-

Posts

1,584 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by John Ruy

-

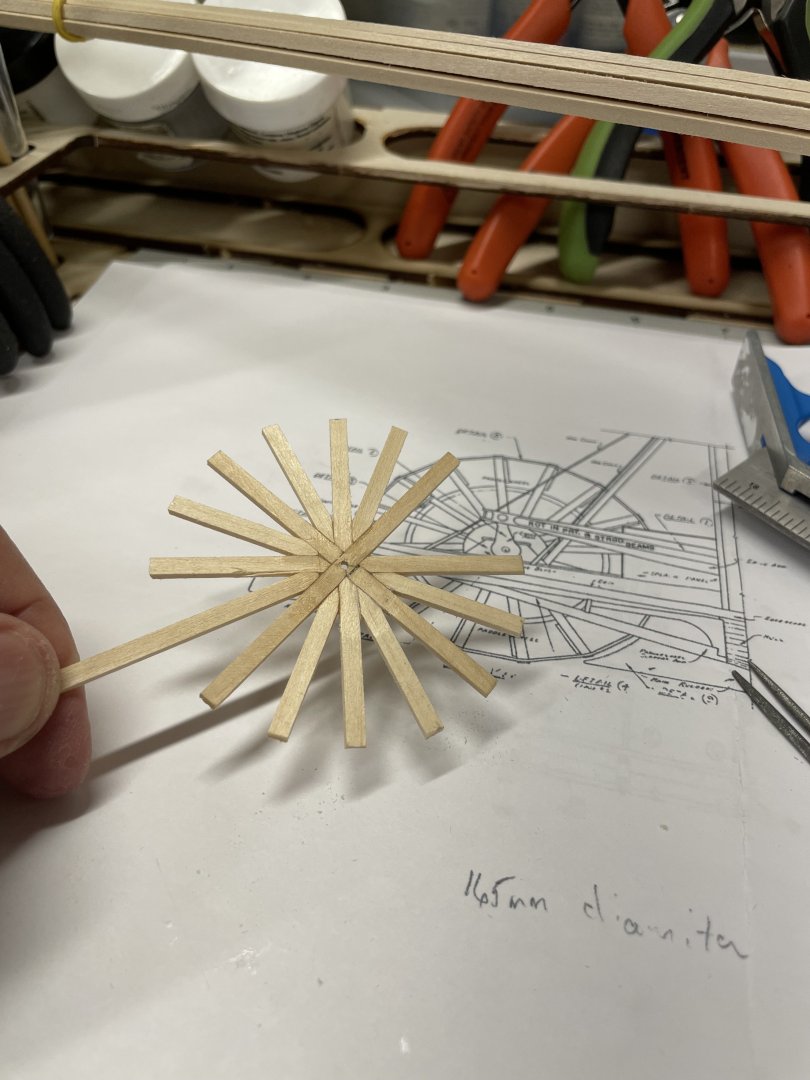

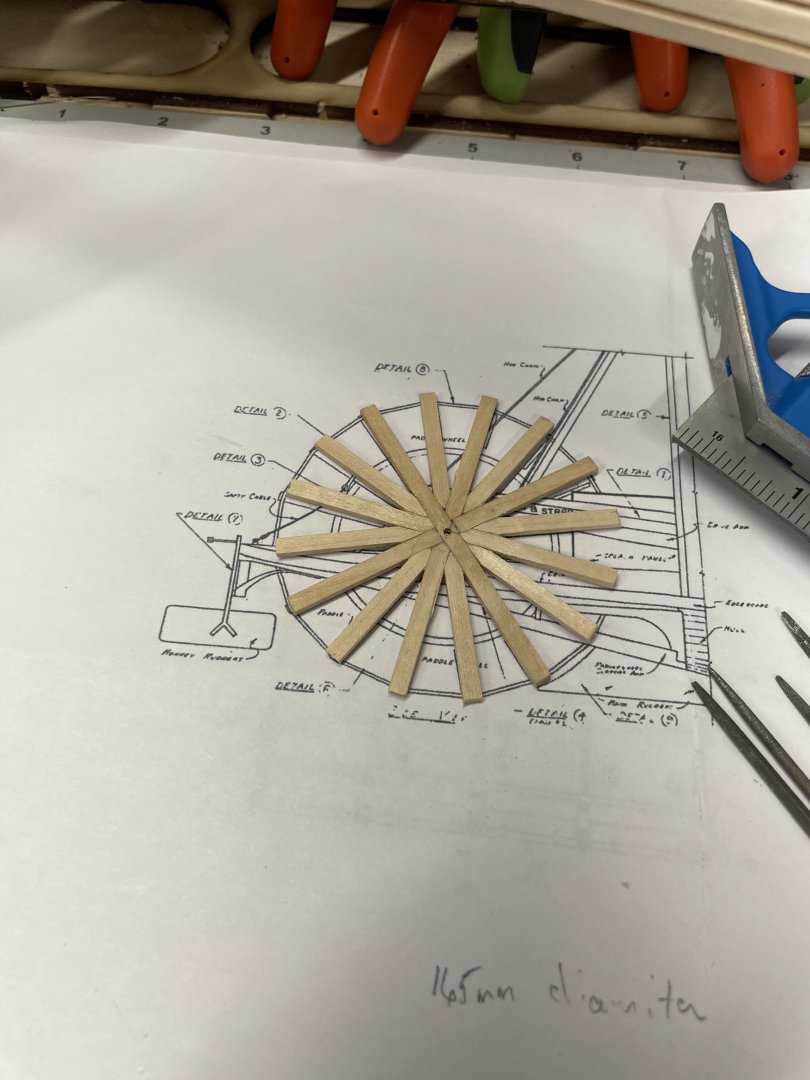

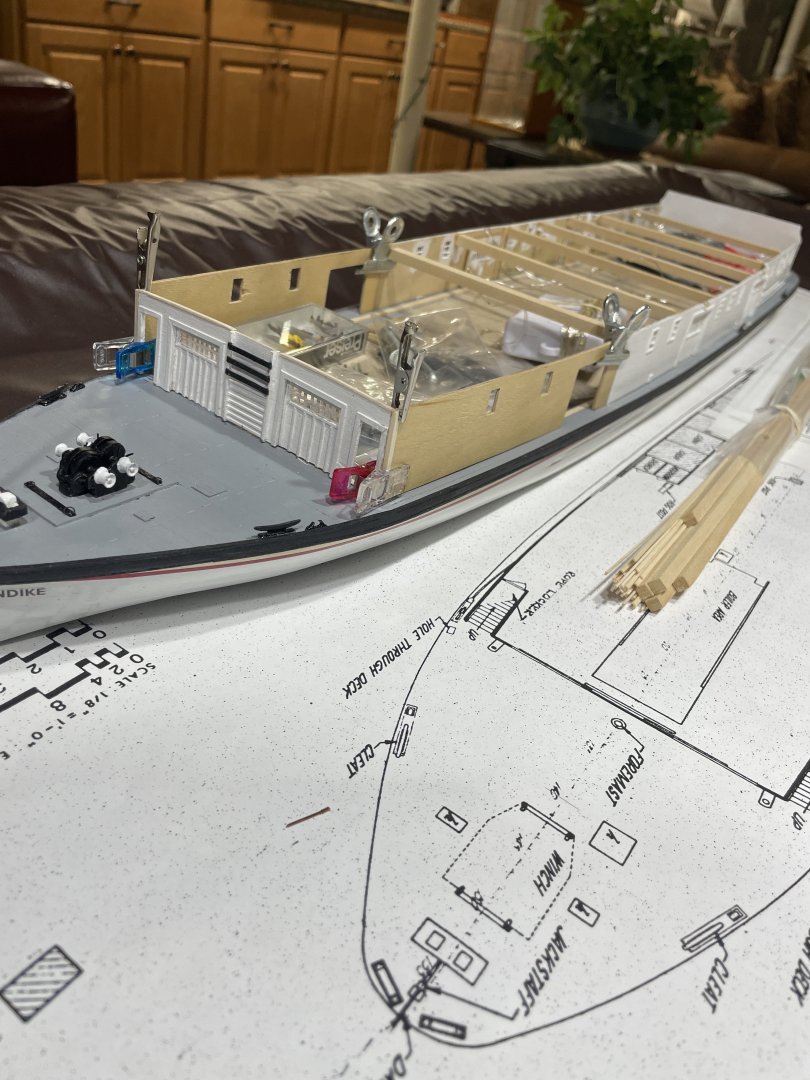

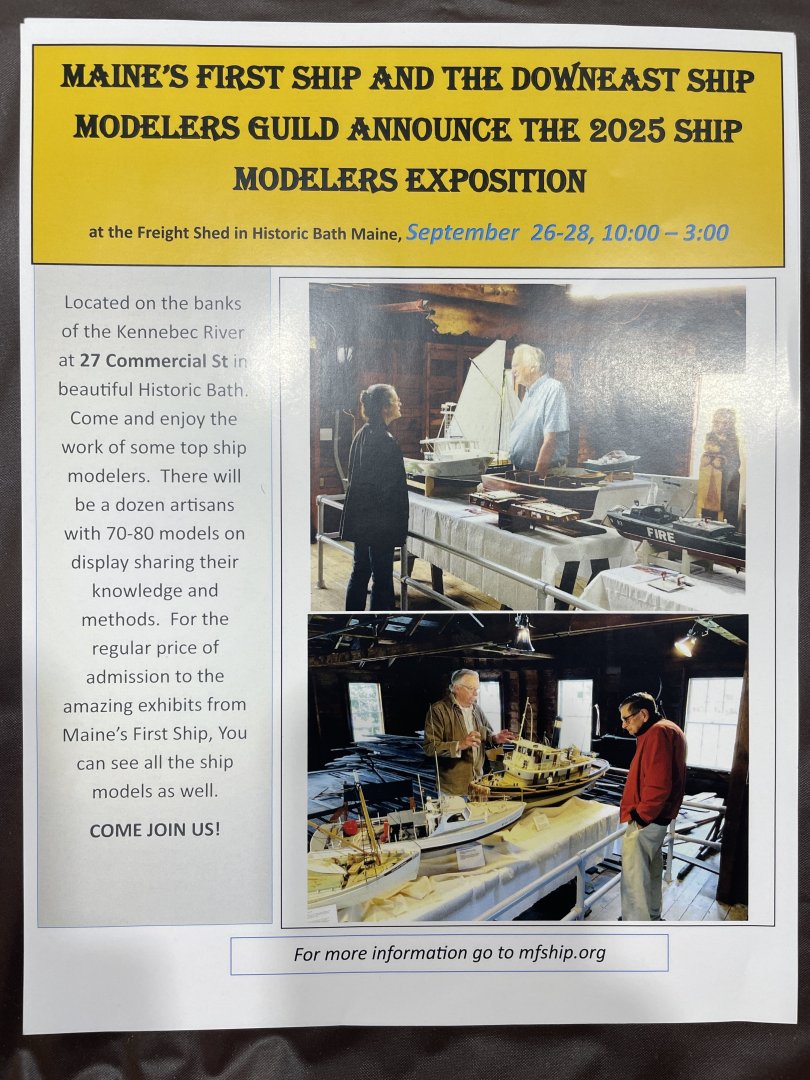

Follow up on the DESMG Expo… I Demonstrated building the Paddle Wheel for the Klondike and Displayed 6 of my completed models. It was a great 3 day Expo held in Bath Maine at Maine’s First Ship Museum. The hours drive up each day was well worth it. Transportation of the models was a bit sketchy but they all survived the trip. Everything is back home, now it’s time to get to work in the ship yard. Cheers 🍻

-

Displayed the Red Jacket (in progress) at our Down East Ship Modelers Guild Expo in Bath Maine. Along with a few of my completed models. Should have more progress to post soon. Cheers 🍻

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

Beautiful Kieth, Incredible work. 🤩

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

I agree Kieth, we here on MSW do inspire each other to do what’s right in our world of model ships. Thank you for your comment, as well. John

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Kieth, I cannot even imagine that something you put together would not be absolutely perfectly correct. John

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

The weathering is incredible. Love the rust hard water staining.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Absolutely amazing Kieth… The detail is just incredible. WOW!😮

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

Nice progress, very nice work on the blocks. 🍻

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

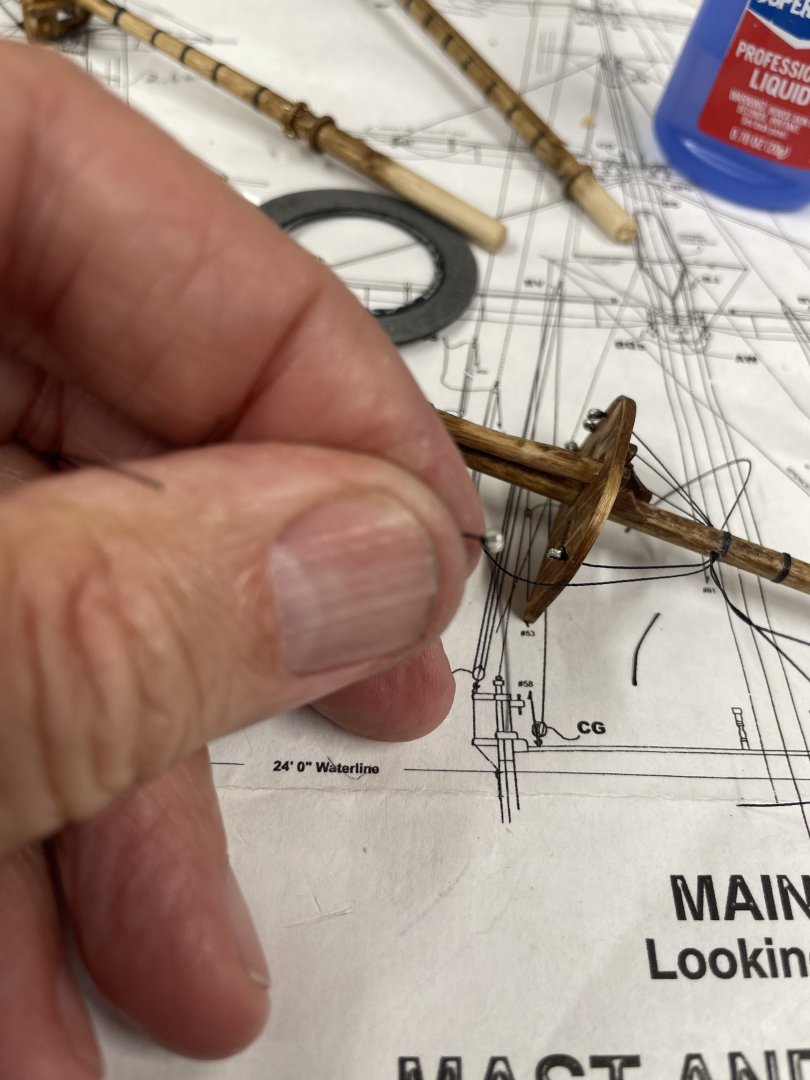

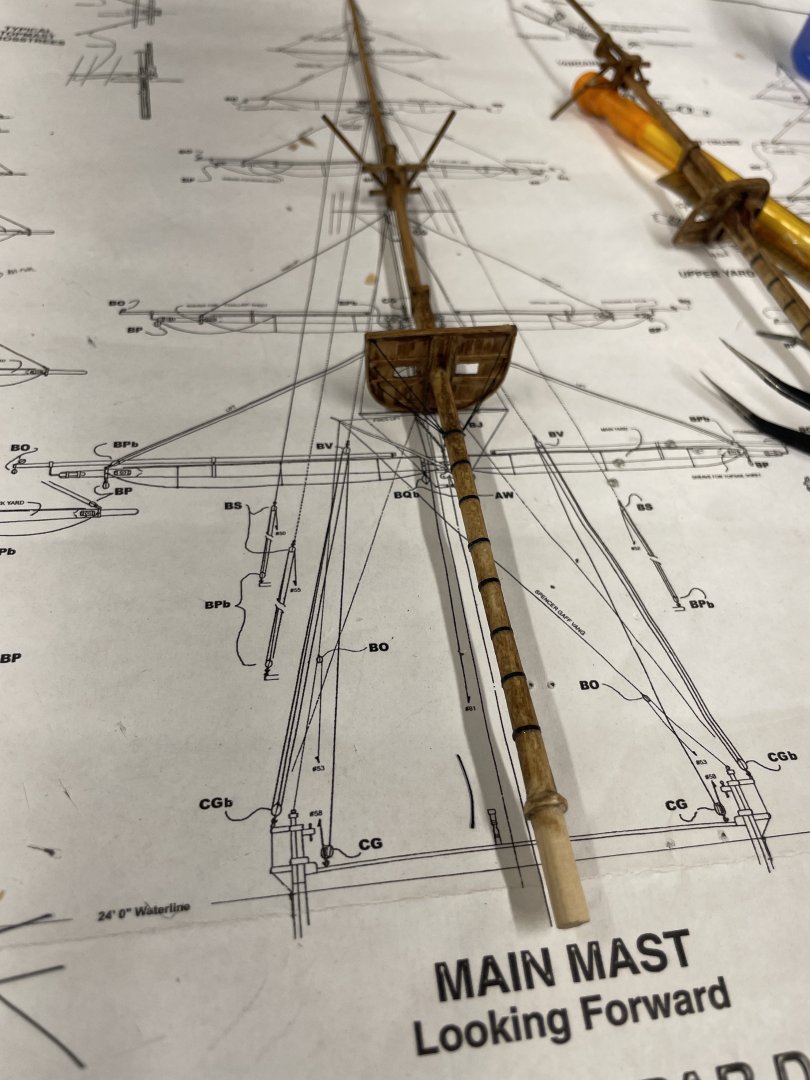

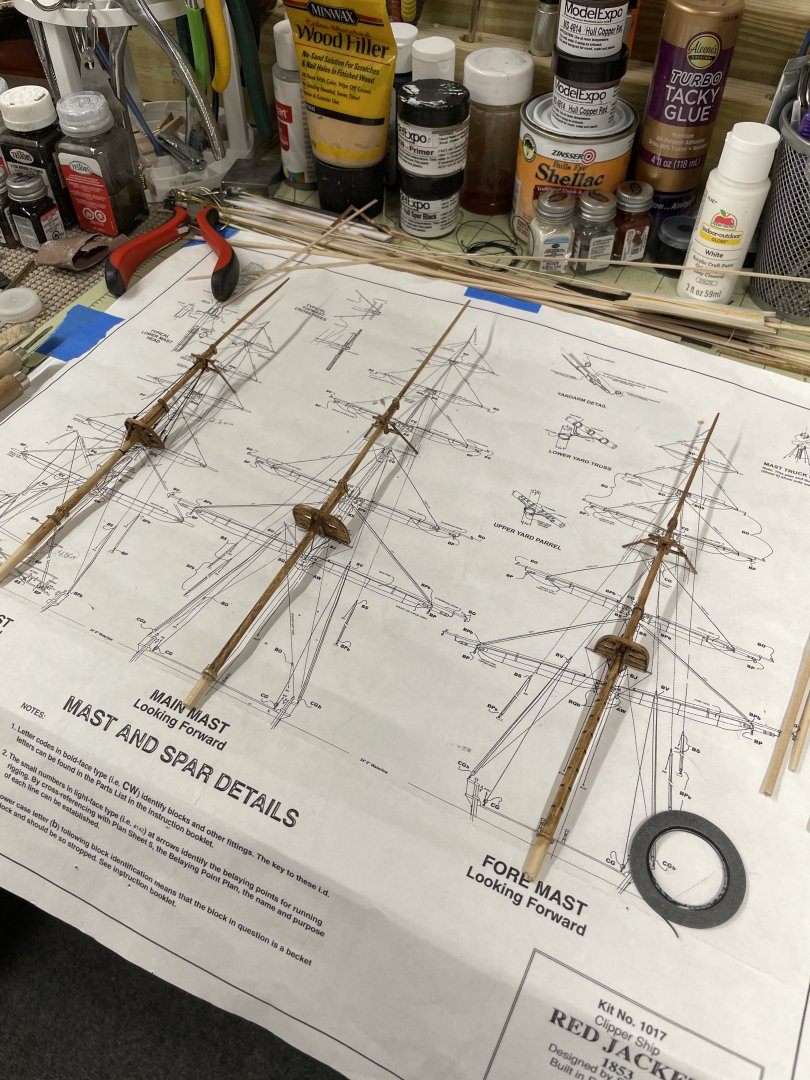

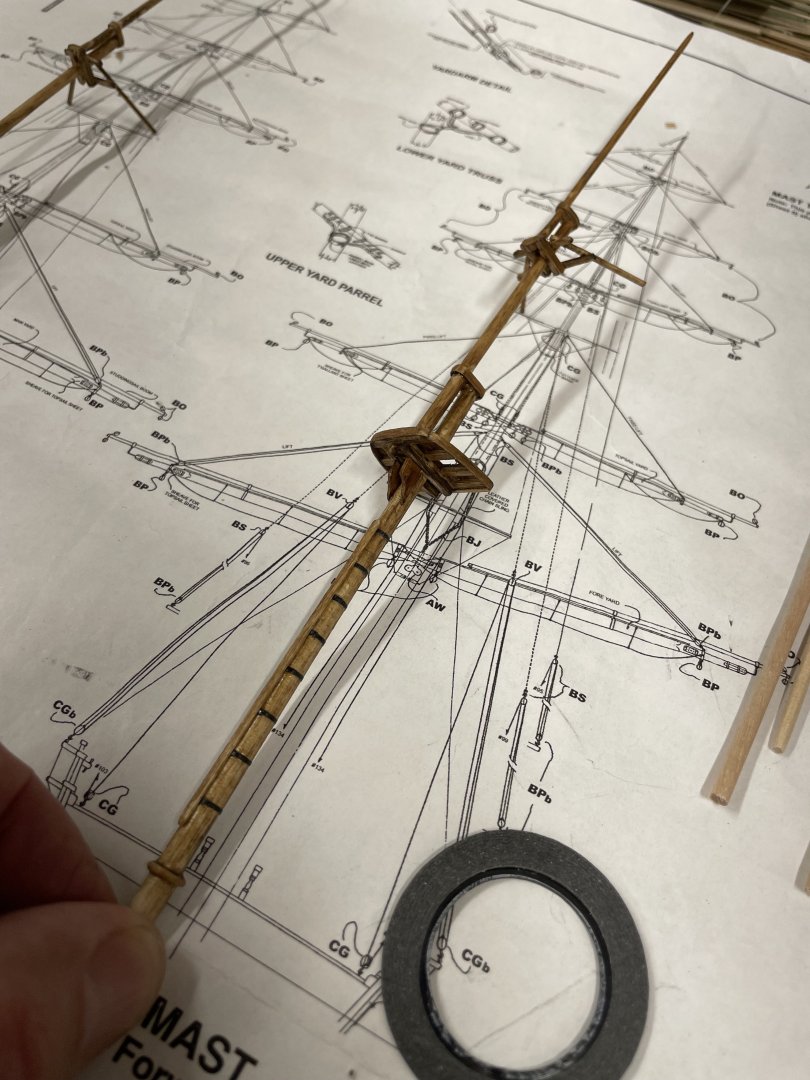

I am back… starting work on the Mast and Spar details. 🧐. Let the minute fun begin. LOL 😆 Iron bands were used to strengthen the lower masts. I used 1/32” vinyl tape to represent those bands. I will be back… Cheers 🍻

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

Love the detail and weathering technics. Awesome work, Keith. Holds up to magnification and inspection. 🧐 John

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Best to stay on that schedule if it works for you and Maggie. John 👍

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Old habits die hard. Who needs sleep at our age anyway. LOL 😂

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Great job Keith, Paddle Wheels have got to be the worst part of building these steam ships. Not looking forward to building the Klondike’s Paddle Wheel. John

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.