-

Posts

1,587 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by John Ruy

-

Thank you Jon for your detailed log regarding your processes to build this model. I am looking forward to watching you create yet another magnificent diorama on the exploration of the arctic. John

- 61 replies

-

- Northwest passage

- Norway.

-

(and 2 more)

Tagged with:

-

Thanks Mike I do appreciate you being my guy on the scene. You can keep an eye on my build and let me know how I am doing. I really don’t think I will need any more photos until maybe we see some progress on the restoration efforts, which I am sure won’t be until spring. Meanwhile a drive by would be sufficient, stay in your jeep. 🥶

-

As she should… No worries, I think I have the pics I need. Maybe next spring, when it gets up to Zero 😆 BTW… those pictures were great, they got me to this point. Thanks I have been in -40 degree weather on Indian Moutain in Alaska at an Air Force Radar site. What are your windchills? We had signs posted that said exposed flesh would freeze in 5 seconds. No body was making any yellow snow. LOL 😆 Frosted my bronchial tubes snow showing into a radio beacon shack. Fun times, stay warm my friend.

-

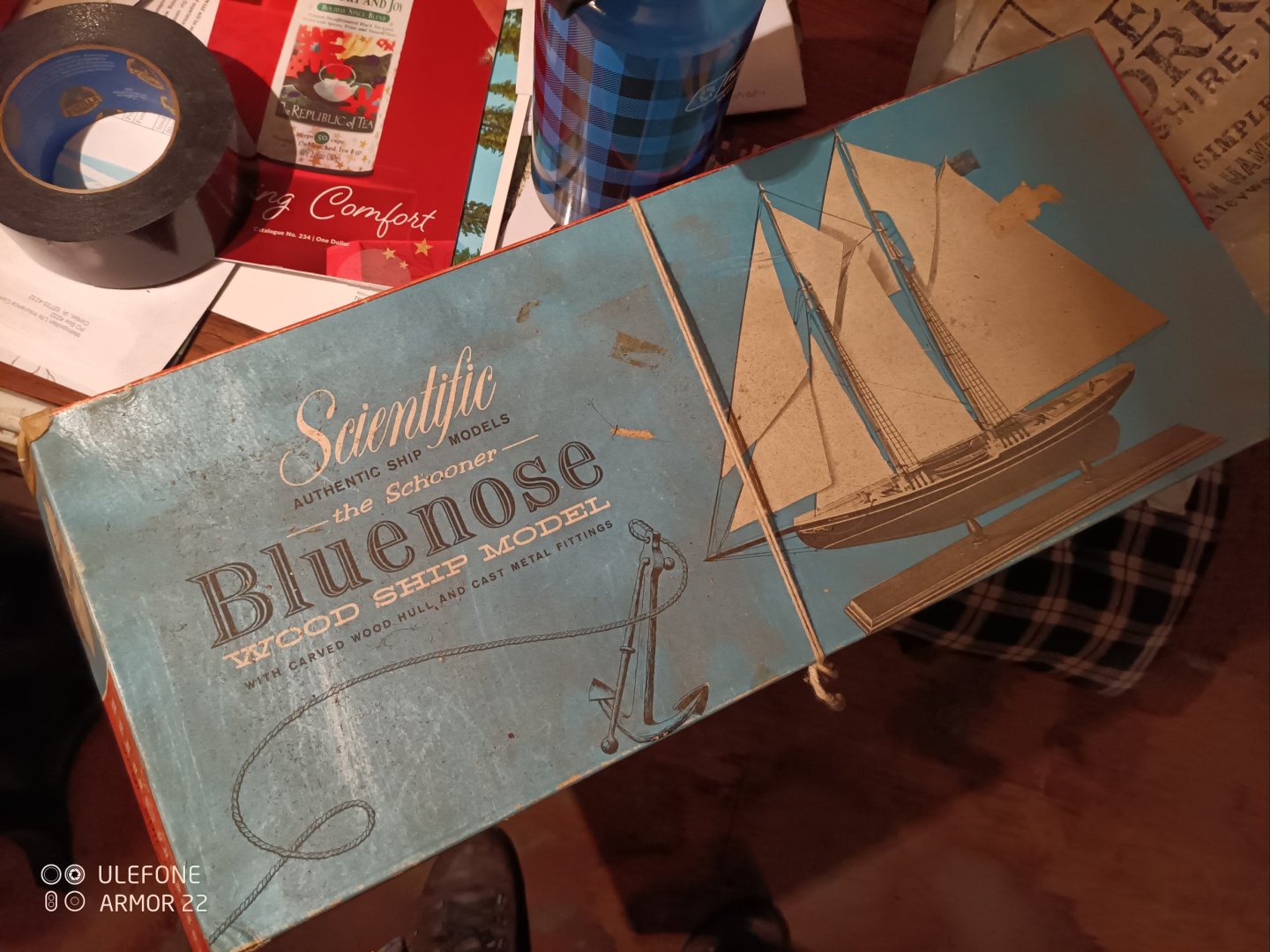

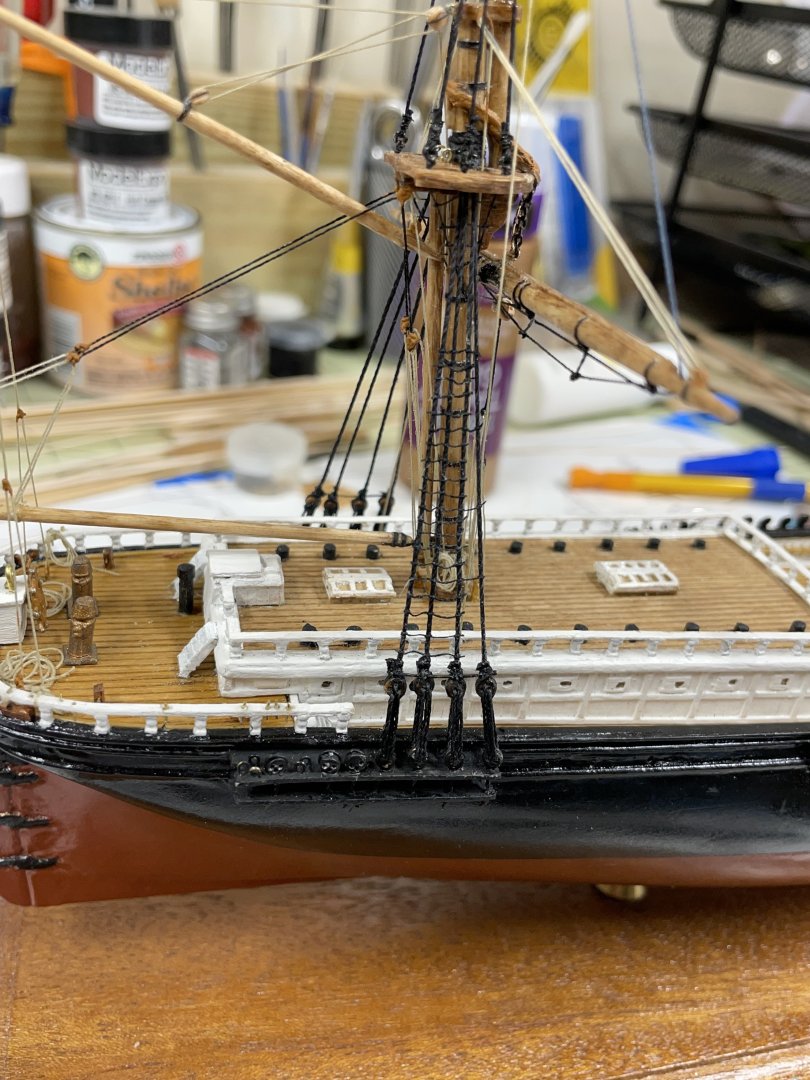

Hi Bob, Looks great… You have done that kit justice. Nice 👍 FYI… I’m building one of these kits for a friend who bought it 50 years ago for her father’s birthday. He never started it before he passed and she kept in the attic untouched until now. No pressure LOL 😆 I used Model Expo Hull Red… It’s a lot darker.

- 44 replies

-

- Scientific

- Billings Boats

-

(and 1 more)

Tagged with:

-

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

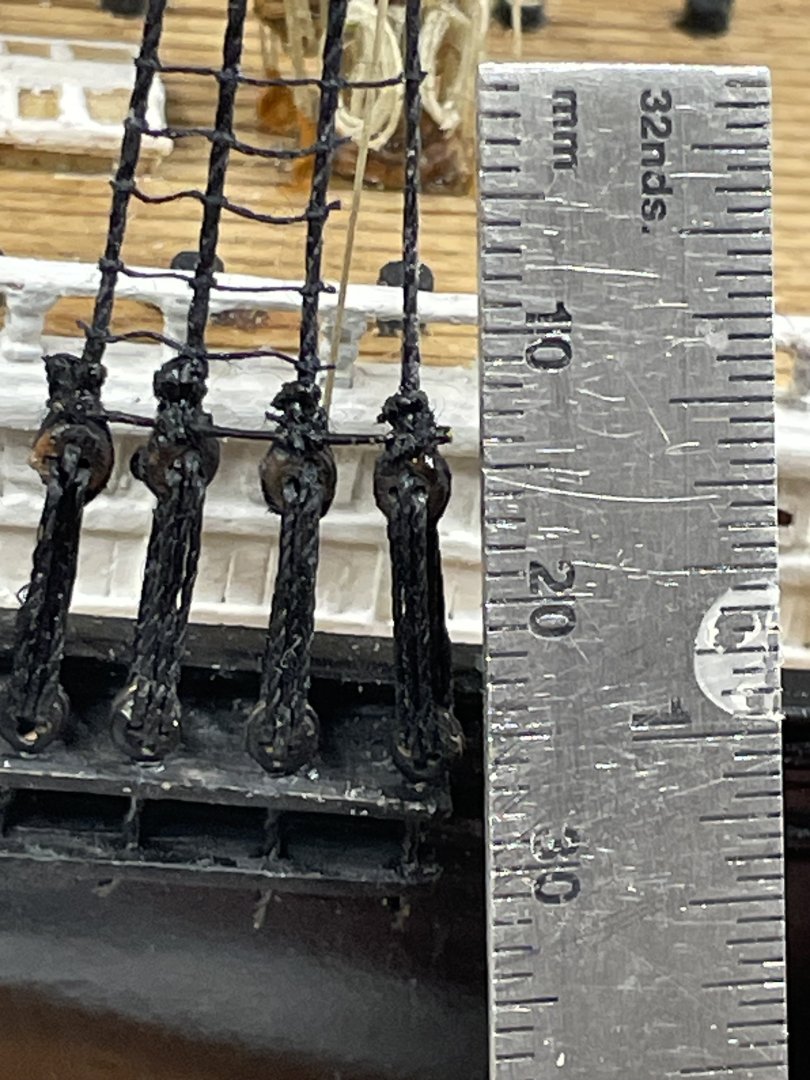

Ian, just some vintage black thread from an old kit. (Sewing thread) Use single half hitch knots only and ‘fray check” to keep it from bing fuzzy. https://www.michaels.com/product/dritz-fray-check-liquid-seam-sealant-10112538 Cheers 🍻

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

Looking Great Jon, I like leaving brass belaying pins brass, too. Helps highlight the details. Like rope coils. 😎 John

- 61 replies

-

- Northwest passage

- Norway.

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.