-

Posts

653 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Washington State, US

Recent Profile Visitors

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

DanielD reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

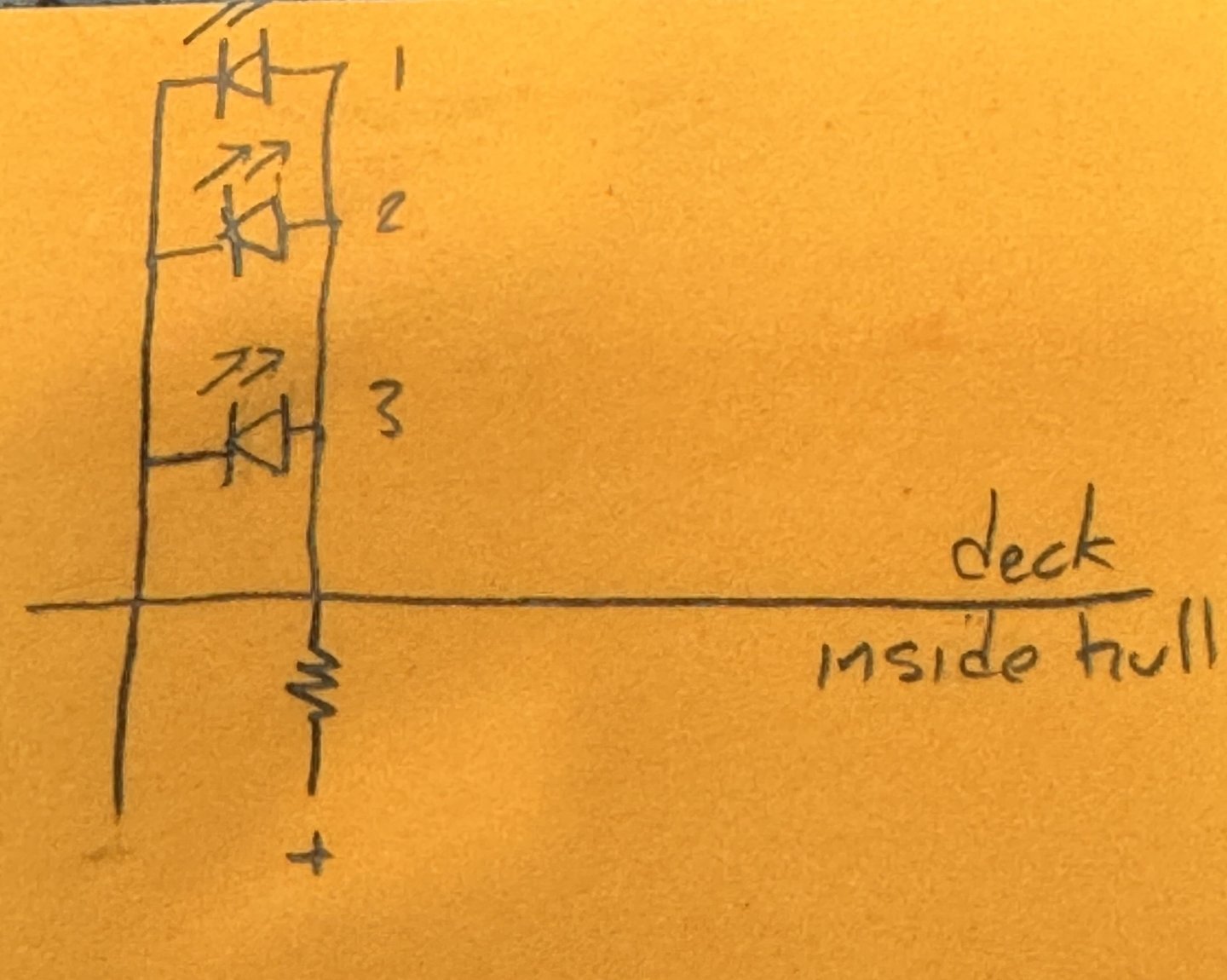

Yes, I planned my wiring layout with this in mind. There is another option, I just did not have the parts on hand. Currently you are using 1/4 watt resisters as they are very small and easy to hide. To run 4-6 LEDs on the same circuit off a single resister you can use 1/2 watt resistor of the same value. These resistors slightly larger but would still easily find inside the hull but are able to handle more current without over heating.

-

Hi Bill, sometimes electronics can be fudged a little, resisters are not precise, voltage drops are not always consistent, etc. Below is a circuit that fudges a little but works great, with one side effect, you will have to turn up the voltage a little to get the brightness you desire. Not too much, and no where close to overload the resister. So, I placed a resister inside the hull on a positive lead, the other side of the resister goes a max of three LEDs while the negative lead goes to the negative side of the same LEDs. This circuit is called parallel, which means that if one LED goes out (unlikely) the others are still connected and work fine. I used 3mm high intensity LEDs for this circuit, 3 LEDs for one resistor. This allowed me to make very small boxes to house the LED as each box only holds just the LED (no resistor). Hope this helps.

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

-

Bill, I have managed to add a wire or dowel to the bottom of most everything so that the parts stick into the deck. The flat pieces, if I could I soldered a pin to the bottom so that it would still fit into a hole. Some smaller things are glued in, but most everything can still be removed at this point.

-

Bill, yes, I added these lights after I did all the initial planing and wiring and after closing up the hull. My mistake for sure as I believe them to be very beneficial to the deck lighting. Oh well, it was an easy fix. I drilled the upright dowels out to accommodate the wires for the new LEDs. Then added a hole in the deck under the uprights. Still to this day I have not glued down my bridge building as it’s just stuck to the deck with 3 or 4 dowel pins, so I just fished a wire through the new holes up into the floor under the bridge. Made the connections to the bridge wires, pushed them back inside the hull, and connected the new LEDs. When the bridge lights come on, in my case along with the deck lights, so do the new LEDs in that structure. I hope this helps.

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

DanielD reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

king derelict reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

king derelict reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

-

Bill97 reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

Bill97 reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

Hi Bill, visual progress is slow for me right now as I’m doing the rigging for the bow. I’m learning how to do furled sails so have a bit of a leaning curve to overcome. I’m also having to “make my own sails” again as the ones supplied in the kit are way too thick to fold up without looking out of place. I’m using tea bag paper, very thin but ultra strong, then make the sail stitching to simulate panels, then stain the sail so it doesn’t look too white, then sew in the rope the runs around the entire sale which allows me to have attachment points for the rigging. Also, each end point that secures to a pin in a normal ship has the special AV storage at the base of each mast, so I planned for all that and it’s tedious work getting the lines tied correctly. I have a few more lines to go to finish the bow sails, so I’ll add a new photo soon.

-

Bill, sadly I’ve done something similar with my HMS Terror. At that time I placed the wiring right under the deck, which when I drilled a hole for some piece of deck equipment, I severed a wire. I had to do micro surgery by taking out a deck plank and add a hole through the false deck, find the broken wire and solder it back together and repair the deck. It was a pain to say the least. Now I don’t put the wires directly under the deck to prevent future accidents. I guess we just learn from our past and move on.

-

The way I accomplished this exact problem is making the hole in the brass the exact diameter of the body of the LED. Slide the LED from the bottom to rest on the lip and affix in place. No need to worry about the leads touching the Mount. Then I painted the bottom of the Led, the underside of the Mount, the same black as the Mount and it becomes invisible.

-

Hi Bill, if I did it again I would do it differently. I soldered about 1” of flat 3mm bar in two places on the back side of the bracket, and then cut two slots into the side of the hull. This more or less made the entire device removable, so I could work behind it, then reinstall. Worked great, except cutting the flat slots into the hull was difficult. Instead, I’d I were you, I would use brass rod, maybe 1mm diameter, and affix to the back of the bracket. Then all you have to do is drill matching holes into the hull and slide in place. Still removable, but much easier construction.

-

LoydB reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

LoydB reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

-

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

DanielD reacted to a post in a topic:

Amerigo Vespucci by Bill97 - OcCre - 1/100

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

DanielD reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

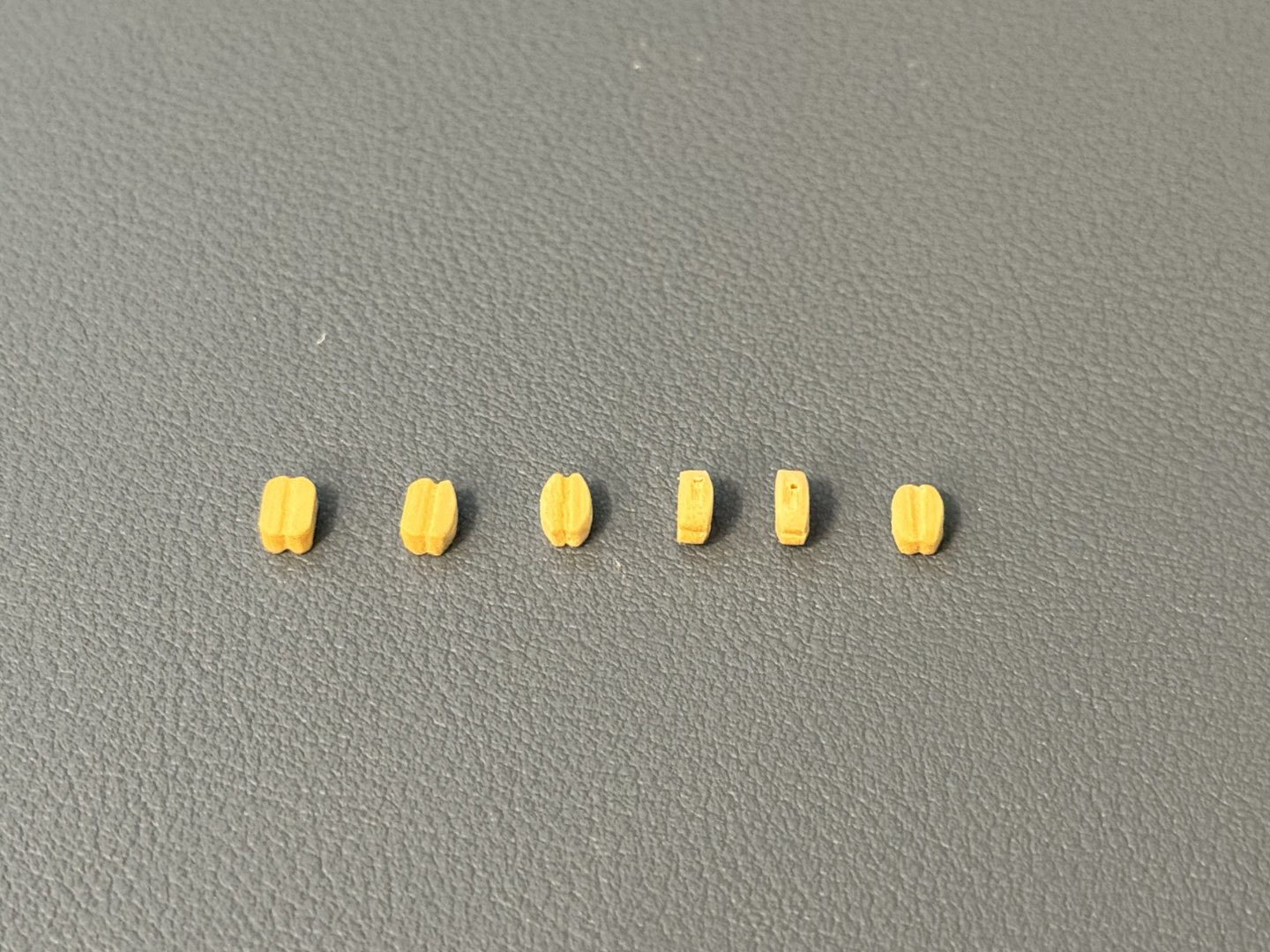

Bill, I found absolutely nothing listed for the AV in the area of rigging. As such, I chose 3 sizes each for black and light tan. When I first bough the lines I’m using I was able to get here in the US. When I realized I didn’t have enough, I had to obtain more from China which took about a month to arrive. So…not likely a good resource anymore. The lines I am using are lightly pre-waxed so no “fuzz” and work well, just current availability is non-existent. As for the blocks, I used the ones that came in the kit but I’m modifying them to be more realistic. Hard to put into words, but I’ll try. Holding the block in a pair of needle nose pliers, sand the corners off the top and bottom creating a curved edge. Flip 180 degrees and repeat. Next grab the block with the pliers along the edges just sanded, 90 degrees from the initial sanding, and sand off the corners again. Flip 180 degrees and repeat. This rounds out the block in two plains, to make it much more realistic. Lastly, I use a triangular file and redo the grooves, top, bottom and both sides. When I get home I’ll upload an image of a before and after. It’s quite the transformation for about a minute of work.

-

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

clearway reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

-

Bill, there is nothing that says the resistor has to be next to the LED, meaning, the resistor can be inside the hull and a wire from one end of the resistor goes to the LED. In my setup, I ran a series scenario with the LEDs, meaning one resistor then the LEDs are run one after the other in series. This type of wiring does have a draw back, for the same reason Christmas lights are wired in parallel now days, if one bulb goes out, they all do. That aside, the resistor is inside the hull making for less hardware in the box.

-

DavidG reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

DavidG reacted to a post in a topic:

Amerigo Vespucci by DanielD - OcCre - 1:100

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.