SIDEWAYS SAM

Members-

Posts

248 -

Joined

-

Last visited

-

SIDEWAYS SAM reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

SIDEWAYS SAM reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

SIDEWAYS SAM reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

-

AJohnson reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

AJohnson reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

SIDEWAYS SAM reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

-

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

SIDEWAYS SAM reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Mr Whippy reacted to a post in a topic:

HMAV Bounty by AJohnson - Caldercraft - 1:64

Mr Whippy reacted to a post in a topic:

HMAV Bounty by AJohnson - Caldercraft - 1:64

-

dunnock reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

dunnock reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

AJohnson reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

AJohnson reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

aliluke reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

aliluke reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

aliluke reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

aliluke reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

aliluke reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

aliluke reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

DaveBaxt reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

DaveBaxt reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

Edwardkenway reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

Edwardkenway reacted to a post in a topic:

HM Bark Endeavour by Sideways Sam - Caldercraft - 1:64

-

Hi and thanks for visiting. Crossjack and topsail yard added to mizzen. Gaff boom will be attached later. Crowsfeet next then stays. I know that the shrouds should be fixed before the stays but due to fat fingers and poor eyesight I am having to compromise with some aspects of the rigging. Not a museum quality model by any means. Best regards, Sam.

-

DaveBaxt reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

DaveBaxt reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

-

Coming along nicely Dave. I used tanganyika strip from CMB to clad Endeavour. I was lucky it all matched and had hardly any grain whatsoever. Had a quick look in the Sphynx box and the strip provided is very high quality. This will be the first kit where I haven't had to replace stripwood. Enjoy your holiday. Sam.

-

Thanks for the comments Dave. If mine turns out as good as your efforts I will be well pleased. Tend to follow your Endeavour rigging sequence except possibly will leave the shrouds till later. Just had a look at your Diana build. Very impressive. Seems I am not the only one having problems with kit supplied strip wood. Thanks for the posts referencing timber supplies. Written these down for the future. Best regards, Sam.

-

Hi and, thanks for visiting. Sprit, fore and main mast yards assembled and located. Next will be the mizzen then the rest of the rigging will follow. In spite of fat shaky fingers and poor eyesight this is going together well. A good kit of parts from day one and the rigging plans provided are excellent. Another couple of weeks and I should be going on to the fiddly bits. Have mixed feelings about that phase of the build. Best regards, Sam.

-

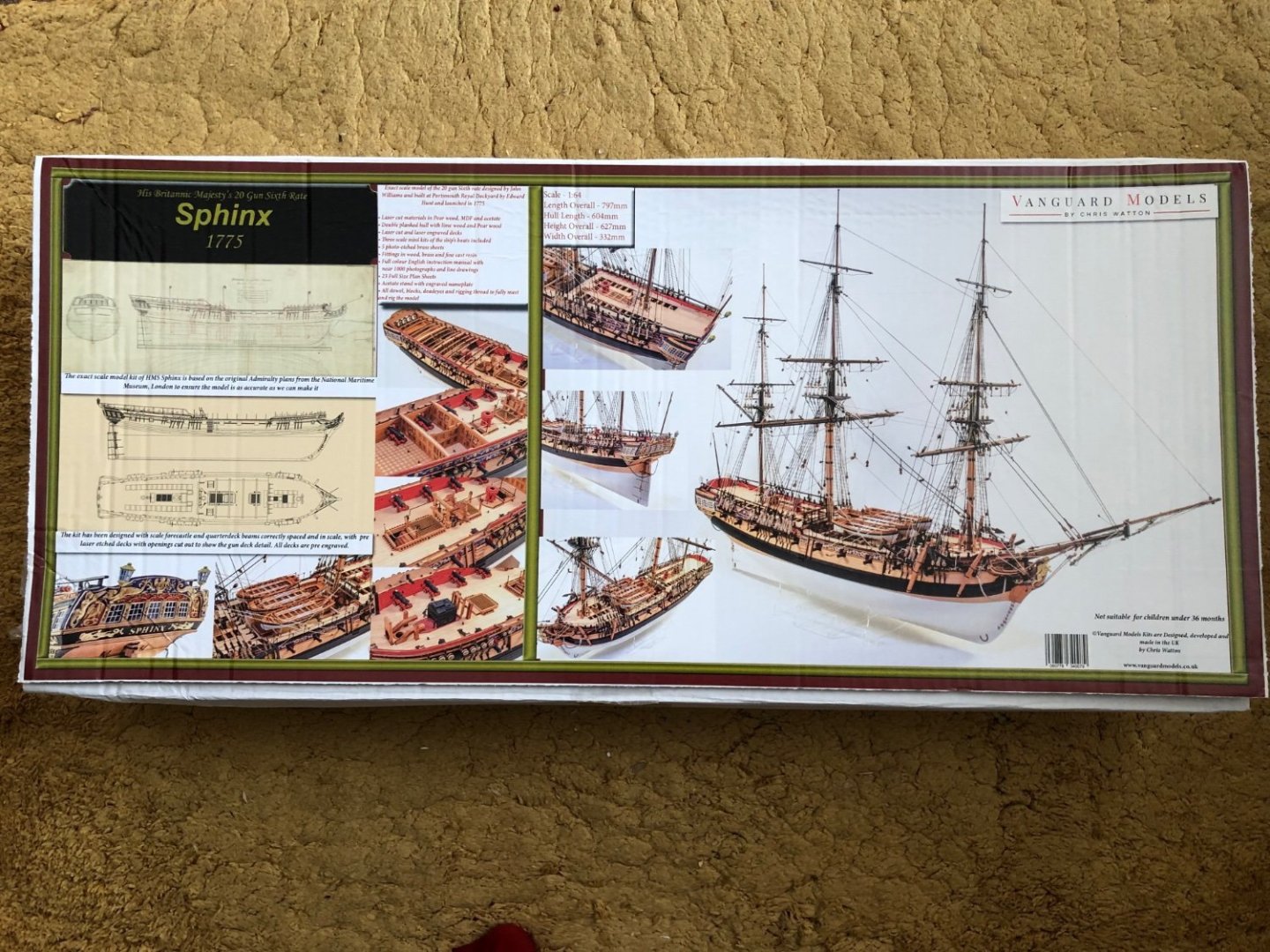

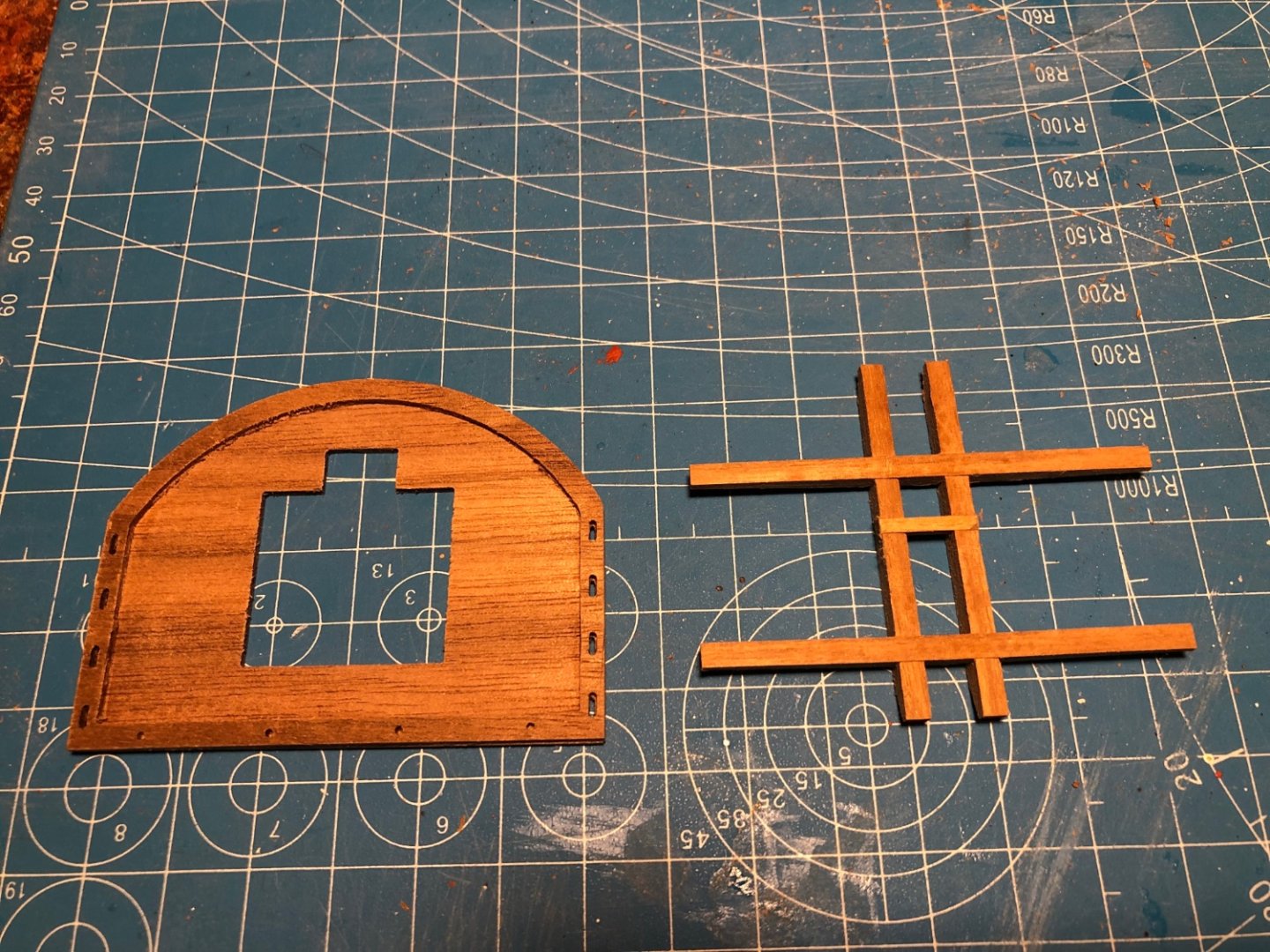

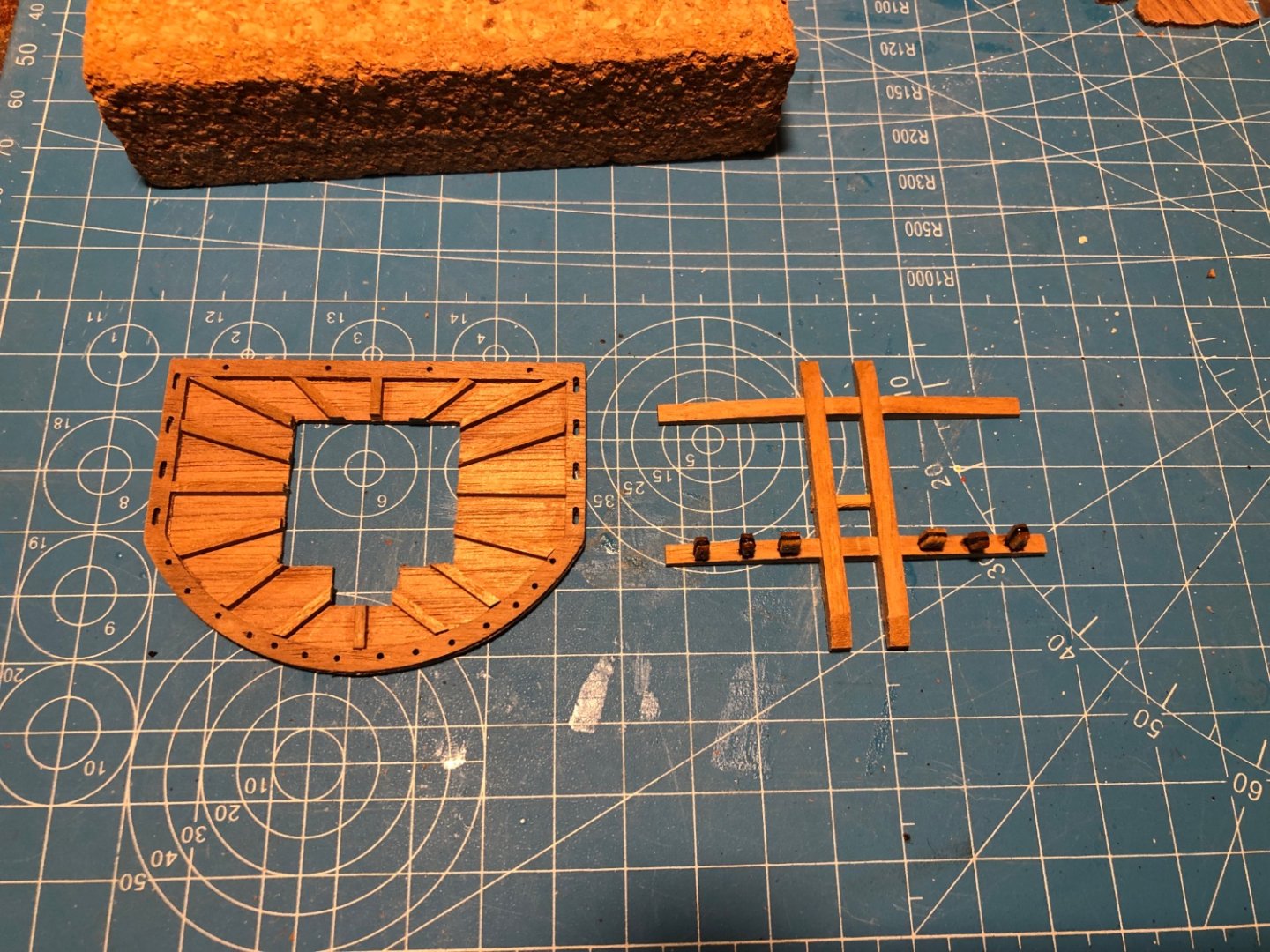

Hi, thanks for visiting and the likes. Dave - thanks for the comments. Next project is already waiting on the shelf. I thought that this would be the first kit where I wouldn't have to buy a load of extras like better planking etc. but I have already purchased cabin furniture for it and, if I don't go down the Navy Board route, I will need the pearwood blocks option. Have already opened the box and the contents are staggering. Best kit of parts ever. Really looking forward to this one. Best regards, Sam.

-

Thanks for the comments Derek. All i wanted was some decent boats for Endeavour and I made the mistake of looking on Chris' site. I ended up bodging the boats supplied by Caldercraft and bought Sphinx instead. Am already saving up for Indefatigable. Have a copy of AOTS Pandora on the book shelf which is providing entertaining reading. Can't wait to get started. Best regards, Sam.

-

Afternoon Derek, I also have a box full of Sphinx goodies waiting on the shelf so will follow your log with interest. Have been admiring your DoK for a while now. I agree with your comments ref. the instruction manual and the plans provided. This is a quality bag of bits and I am looking forward to starting building in May or June this year. I like the idea of building a Navy Board version but have a few months yet to decide. Blue Ensign's log looks very impressive. Best regards, Sam.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.