Geam

-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Geam

-

Finally managed to produce the FWD window unit complete with a Wynn linear windscreen wiper. I see now (too late) that I should have used slightly wider strip to make the 'aluminium' window frames. This would have made it easier and tidier to glue in the window glazing. Any way, this weekend will hopefully see the whole wheelhouse section looking more complete.

Next is the coach-roof sections.

George

-

I've been planning building sequences and doing some small jobs on the Fisher but I can't say there's been much noticeable progress. I've been 'hovering' around the fact that I have to get going with gloss paint on the coach roof and wheelhouse roof sections. Made the grab-rails and 22 small stand-offs/bases. The grab-rails will be glued onto the bases after the coach rooves are glossed white. The requirement for removeable top sections is causing some head-scratching as to where to cut for the joins to be least noticeable, but generally all joins/cuts will have to be abeam the main mast P&S.

The photo shows the grab-rails just loosely placed on top of the bases. The wheelhouse FWD window frame is also just 'placed' -not glazed yet nor faired/glued in place

George

-

Build progress:

Started getting tired of painting white cabin-roof panels! Just one more undercoat to apply then sanding down for the gloss finish. Gone over to an attempt at wheelhouse interior furnishing and upholstery. Curtain material used on the cushions is a bit thick -which resulted in untidy corners. Will tidy it up a bit later. I wanted to try making the 'dolls-house' furniture and fittings for a while before going back to painting. Wheelhouse interior now with upholstery and teak stain on the woodwork. Front window frame is not glued on yet -just sitting loose.

-

Received info' from the Maritime Museum about the Colin Archer RS14 'Stavanger'. Also a reference to the book by Bjørn Foss about the rescue ships -'redningsskøyter'- .

RS14 was the 2nd of the 'Svolvær' type vessels. RS 12 "Svolvær" was the 1st of these. The Svolvær types were 35 cm longer than the Colin Archer type (RS1, RS 6, RS8 and others) and were 5cm narrower and 5cm less draft. The masts and sailplan were not changed from the original RS1. There was also a lager (heavier ?) keel. The bow shape above the waterline seems to have a bit more rake -looking slightly more 'streamlined'. Ref; a drawing in the Bjørn Foss book.

In my mind there should be no real problem to use the Billing Boats RS1 kit to produce a model of the newer (from 1897!) Svolvær types vessels.

It will be interesting (for me anyway) to hear from Andreas Sundt later when he has visited the RS14 at the museum in east Norway.

George

-

I have been advised by a Colin Archer rescue boat expert that the RS14 version was not the same hull shape as the RS1. So to be authentic, the second Colin Archer kit will have to be built as one of several other versions: RS6, RS10 or about 3 other build numbers. Not very important actually. So long as the correct number is on the sail hardly anyone would notice the difference...Oooops I should not be saying such things on this site!

-

-

I must confess......I was quietly browsing on the local 'for sale' site here in Norway -actually looking for a book on the old Colin Archer rescue skips when....suddenly.... there was a Colin Archer 414 (ABS hull) kit for sale. It was only 20 minutes drive from me so I when to see it.

Some mildew (jordslag) on the sailcloth, the wood didn't smell too fresh either so I bought it😬! Did not take the original box though, that did not smell good at all.

Once home, I sprayed the sailcloth with 7% vinegar and sprayed everything else with Cavicide (a surface antibac spray) to kill the mildew bugs.

This new (old) Colin Archer will be built as the RS14 which was launched in 1901 and named 'Stavanger'. It's 1' longer than the RS1 -don't know why yet. The full size RS14 is on land at the Colin Archer museum in Larvik east Norway.

There, I've confessed,

George

-

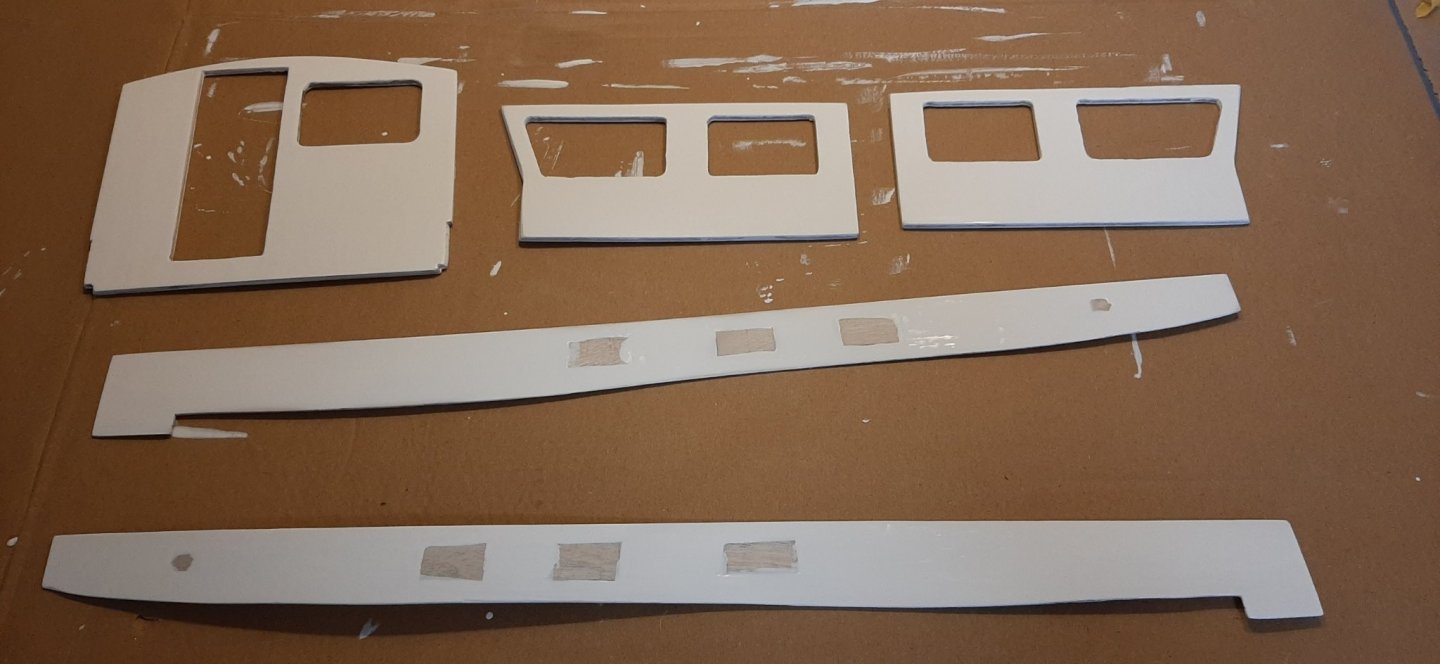

I was a bit unsure when I woke up this morning about using the ready made Cap Maquettes window frames on the cabin sides instead of cutting out holes and framing as with the wheelhouse bulkheads. But they got glued onto the cabin sides yesterday so it was a bit late to have doubts this morning!

I loose fitted all the parts this afternoon and took many photos just evaluate the 'look' of it.

Still not sure,

so I will leave well alone and think about it this weekend.

so I will leave well alone and think about it this weekend.

A bit 'harry' to have photos of the Admiralty and I peering out through the windows on both sides simultaneously...but it seemed like 'novelty' idea yesterday!

Wish all a peacefull and safe weekend.

George

-

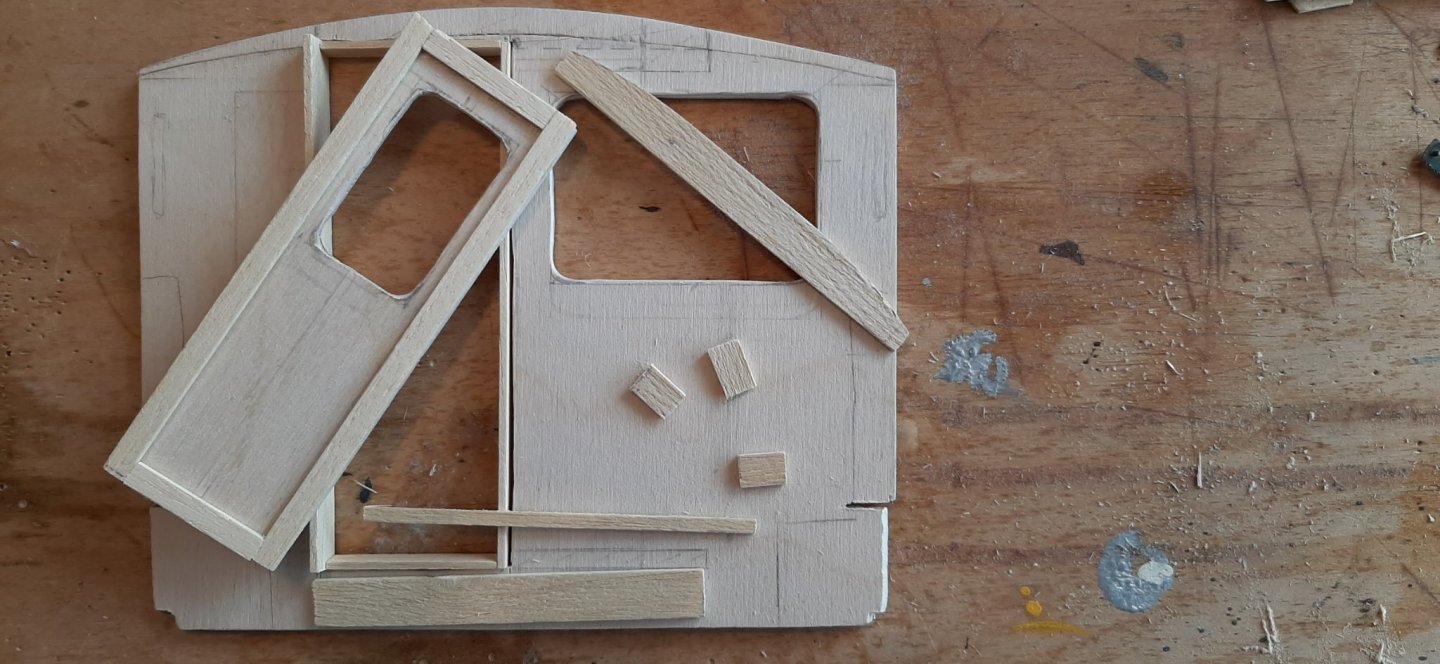

Components of the wheelhouse aft bulkhead have now been glued in place and test fitted to the cockpit. The aft part of the roof-top is only 'balancing' on the top of the bulkhead. It will be fitted after the whole rooftop is prepared.

Wheelhouse sides were produced yesterday -but no photos available yet.

George

-

Had a long pause recently due to working on my daughter's car. It failed the 2-yearly "EU- control" check, and needed some serious attention.

Done some re-painting of the wheelhouse and cabin-top sides due to very poor topcoat finish. Sanded down with wet&dry ready for a new topcoat AND a new paint. Carsten's recommended (?) Bengalack! in gloss white. Hope this will flow out better and give a smoother finish than the previous 'full-size yacht paint'.

Tried glazing and framing the wheelhouse sliding door. Not great, but it will have to do. My eyesight is not quite up to the required standard for a really fine detail work. Framing the windows in 2.5mm strip is a bit ambitious and I had to drop the plan of inside curves around the corners!

George

-

-

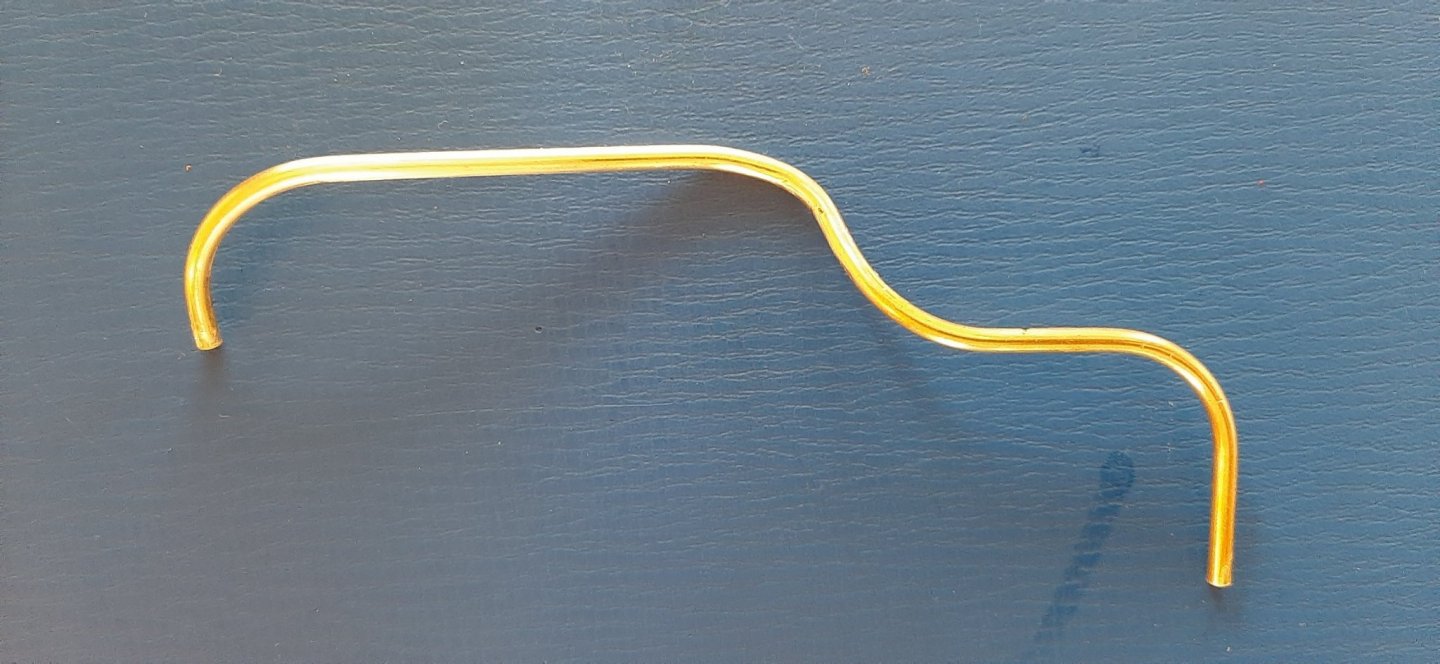

Hi Andreas, answered your question about brass tubes below your posted question. Should have written it up here so you could see it easier! Included 2 photos. The plan is to control the large genoa with 2 servos, one for port tack and one for starboard tack. Hope it works!

George

-

I've been working on the Fisher 34 since the Colin Archer went into storage. The cockpit area on the Fisher has a lot of curves and has taken time to get right. It's now been brush-painted with one coat of gloss -on top of all the other coats of 'stuff'. Started yesterday on the wheelhouse aft bulkhead and sliding door arrangement and produced what I think is a 'sliding door kit' which will be stained 'teak' and added when the bulkhead is prepared and painted white.

-

.thumb.jpeg.ee4d205046163acd786c8b7e92026d43.jpeg)

-

Hi Andreas, did not see your post until this morning. The brass tubes are guides for the sheets to the clew of the genoa sail. They were planned and installed very early during the build process and are a bit too long but I could not see that until the cockpit combing was shaped and glued on. The tubes bend and curve all the way down to the turnpulleys in the bilge so hope there is not too much friction. Posting photo of one tube. Also photo showing sheet exiting from guide tube to pulleys on genoa track. Don't know if this system will even work properly ! 🥴

-

-

My Colin Archer is now 'airbrushed' as much as I dare until the rest of the boat is completed. I expect that I will have to give it more coats later as there will certainly be some damage while handling during the build. I wanted to test the whole 'airbrush thing' and ended up using the CA as the extended testbed. The finish so far is silke-matt. It's now going down to the cellar storeroom until I get more progress on the Fisher 34.

George

-

-

Regading the RUBY air gun (not RuDy as I wrote earlier!). The compressor I have now would not produce enough air pressure to blow through the wider nozzle 0.8 mm. It's OK for my small airbrush 0.3mm nozzle but not the 0.8mm Ruby gun. I do not want to buy even more gear for this (ie larger compressor) so I have returned the Ruby to the dealer.

Had another go at airbrushing the Fisher hull with my small airbrush -this time with added 'paint retarder' to the thinned clear gloss. Got a reasonable silky-gloss finish which I think is acceptable.

Next job is to try to repeat the process with the next hull: the 1/15th scale Colin Archer. Don't need a glossy finish on that so should be able to manage a reasonable result with the smaller airbrush. I'm going for Bob's info regarding a varnished top-coat to give a bit of resilience to the surface. Without retarder it'll probably dry fast enough to give me a silk-matte finish.

I find it a bit stressful trying to do things which I can't do 😬 but before too long it'll be one more thing I CAN do😁

Regards

George

-

Further to the last info about the Rudy: as half the world will already know, the Rudy can be adjusted to spray in a fan shape as apposed to round spray. This gives a better chance of laying down enough paint on larger surfaces to achieve a glossy finish -I hope! I'm very new at this, so I apologise if I'm stating what every body

I'm working on the aft combings of the Fisher 34 motorsailer. Have been unsure as to how to construct the combings. Started off with a plan to construct in 1mm aircraft plywood but that seemed to be very fiddly. As the photos show I'm going for carved balsa block. Won't get a perfect finish but we're talking 'stand-off-scale here' not 'microscope viewing'!

-

Picked up my Hobbynox Ruby airbrush and two jars of Tamiya clear gloss acrylic today. Instructions for Ruby were encouraging by confirming that it's good for larger hulls and aircraft projects. As I mentioned earlier, I think that may be why I could not get a glossier finish on my Fisher hull. But the present finish is not too bad and like some others suggest, it may be smart to leave it as it is. I'll need the new airbrush for the next hull -Colin Archer RS1- anyway. Maybe I will test it out by trying gloss on the Fisher silk-matte finish. Maybe I will chicken out, we'll see.

Regards, George