Randy Todd

-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Randy Todd

-

-

Hi Ed,

Sorry to take up the space. Early on we discussed a builder's log and it's not something I'm inclined to sink any time into (best to keep the marriage healthy). I thought you mentioned some interest in seeing my progress. Sorry for the misinterpretation and I'll stop sending photos (hate taking them anyway). I'll confine my correspondence to questions about Volumes 2 and 3- never done any home milling before so I'm sure I'll have plenty.

Randy

-

-

-

- billocrates, berhard, Knocklouder and 3 others

-

6

6

-

Hi Ed,

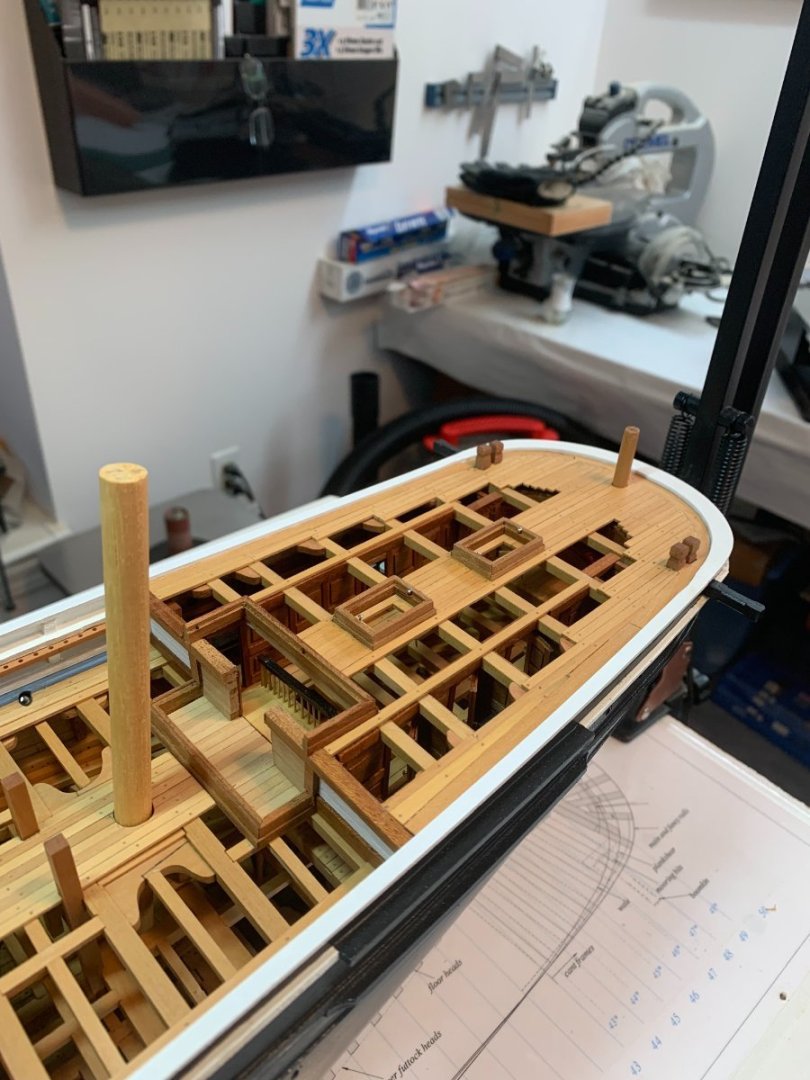

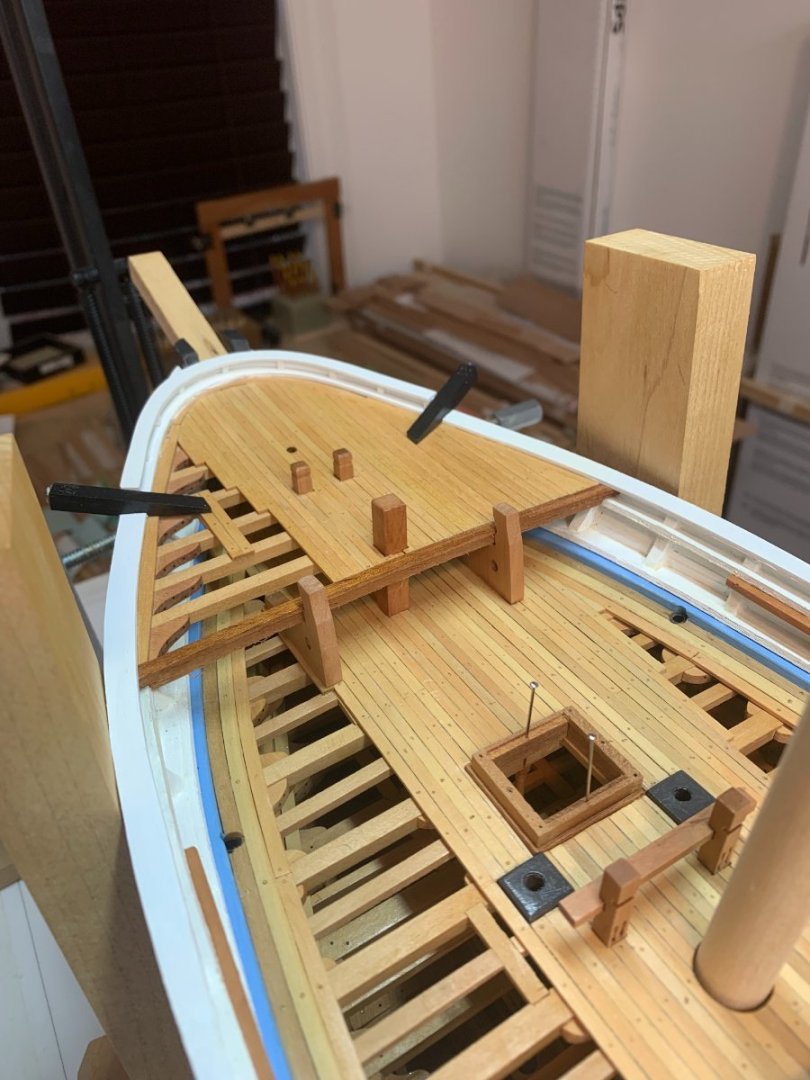

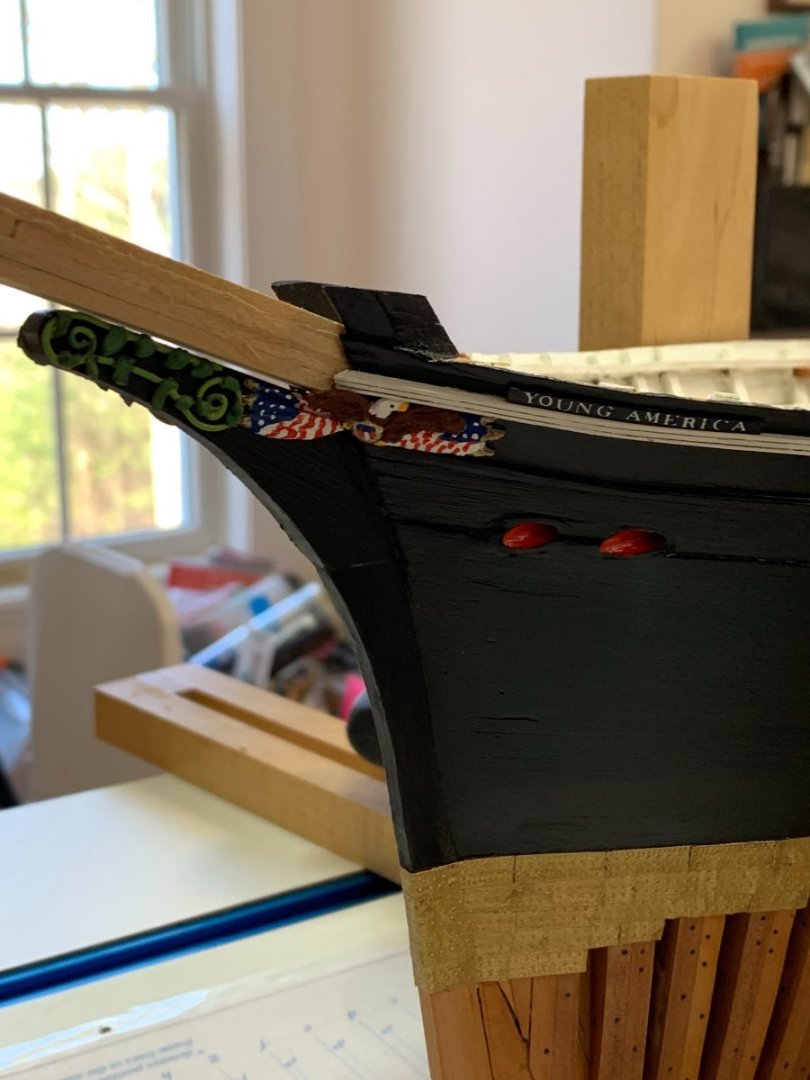

Here are some progress pictures that you requested. Sorry for the long delayIMG_2345.HEICIMG_2347.HEICIMG_2346.HEICIMG_2351.HEICIMG_2349.HEICIMG_2348.HEIC

Let me know what you think,

Randy

-

Hi Ed,

Just want to confirm something before I begin. Do you have a reference confirming Young America was sheathed in yellow metal and not copper. On Crowther's table on metal sheathing on era ships, Celestial (1850) and Gazelle (1851) were copper sheathed. Challenge (1851) was sheathed in yellow metal. Crowthers has no reference for either way for Comet (1851), Invincible (1851), Young America (1853) and Flyaway (1853). There is a Remark that Young America was sheathed in yellow metal in November 1879 but it us unclear if this represents a change from copper. Many other builders were using yellow metal, but I'm having difficulty identifying the sheathing material used in 1853. I have material for either approach. Do you remember how you decided which to use?

Thanks again!

Randy

(I have not forgotten the progress pictures but things are a bit of a mess. I'm hoping to remount my hull back on the shipway soon, then I'll send some along for you)

-

Hi Ed-

Not to get too fixated on scuppers but looking at Crowthers book, there appear to be four on each side (at the [1] break of the Forecastle; [2] between 1 & 3; [3] low point in the waist; [4] break of the poop deck. He couches this generalization by saying this 'rule' varied by ship design. Do you remember if you found a reference of the number/location of the YA scuppers or made a (very) educated guess? Remembering my hull iron banding fiasco (Admiralty vs Lloyds), I thought I'd check in again before drilling.

I know Mystic has a virtual warehouse of models and not all are on display. I trust your YA is viewable by the public-it might be worth the trip.

I will definitely share some pix with you. You've been very generous with your time. Let me finish off a couple things before taking some progress photos. It is starting to look like a ship.

Randy

-

-

Thought I'd share something that has been working for me. To prevent debris and parts (and their retrieval), I made two deck-shaped drop clothes (out of a rag) and cut a slit up the middle (to allow placement of the pillars). It not only has saved me from having to fish fallen timbers from the hold, but the surface is easily vacuumed. Deck cover.HEIC

-

I am having troubles getting to Ship Ahoy's website to get the Pre-ac motor replacement: I get an Asian, unsecure website instead. I have typed http://shipahoymodels.com. Do I have the wrong information?

-

Grant (or Ed)

I also purchased the Proxxon MicroMill Mf70 37110. I got both because they seemed to have a small footprint (I have little space), looked simple and adequate to complete the YA project. Should I try to return these? If so, what would you recommend I purchase?

Thanks in advance for your help/advice,

Randy

-

Grant-

Any ideas how I can set up my lathe to make these turned pillars? I have no experience here. I need some guidance.

Randy

-

Hi Ed,

I am trying to get things set up to fabricate by turned pillars. I just purchased a Proxxon DB250 wood lathe and am very new to this equipment so please have patience with my questions.

[1] In figure 9-48, you show a 5/32" diameter brass tube in the tailstock. This is to prevent splitting the wood. However, the tailstock to my lathe comes to a point. I do not believe Proxxon has a similar set up as you show. Is there an alternative way to protect the wood?

[2] Is that a clamp on your tool rest that is holding your bit (Figs 9-48 and 53)? My lathe has a simple rest, but no clamp. Do you have any suggestions?

[3] What is your bit made out of (Fig 9-50)?

These are my questions for now. I'm sure there will be more. Hopefully, I'm being clear.

Randy

-

Hi Ed,

Finished the Lower Deck. I learned a lot but am glad my mistakes will be largely buried from view. Middle deck should be better. I ordered my lathe for the pillars- should be an adventure. Your book and log complement each other well and have been a big help so far.

Happy New Year,

Randy

-

Hi Ed,

Quick question about dimensions: The filling strakes are 6" thick but how high? Common planks are 3.5" thick but how wide? I'm sure they are somewhere, but I can't seem to find these numbers.

Thanks!

-

Hi Ed,

Thanks for your quick and thorough replay. I have been leaning towards the Sherline machines but wanted to make sure I wasn't overdoing it (the grief I am going to get over cost will be mighty). While in some ways attractive, the modular aspect of the Unimat system made me uneasy: I would have preferred to be able to see how sturdy it is first and some of the configurations are completely unnecessary. I want to avoid falling into the Peter Principle with work-arounds, so it is time to settle on a milling machine/lathe soon. At least I can go into it now with a little more confidence.

Randy

-

Hi Ed,

I've put off buying a milling machine/lathe long enough: it is time to put my marriage to the test! At your recommendation, I have read through the Joe Martin book. Your instructions in the YA texts seem pretty detailed for the specific tasks. However, I have no experience with any of this (other than some keen lathe work in 7th grade woodshop). My goal is to have a set-up that will allow me to complete this specific project with as few 'extras' as possible ( I have no immediate plans what direction I will pursue after completing the YA). There are dangers of going 'too simple' and 'too complex'. In the Micromark catalogue, there is a Unimat 6-in-1 modular system that seems simple and space efficient. I believe you reference using a Unimat in Volume 1 but I'm not sure we're talking about the same system. Sherline has many options, but all seem much more complex and space consuming. I know this puts you on the spot, but any advice regarding an option that should allow me to complete this project without going overboard would help greatly. I'm concerned my inexperience may lead me in the wrong direction. Any thoughts?

Randy

-

Hi Pat-

I was thinking about something along those lines. Glad to hear it works. As the decks are framed, I'm anticipating the hold collecting a lot more than bilge water.

Randy

-

Hi Ed,

I have a housekeeping question: As the decks are installed, how do you remove wood shavings/dust that collect in the hold. Right now I'm only working on the lower deck. As the other decks are added, removal of debris seems like it will get more and more difficult. How did you address this issue?

Randy

-

Yes! Thank you!

I missed Figure 10-11. In earlier figures, the pins looked more angulated (and I assumed the holes -and later bolts- entered the frame rather than remaining in the deck clamp alone). Glad I waited and asked.

-

It looks like a hole is drilled through each end of the deck beams. The hole seems to be angled towards the deck clamp and I assume into the frame. Do I carry the hole through the entire thickness of the frame or stop before going through?

-

Hi Ed,

Hope all is well.

I've re-started my YA project and am now fabricating/fitting/pinning the lower deck beams. Should I drill through or just into the frames when making my pin holes?

All the best,

Randy

-

-

Wonderful photo. Another good reference!

Young America 1853 by EdT - FINISHED - extreme clipper

in - Build logs for subjects built 1851 - 1900

Posted

Hi Ed,

What is a good source for high quality brass, copper bands, etc? I used to think all metals were the same until I got some blades from China that did nothing but fracture. If things go south as I start milling, I want to make sure it is the Indian and not the arrows....

Thanks in advance,

Randy