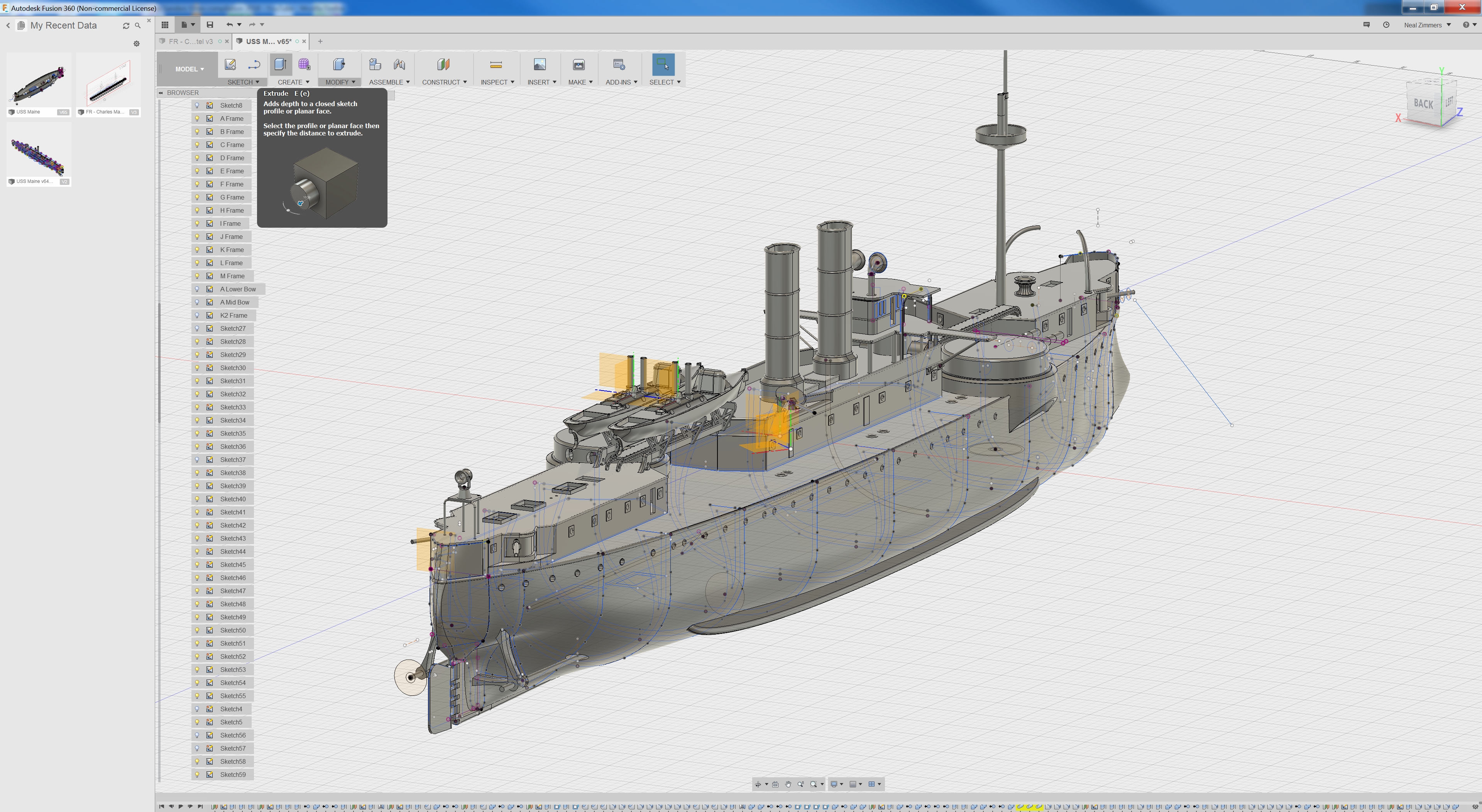

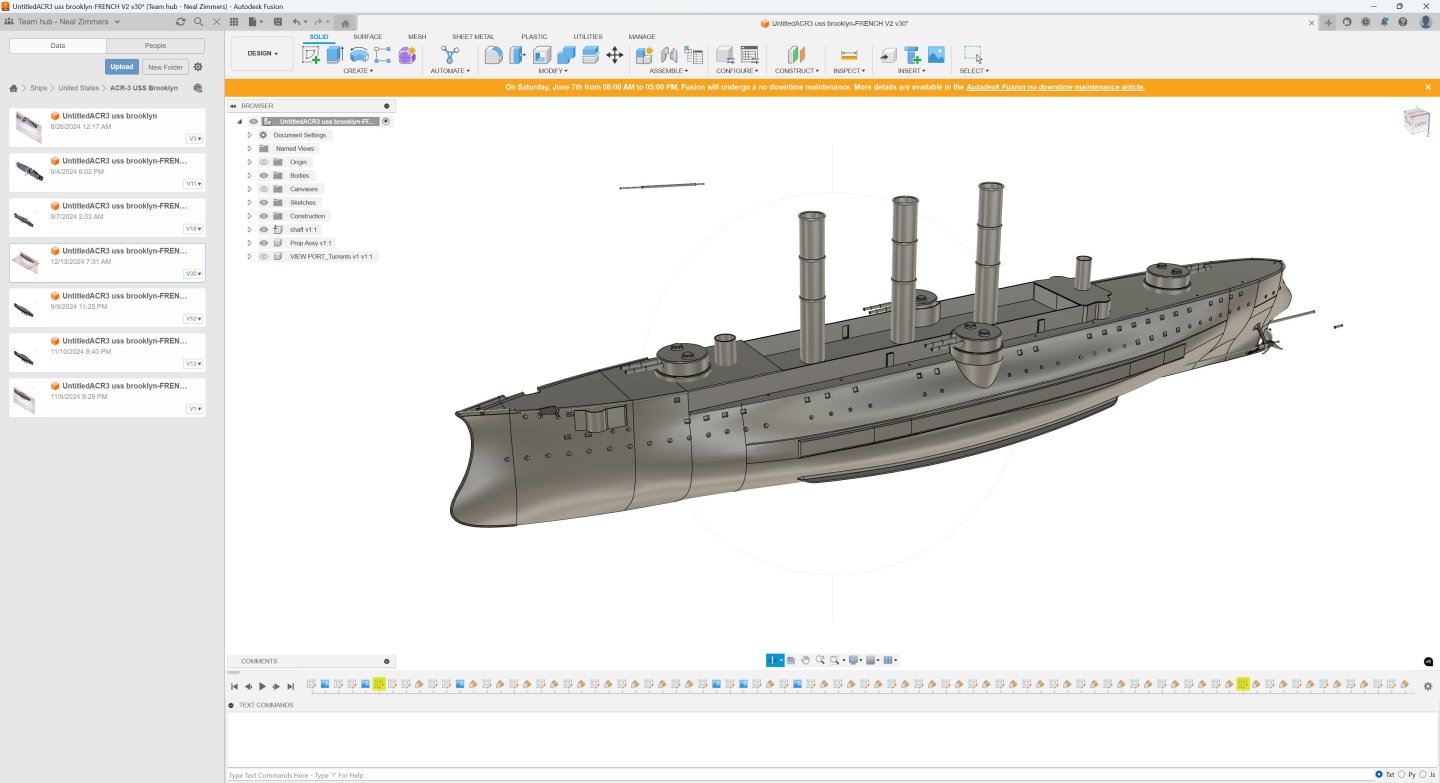

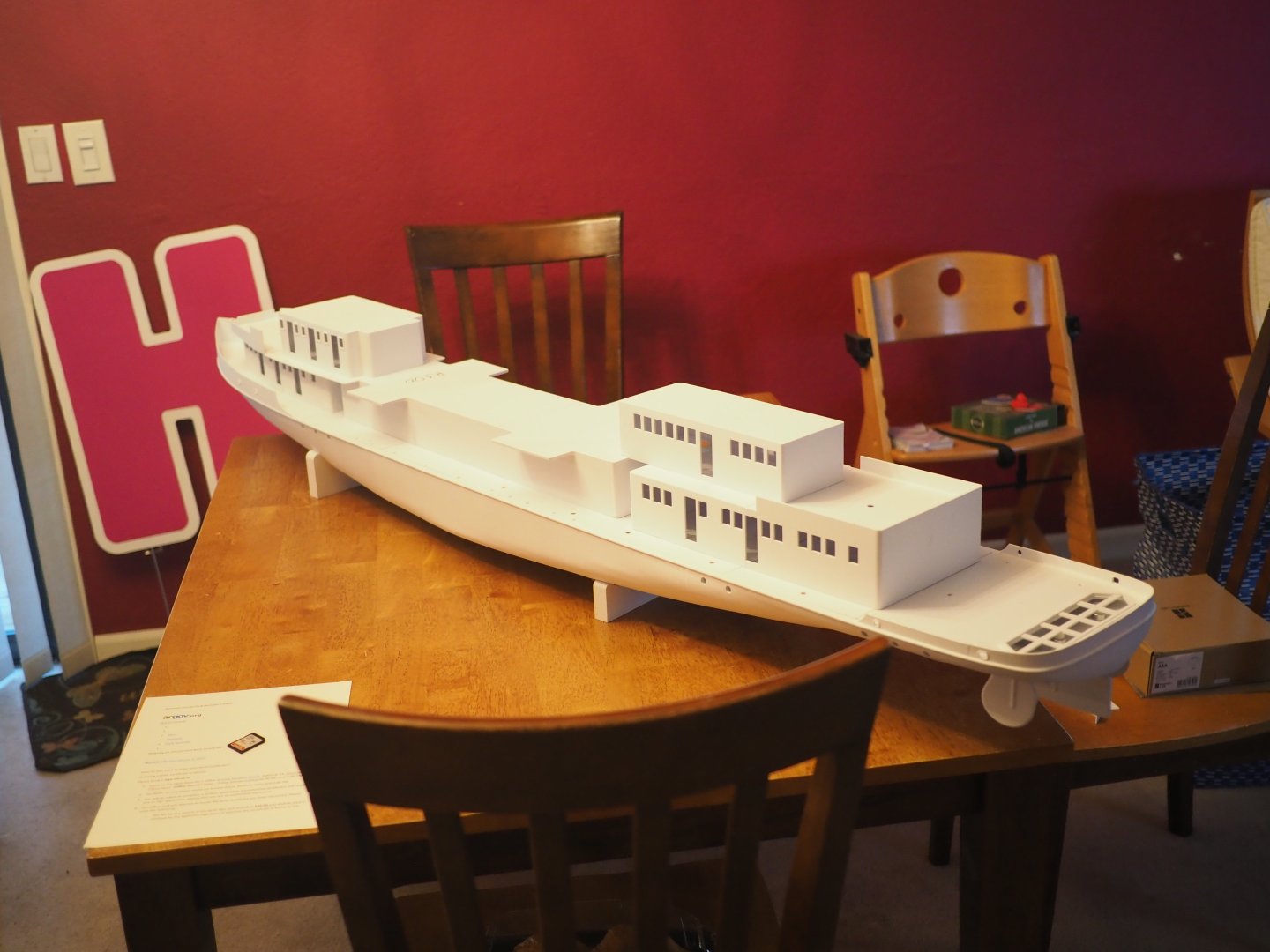

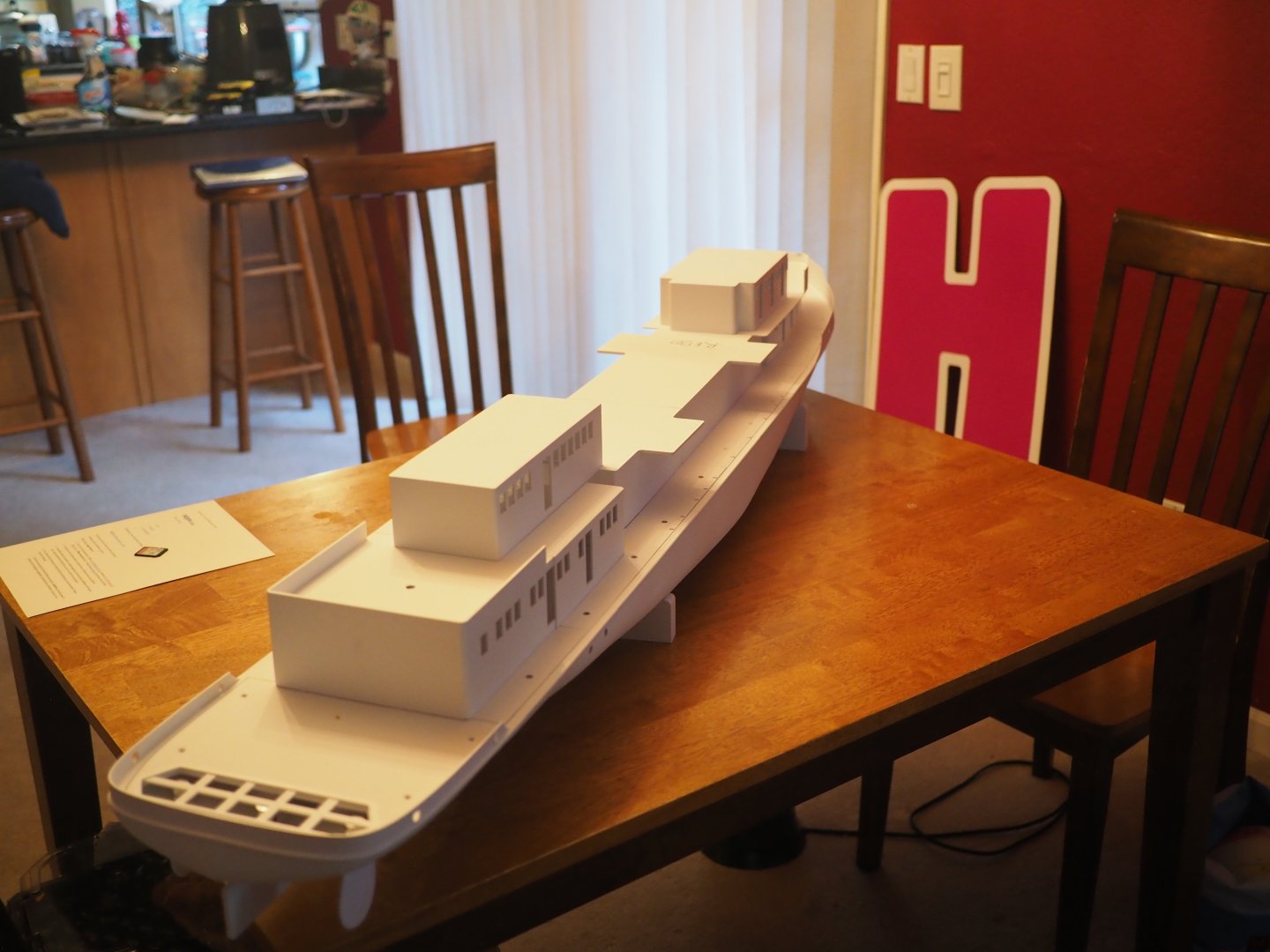

Hi Folks, I know it's been a while since I update the progress of the USS Panay - so adding some photos here for those that are interested. I still have a far amount of work to do but I'll get there eventually!

-

currently I use PLA+ which is not at susceptible to heat as regular PLA but for ships that would be painted black for authenticity I would choose ABS or ASA, but if they are painted white they tend to do pretty well. I've tested some hull sections made in white PLA+ by putting them out in the sun and left them outside over two years and they were fine. However one of the hull I painted in green and exposed it to the sun during summer warped pretty bad withing an hour. small thin detailed parts that are not painted white or light brown for instance should be abs or ASA otherwise they will warp or deform. I don't use PetG as it's more difficult to sand out the layer lines and the region I live in usually doesn't have alot of sun and heat. if you live in arazona pet G, asa, or abs would be necessary

-

Hi Yves, technically the hull is assembled but it's not permanent at the moment - I use heat-set inserts and machine screws to join the sections and to ensure things line up right - once everything looks good I'll spread a thin layer of epoxy one the faces of the hull sections and screw everything together permanently. Below are some pictures of the hull sections - Haze Gray

-

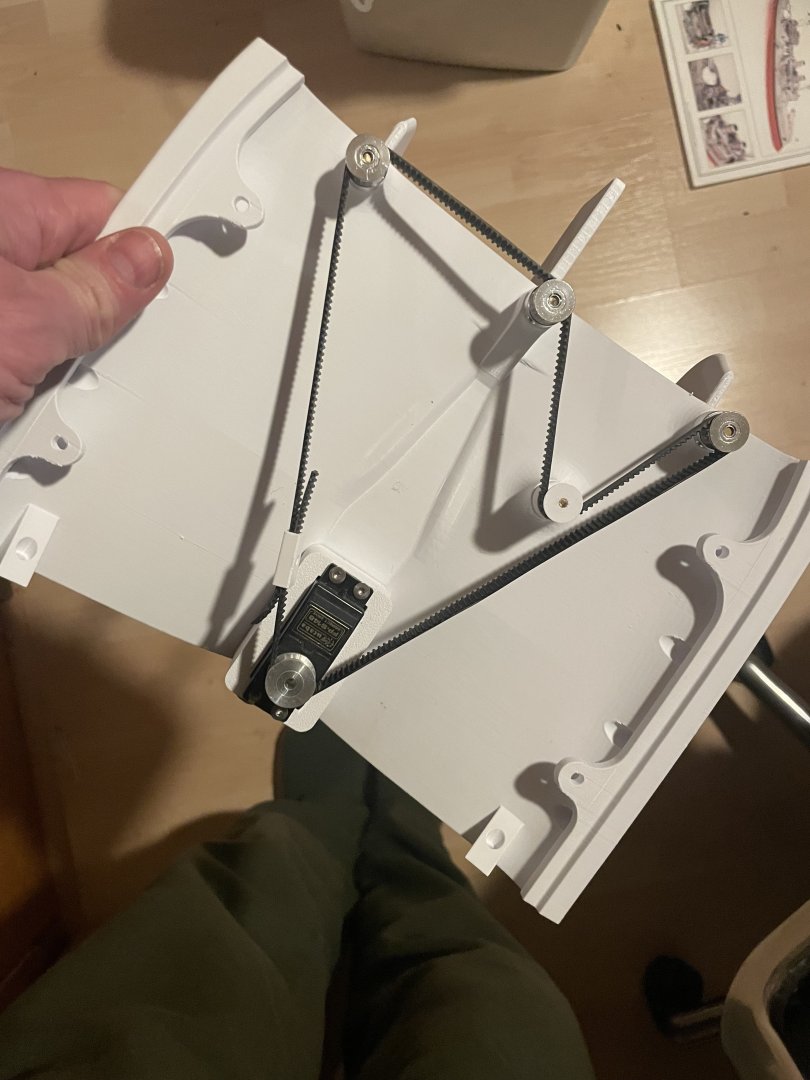

As you can see I've been working on the hull alot and figured out a way to drive the three rudders at the same time using a single servo since there's not much space in the aft section of the ship - Haze Gray

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.