DavidEN

Members-

Posts

136 -

Joined

-

Last visited

Recent Profile Visitors

-

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

dafi reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

dunnock reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

dunnock reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

DavidEN reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

DavidEN reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

DavidEN reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

DavidEN reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

TheDuckDetective reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

TheDuckDetective reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

ccoyle reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

ccoyle reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

brunnels reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

brunnels reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

Cathead reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

Cathead reacted to a post in a topic:

HMS Diana by DavidEN - Caldercraft - 1:64

-

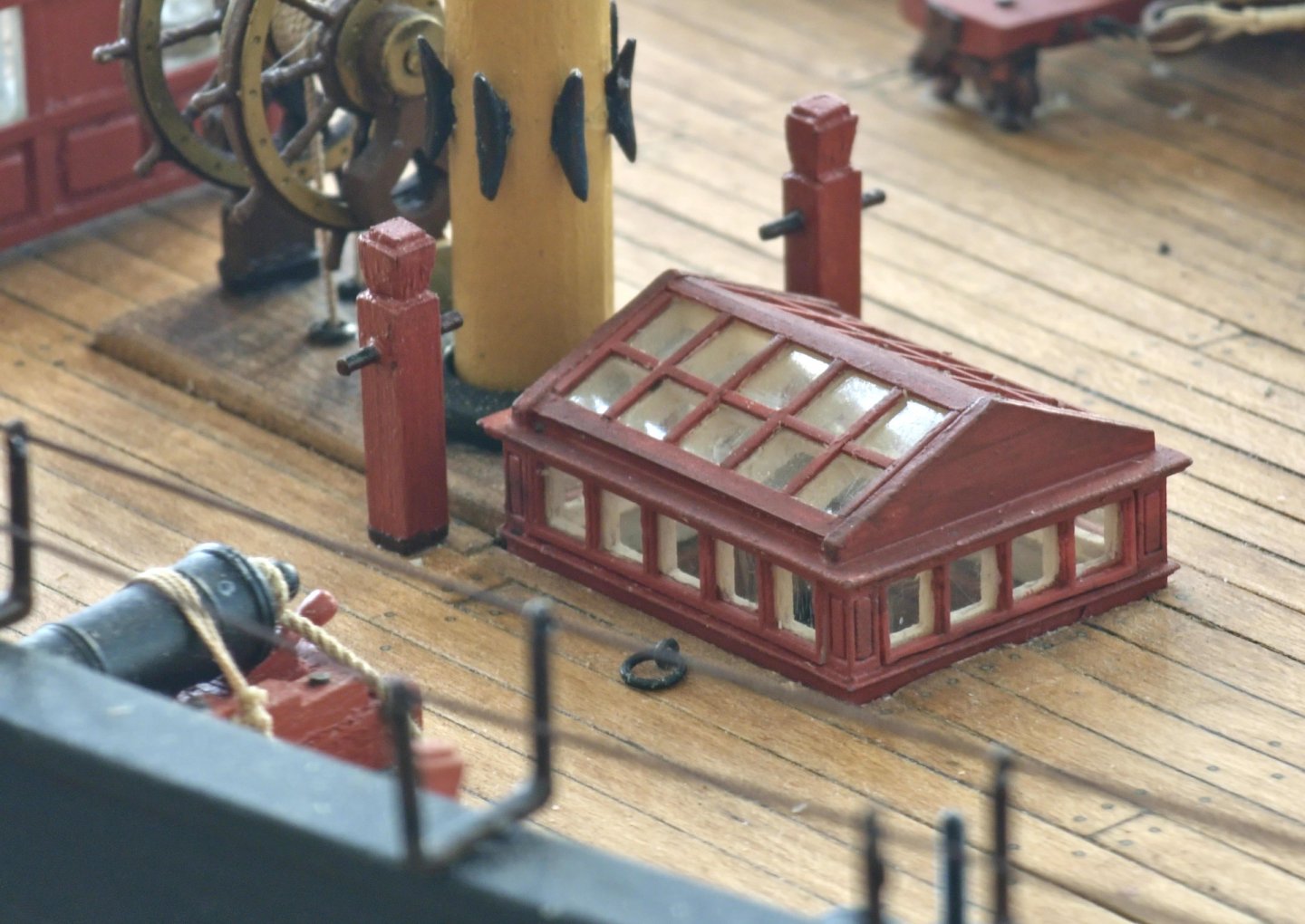

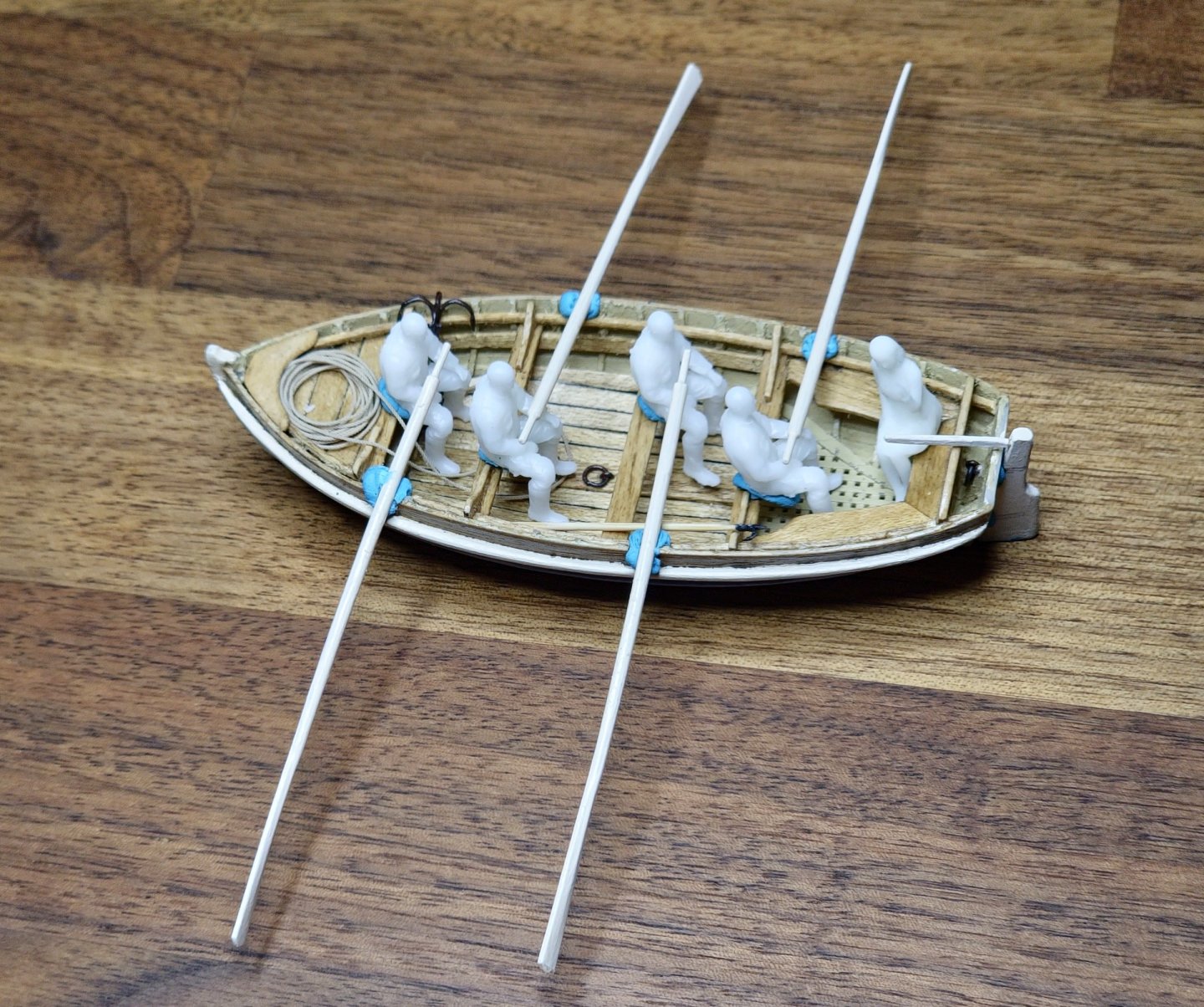

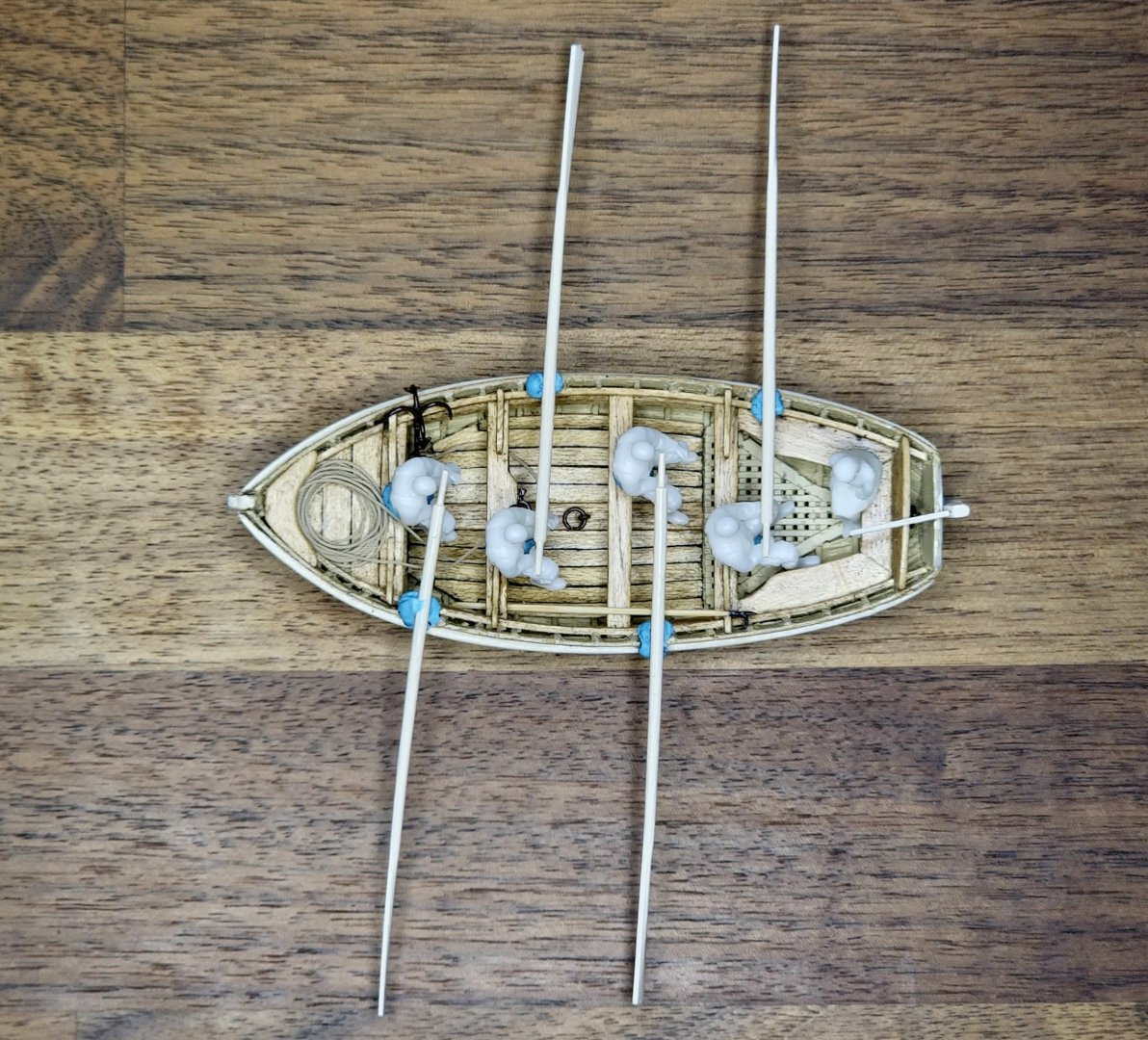

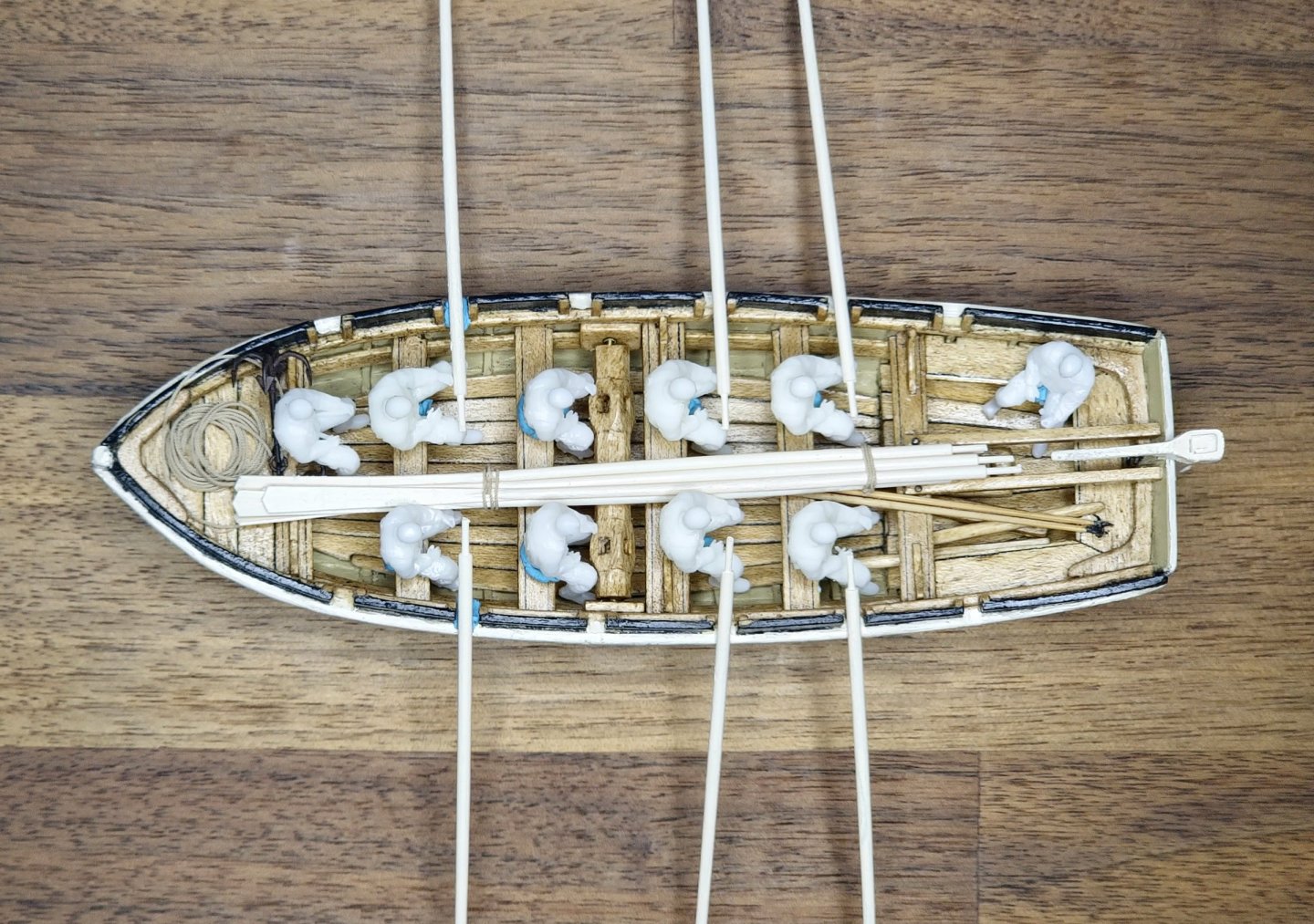

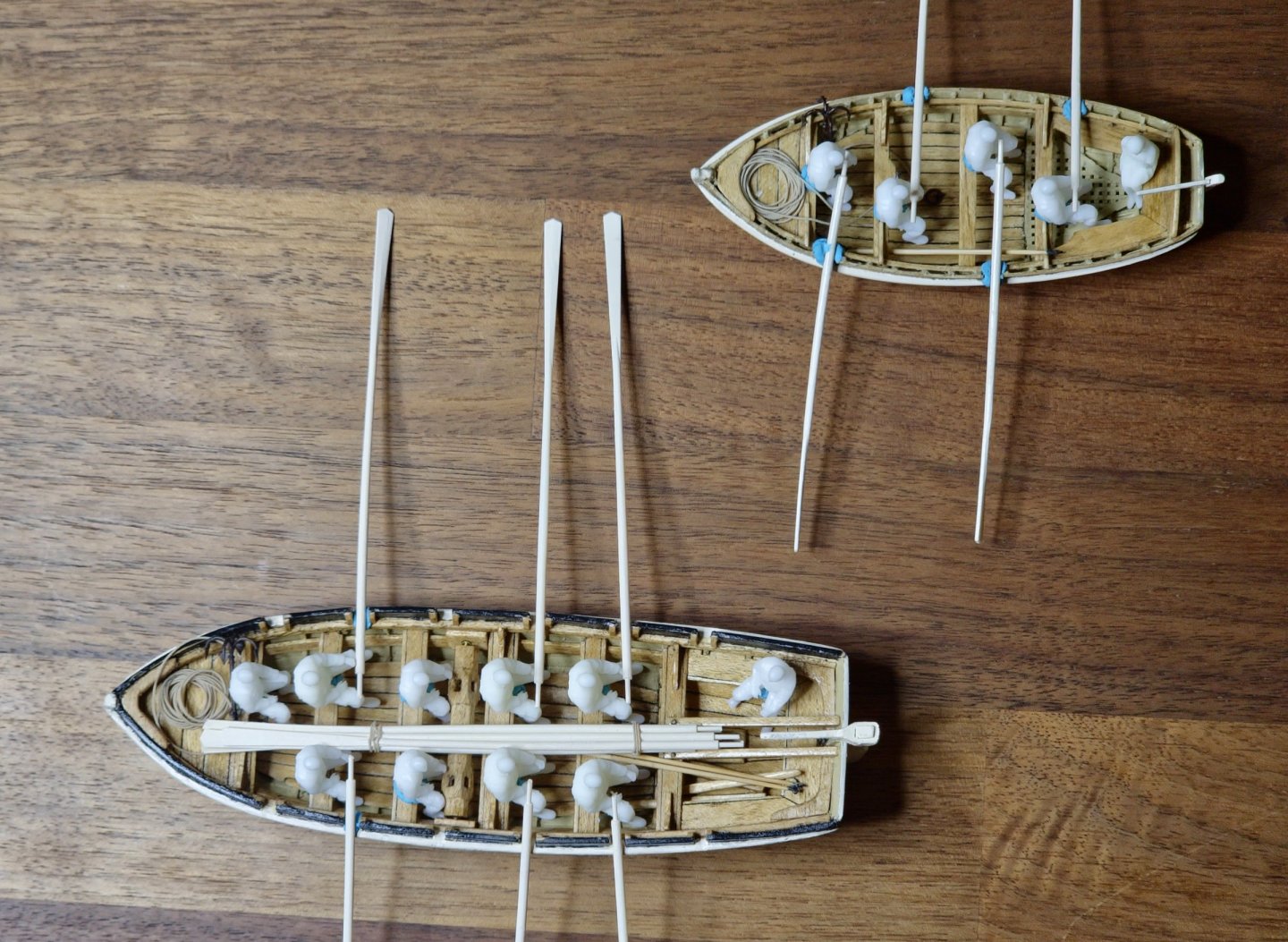

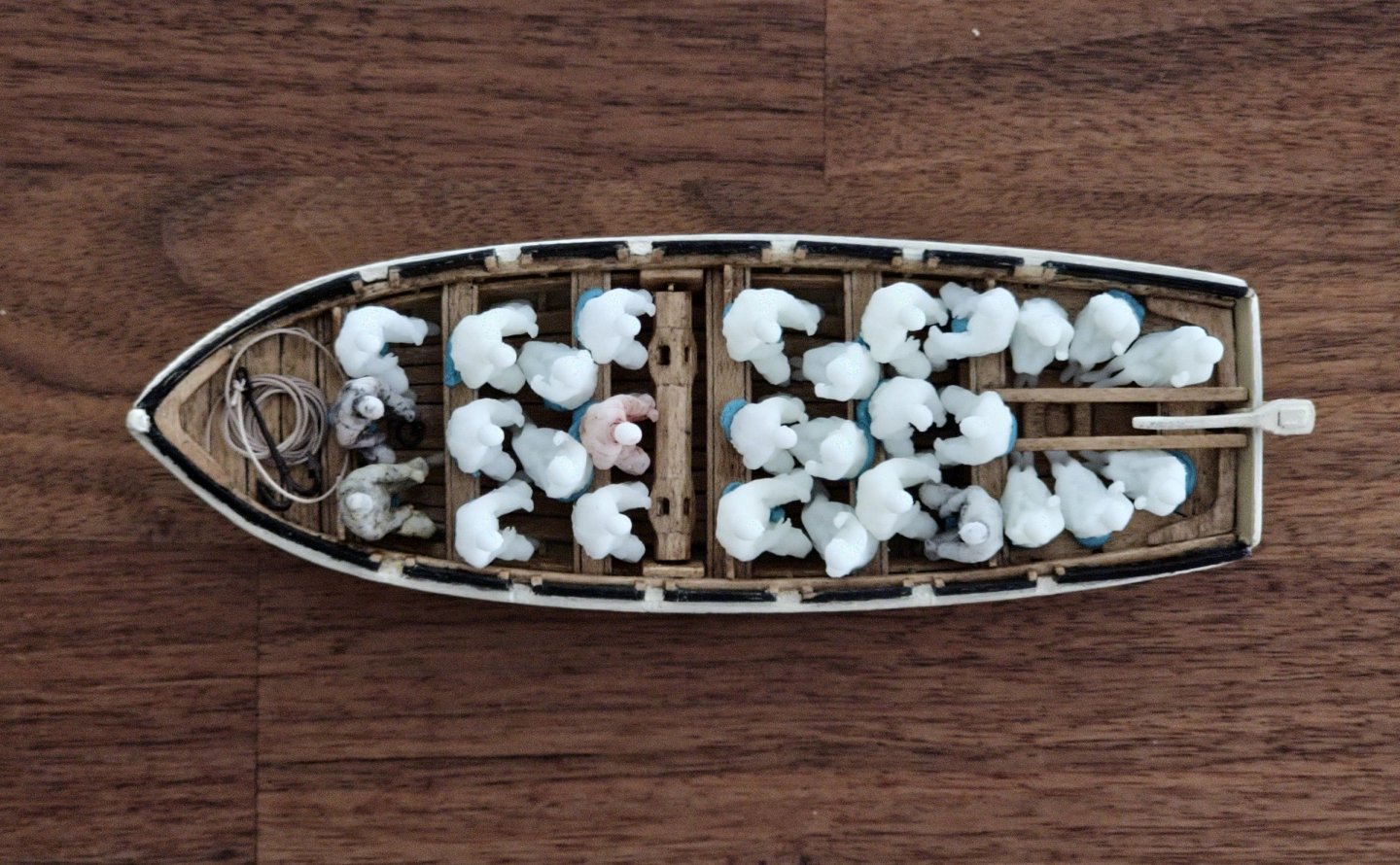

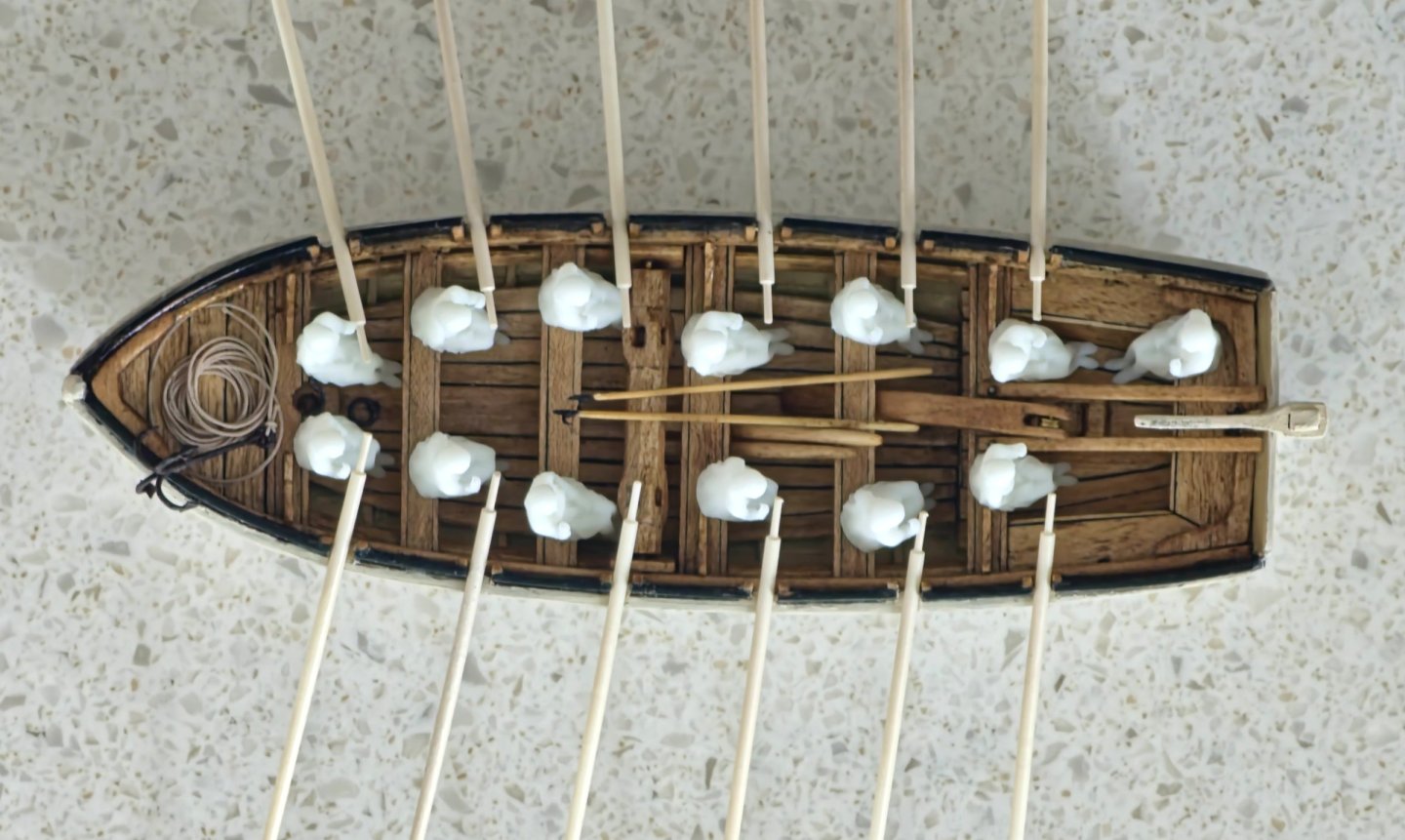

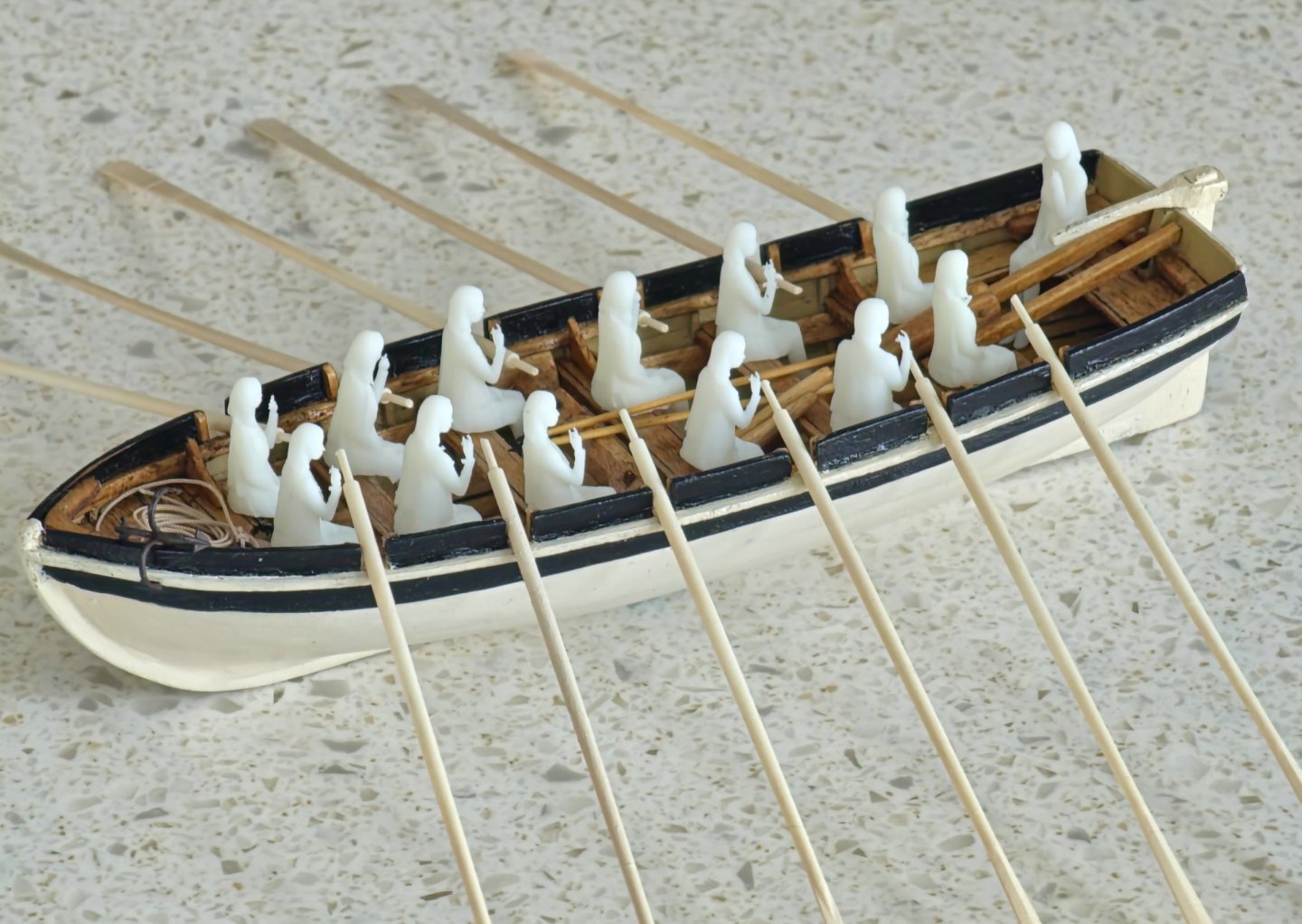

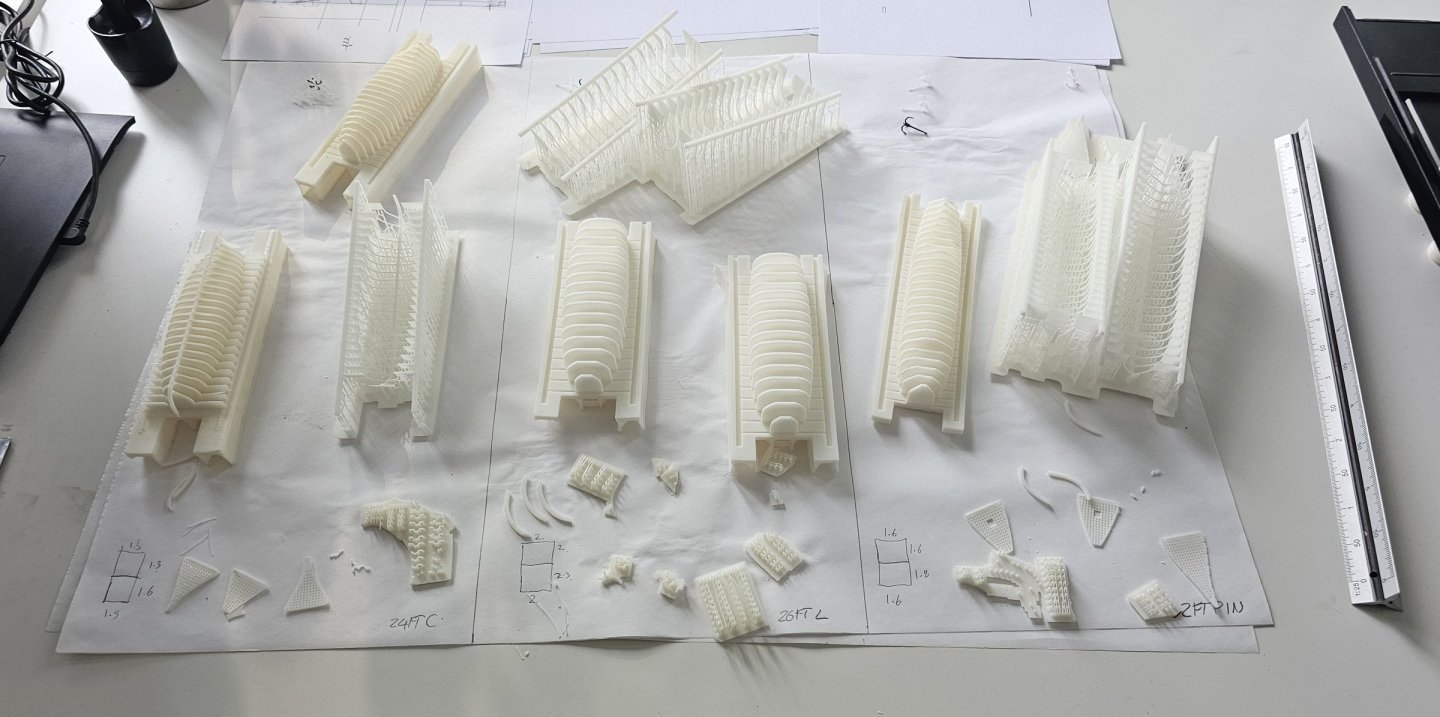

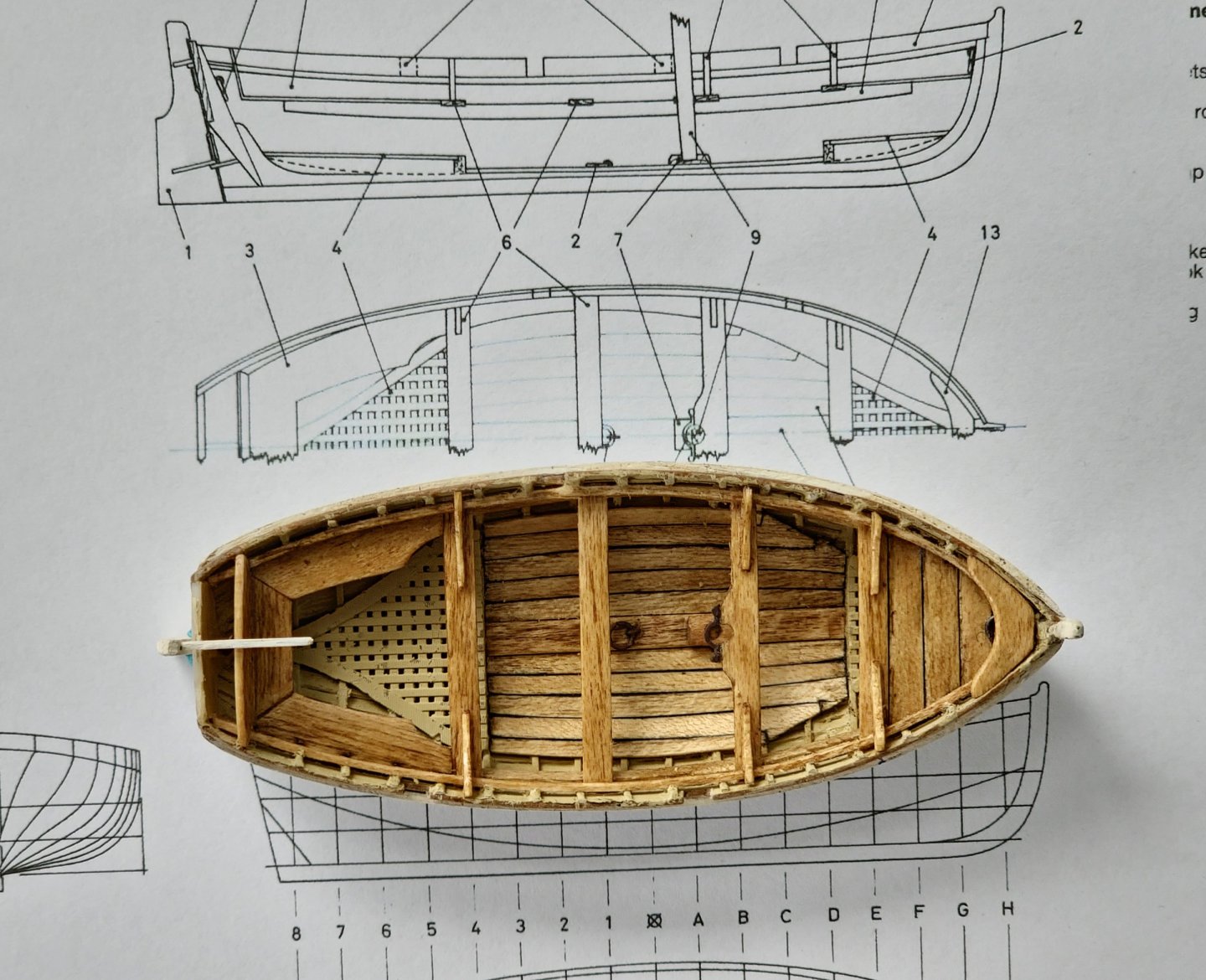

Gosh! It has been a while since my last post. All work ground to a halt while I did other things and the ship just sat there gathering dust. Once you stop pedalling on a hill it is hard to overcome inertia to get going again. It was such a long time that I even forgot my password to this site and could no longer log on. I decided that I need to pull myself together and make a push for the finish line. I thought that I should start with some gentle tasks to get me back into the swing of things so I took the opportunity to swap out the companion with the new 3D printed one I made a while back. I was not altogether convinced by it but I thought that I would see how it looked in place. The old one was well glued and I had to resort to the heavy pliers to get it out albeit in many pieces. I shoved the new one in to the accompaniment of ominous cracking sounds emanating from the deck planking. Seeing that the old one is now kindling I will have to live with the new one. I managed to secure some more manly 3D models of seated figures to test out the small boat dimensions. These are not period figures. I think they are some sort of oil rig workers. With their greater bulk and manspreading they really fill up the boat a lot more than the fashionable ladies. I gave them a quick measure and found out that they are over 6ft tall. Google tells us that the average height for an 18th century seaman was around 5'6" so I scaled down a batch and now the boats look less like a clown car. 18 ft Cutter (Jolly Boat) 26 ft Launch I started up on the final two ship boats namely the 24 foot cutter and the 32 foot pinnace and am in the hull planking phase. I have not progressed very far on these but I am easing myself back into the building routine. It is amazing how much I have forgotten in the last year. Luckily this site is quite a useful tool as an aide-memoire but I am still puzzled as to how I did things the first time around. The thought of all of those tiny planks was giving me the fear so I thought that I would procrastinate some more. Coincidentally I had just been reading the narrative of the wreck of the Medusa and was astonished to see that they managed to fit 42 persons in a 14 oar boat which is presumably a 30ft cutter or launch. They also had 15 persons in a small boat which is possibly equivalent to a Jolly Boat, though the author does refer it to a pirogue later on in the manuscript so it may be a lot smaller and narrower than a Jolly Boat. I guess snugness is a relative term. I tried 15 folk in the 18ft Jolly Boat and they just about fit and I managed to get 29 people in the 26ft Launch. If I were to remove the windlass and increase the length of the boat to accommodate an extra thwart I imagine you could just about get 42 people in.

-

DavidEN reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

DavidEN reacted to a post in a topic:

HMS Diana 1794 by DaveBaxt - Caldercraft - 1:64

-

DavidEN reacted to a post in a topic:

Swan class 3D model in progress

DavidEN reacted to a post in a topic:

Swan class 3D model in progress

-

DavidEN reacted to a post in a topic:

Armed Virginia Sloop by CiscoH - Model Shipways - 1:48

DavidEN reacted to a post in a topic:

Armed Virginia Sloop by CiscoH - Model Shipways - 1:48

-

DavidEN reacted to a post in a topic:

HM Cutter Trial 1790 by AJohnson - FINISHED - Vanguard Models - 1:64th

DavidEN reacted to a post in a topic:

HM Cutter Trial 1790 by AJohnson - FINISHED - Vanguard Models - 1:64th

-

DavidEN reacted to a post in a topic:

HMS Diana by Sizzolo - Caldercraft - 1:64

DavidEN reacted to a post in a topic:

HMS Diana by Sizzolo - Caldercraft - 1:64

-

DavidEN reacted to a post in a topic:

HMS Speedy 1782 by dunnock - FINISHED - Vanguard Models - 1:64 Scale

DavidEN reacted to a post in a topic:

HMS Speedy 1782 by dunnock - FINISHED - Vanguard Models - 1:64 Scale

-

DavidEN reacted to a post in a topic:

HMS Speedy 1782 by dunnock - FINISHED - Vanguard Models - 1:64 Scale

DavidEN reacted to a post in a topic:

HMS Speedy 1782 by dunnock - FINISHED - Vanguard Models - 1:64 Scale

-

DavidEN reacted to a post in a topic:

HMS Speedy 1782 by dunnock - FINISHED - Vanguard Models - 1:64 Scale

DavidEN reacted to a post in a topic:

HMS Speedy 1782 by dunnock - FINISHED - Vanguard Models - 1:64 Scale

-

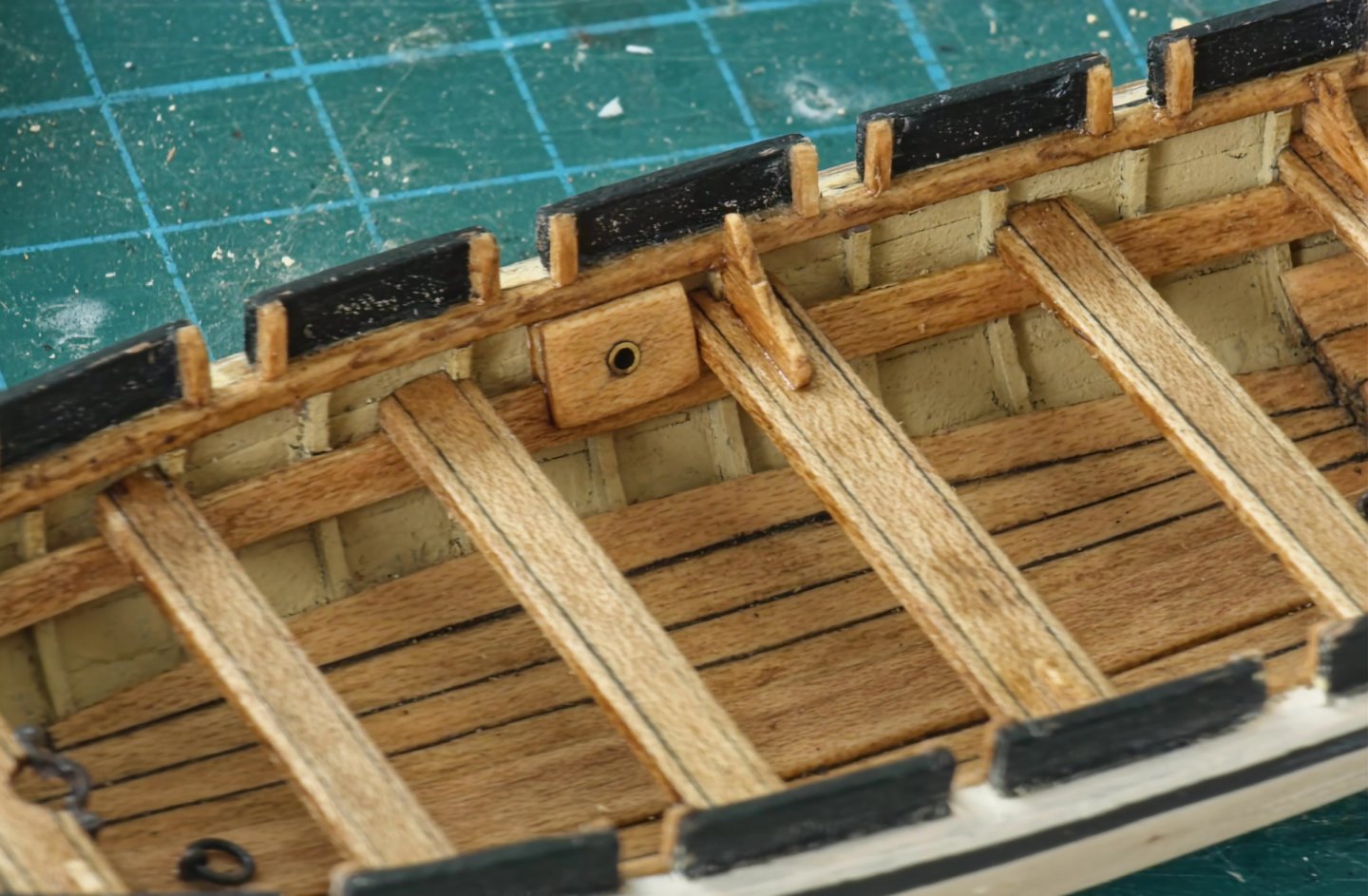

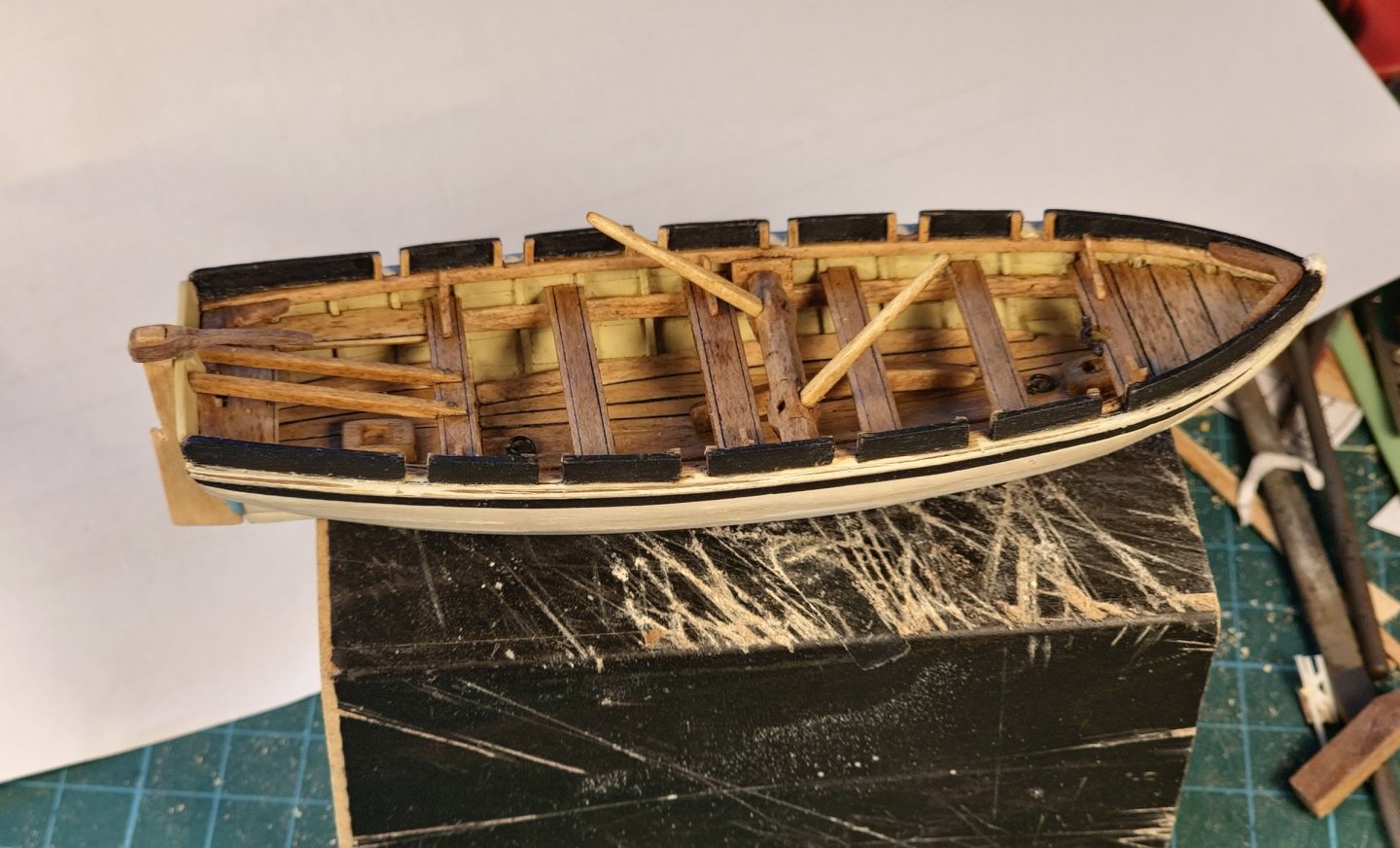

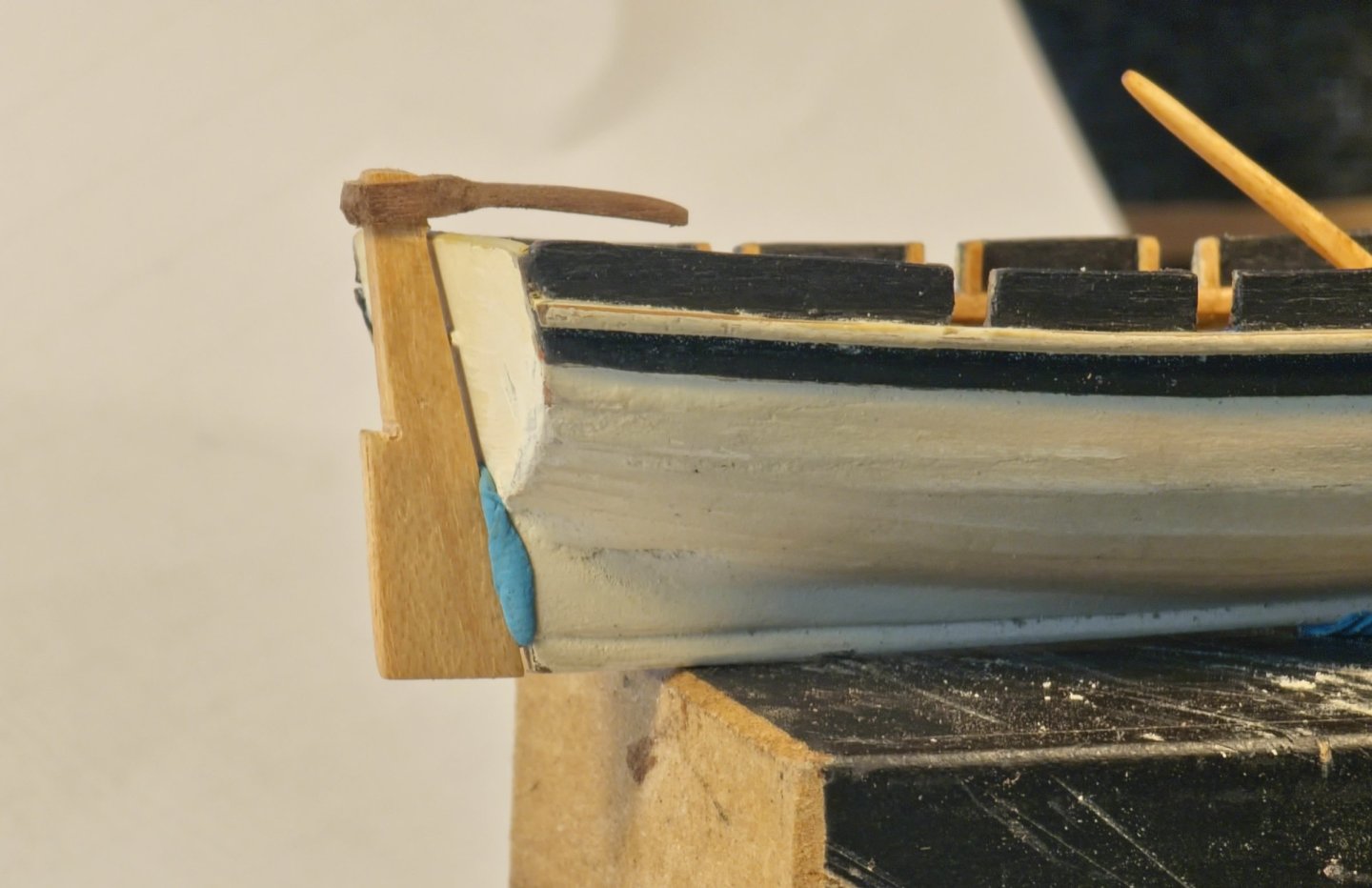

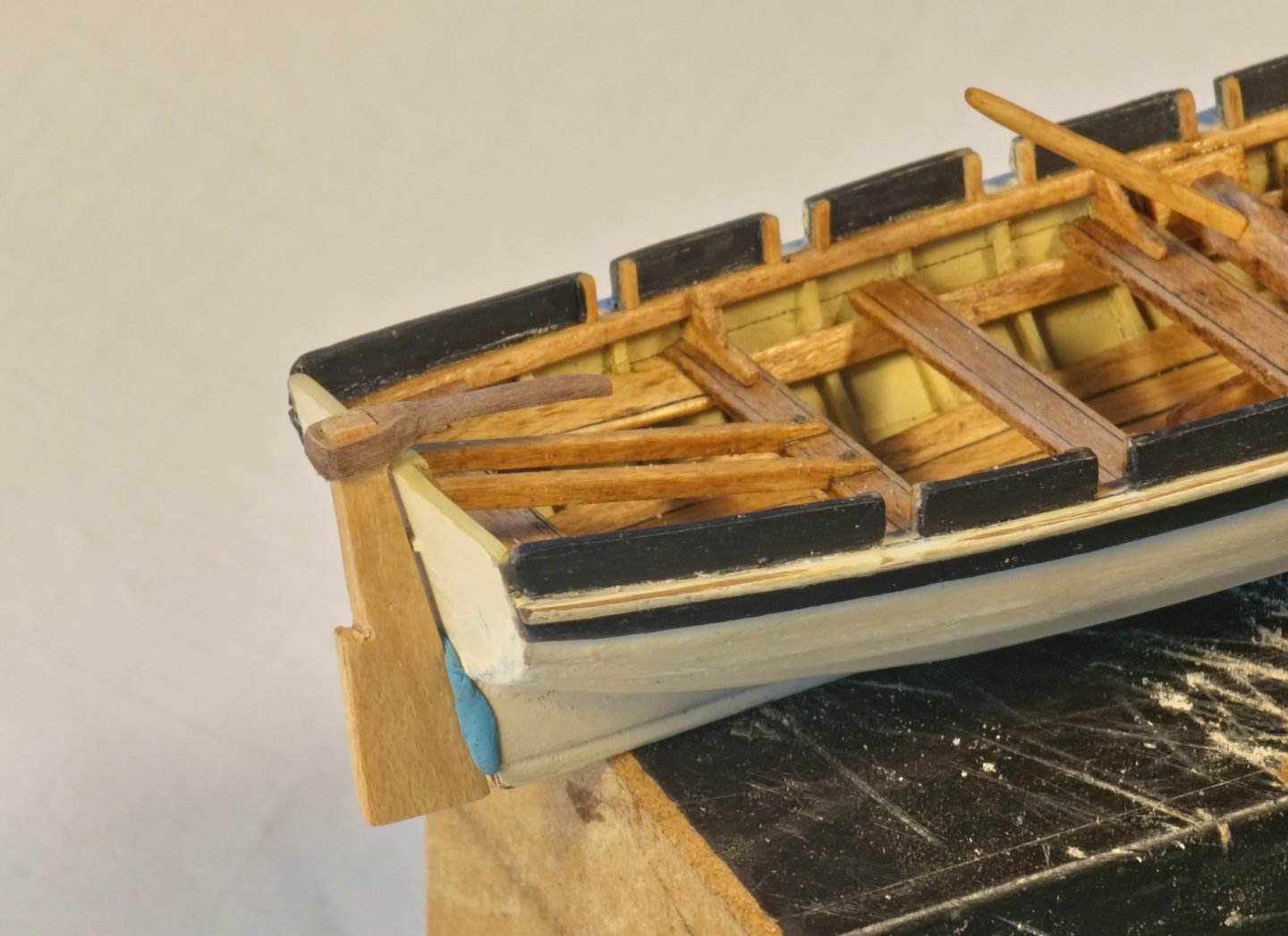

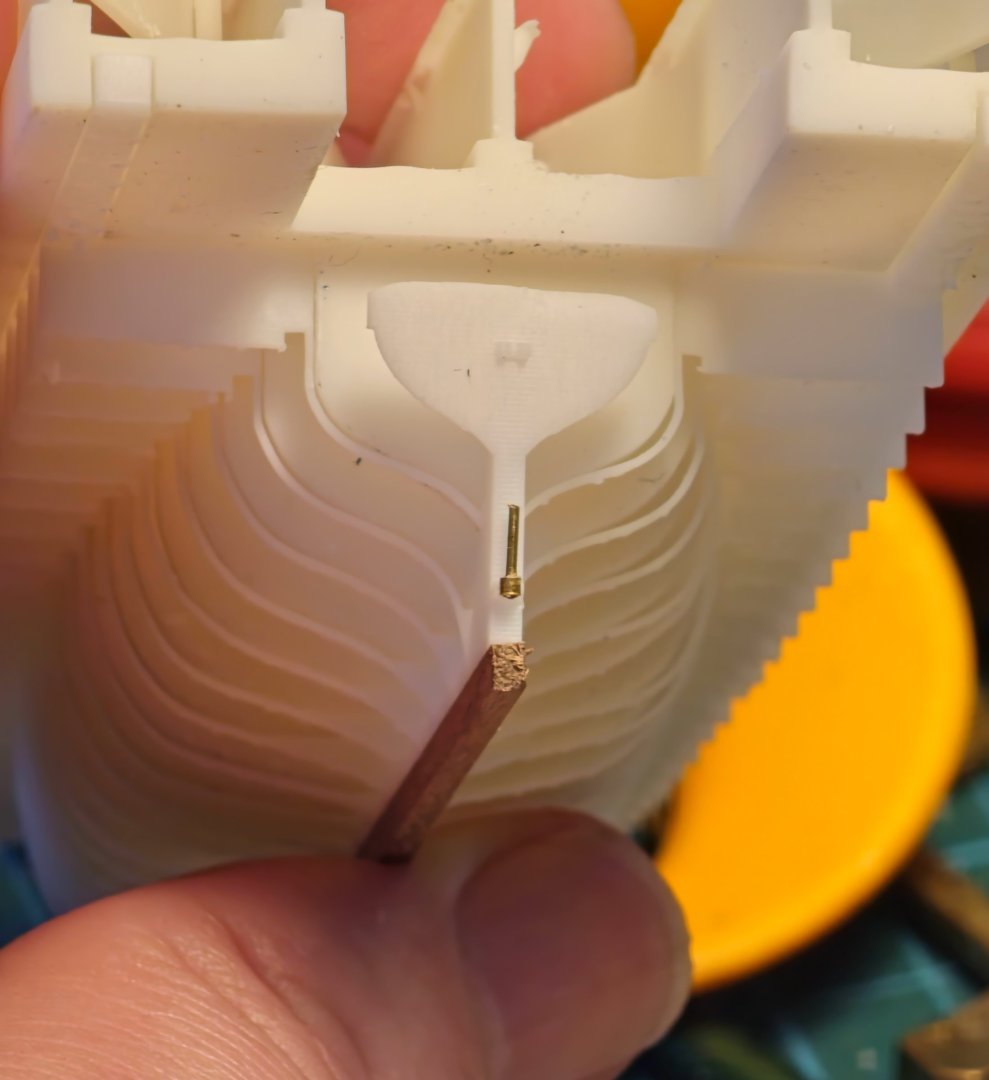

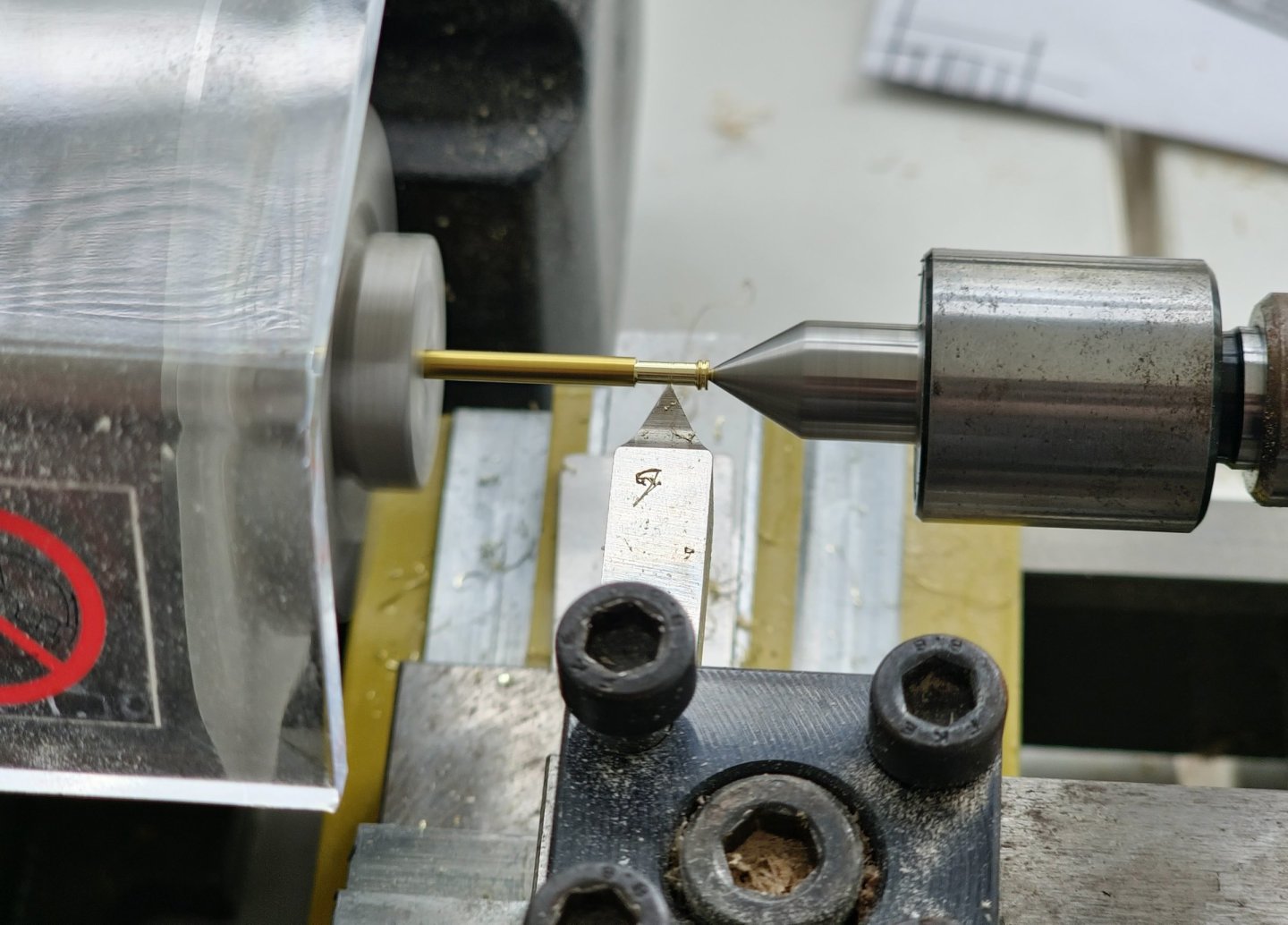

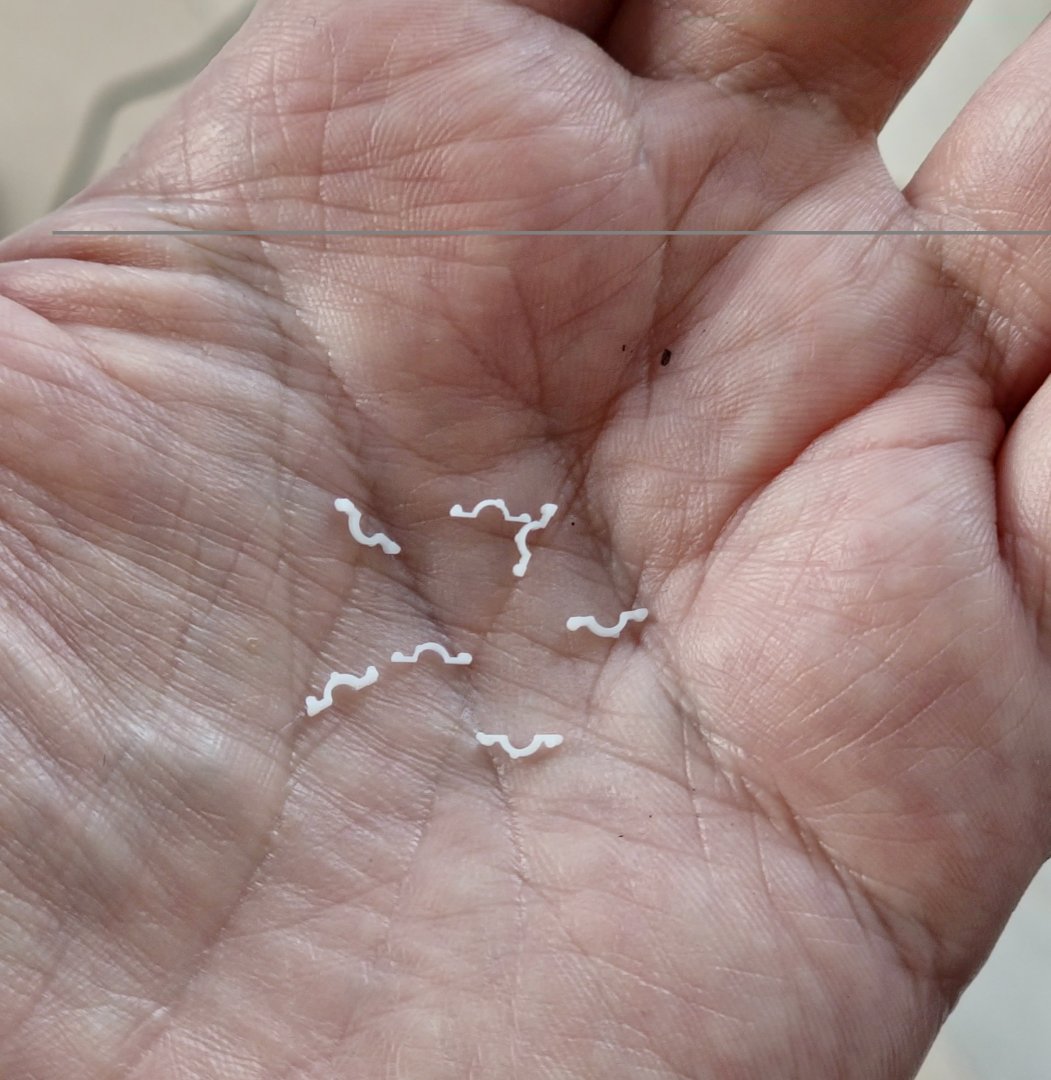

A minor update. I decided to press on and get the last bits and pieces of the launch out the way. These were the breasthook, windlass and rudder. They are fiddly little pieces that take a lot more time than their size would suggest. I did not have maple of sufficient thickness for the windlass so I ended up sandwiching three thinner pieces together. This was a particularly annoying piece to make. I cut the chamfers on the milling machine but it was one of those pieces where one false move out of the countless moves meant that I would have to chuck it out and start again. This happened on more than one occasion. Fitting it into the hull was also quite challenging but I used some thin-walled brass tube for the housing and brass rod for the axle to ensure that it does indeed turn. I drilled a hole in the side mounting block and then glued the first one in place and the fitted the second one along with the windlass. I had some problems with my geometry but I am not going to worry too much about it as it is pretty much hidden by boat structure. Handles were shaped out of 1.2x1.2mm maple. It took several goes for the breasthook as no matter how I orientated it I was always left with a terminal weakness due to the grain of the wood. I persevered and eventually got one that did not snap in two which sadly was not the shapeliest one. I fashioned the rudder and then tried a new tiller arrangement. I carved this out of a block of walnut. It looks quite clunky but I was a bit fearful of thinning it down even more as it was very fragile and I felt that it was about to snap with every pass of the file. It might be a piece more suited to 3D printing. I have yet to settle on the pintle and gudgeon detail. They are too fragile and I keep knocking them off. I may have to resort to epoxy. Another piece of equipment that I added at this time was the boat hook. I had previously made one on the CAD according to the size of a historical example but this turned out to be far too small to be printed out successfully so I had to exaggerate the dimensions to get something workable. I doubled the size but this looked a tad overscaled when sat next to my trusty sailor. I wanted something more in keeping with the example shown in the famous 17th Century Rembrandt Van Rijn painting. This is over 100 years earlier than my version but I suspect that boat hook technology did not advance much as the hook on the end of a pole concept is hard to improve on. You can buy similar models today although newfangled aluminium telescopic poles are now de rigueur. I tried to print out a smaller version, which was the devil to work with, but I am happier with the result. I initially printed it out all in one piece with head and handle but then decided it would look better if I printed the head separately and made the pole out of wood. I thinned out a toothpick to around 0.8mm diameter using sandpaper on the lathe. This equates to two-inch diameter in real life which is not outrageous. I made them around 2.4m long or just a shade under 40mm. I printed out 42 of the smaller heads and managed to safely release only 9 from the support raft and lost 3 of those to over-exuberant tweezer action and another two mysteriously vanished leaving me with a paltry four that made it onto their poles. I had noticed that during some of BlueEnsigns build logs he populates his craft with a scale seated sailor figure to check the height of the thwarts and to see if everything is in place. Not wishing to over capitalise on the build, I thought that I could probably find a similar seated figure online for free and then print it out at home. I admit that I did not spend too much time searching but the only free seated figure I could find was a well-heeled Japanese lady. I figured that it would suffice for my purposes so I printed out a few to sit about in the boats and test out the equipment. Please note that this is just an exercise to check the scale of the built elements so I hope there will be no lectures about how it would be highly unlikely that an 18th century ship's boat would be crewed by posh Japanese ladies in high heels. It was a fun but quite useful exercise as it gave a good illustration of the size of the boats and the heft of the equipment that I had produced. I had initially thought that this equipment too delicate but it turns out that I am erring on the beefy side. I am not going to do anything about it as I am at the limit of what I can produce with my shaky hands. I may have to consider the jump to 1:48 scale should I ever get round to finishing this ship and starting another.

-

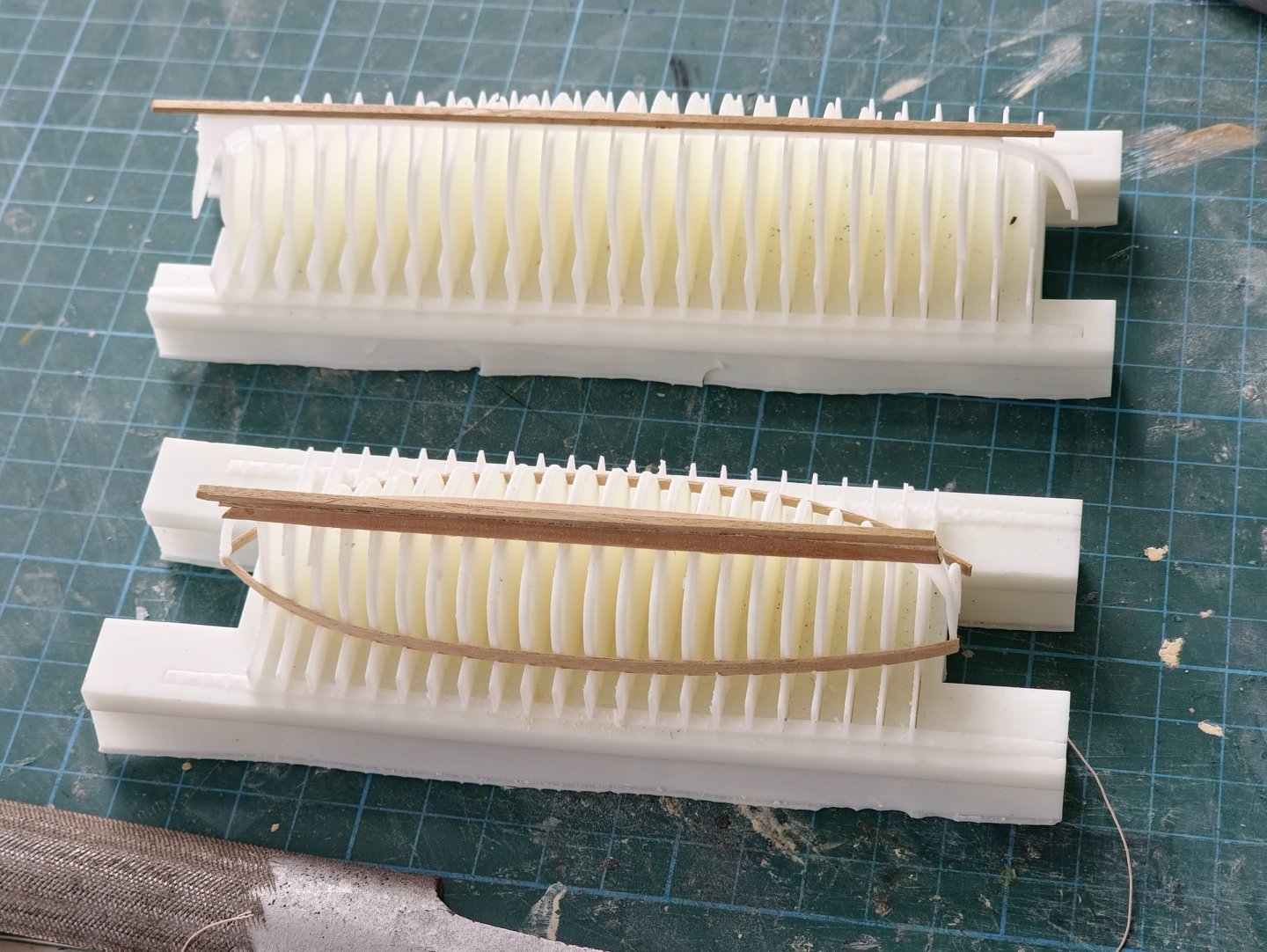

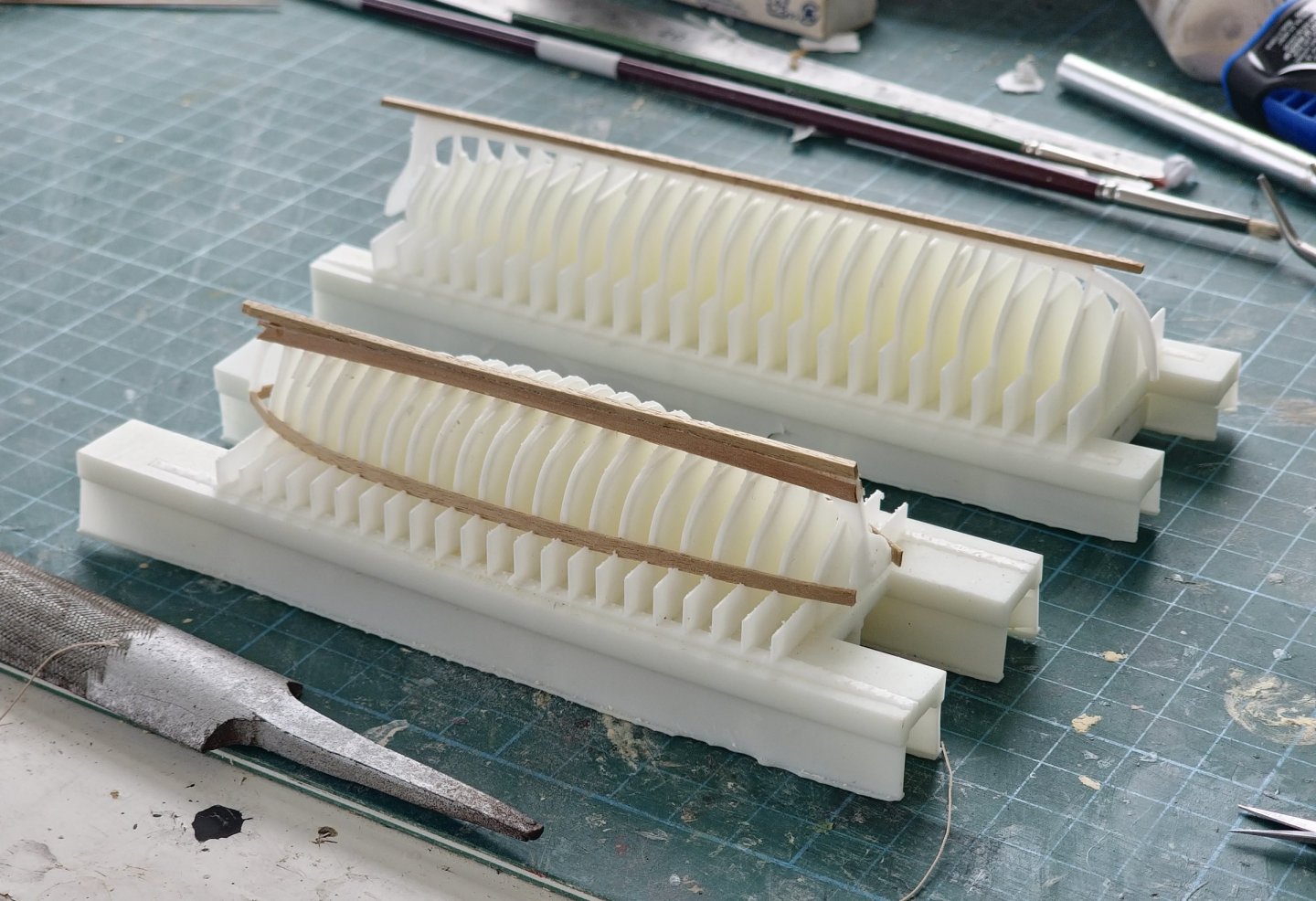

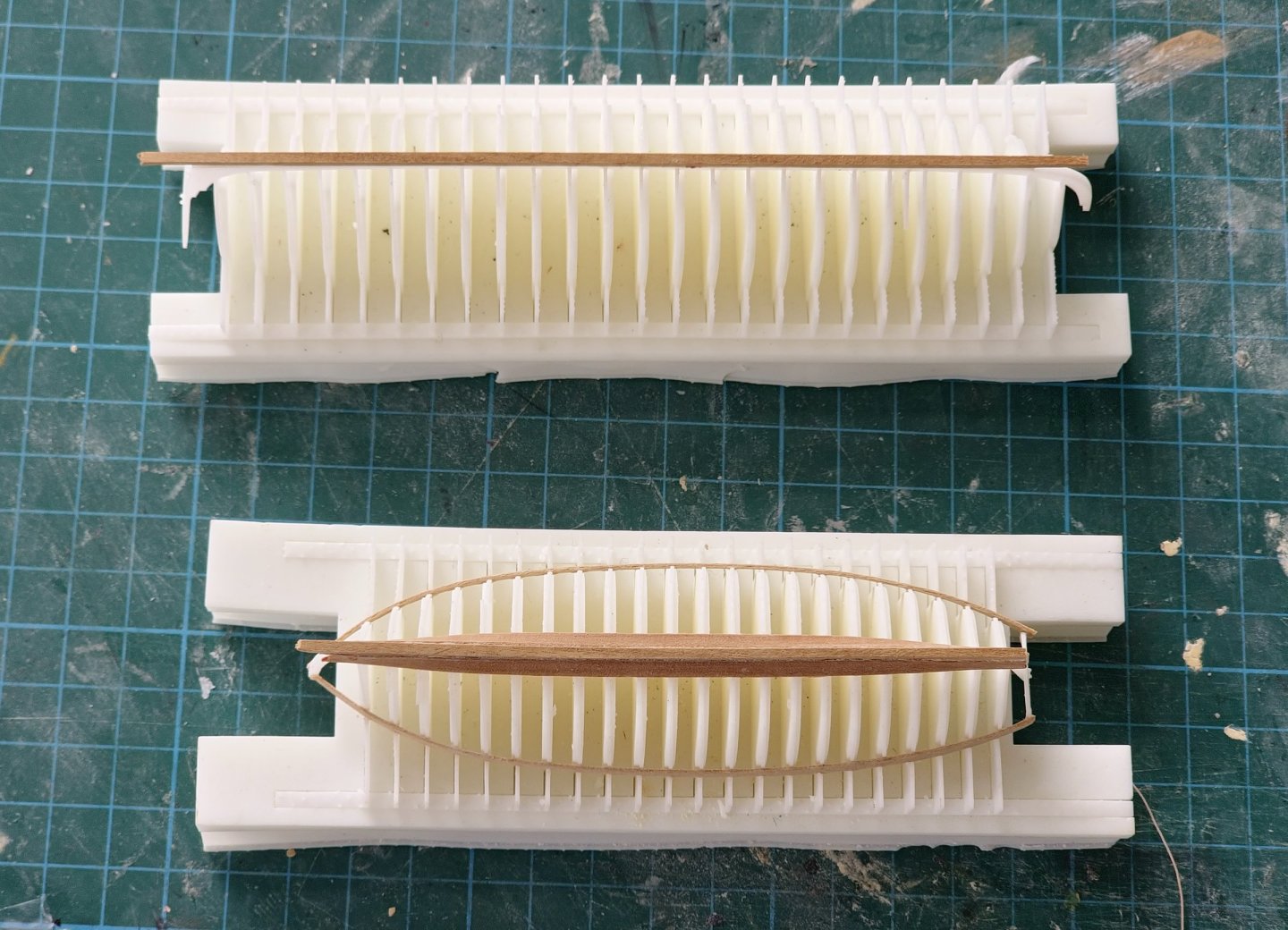

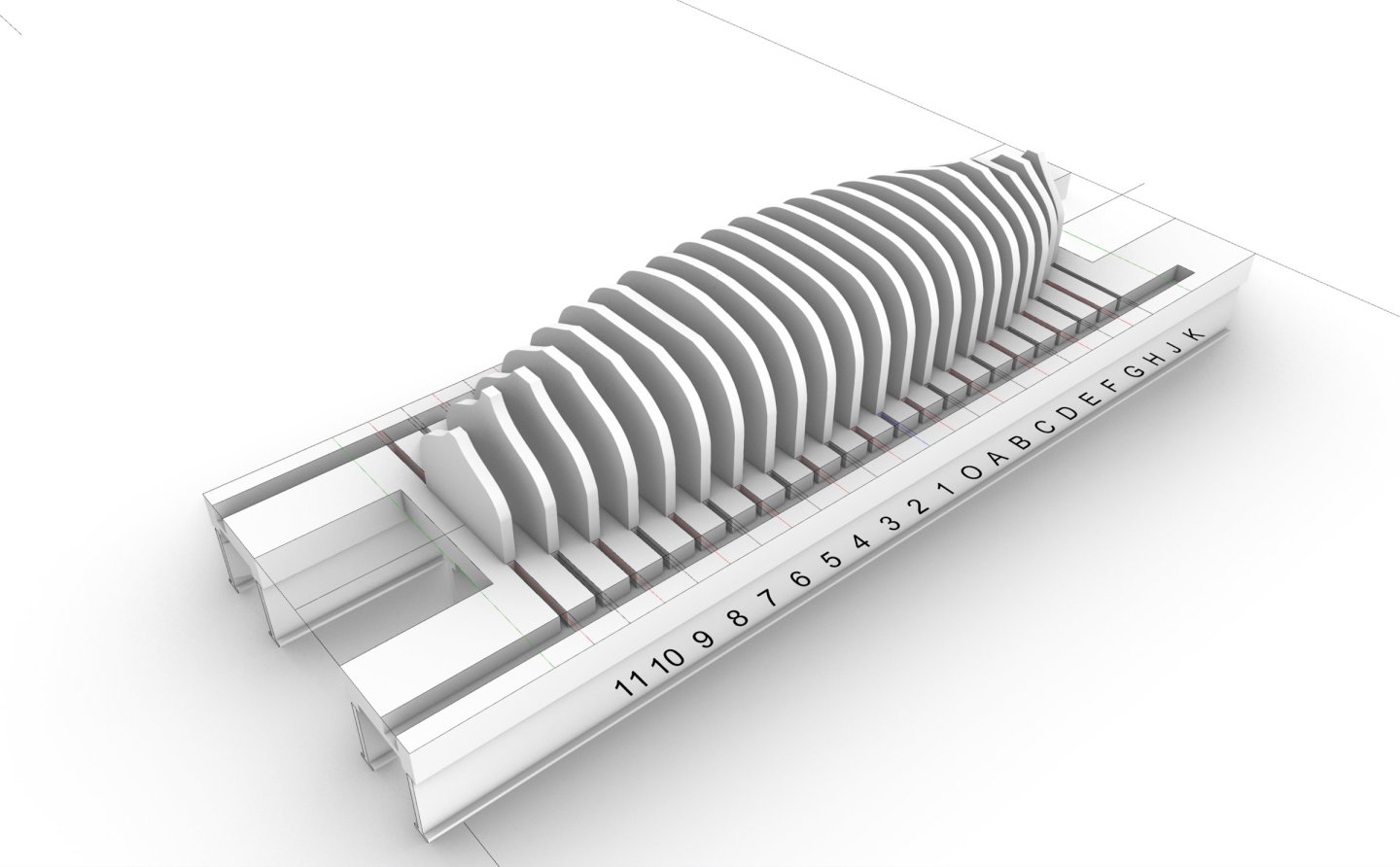

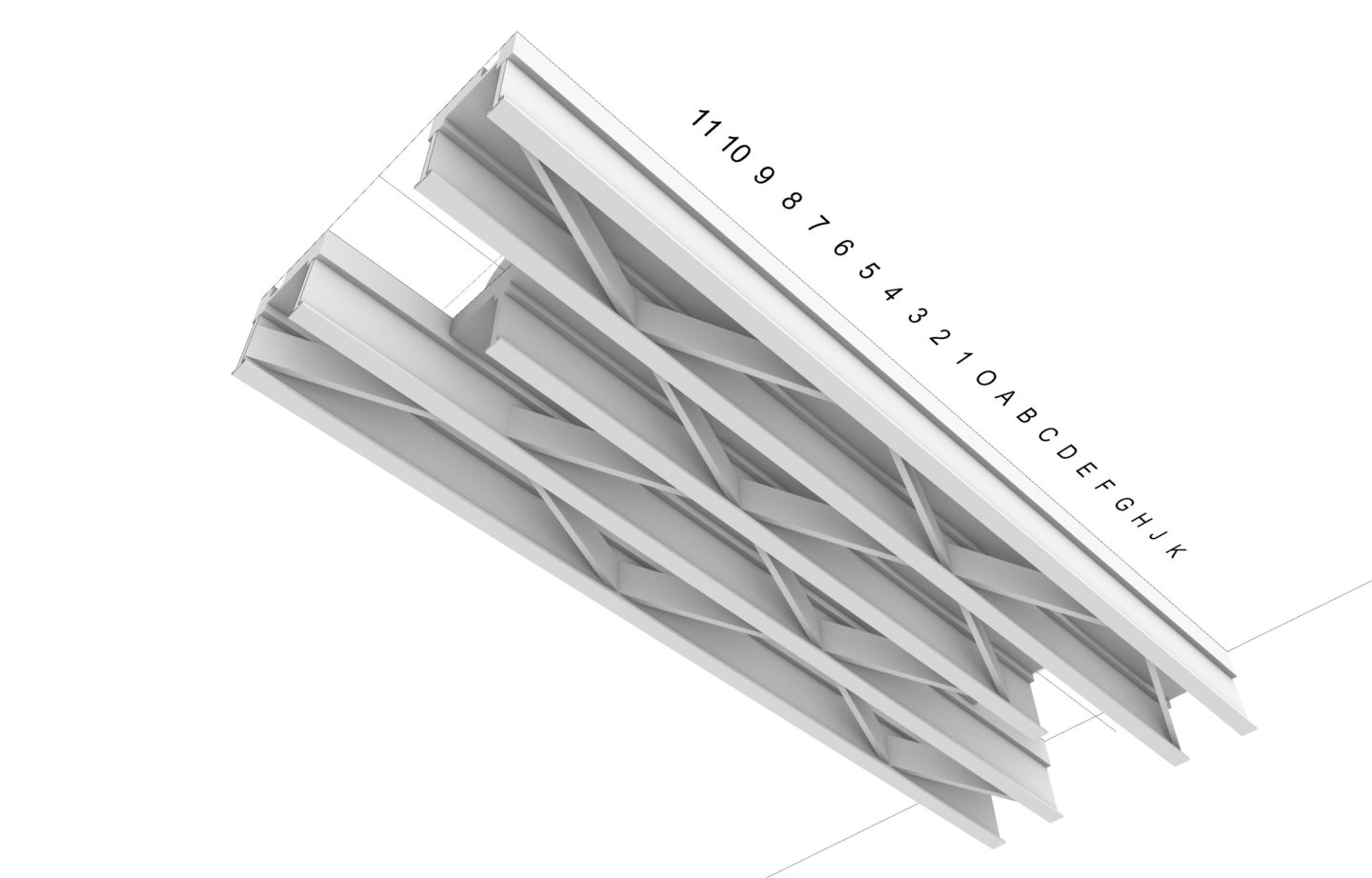

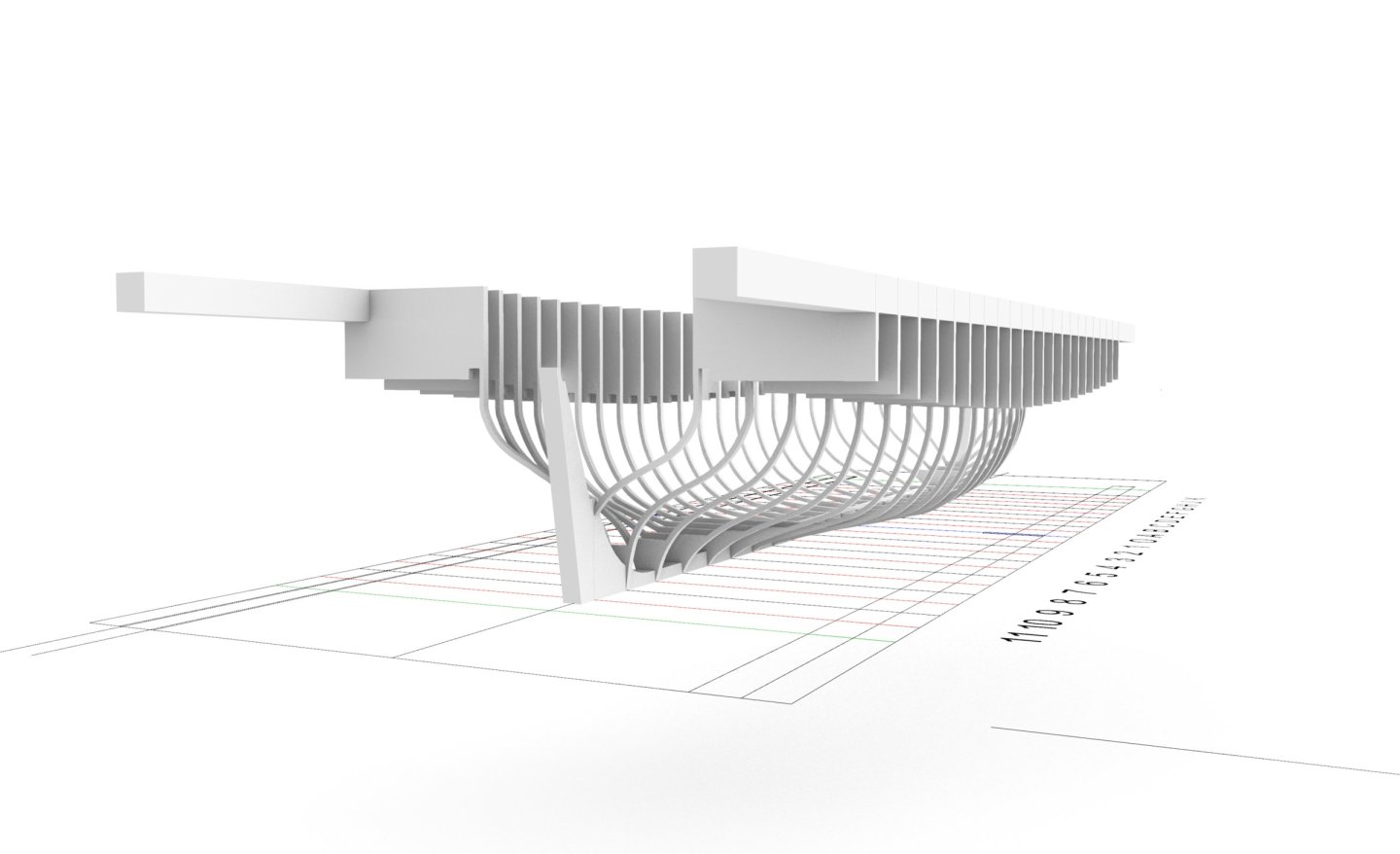

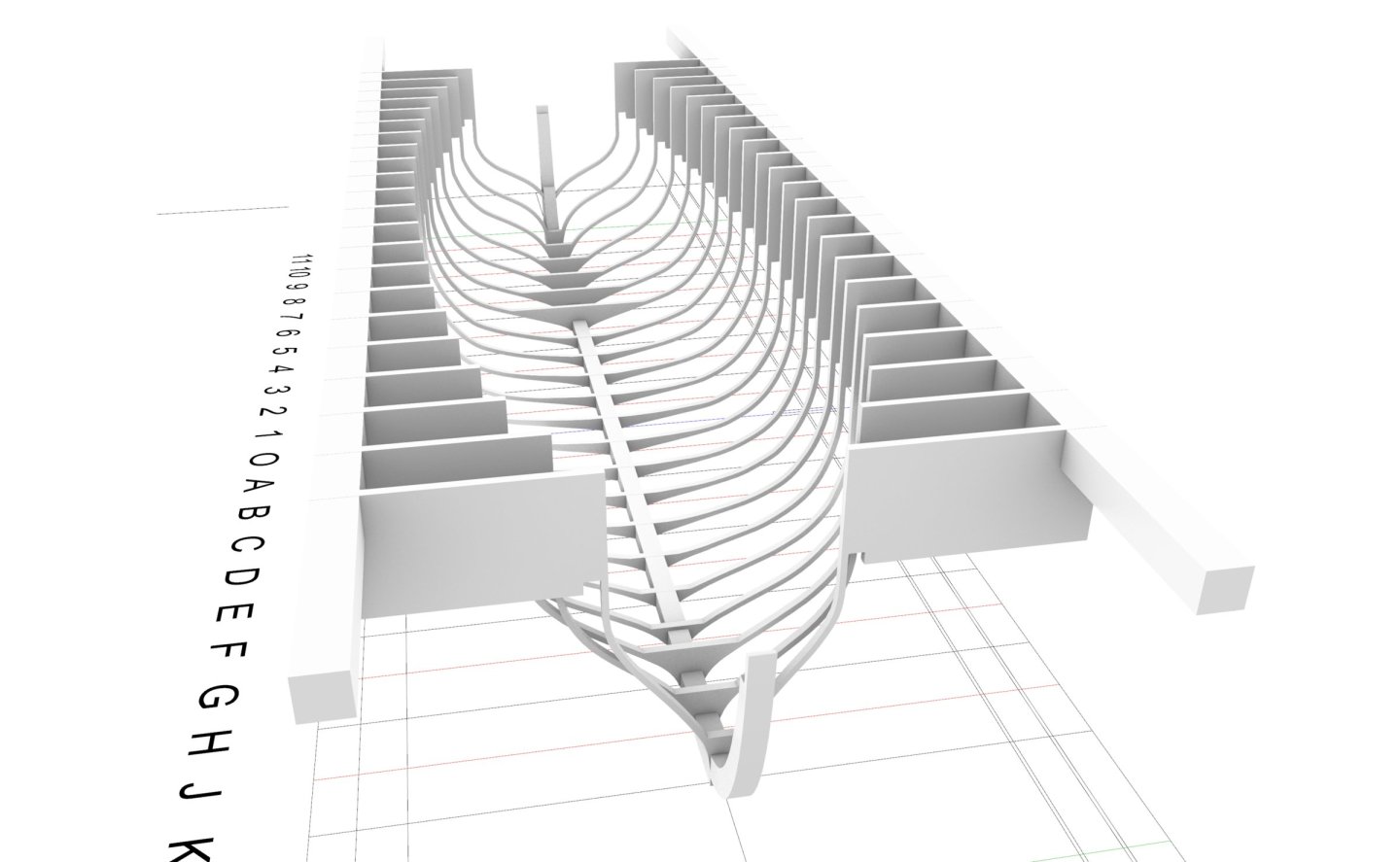

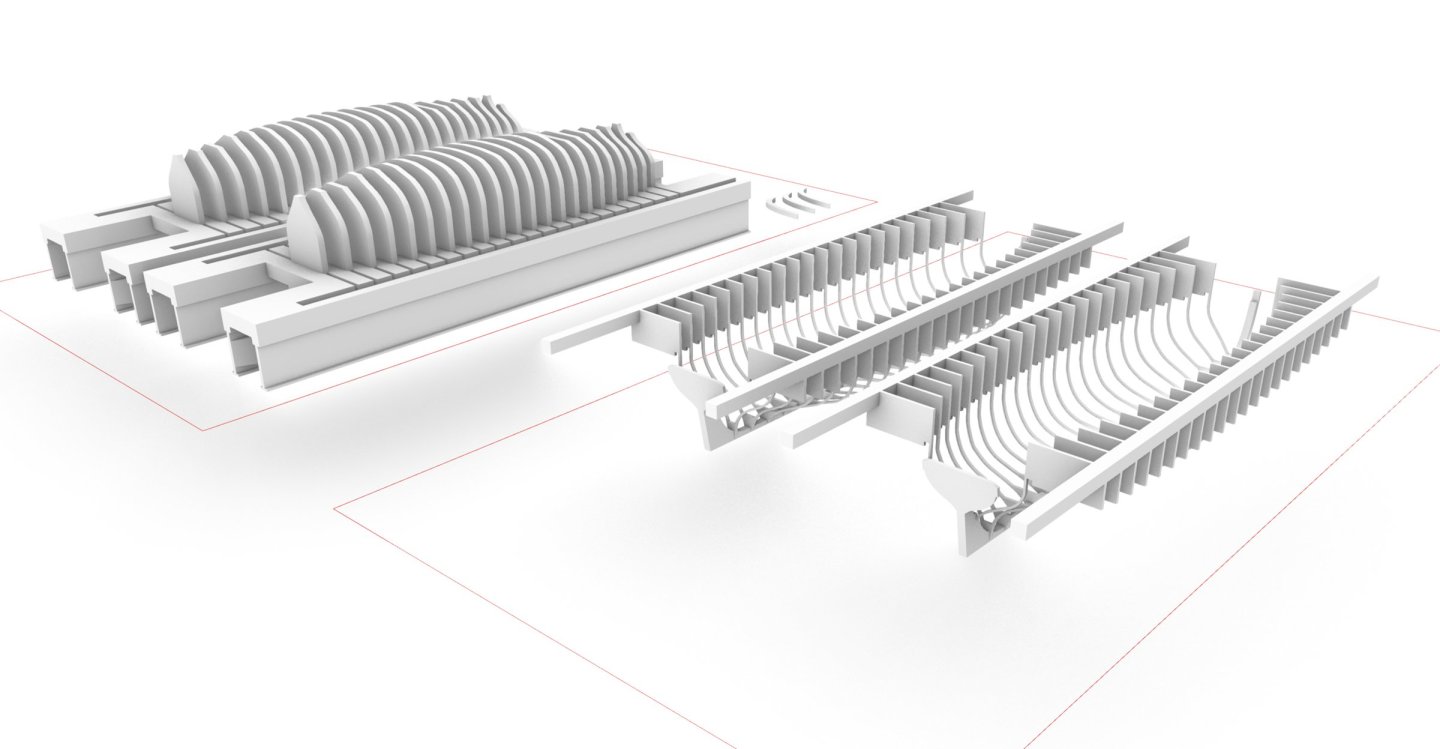

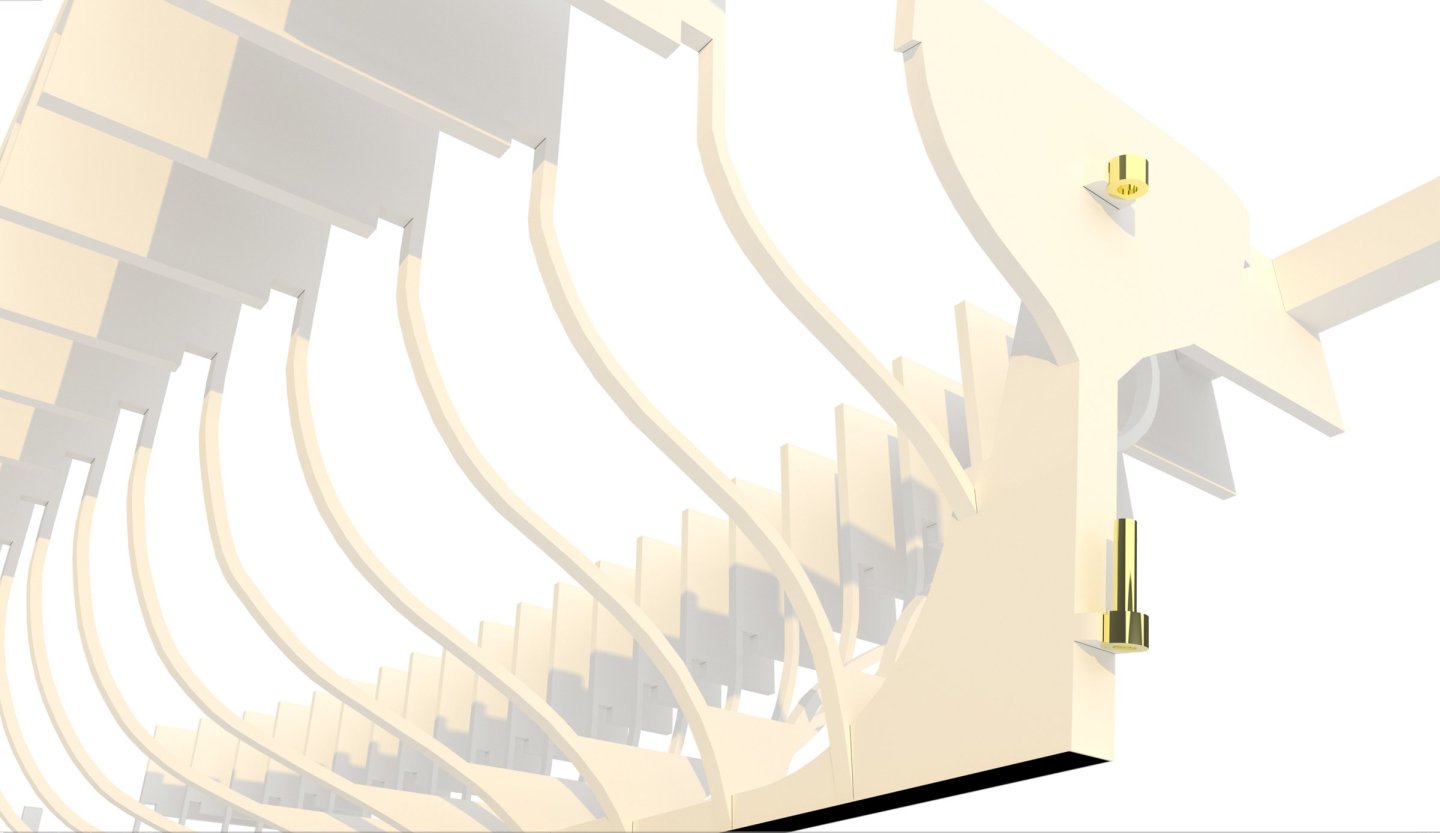

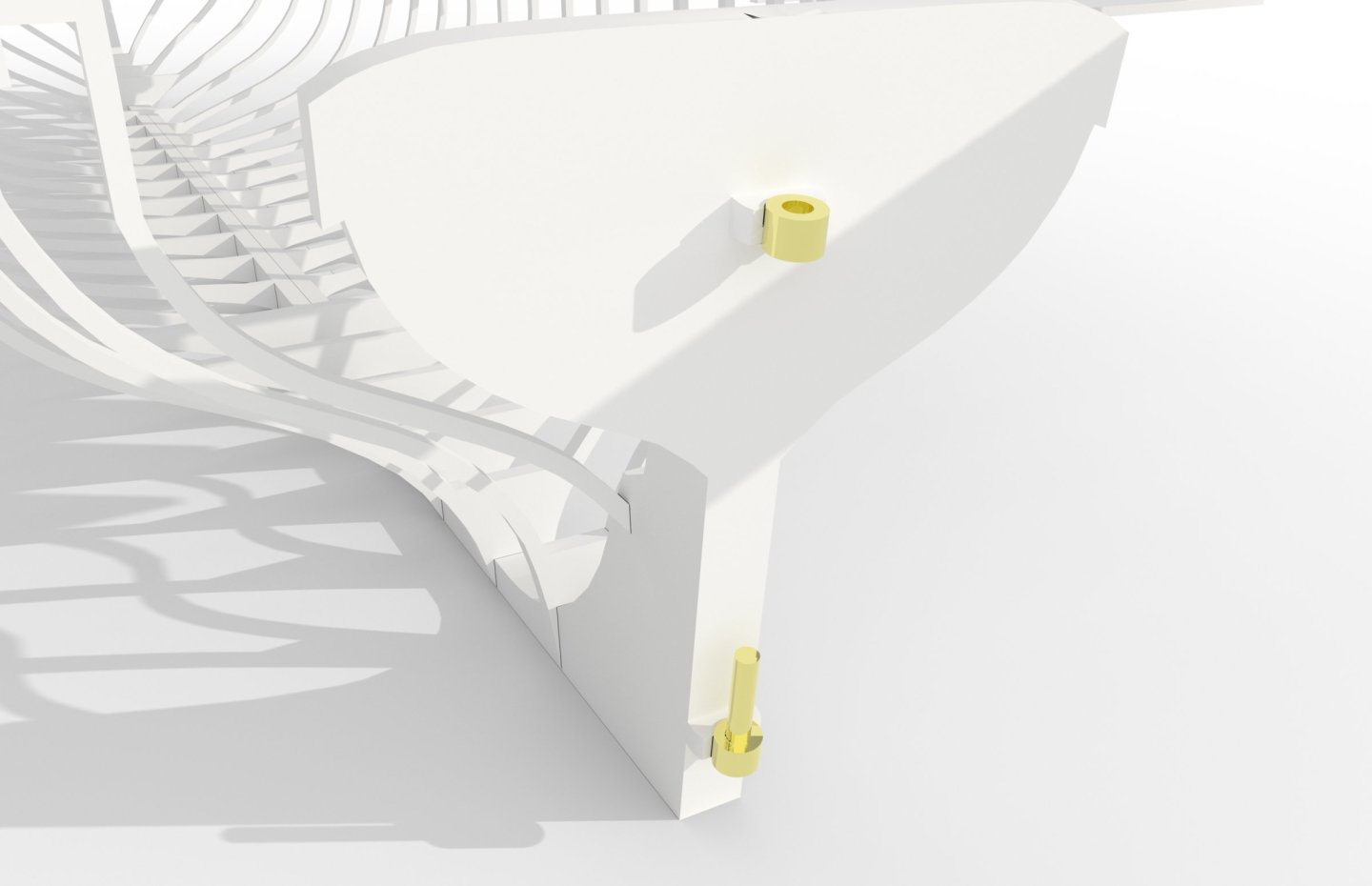

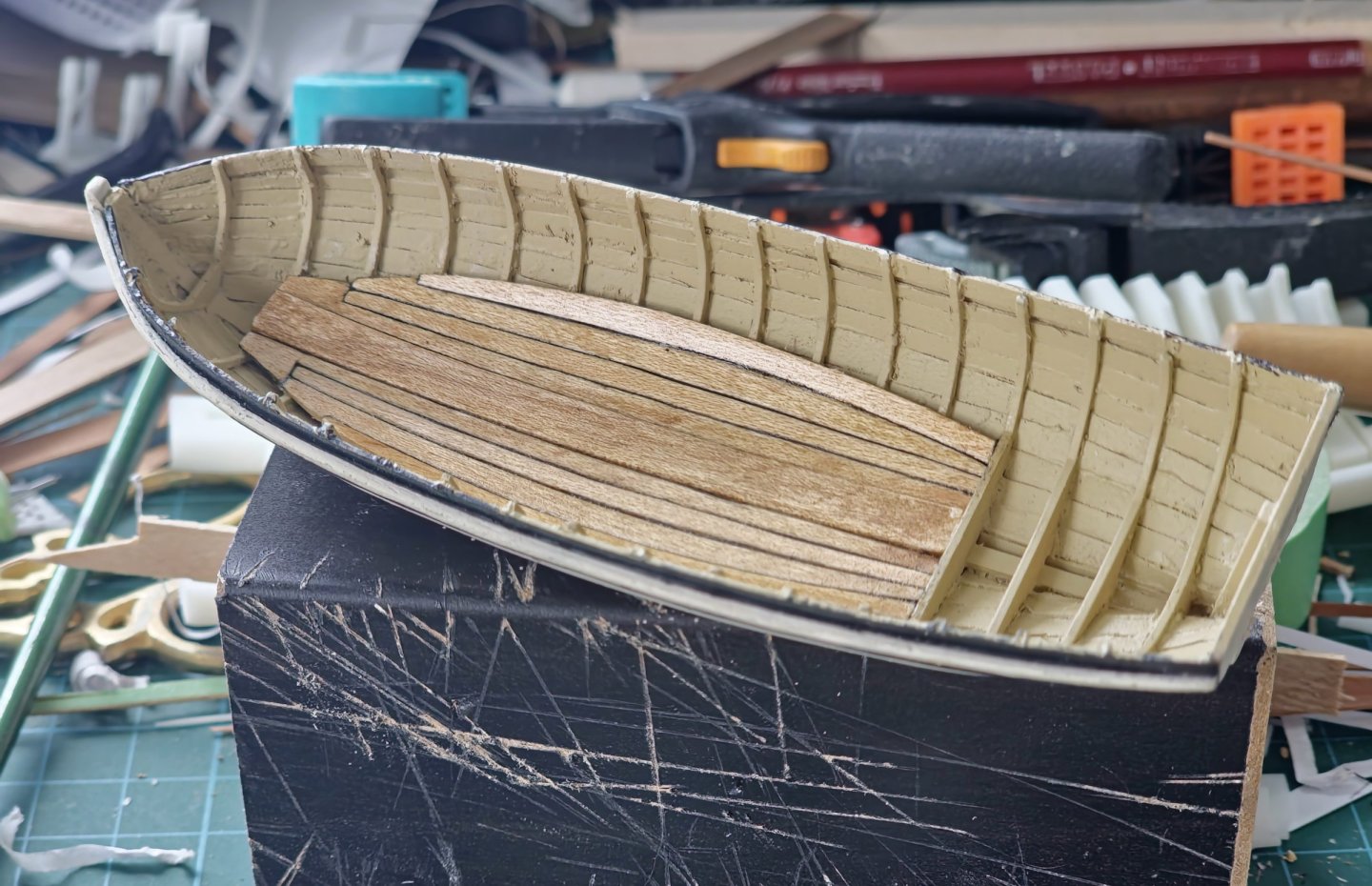

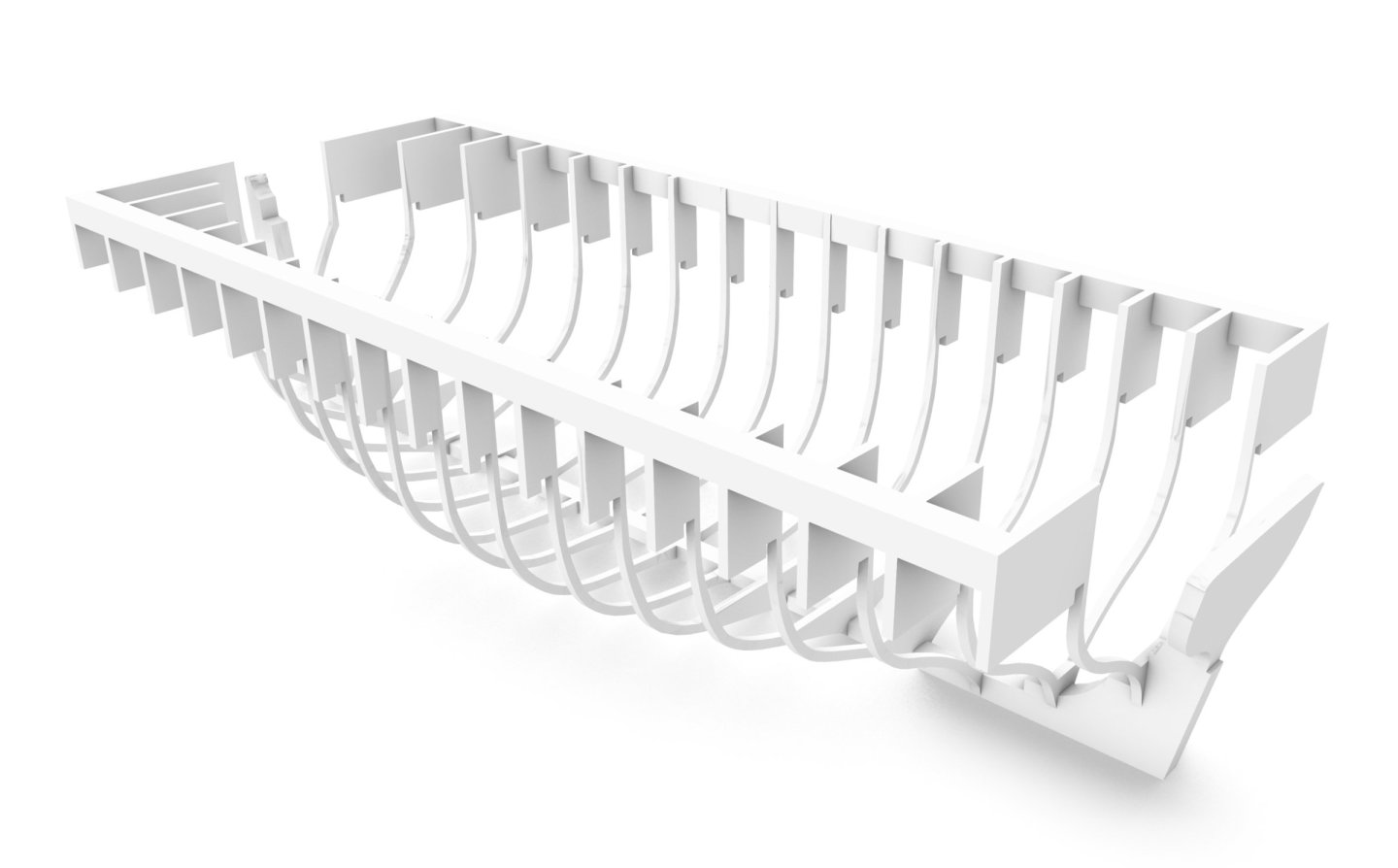

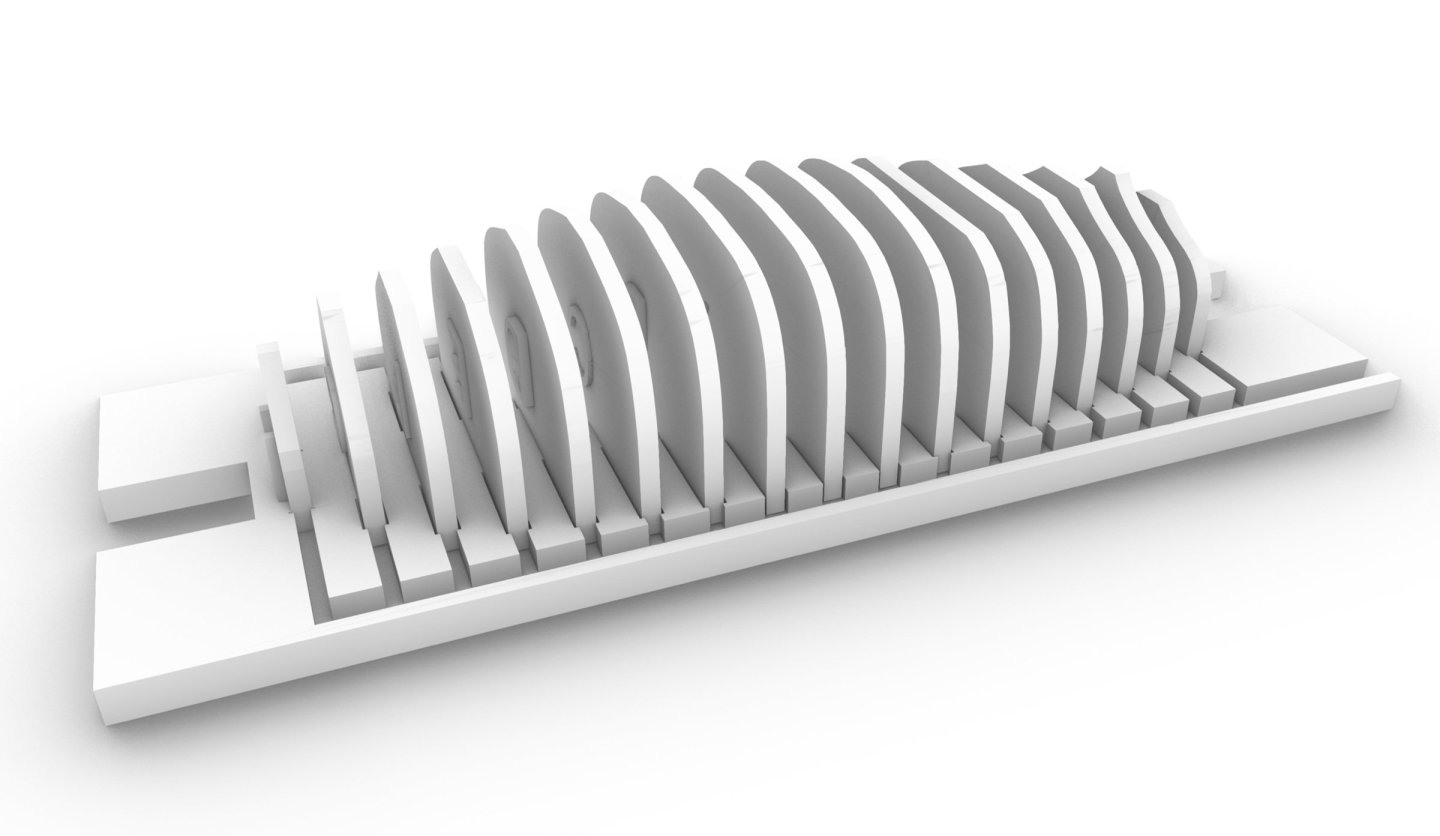

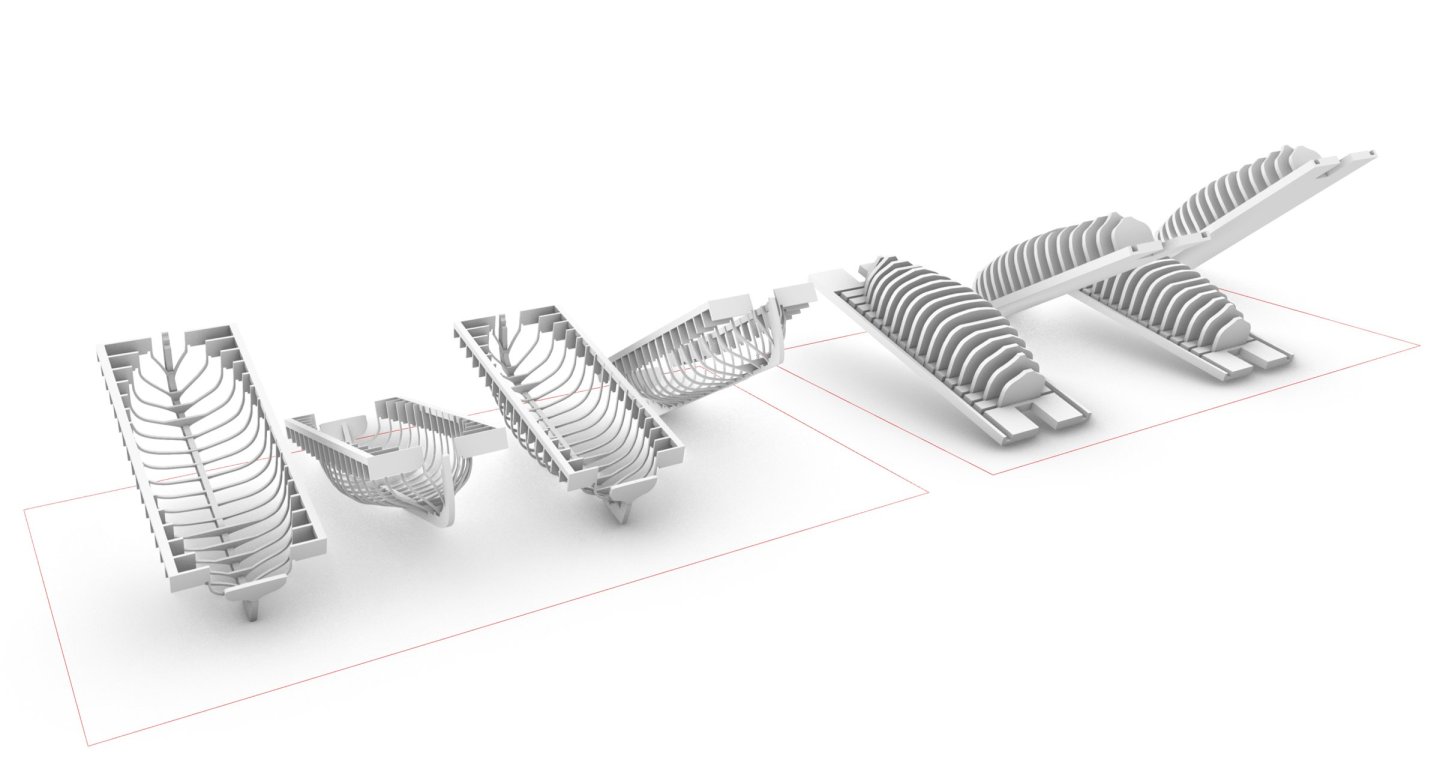

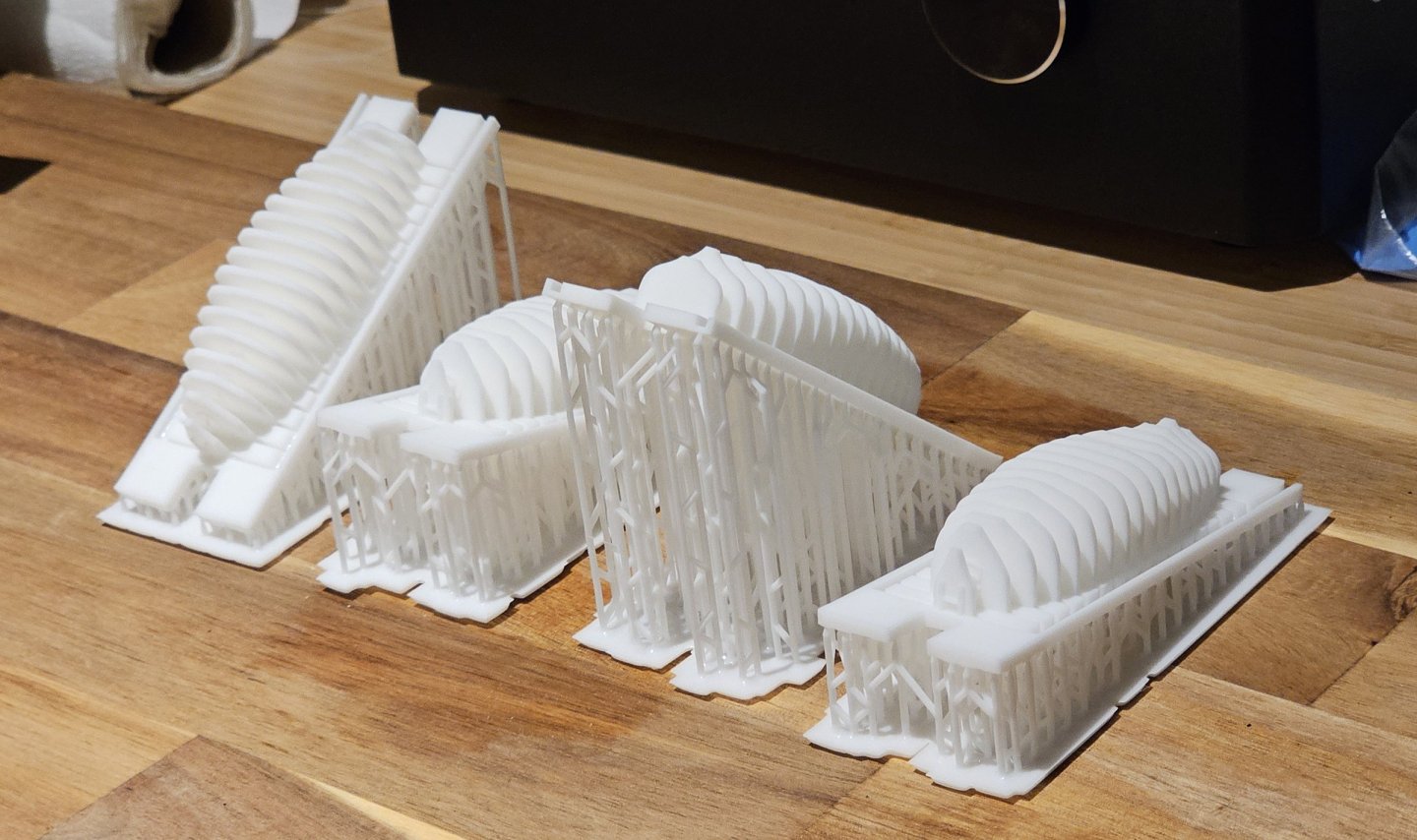

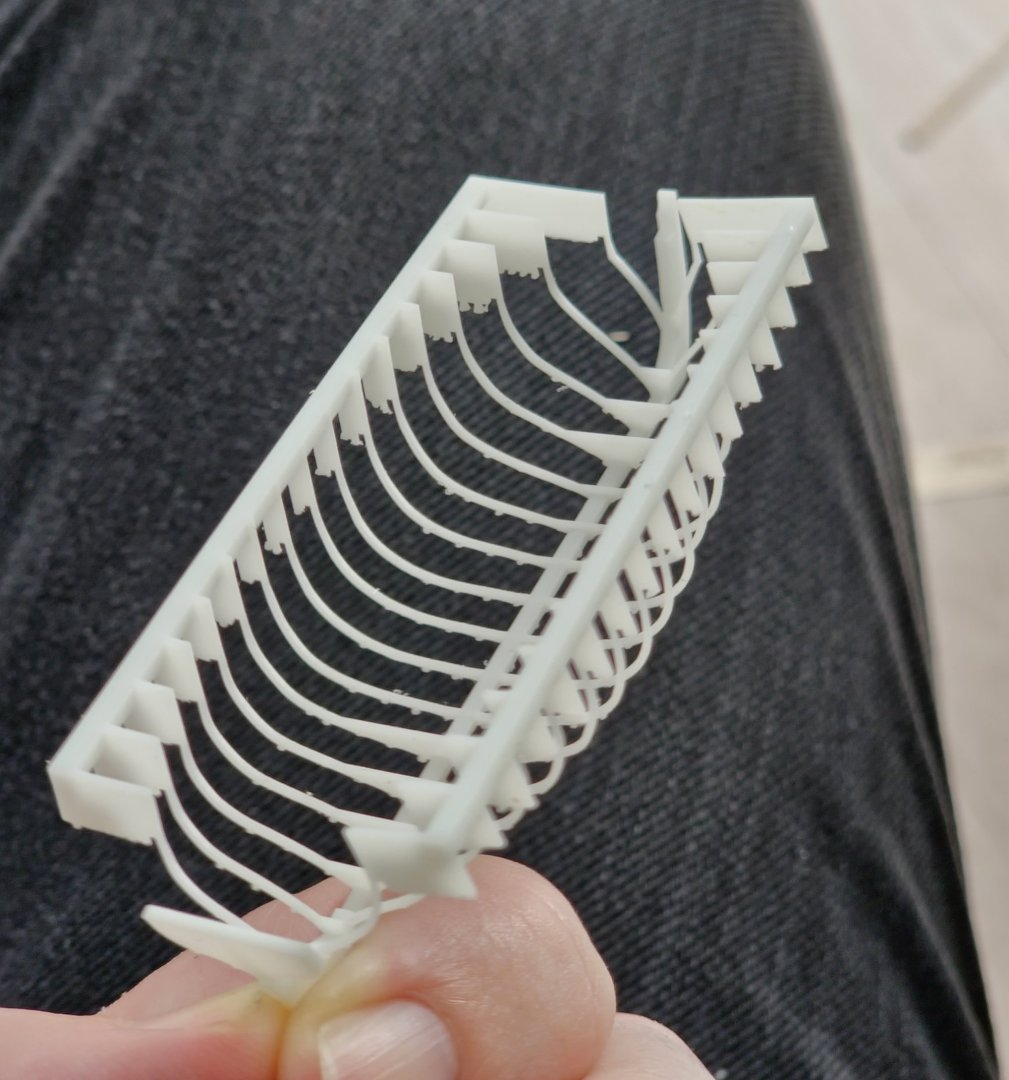

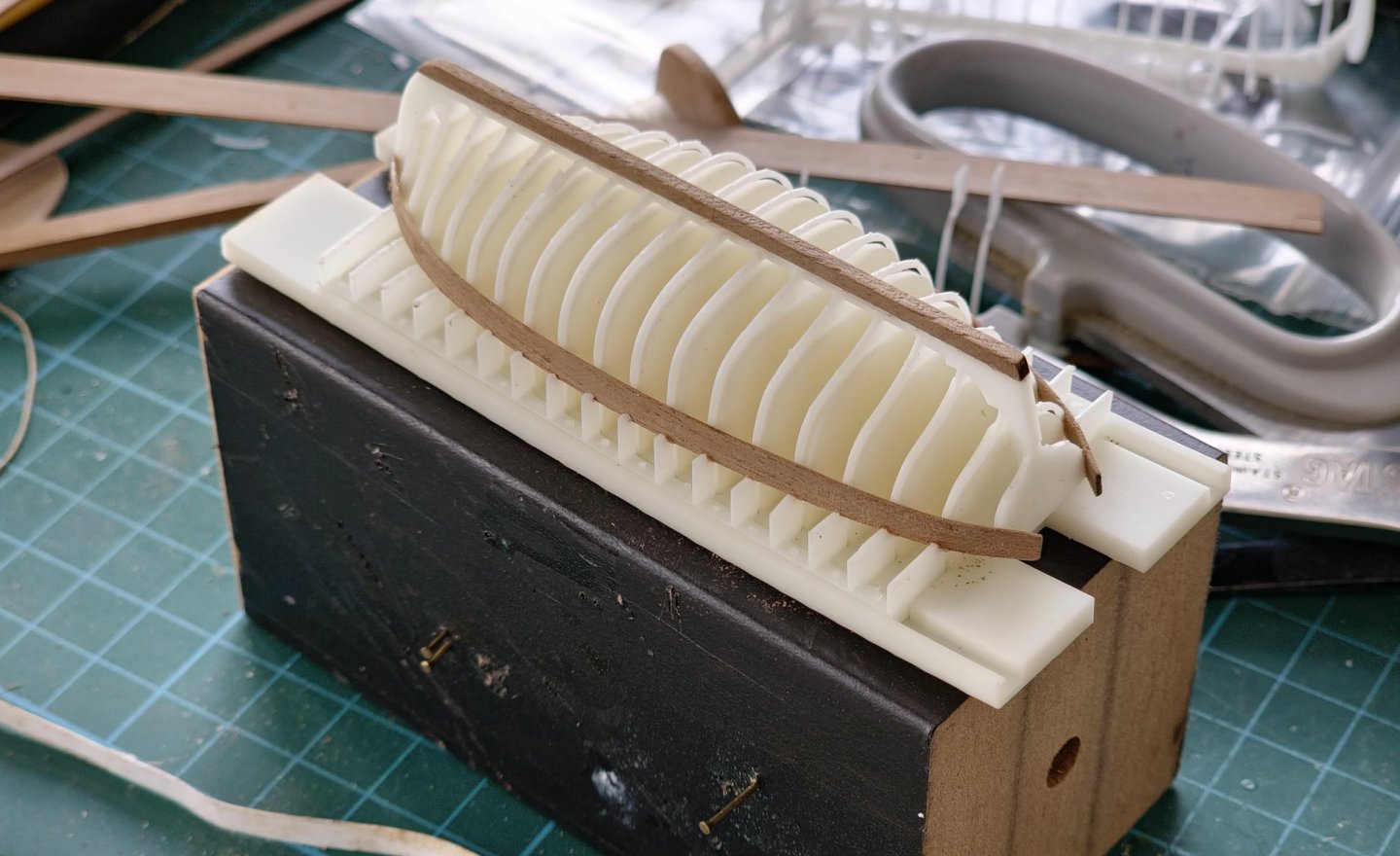

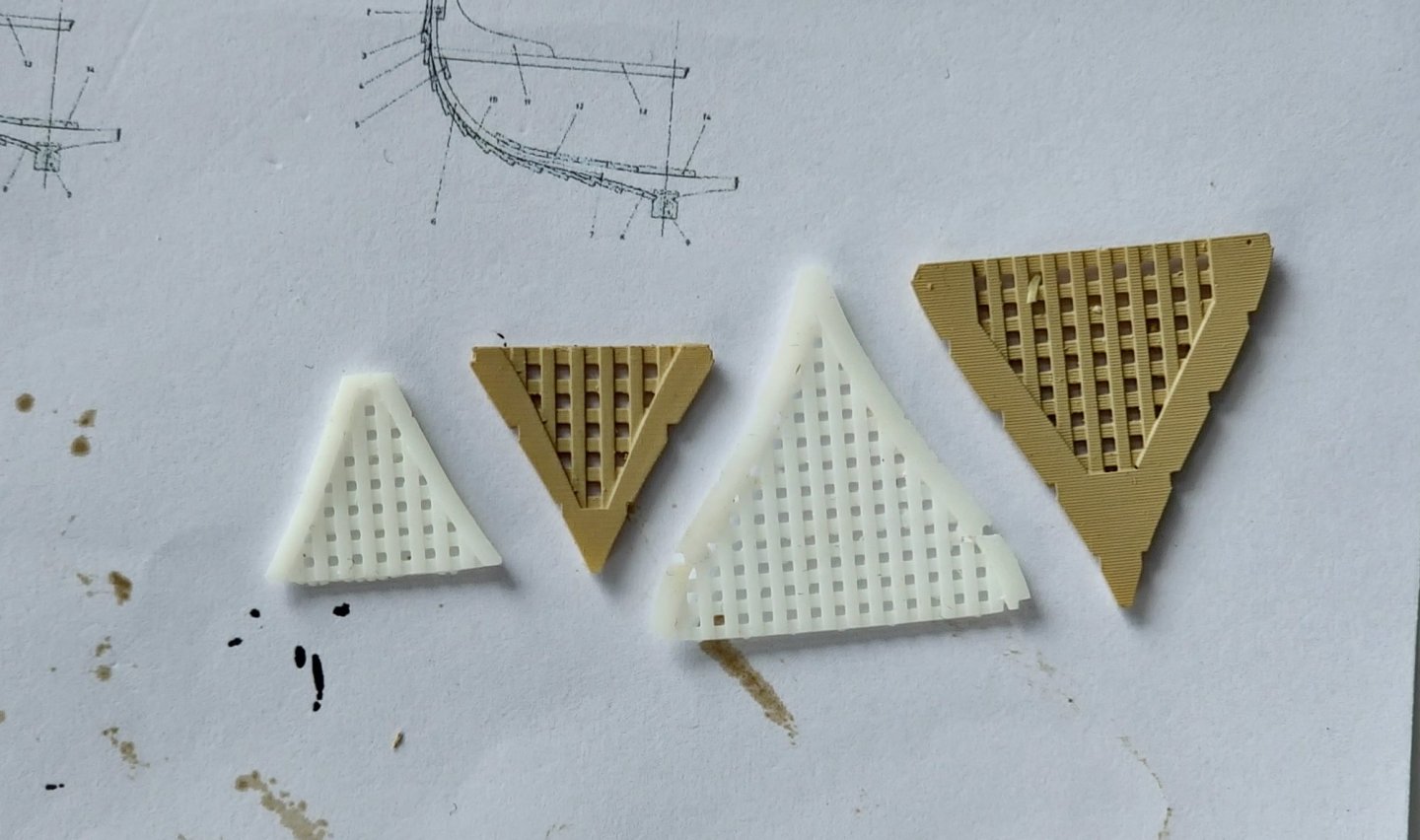

After completing most of the work in the jolly boat I had the urge to do something other than another small boat but much like washing the dishes or writing the minutes of meetings it is always best if you leap on to them straight away and not let them fester otherwise, they will never get done. I therefore decided to try and build the remaining three small boats concurrently. That way I would be able to capitalise on the recently acquired knowledge while it is still fresh in my mind and I should hopefully be able to get a good rhythm going and muscle through all the CAD work and then have a couple of days devoted to printing rather than doing it piecemeal thereby tripling the amount of cleaning of equipment. I was on the fence as to whether or not to include the 24ft cutter but decided to press ahead and build it. I can then make the call later if I should install it. The basic techniques for the additional boats are pretty much the same as the jolly boat although every time I make another one, I tweak the 3D models somewhat to try and overcome difficulties encountered in previous attempts. I noticed that the formwork for the jolly boat started to bow as it sat on the desk. As I am new to the resin printing world I do not know if this is because the base is too thin to resist the stresses of curing or if the base is too thick and the mass of resin is imparting additional stresses during the curing process. To attempt to mitigate this I added some fanciful engineering to the base of the formwork to hopefully keep this straight. This did not work perfectly in practice so I have come up with some other ideas to achieve a better success rate if I should ever again attempt a small boat. This new technique would involve adding metal or wood stiffeners as soon as the print was free of the support structure. The 3D model would be modified to accommodate these. The cutter is just a slightly bigger version of the jolly boat but with slight modifications to the floor and grating. I had been thinking about how to tackle the pintles and gudgeons on the jolly boat and it is causing me no end of headaches. BlueEnsign has some good information on how these work in one of his build logs with the longer lower pintle that facilitates installation in rough seas. It occurred to me that I could save myself a step if I included the fixing points in the 3D model which should help with stability and accuracy. I figured I could make the pintles out of 0.5mm diameter brass rod inserted into 1mm diameter thin-walled brass tube. It is very easy to draw this but building it will be a lot more difficult given the tiny scales and I doubt that I will be able to achieve acceptable gaps and tolerances between the keel and the rudder. Once the model has been printed out the fixing point is a microscopic blob of resin. Once you zoom in using the magnifier function on the phone you can see that all the detail is there. It is just not visible to the naked eye. The launch is a different beast from the previous cutters. It seems to have wider spaced futtocks that are slightly beefier. The breadth is nearly 8 feet so I am making this one double banked. There is also a lot of additional equipment with the windlass and davit and it is carvel built rather than clinker. Lucky there are no gratings which are a pain to draw but it does mean that I will have to do some in-situ planking later so swings and roundabouts. The 32ft pinnace is also carvel built but closer to the cutter in terms of the distribution and size of the futtocks. It is quite narrow so will be single banked. The drawings in the AOTSD show a bench running down the middle. I have noticed in some drawings and models that there are small posts that sit on the keelson and support the thwarts. I am not sure that I will include these. The detailing of the pinnace looks like the most complicated of the three and will need some further study. Although quite tedious I sat down and built the three basic structural models as well as the formwork upon which they will sit. I printed out two of each as there is a lot of potential for breakage when liberating the models from the temporary support structure. The total print time for everything was just over 18 hours so it is a two-day exercise which works out quite nicely as I am using two different types of resin. I had to clear a space on a desk to keep all the pieces segregated before I started on the assembly as I did not want to get them muddled up. I had the idea of completing all three hull planking exercises at once. The advantage of doing all three at once is that you can paint them all in a production line which is a good saving in time over than doing them one by one. The disadvantage as it turned out is that all of the hull planking at one go is too much for me to stomach so after planking the launch I decided to carry on building the rest of it to break up the monotony. I used the same basic colour scheme as the jolly boat except with a black identification stripe. The washboards are looking a bit tentative though, so I will revisit those later. As it is so much larger than the jolly boat the area of white hull is giving me palpitations. I probably should have left some of the planks au naturel and just painted below the waterline but too late for that now. I used the oak stained maple for the footwalling but went for a slightly thicker plank as the in-scale version was prone to disintegration. There are no gratings but there is some steensheet footwalling which was also made from the maple. The AOTSD drawings do not show any lifting ringbolts but these are present in all the other small boats so I am inclined to blame a lazy draughtsperson for their omission and included them on the model. The rising and thwarts are also maple. May notes that the main thwart is wider and thicker than the rest. This is a detail too far for me so I kept the same thickness throughout but increased the width of the main thwart. I did make them fancy three-piece thwarts though but you really have to peer closely to pick this detail up. The overall shape of the launch is causing me some concern. I have been dutifully following the dimensions set out in the AOTSD drawings but it looks quite beefy in the backside and quite deep dish. I was wondering if I had bungled spectacularly in transposing the dimensions in the CAD process but when I lay it over the drawings it does match up so it may be that I just overdosed on the Jolly boat shape after building so many prototypes. I knocked up the davit and support structure out of maple with wire simulating the bolts. The sheave was lathed out of some 2.5mm diameter brass rod with a 0.5mm diameter brass axle. I added the transom knees and the various steps. I then tried to replace the washboards with some that are slightly thicker although the demolition phase caused much grinding of teeth and destruction of parts of the model that were not slated for demolition. It ended up a bit of a bodge. Still looked a bit funny so I added some reinforcement pieces at the rowlocks, which is a detail I have seen before, to tidy this up. Knees were installed on the fixed thwarts. I was dithering about which anchor to include I was going to use the 78lb version as it is quite a hefty craft but Lavery hints that these boats would be equipped with a 40lb version. I may go with my smallest one which is 54lb but there is not much visual difference between the two to be sure. I must add the breasthook and then tackle the windlass which looks like quite a fiddly little exercise. I also need to print out some additional oars as I only have four of the 19ft versions although while poring over the drawings of the windlass I noticed that I will not be able to present it with the oars laid across the thwarts as the windlass sits above the level of the thwarts. Perhaps I will leave off the launch oars in the final setup. I still need to touch up the paint job but I think I will move on to one of the remaining two boats for a change of pace but the fleet is growing albeit slowly.

-

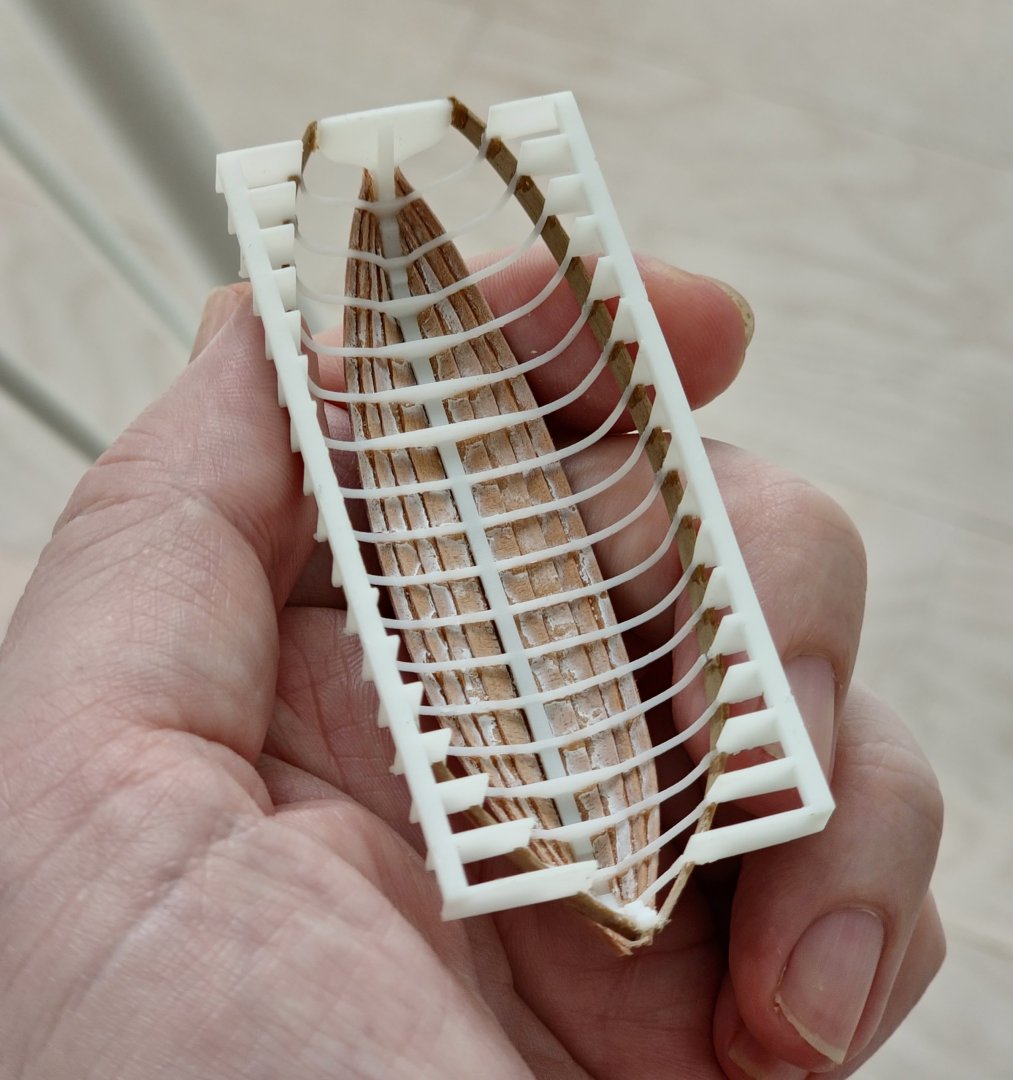

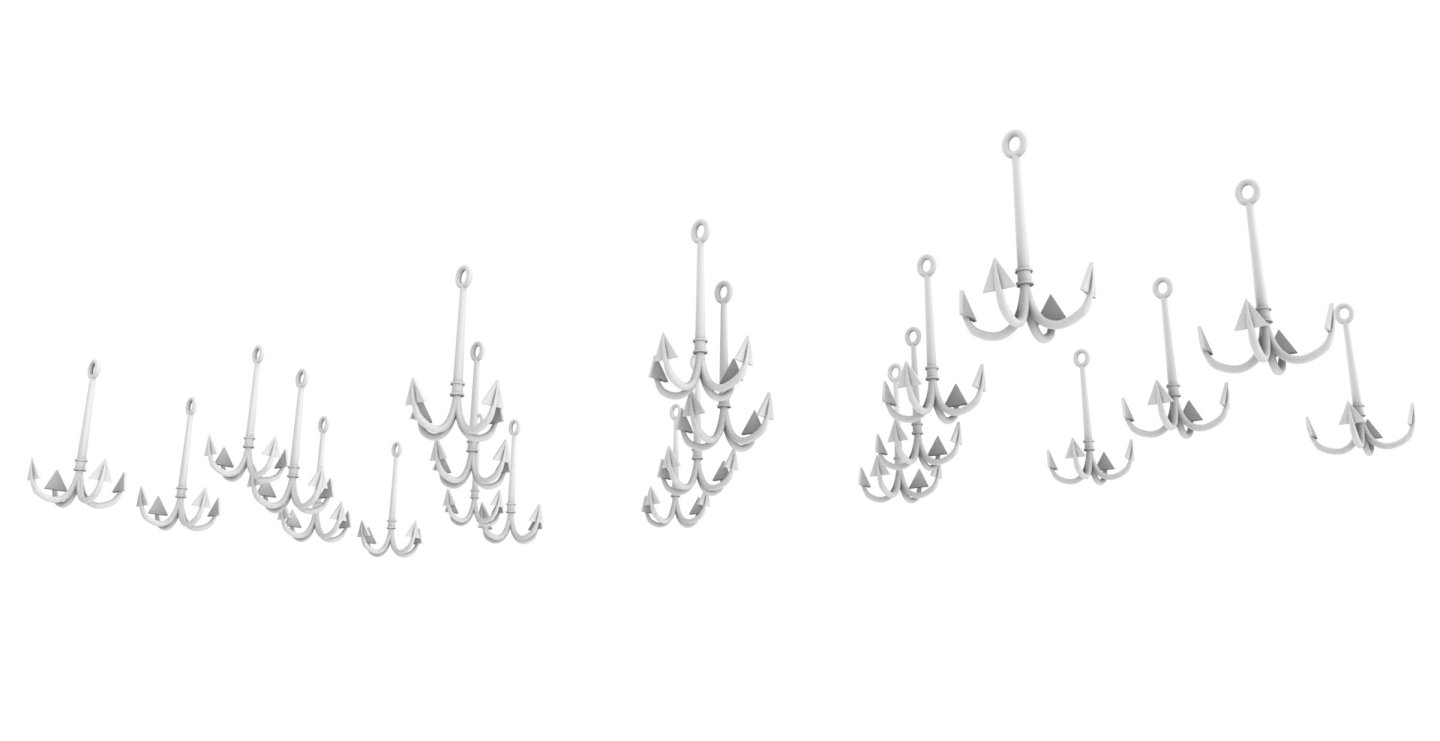

I foolishly stopped working on the model and I have had a real problem starting up again. This is the second time I have fallen into that trap. I should have learnt my lesson the first time. To get back into the swing of things I decided to have another stab at my nemesis, the 18ft cutter (jolly boat). I think that I am into double figures with my jolly boat attempts. I have picked up a thing or two from the previously discarded prototypes so I went back to the CAD model and made some modifications. I found that trying to insert the individual futtock heads into the formwork was a real pain so I joined them all together at the top with a sacrificial beam and then modified the formwork so that it could accept these beams which will allow the futtocks to line up with relative ease and they will hopefully remain evenly spaced. I went out and purchased some engineering grade resin to try and overcome the failure of the futtocks when releasing from the support structure. I found that it is advisable to put off the curing stage until later as this gives the material some additional flexibility and reduces the chance of sudden fracture. It is more of a faff to use as the model must be cleaned with alcohol rather than water. Once printed out I married the two components together and installed the wash strake first to overcome the futtock distortion problem I previously encountered. I then placed the rest of the keel, garboard stakes, and continued the rest of the planking in my usual haphazard manner. I start out with the best of intentions but soon lose my way. I had some real problems at the pointy end but I realise where the mistake lies and could modify the CAD model to mitigate this in future builds. I decided to just press on with this one as I could not face starting again. The good thing about the new sacrificial beam design is that I can remove the model from the formwork from time to time to see how it is looking from the inside. Not great to be sure mainly due to my munificence with the CA. Despite deploying the engineering grade resin, the dimensions of the futtocks give them the same structural integrity as the bones of a well boiled kipper and they snap off at the slightest touch. I had to replace some parts by organ harvesting from previous model prototypes but I am hoping that a thick layer of paint will keep everything intact. I gave the exterior of the hull a few coats of acrylic paint. I have fallen into the trap of going for a too white paint but I used something called parchment this time. I think I could probably go for one more shade shabbier, which was linen, as it still looks quite bright to my eye but that will hopefully dull over time as it picks up dust and grime from constant handling. I continued my tradition of the admiralty blue identification stripe and added a rubbing strake picked out in white to give it a racy feel. I kept the washboards in a natural walnut finish rather than carrying on with the blue just for some visual interest. For the interior I started off by laying down a few coats of light ochre colour. I found this in the model figure painting section of the hobby shop and it is apparently the colour of the bones of some mythical beast but it had a nice utilitarian look although I was rather taken with the light blue that BlueEnsign used in his pinnace on his Indefatigable build. I was not happy with the grating that I had 3d printed as the perimeter timbers were too wide. The geometry is quite complicated as it needs to fit snugly in the as-built space but I bit the bullet and redrew these to come up with something that was closer to the drawings shown in the AOTSD. I used maple for the keelsom and footwalling. I left this a natural colour with a golden oak stain to highlight the complicated planking layout that took me a while to achieve although the joints are messy and the shape somehow got distorted. This position of the footwalling was the whole reason for embarking on the jolly boat journey as it was sitting too high in the kit supplied version with no way of lowering it. Thwarts, knees, sternsheets, risings, gunwales and decking were all made from the golden oak stained maple to match the rest of the interior timber work. This also ties into the deck colour of the ship so it hopefully does not stick out like a sore thumb. I slightly bumped up the thickness of the thwarts over the dimensions shown in May as the scaling down of this element caused it to appear too insubstantial. I added ringbolts and other bits and pieces. I 3D printed the mast clamp as it is a very delicate piece. I even had to exaggerate some of the dimensions as the dimensionally accurate one was so fragile that it tended to crumble to dust in my fingers. I 3D printed some oars with a view to making them out of timber but once I had them in my hand, I realised that they are too delicate and would therefore be too frustrating to construct from any of the timber in my stock. For fiddly pieces that need to be produced in multiples, the 3D printing process is so much easier. I used the dimensions from Steel based on the 6ft breadth of boat but the length of the oar at 19ft turned out to be longer than the boat which was not what I expected. Further investigation revealed that the oar size can be in a range of 2.5 to 3.5 times the breadth of the boat. I noticed in May that he states the oar length for an 18ft cutter should be 14ft. This is however for a 19th century boat. I knocked out some a few 15ft examples for comparison, as they do not take that long to draw, and I am much happier with the proportions. I made the looms round as Steel notes these were often made round for the ship’s boats. Along with the oars there are other bits and bobs scattered about the boat. One of these is the anchor. Quite a while ago I had purchased the smallest grapnel anchor that I could find on the CMB website. This was a 20mm long version. I had to rummage around before I managed to locate it in the back of a drawer. I glued it together and tossed it into the boat and found out that it was much too large. I drew something up on the computer loosely based on the drawings and dimensions in Steel. I went with the four flukes rather than the five fluker he has drawn (and he does note both are acceptable). Even the slimmed down version was probably too big for the jolly boat and more suited to the pinnace. I scaled the original down in two stages based on what I thought might survive the printing process and came up with three different sizes. Steel notes that the weight for these anchors ranges between 112lbs to 30lbs. An advantage of working in CAD means that I could get the volume of the model and thus calculate the scaled-up weight. The three versions I produced theoretically weigh 106bs, 78lbs and 54lbs which puts them right in the ballpark. For the jolly boat I plan to use the smallest of the three. While this is not down to the 30lb weight, the anchor is so insubstantial that when I had an ant infestation in my workshop the other day and I was worried that they might carry it off to decorate their burrow and I would never see it again. According to Steel the anchor rope is just under an inch in diameter and 40 fathoms of long. This scales to about 0.37mm in diameter and over a metre in length. In an attack of frugality, I decided to only equip my jolly boat with 20 fathoms of anchor rope, which still looks like a lot. I just need to practice making a convincing looking rope coil that stays in place which is a skill that I have yet to master. I repurposed the rudder from version X and. I guess the rudder should be stowed in the boat until it is deployed so I may not fix it in place. I have yet to decide on which route to go which will determine how I construct the rudder fixings so I will leave that for now and stick it in place using blu-tak for the time being. The finished boat is the best one of my prototypes to date. There is still room for improvement but I am going to call it a day on the jolly boat odyssey as I have, more or less, achieved the goal of producing something that is a bit of an improvement on the kit supplied item. It is high time that I returned to the ship itself. I have made a real botch in the rigging department and will have to get busy with some dismantling work.

-

Thanks Ian. When I was buying the printer, I noticed that they had some laser cutters on display and I was sorely tempted however I do not need one to finish this model and to be fair I have also run out of counter space for equipment. I am going to have to redesign my workshop layout before buying one. Regards, David

-

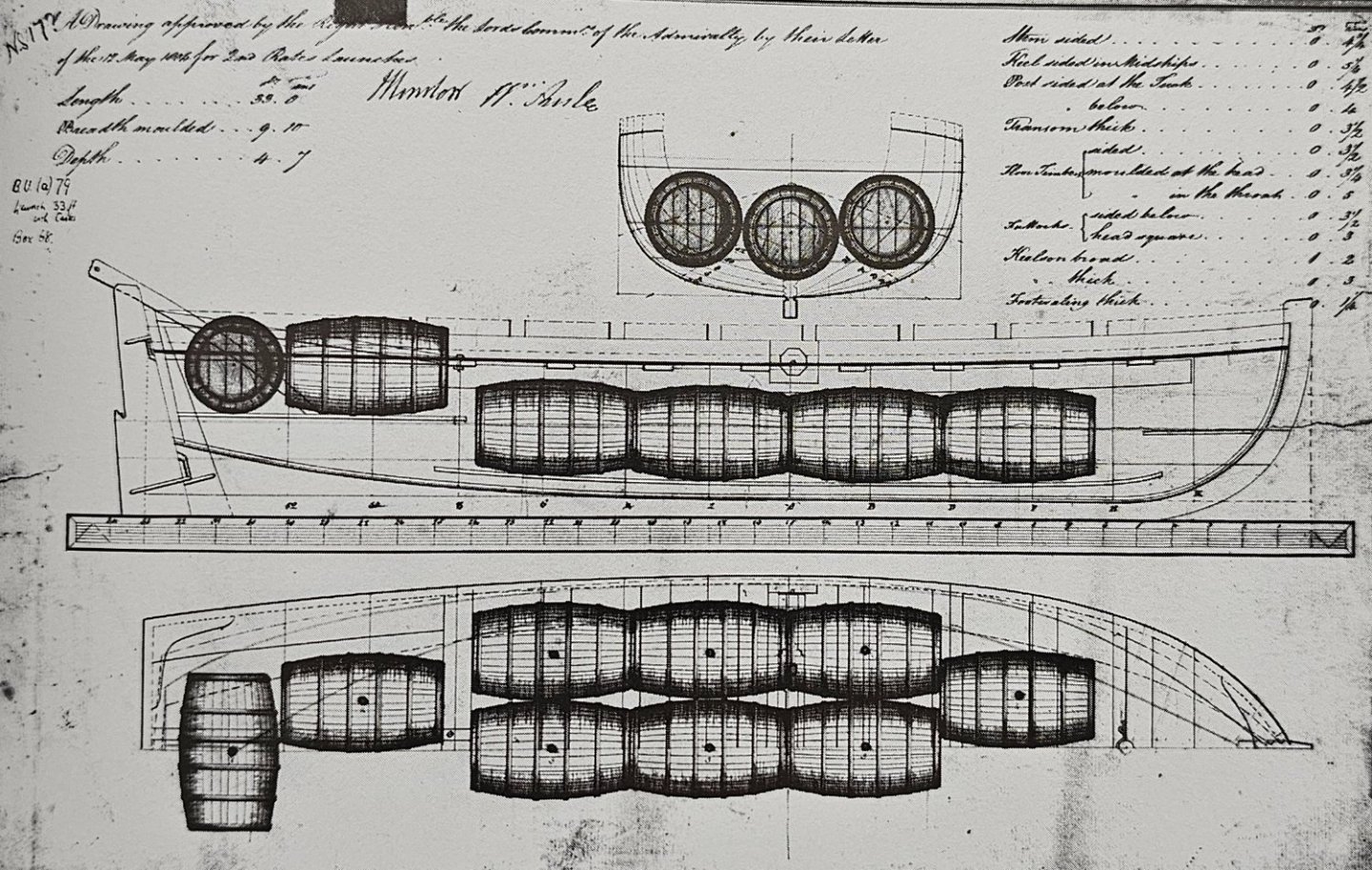

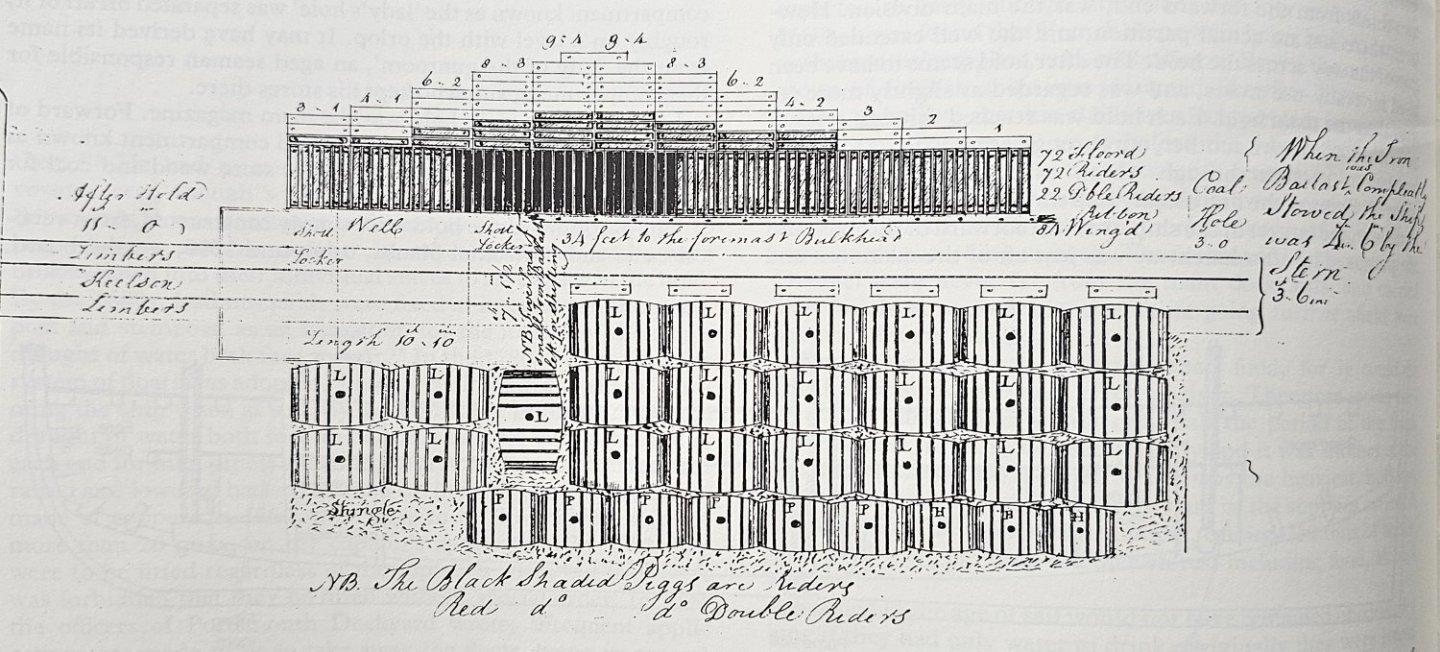

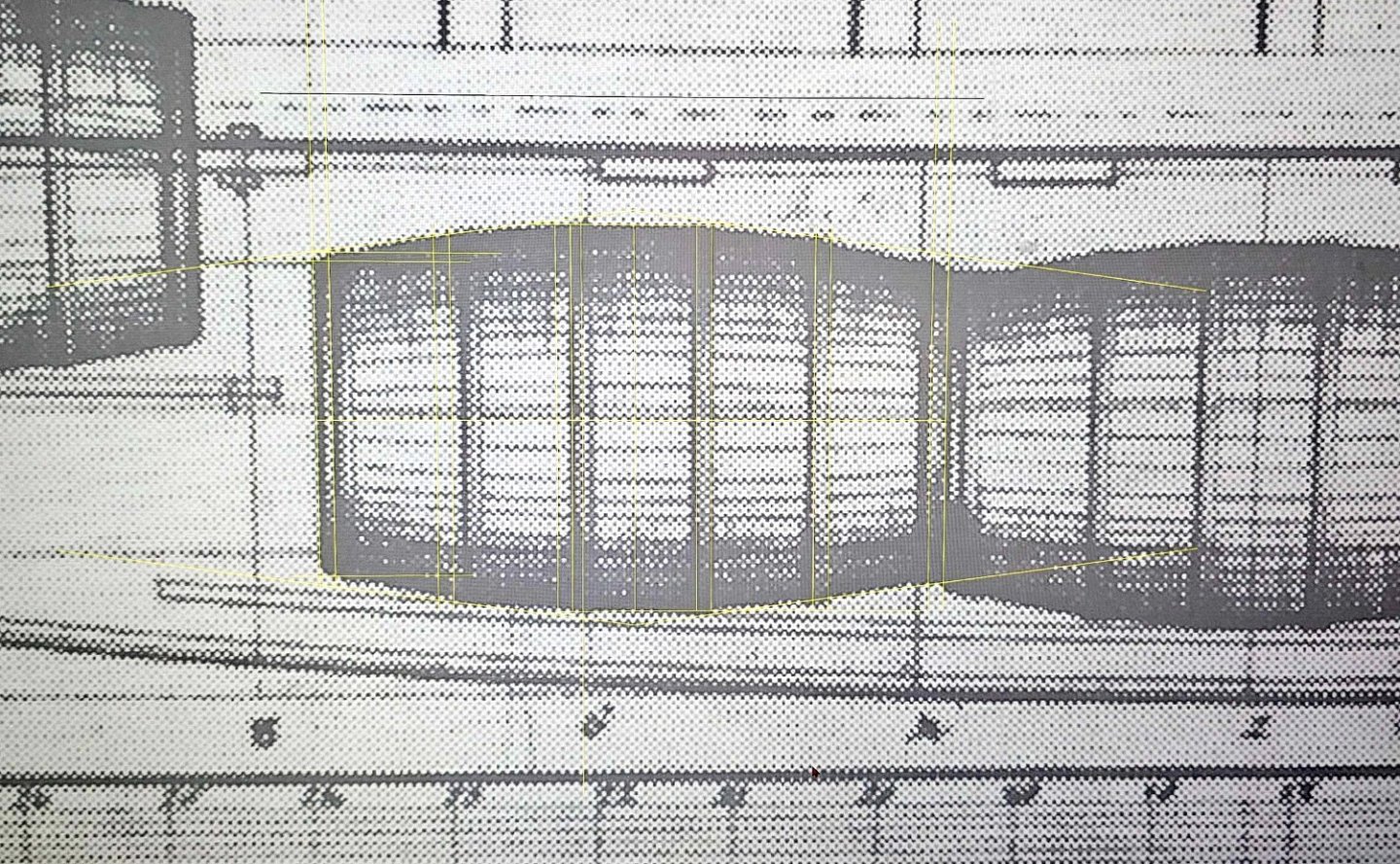

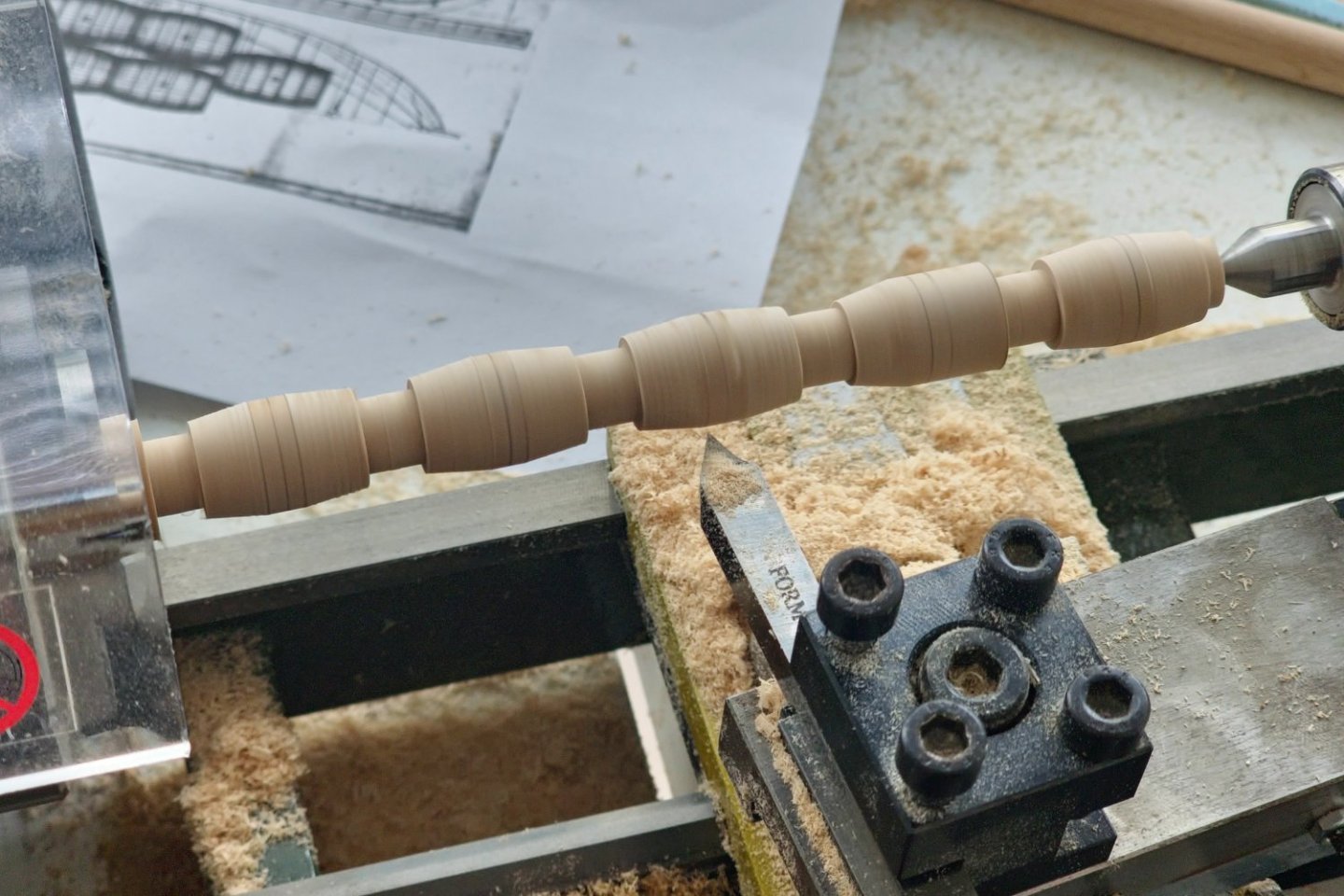

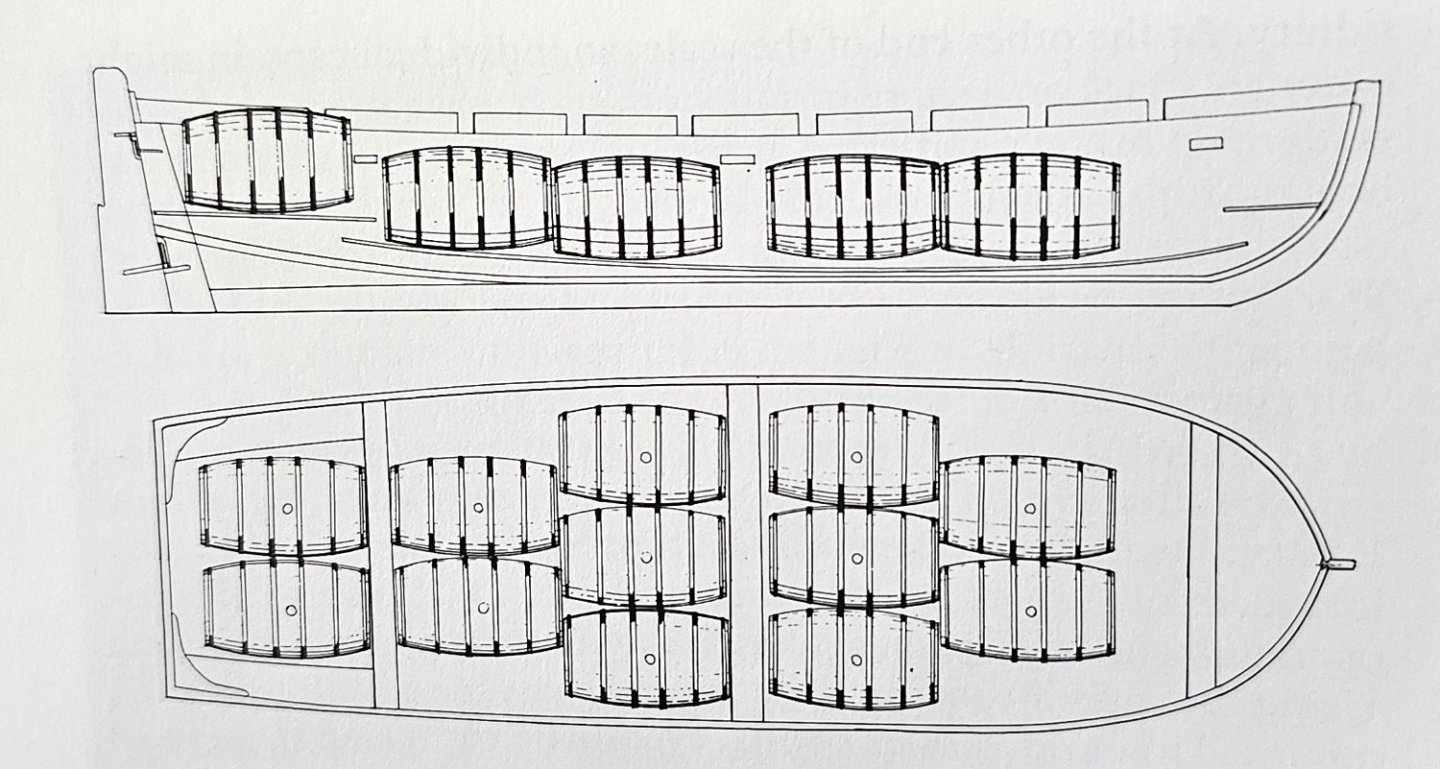

Not much of an update but after idling my time away playing with the printer and then doing nothing for a month, I felt in need of building something using tools. Nothing too ambitious mind you which ruled out the yards. I had a notion to display one of the ships boats being hoisted aloft in the rigging as though it was being launched. If I did, I thought I should include some cargo for added interest. A few barrels sprung to mind as the ship’s boats were often used to ferry barrels ashore to be replenished with fresh water. Lavery notes that the ships were provisioned with 6 month’s worth of food but only 3 months of water meaning the captain would have to stop off near some handy water source to fill up his barrels. May has a copy of a contemporary drawing showing a 33ft launch filled with 14 leaguers. These are the largest standard barrel carried and have a capacity of 150 gallons. I have often wondered why only some thwarts have knees and it seems that those without are removable to allow the loading of cargo. The whole arrangement looks somewhat like a theoretical maximum as I cannot imagine it would be all that easy to pilot that boat through heavy seas with that amount of cargo. At least it gave me a dimension for the barrel which was a start. Lavery has a handy contemporary drawing showing the placement of casks in the hold of the frigate Artois, sister ship to the Diana. This shows that it did indeed carry leaguers and confirmed the dimensions shown in May. Given the leaguers dimensions of 4ft. 6in. height and a diameter of 3ft. round the middle I started off with a 15mm diameter beech dowel. This was inserted in the lathe and then reduced to a 14.2mm diameter and divided up into five 21.4mm sections in the hope that I would get at least one barrel out of the five. I then bevelled the ends at 7.85 degrees. This was the first failure as the markings on the lathe that I thought were degrees turned out not to be. Angle corrected I proceeded with the rest. These sharp angles were then softened into a barrel shape with sandpaper. I scored lines along the length of the barrel using a scalpel to imitate the staves. There should be upward of 30 staves to a barrel but as the beech was quite hard, I only included 15 as it was tricky to accomplish and you are guaranteed to jab the scalpel into your palm every 12 or so staves. I milled out grooves to countersink the metal hoops which I made from styrene strip painted black. A recess was milled in the top and bottom to simulate the lid and I rubbed charcoal dust into the stave grooves to give them more prominence. I gave the barrel a stain of walnut and stuck in a cut off toothpick for the bung. Once it was placed into the Jolly boat prototype the crew were heard to comment that they needed a bigger boat. There is a drawing in Lavery that shows a layout of a launch carrying 12 of the smaller butts which are only 108 gallons. They note that a first rate launch can carry 14 butts but a third rate only 12. I decided that perhaps butts were the way to go. I found a table in Steel where he gives the overall dimensions of the various types of casks stored on a ship so I used these for the smaller barrel which turned out to be 20.6mm in length and 12.9mm diameter around the middle. As the beech dowel was quite hard to work with, I used a different wood for the butts. I found it in a drawer so I do not know what the timber was but it was a lot softer. Probably too soft. It was easier to score the grooves for the staves though so I increased the number to 24. The barrel was made pretty much the same way as the leaguer but I used a smaller styrene strip for the metal hoops. I really needed something a bit smaller and thinner but they do not seem to make strip of the dimensions I required and cutting them out of larger sheets proved to be too frustrating and inconsistent. The end result was a bit shaky but sat more comfortably in the Jolly boat so should be even better in the launch if I ever get round to building it. I do not think that twelve casks would be all that practical though and a rough measure with the scale rule would seem to suggest that six is crowded enough.

-

Well done David. It is an impressive addition to the room. I like the way you have incorporated your reference books into the display. Your build log has proved very to me as it has to others I am sure. Regards, David

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.