-

Posts

589 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Halifax NS

Recent Profile Visitors

-

NavyShooter reacted to a post in a topic:

5 Cylinder Radial Engine BUILD REVIEW (TECHING) - EngineDIY

NavyShooter reacted to a post in a topic:

5 Cylinder Radial Engine BUILD REVIEW (TECHING) - EngineDIY

-

NavyShooter reacted to a post in a topic:

5 Cylinder Radial Engine BUILD REVIEW (TECHING) - EngineDIY

NavyShooter reacted to a post in a topic:

5 Cylinder Radial Engine BUILD REVIEW (TECHING) - EngineDIY

-

NavyShooter reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

NavyShooter reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Paul Le Wol reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Paul Le Wol reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Paul Le Wol reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Paul Le Wol reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

yvesvidal reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

yvesvidal reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Ian_Grant reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Ian_Grant reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Canute reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Canute reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Canute reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Canute reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Canute reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Canute reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Titanic and the new Sackville model have been launched into the Halifax Public Gardens for the season! I forgot to factor in the weight of the anchor chain on Sackville when I ballasted her, so she's showing as down by the bow just a bit. Oops. In the photo with two people holding the Sackville - I'm on the left, and Mr. Woodburn is on the right - he's the Chair of the Canadian Naval Memorial Trust. The Titanic Society of Atlantic Canada have a function this weekend, so the launch was well attended by them!

-

Ian_Grant reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Ian_Grant reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

ccoyle reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

ccoyle reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

yvesvidal reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

yvesvidal reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

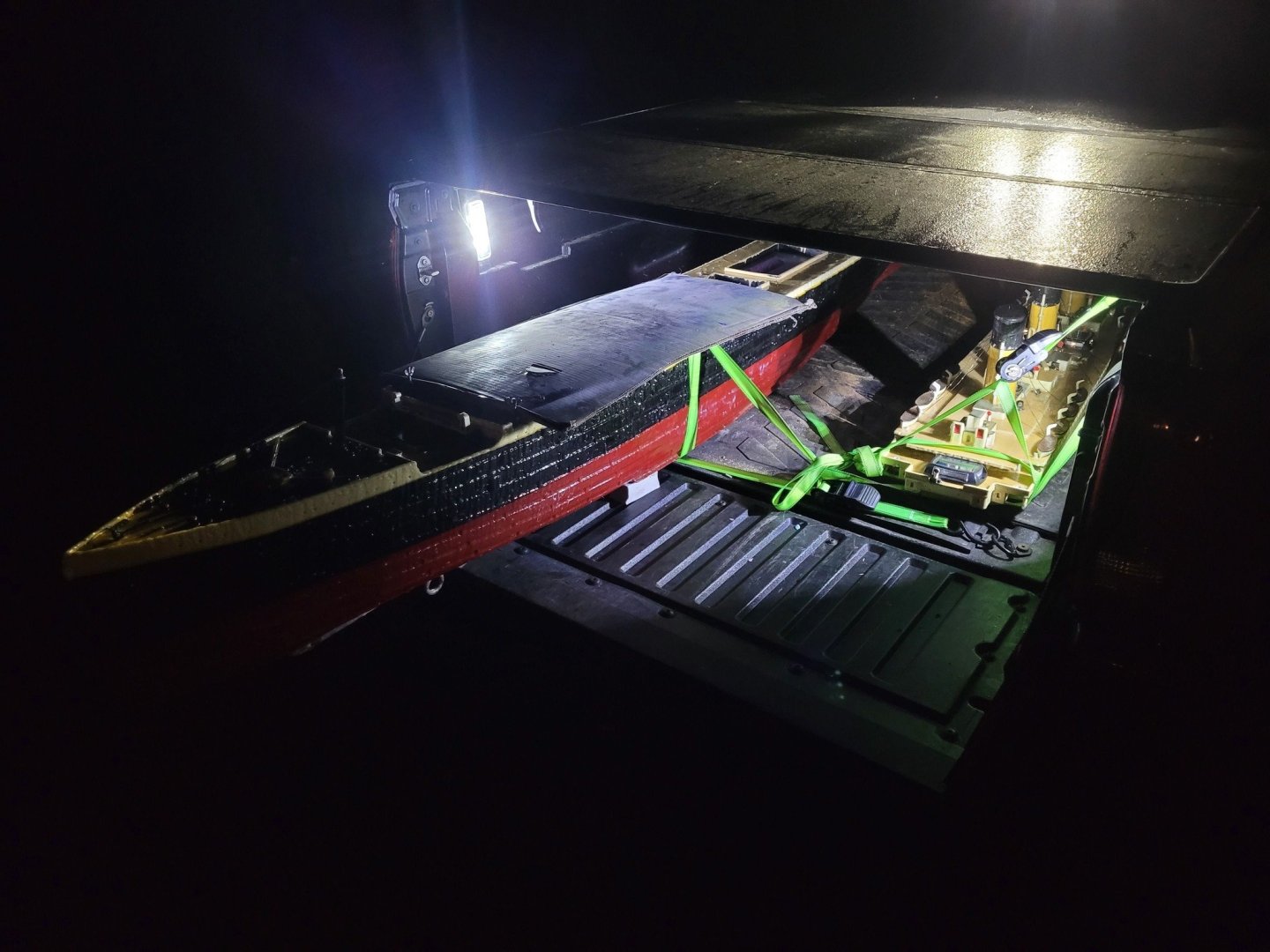

We'll be launching the Titanic again on Thursday at 1 PM at the Halifax Public Gardens! I've redone some of the interior fiberglassing and put a fresh layer of epoxy resin on the entire outside. Additionally, I decided to add some 'puck' lights - so the upper decks will get lit up in the evenings. Pictures will follow!

-

NavyShooter reacted to a post in a topic:

LPH-11 USS New Orleans by Spaceman Spiff - FINISHED - Iron Shipwrights - 1/350 - RESIN

NavyShooter reacted to a post in a topic:

LPH-11 USS New Orleans by Spaceman Spiff - FINISHED - Iron Shipwrights - 1/350 - RESIN

-

NavyShooter reacted to a post in a topic:

De Havilland Tiger Moth by Lt. Biggles - Airfix - 1/48 - PLASTIC

NavyShooter reacted to a post in a topic:

De Havilland Tiger Moth by Lt. Biggles - Airfix - 1/48 - PLASTIC

-

NavyShooter reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

NavyShooter reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

NavyShooter reacted to a post in a topic:

HMS Lion by Ian_Grant - 1/150 - RADIO - RESTORATION - WW1 Battlecruiser

NavyShooter reacted to a post in a topic:

HMS Lion by Ian_Grant - 1/150 - RADIO - RESTORATION - WW1 Battlecruiser

-

My experience with them was with the RCN on our Halifax Class Frigates - we didn't have the below deck VLS, we had above deck 8 cell VLS packs on each side - the missiles would come aboard with a data pack, and would need to get cycled through the Magazine/Depot every so often as they would do the maintenance ashore. All we had to worry about was hooking up the cables, unlocking the cannisters, and making sure they synched properly with our FC Radars on installation. If that worked, they were good for a while onboard. As Magazine Custodian, I signed for the missiles, torps, and all other energetic 'stuff' onboard...to the tune of over 6000Kg NEQ (12,000 pounds or so). NS

- 54 replies

-

- 3d cad

- cleveland class

-

(and 1 more)

Tagged with:

-

NavyShooter reacted to a post in a topic:

USS Oklahoma CIty CLG-5 (1971) 3D CAD model

NavyShooter reacted to a post in a topic:

USS Oklahoma CIty CLG-5 (1971) 3D CAD model

-

A true labour of love here - well done on the 3D modeling. The complexity of the Talos missile system is fascinating. Having sailed on ships with VLS, it certainly makes me understand why they transitioned from the Talos to the VLS. The simplicity of systems for a cannister based missile system makes it so much easier to maintain. NS

- 54 replies

-

- 3d cad

- cleveland class

-

(and 1 more)

Tagged with:

-

NavyShooter reacted to a post in a topic:

USS Oklahoma CIty CLG-5 (1971) 3D CAD model

NavyShooter reacted to a post in a topic:

USS Oklahoma CIty CLG-5 (1971) 3D CAD model

-

NavyShooter reacted to a post in a topic:

USS Oklahoma CIty CLG-5 (1971) 3D CAD model

NavyShooter reacted to a post in a topic:

USS Oklahoma CIty CLG-5 (1971) 3D CAD model

-

Here's a video that talks about it a bit. Option 13 for the PWM frequency will set it to higher frequencies - ideally go with the 16KhZ which is almost beyond the audible range, and makes it effectively silent!

- 184 replies

-

Suggestion - if you go with a Hobbywing 1080 ESC, you can adjust the internal frequency that they operate at - when operated at lower frequencies, they 'whine' like most ESCs do. If you adjust the Freq to the higher end, the ESC whine effectively disappears. I've got a video somewhere about doing that...let me dig up a link. I don't know if your 1060's are able to be programmed the same way.

- 184 replies

-

Looking at your results with those, I'll suggest trying a 0.25mm nozzle with your FDM and slow down your printing speed a bit - you'll end up with a finer bit of detail, and a nicer finish. The funnel and vents may turn out OK!

- 184 replies

-

I'm not a railroad guy, but damn....this is beautiful work. Your subject matter is interesting, and the history that all of this ties together is amazing...from the tales of how grain elevators worked back in the day to your leaf grinding...wow! Definitely following this thread going forward! Great work! NS

-

I came across this site a while back talking about WW2 Royal Navy Ship's boats: Royal Navy Ship’s Boats of WWII – On The Slipway And, if you're looking for some minimally detailed ship's launches, here's a site that may help: (you may have to sign up for this forum to access them though) RN Steam Launches | R/C Warship Combat Ship's boats and liferafts | R/C Warship Combat

- 184 replies

-

Welcome aboard! What part of the world do you live in? NS

-

The verdict about what I was able to get done in a week was - not much - I was sick in bed for most of 3 days. Ended up with this for presentation - no - some of the aircraft ain't right - no - I don't care. It was done specifically to tweak some Air-Force types who were visiting to have a look and we had a good laugh about it. 🙂

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.