-

Posts

4,375 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Egilman

-

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Egilman replied to CDW's topic in Non-ship/categorised builds

Oh please don't, (aside from normal streaks & stains) way too many of these birds are made to look like they were flying out of garbage heaps or never got any maintenance on the flightline... They were always being wiped down and cleaned, the ground crews were very proud of their planes and pilots and kept them looking their best, Especially in England... (flying side by side with the RAF almost mandated it, they wanted them to look their best...) -

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Egilman replied to CDW's topic in Non-ship/categorised builds

Me neither, I tried them a while back using the Micro sol trick with them, didn't work for me.... they all tore in some fashion, at least when a standard decal tears, you have a chance to recover from it, with these wet-transfer decals, no chance if they tear... You cant reassemble them into a useable decal.... Next to impossible to get them off cleanly once they have fractured as well... Not worth the risk IMHO... -

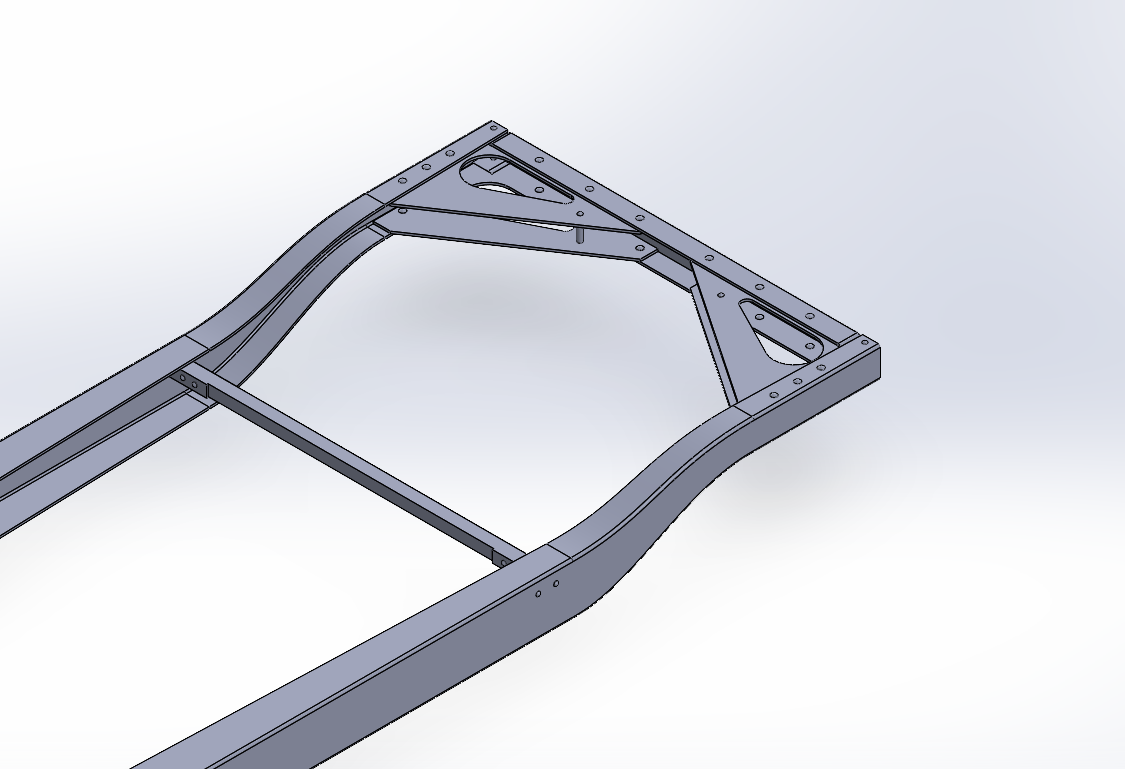

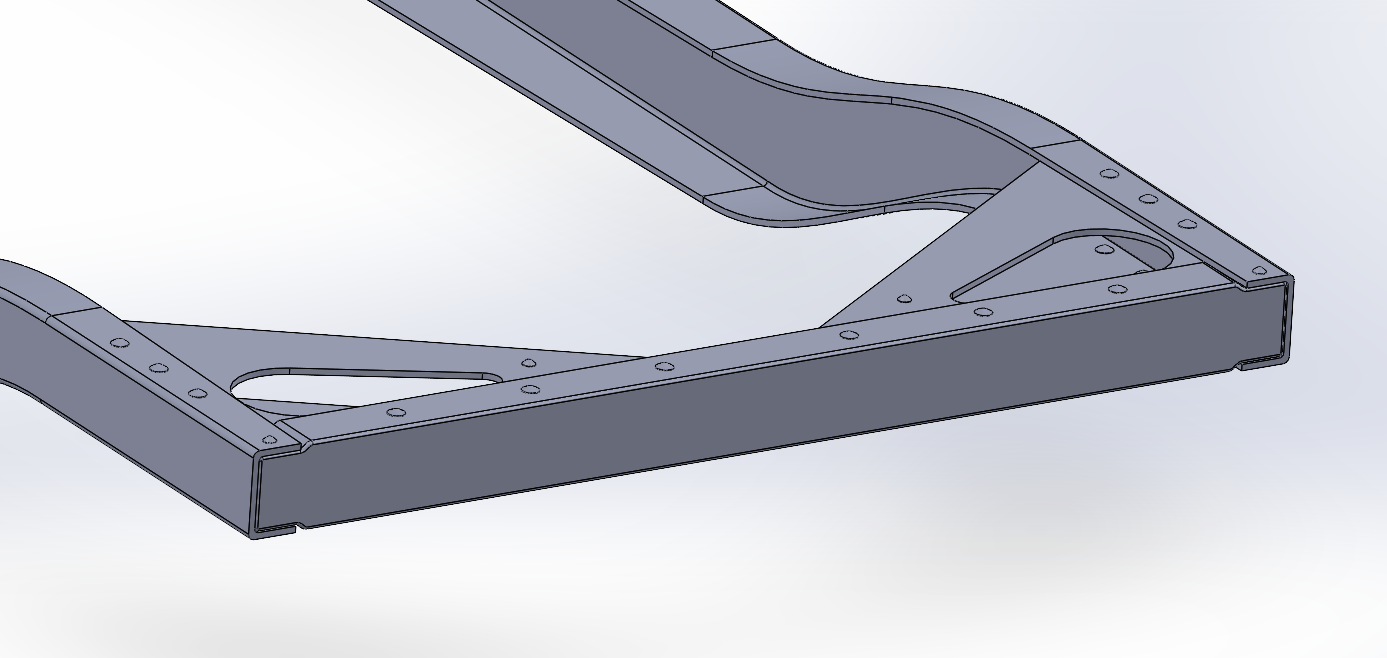

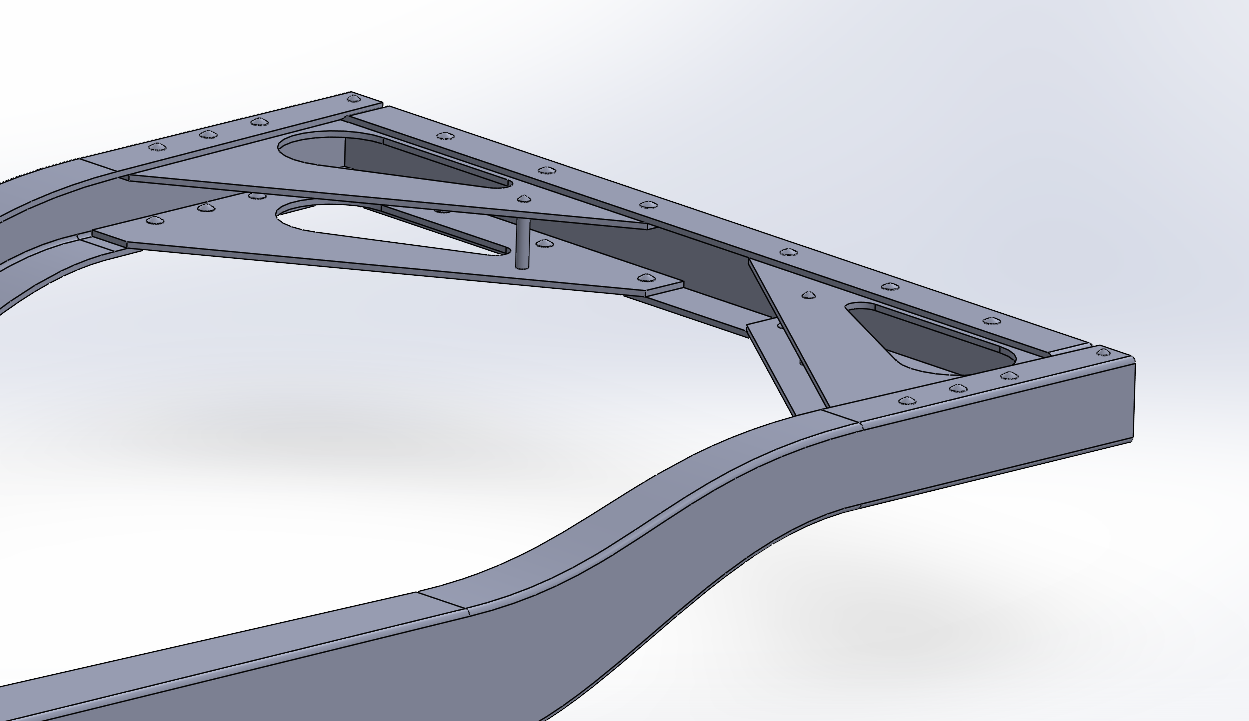

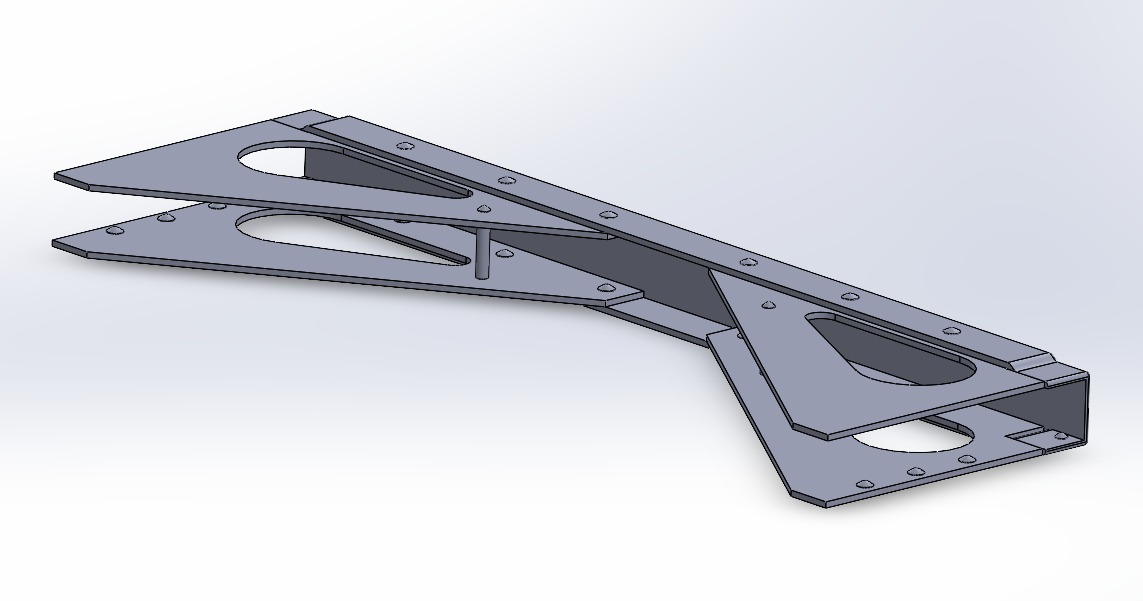

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

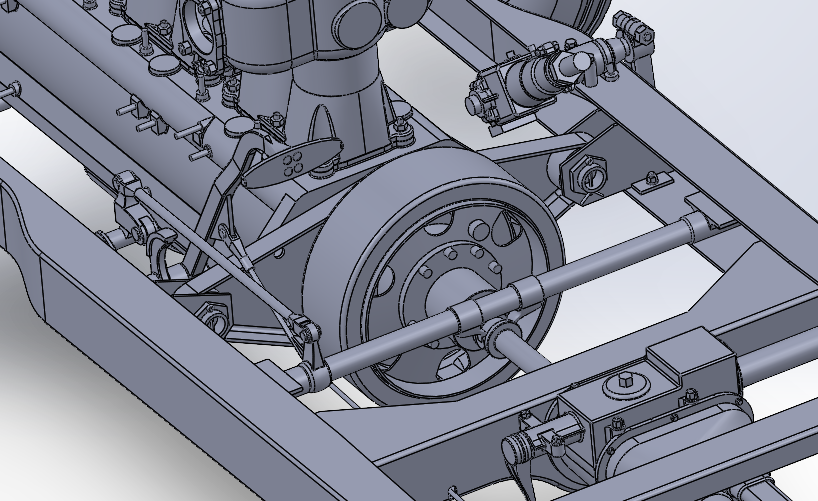

Another update.... The first two crossmembers, now modeled accurately... Rear Cross member.... With the frame rails... Reverse side.... And finally the rear firewall crossmember.... Accurate to what is really on the car.... Still making progress... Onwards... -

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

Not sure yet Brother, gots to get it designed first... Then reduce it to a scale which will preserve it's details yet allow it to be printed.... I'm still a long ways from there..... But I'm going to finish it..... and then decide.... -

Krupp 420mm Big Bertha by Haliburton - Takom - 1/35

Egilman replied to Haliburton's topic in Non-ship/categorised builds

Yes, long about 1908 the differences between the three types began to blur....WWI brought it to a concordance... Afterwards, mortars were trending downwards in size, (becoming an infantry weapon) howitzers stabilized at around 150 or 155 mm, (but the largest were still 240mm class) and were the heart and soul of the artillery branches and guns became anything firing in a flat trajectory in direct fire, however with a lot of overlap in application... By the end of WWII massive howitzers and guns had no real distinction on the battlefield, they both could do the same jobs... This is clearly seen in the usage of the 155mm & 8" guns and howitzers of the US army the 280 mm Atomic Annie was classed as a gun rather than what it actually functioned as... With Big Bertha, in1914 they reduced the weight of the explosive charge from just over 900 kilos to less than 800 kilos and gained some 5,000 metres in range out of the exact same barrels... Ballistics is always a relative game, you identify what you need your weapon to do and design it to accomplish it... Once that's all done, someone who knows less than the designer slaps it with a type name and it is forever typecast into that.... Metallurgy is a science, and a very extensive science at that... And yes Chilled Iron for a long time was considered the best armor one could buy and was one of the hardest metals produced, but by 1936 most high velocity guns could easily penetrate it and armor production moved into homogenous plate and cast high carbon steels at much lighter weights.... Chilled iron armor also had the very bad habit of fracturing into hundreds of small pieces, when it failed it became it's own shrapnel... One of the drawbacks of Chilled Iron for artillery shells is sometimes it was just too tough... They would hit and go off but the casing wouldn't fracture, they would blow the fuse out of the tip when they went off... this is why there are thousands of big artillery rounds that have been recovered from the WWI battlefields... Essentially buried intact but with no fusing or explosive charge.... Yeah the Carbide cutter, and in 1936 the diamond tipped cutter.... (Hughes Tool Company) But then again it wasn't just metal cutting tech that improved, steelmaking did as well, pretty much leaving cast iron methods behind -

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Egilman replied to CDW's topic in Non-ship/categorised builds

When she is done, I hope we can get a look at her in natural sunlight.... -

Krupp 420mm Big Bertha by Haliburton - Takom - 1/35

Egilman replied to Haliburton's topic in Non-ship/categorised builds

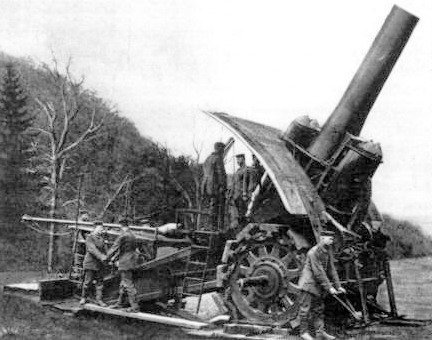

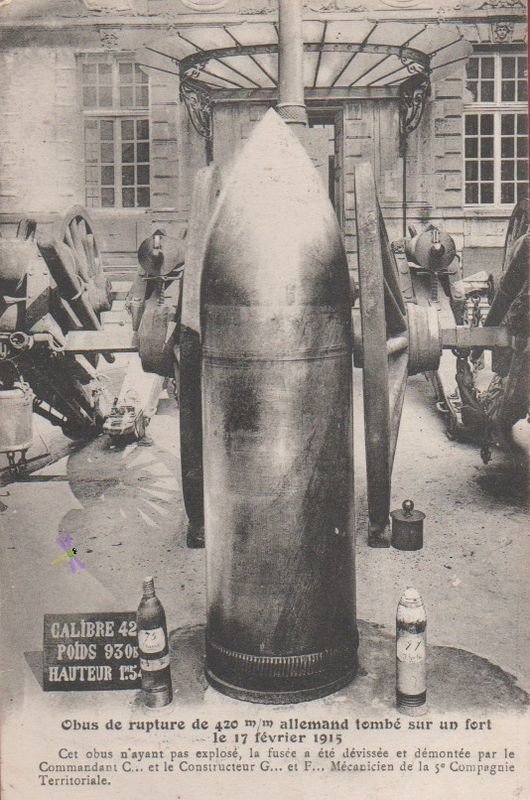

Ok, does anyone know the difference between a Mortar, Howitzer and Gun? Big Bertha was a Mortar, (Morser in German) the British and American 9.45" (240mm) Gun was a Mortar.... The difference is in the angle of fire they produced, Mortars are relatively short ranged weapons to deliver plunging fire, when originally designed Big Bertha only had a range of 9k metres... extremely short for an artillery grade weapon. But, it fired a projectile that could penetrate 1.5 meteres of reinforced concrete, 4.5 meteres of cast concrete and created craters that measured 6 meteres deep and 30 meteres wide... As you see in the video, large shells were pressed into basic shape while white hot then hammer forged and allowed to aircool this had the effect of aligning the grain of the steel and eliminating any stresses created by forced cooling, toughening the steel but leaving it malleable... (as the press forming of the casing showed in the video establishes) There are two ways to quick cool newly formed steel, water and oil, both create a hard outer surface and a tough grain aligned interior material it's generic term is called case-hardening.... High carbon steel is heated to an orange color, (do enough of it and you quickly learn to judge temps by the color of the metal) then plunging it into various liquids to cool it rapidly, what happens is the surface of the metal crystalizes and when cooled it creates a hard outer casing and a tough inner material... for steels that have less than 3% carbon content, the steel needs to be carbonized first before the process of case hardening it can be done... But the idea is to create a very hard outer surface with a tough inner core... That is not what is being shown in the videos.... 'Hartguß' or Hartguss, is the German name for Chilled cast iron, part of the ductile iron class of materials specifically... Yes it can be formed in press machinery like in the second video, but it is difficult to machine given it's formulary makeup, it can be ground though and is used to make camshafts and other such long wearing products... It acts in industrial uses like Case Hardened Steel... It is easier to produce than steel but harder to work into useable parts... I imagine they can make shells from it and looking at the old deteriorated examples in the museums I would say they did.. (they look like rusted corroded cast iron).. If you want, I can dig out my Machinists handbook for the section on hardening the various types of metals for more accurate info.... Not saying your wrong, just saying that from specific knowledge I know that artillery rounds were not made from case hardened materials, it made them too hard.... -

Krupp 420mm Big Bertha by Haliburton - Takom - 1/35

Egilman replied to Haliburton's topic in Non-ship/categorised builds

And this video shows the German process of forging large artillery round blanks before machining.... I believe it's from the Krupp works long about 1918.... -

Krupp 420mm Big Bertha by Haliburton - Takom - 1/35

Egilman replied to Haliburton's topic in Non-ship/categorised builds

Artillery Shells weren't cast anything, they were usually made of a steel alloy from sawed off round bars... This process started as soon as they started using rifled barrels.... Here is a British Pathe' film of ladies making artillery shells in the process used in 1914-18.... Pressure rings or "Sabots" were usually hard bronze and machined as part of the shell once they were swaged onto the projectile... No casting of anything, bar stock straight from the mill to the saw shop... Everything from 20mm all the way up to 480 mm... They would have a shiny smooth machined surface usually +/- .0005 in surface irregularity... There are plenty of photo shots of shiny shells lining the trenches waiting to be fired... Or, period pics like this on of a Big Bertha with a Shell ready to ram... You see how shiny the shell was? Yes they would stencil explosive information as to type of shell it was on the sides, but they wouldn't be painted like they were in WWII of even today... The French army started the war with 5 million shells of all calibers in the arsenal, they went through them in three months... The German Army had 12.6 million artillery rounds to start the war... NO ONE had any conception of how fast the modern weapons could be fired so their prewar stocks were established under rules dictated by 1870's rules of artillery use... They were making shells as fast as they could, and in 1915 there was an actual artillery round shortage (on both sides) where a battery of guns might have 20 rounds between them... They didn't have time to paint artillery rounds... -

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

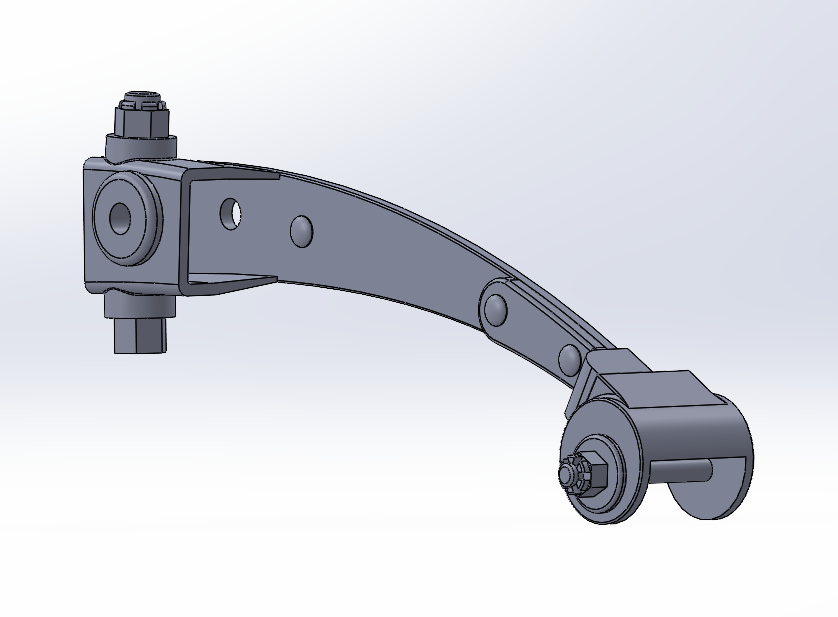

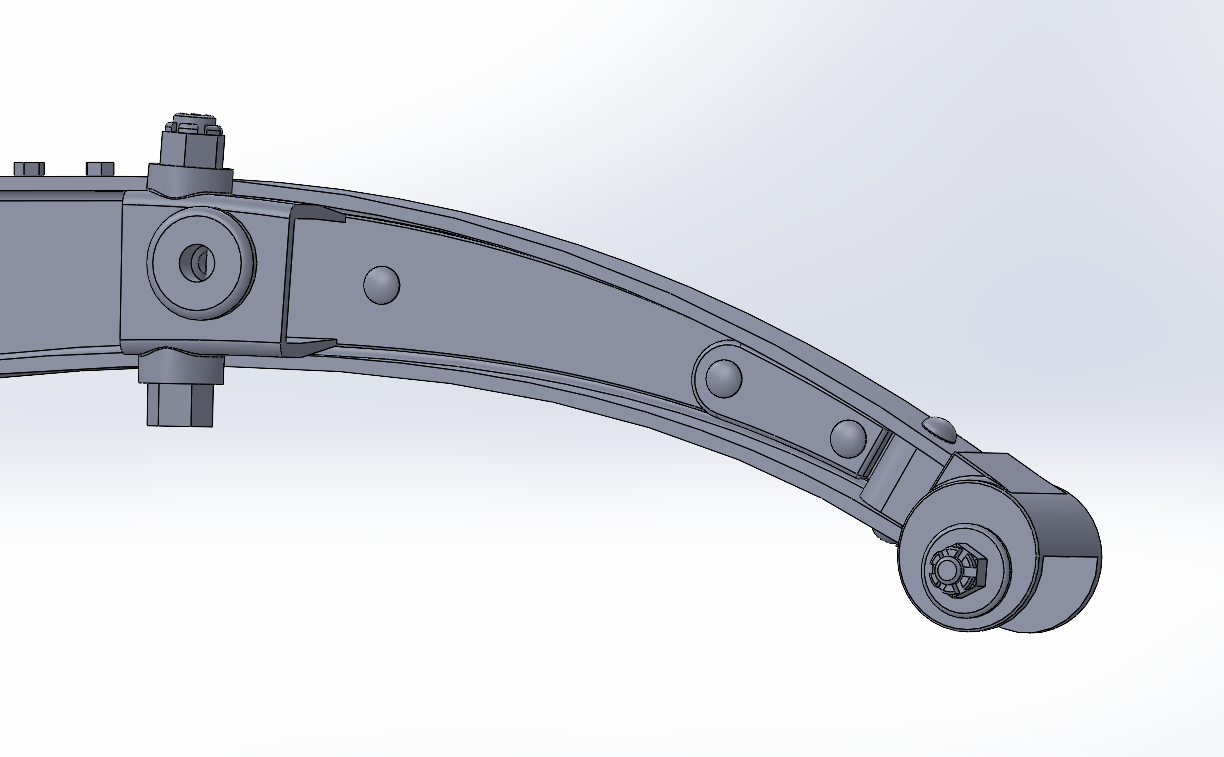

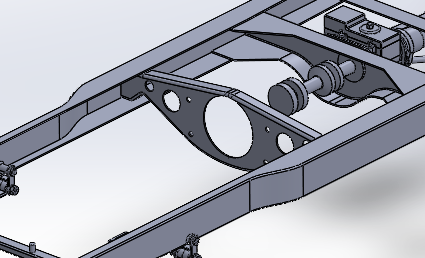

Short update... Front Suspension Bracket.... Where she resides.... And the individual part... Making progress.... Onwards.... -

Not a big seller for Tamiya, that's why it costs so little, but it's the only real game in town for that particular model.... It's pretty accurate and cleanly molded... Would benefit from aftermarket tracks though, T91E3 Workable Track Links 1-35 AFV Club It's had an undistinguished career as a tank, designed to be a light recon tank, but sized more like a medium tank, it never really fulfilled either role well... After the initial issue to US troops, (who didn't like it) the remainder of production was sent to foreign allies.... Aside from Vietnam where the bulk of it's combat history took place with the ARVN, (who loved it) it's only real combat capabilities were revealed in the CIA backed Bay of Pigs invasion of Cuba, 8 of the 16 tanks landed held off three companies of T-34-85's in the only successful incursion off the beach, they eventually ran out of ammo and were destroyed or forced to surrender, the other 8 were abandoned on the beach... It was a good tank, but by the time it was being issued, the whole concept of heavy, medium & light tanks was passe'.... The Main Battle Tank concept was being developed along with the M-48 Patton.... I'm down brother...

-

Krupp 420mm Big Bertha by Haliburton - Takom - 1/35

Egilman replied to Haliburton's topic in Non-ship/categorised builds

-

His web store is Scale Collectables.com... The owners name is Dan Silvestru... He's a great guy... A little over a year ago he offered to collaborate with me on the creation of models, I would create the STL files and he would create the masters for production... It looks like he still does that for designers....

-

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

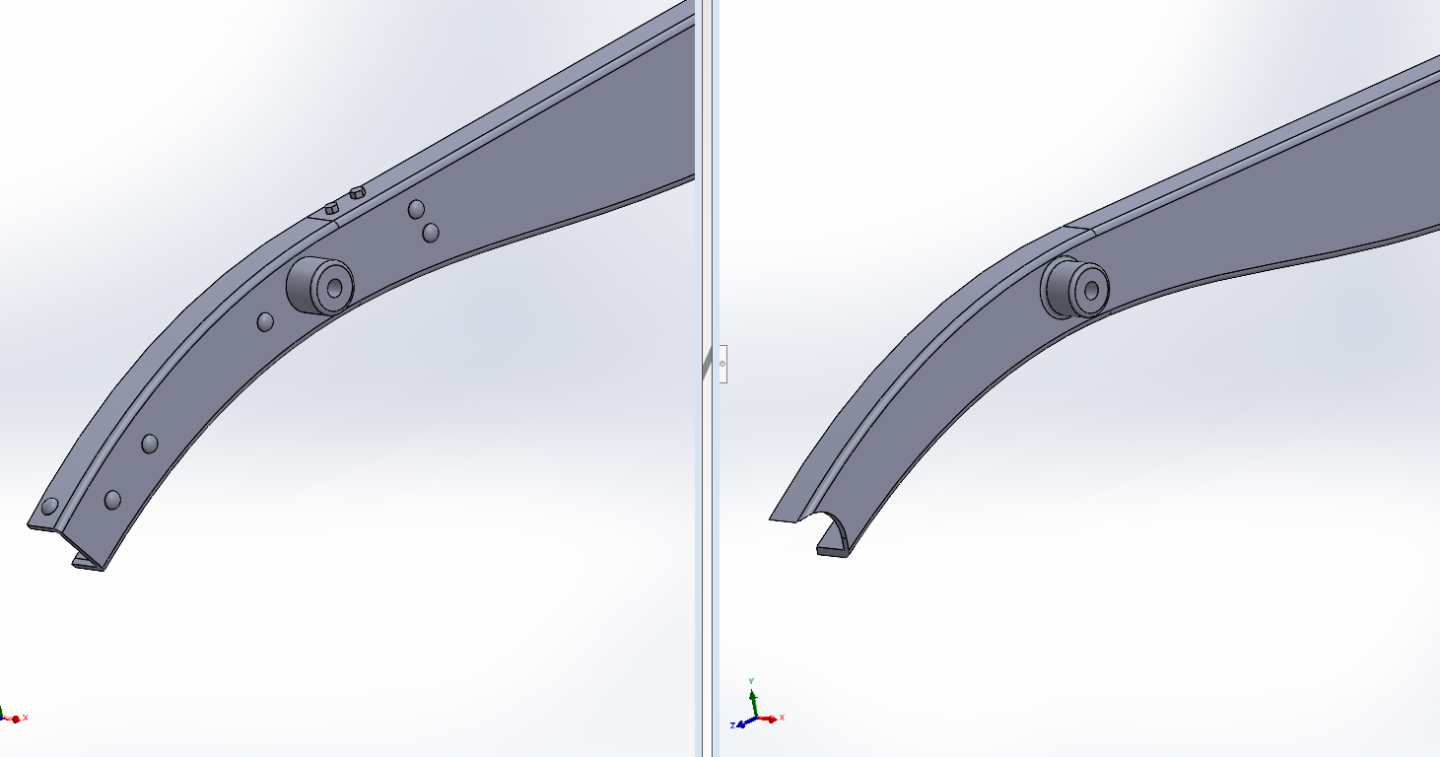

Thanks Rob.... Not really a drawback, it's an expansion of knowledge.... With the extra images to study it makes for an even more interesting build.... More practice as well.... An example of why I had to start over... Frame rails... the first part modeled.... On the left is the new version, on the right is the old version... Currently figuring out the suspension bracket that inserts into the frame rail on the forward end... (it's what those rivet's are securing inside the rail) The new pics give me a lot of that exterior detail... Back in the age this car was built, (and most cars of the period) welding wasn't something that was widely employed... Today a car like this would be completely welded together and my first drawings didn't make this delineation... Another thing, there isn't very many washers used, it seems that generally they just bolted and nutted straight to the parts, unheard of practice today... Today you do not design or build/assemble machinery without washers... {chuckle} Little details.... Well, the Doc is very optimistic, Me, all I can do is learn to live with it, it's not the end of the world....... Keep plugging away.... -

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

Welcome to the Log, and Yes it is, no easier way to change things on the fly... I'll try to keep it interesting..... Thank you... -

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Egilman replied to CDW's topic in Non-ship/categorised builds

That is the finish of a brand new bird fresh off the assembly line.... The minute it hits the outside air it will start to turn dullish white/grey... Takes about two months for the metals natural oxidated protective surface to come out in real life... Very very good job spraying that surface.... A little too shiny for an in theater service bird, but hey, that finish is extremely hard to duplicate.... By the time this particular bird reached service, 27 days from delivery to first mission, this is exactly what she would have looked like getting her unit markings and colors... No one could do it better my friend... WELL DONE!!! -

Thank you for signing up to ask me a question about truck trailers... In response, maybe you can explain why Truck Paper has an auction listing for a 1977 52' Hobbs Dry goods van which sold for "$645.00 Christmas Eve 2022? They listed it as a '77..... How about you taking a look.... For example.... 1978 UTILITY 48 ft x 96 in sold just 4 months ago.... In fact I pull an internet search there are still some 1977 48' van trailers around selling for peanuts at auction.... I mean they are used for storage only they aren't really road worthy, but they are available today... If they are still available today, they were available back then... Maybe you aught to explain to those auction companies how they can't possibly have sold 1977-78 48' (and longer) trailers to people cause they simply weren't being made back then...

-

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

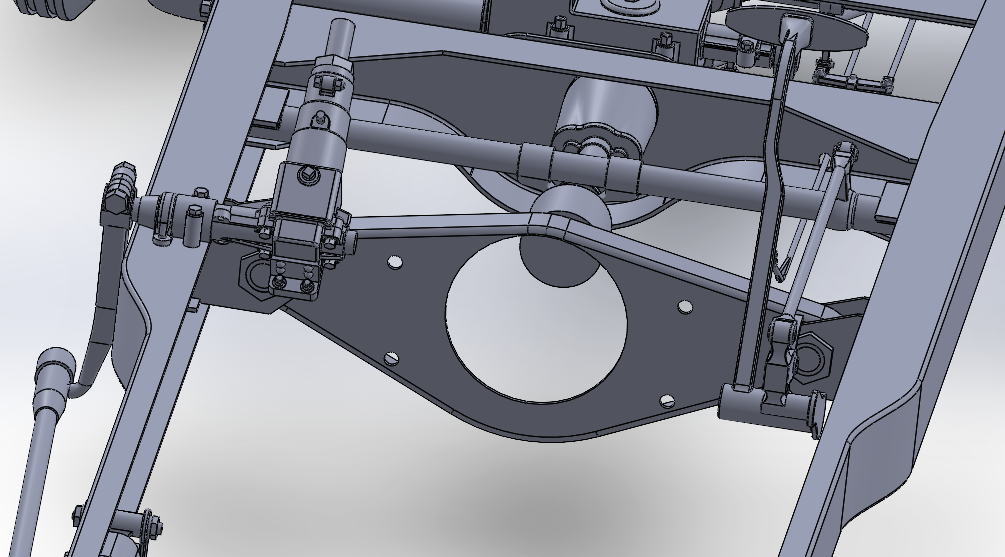

Anyway a new update on the progression if this exercise.... It's time to assess the progress to date.... So far everything done has been the result of collecting pics and data off the net... Some good data and very nice pics, but since the coverage is sparse and distant many of the small details are lost in translation... But, I have had a benefactor step forward.... A Gentleman that is kind and gracious and very generously offered me detailed images of the Marmon Wasp... Unpublished images, about 100 more or less of various sections of the car that no amount of picture taking from behind the ropes will cover... In perusing these images, it has become painfully clear that I need to do a redesign... Not that I'm completely wrong with what I have done so far, but it would take three times more work to redesign many of the current parts to match what is now known to be real on the real thing... 3/4ths of the current design needs some level of work to bring it up to the current level of knowledge and factual imagery... For example, take a look at the rear engine mount crossmember.... That is what it has looked like as I had no references to how it was affixed to the frame.... This is what it looks like today.... Accurate motor mounts.... Above the front side, below the aft side.... Getting that detail added required an almost complete redesign of the cross member.... And yes I have absolute photo proof that is the configuration of the Marmon Wasp's rear motor mounts... Almost every part I have designed to the best of my abilities and experience has issues like this on this model.... So I'm going to start a Version II of her... I will be using many of the parts I already have done as the basis of the redesign, but it will be a completely new model.... Given the new info I now have, there are too many parts that would need complete redesign to make them fit the pics I now have.... Currently I'm in the process of indexing better drawings for use as base images in SW and restarting the model... Look at it this way, you get to see it build up from base images and I can explore the process of creating something like this... I know it may feel like we are retracing the path we have already gone down, but in the end, we will have the most accurate model representation of the Marmon Wasp around.... (at least as accurate as I can make it) Thank you for putting up with me and following along on this excursion into fantasy.... Version II coming soon.... EG -

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

Amen brother, the Admiral, a former nurse says much the same thing.... (all the time, chuckle) Thank you.... -

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Egilman replied to CDW's topic in Non-ship/categorised builds

Yeah the eduard Mustang has those canyons for panel lines... Very well, I concede the point my friend.... That's a model manufacturers engineering error/failure... Yes they are puttied to smooth the wing, you have to fill them to get a decent build out of that kit... Modelers have been doing that for years... {chuckle} But in scale, 1/48 & smaller shouldn't have recessed panel lines they would also need to be filled on a 1/32 scale model as well... On the 1/1 bird they were filled to cover the micrometer sized edges and gaps, maybe only a few thousandths of an inch. This is why when the paint is stripped off you don't notice the fill... Windtunnel testing in 1940 established that the filling/smoothing added 20kts to the planes top speed... The practice continued into the 50's... North American deleted the process on the F-86 when tunnel testing showed that it made no difference to the planes top speed... Laminar flow was dropped when power overcame drag sufficiently till where it just simply didn't matter anymore... In the 1940's they were looking at everything that could conceivably make a plane go faster, Laminar Flow gave the Mustang a 5% boost in airspeed, with the supercharged Merlin, that boost became 10% over 20kft, and created a legend. Scaling it down to show it on a relatively small scale model, what's the point? you can't scribe a line small enough to represent the actual size of the panel gaps from a real P-51... Engineering defects caused by deficient thinking in the production of a model aren't the fault of the airplane being modeled and we as modelers have been fixing such for generations... It all comes down to the modelers minds eye and what he/she sees when they look at the real thing... It's why we build to suit our view of the subject... I didn't check to see if the Airfix or Trumpeter kits has those canyons, but the newer Tamiya's don't... (At least the one I have doesn't) I'll put it this way, the filling and smoothing done in the factory was never really noticed in the field when they had to strip and repaint the aircraft, that's how small the effect was... And thank you Dan for reminding me that we shouldn't be derailing a great log... My humble apologies.... -

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Egilman replied to CDW's topic in Non-ship/categorised builds

Absolutely, it was restored to be displayed and demonstrated at airshows, they would do it that way... Besides the aircraft is never going to be required to perform where the absolute smoothness of the wings matters.. ie. never over 30,000 feet at 400+ kts and have to do combat maneuvers at that altitude at the same time.... That is what Laminar Flow provided the aircraft.... It's combat days are long over.... So make it purty to impress the crowds who have never seen one up close.... -

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Egilman replied to CDW's topic in Non-ship/categorised builds

No problem, you didn't... Not at all.... Any true restoration of a 1 to 1 P-51 aircraft should be finished that way as that is the way the real ones were done, the point was doing in in scale.... And yes that is a restored full scale P-51.... I've yet to see a scale model of a P-51 that has had it's wings puttied and painted over trying to simulate something that at it's thickest would be around 10-20 mils thick in real life.... (less than a thousandth of an inch in scale) as far as color goes your correct, they should be painted high gloss aluminum not bare metal like an F-86.... But then the example your showing is a museum warbird and the fuselage is semi polished, (seen by how reflective it is) which they never were in operational service... They would be barely reflective as a bluish white/grey shiny metallic surface, Modern models don't have the deeply engraved panel lines of earlier models, which a good modeler would fill in anyway.... So the issue is forget the filling, sand off the rivet bumps and just paint it the right color in the first place... Besides most casual observers don't know the difference, and wouldn't notice it... And the ones you see at the airshows with shiny bare metal wings are not full historically accurate restorations... They are nice, and representative though and really impress a person when standing next to one.... Do me a favor, show us a modern model where the modeler filled and sanded the wing to get that color effect.... I've been unable to find one.... EG

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.