Geam

-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Geam

-

-

Done a few more details recently. Installed a small stove in the forward cabin. Should have done it before the deck went on but managed to squeeze it down the hole. Made companionway steps for the fwd cabin too.

The flue for the fwd cabin stove has been made removeable to facilitate retracting the bowspit aftwards to avoid transport damage (and get the RS1 in the car!).

The local seagull seams to think the build is going a bit slowly

George

-

Done some small jobs this weekend.

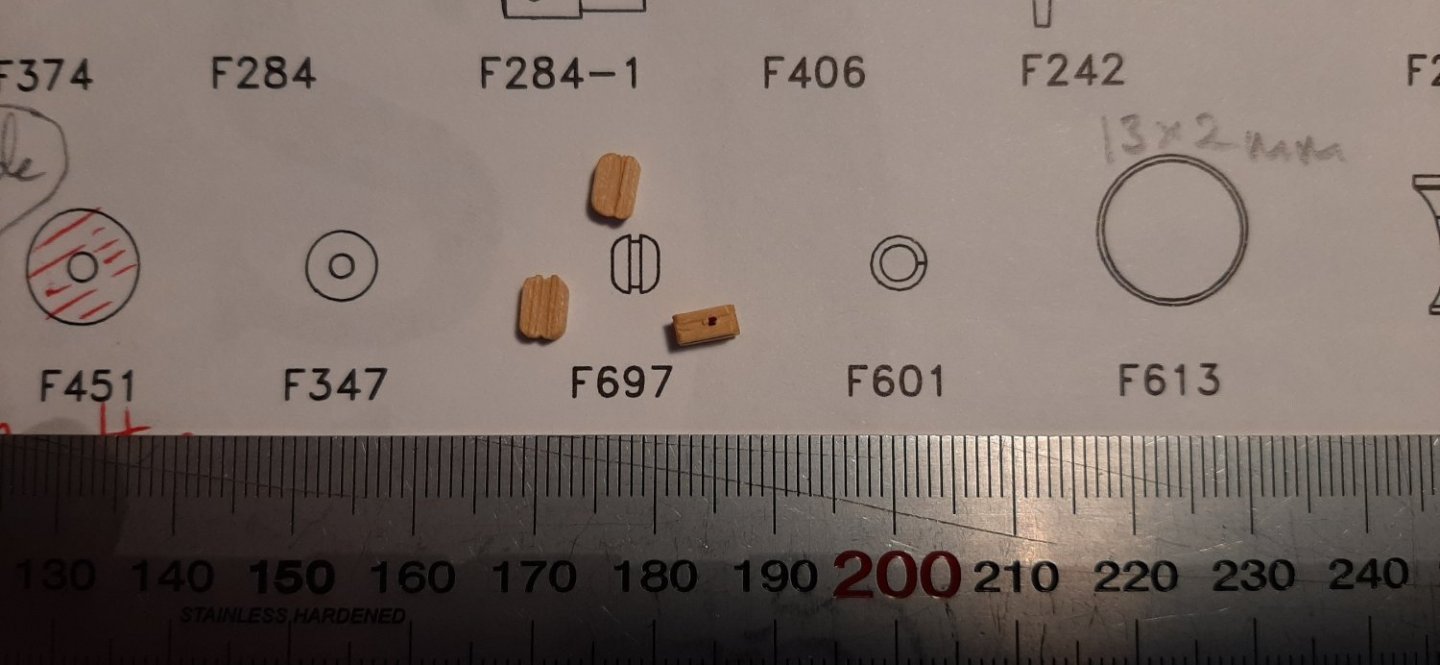

Catheads shaped and faired, ready to go onto the foredeck later.

Main companionway steps fitted. They are secured by just two brass pins set into the cabin sole. They are removeable to allow access to the motor cover beneath the steps.

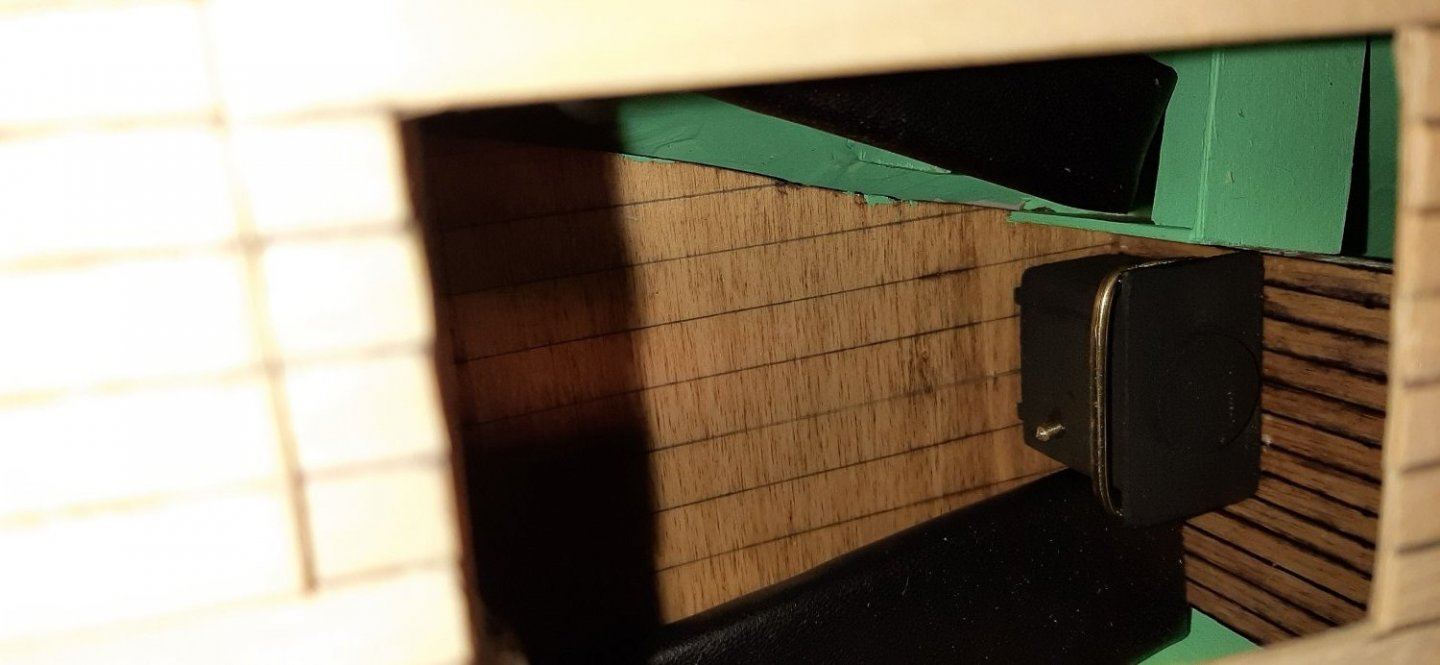

Companionway hatch is hinged to permit a rather restricted view 'down the hatch'.

George

-

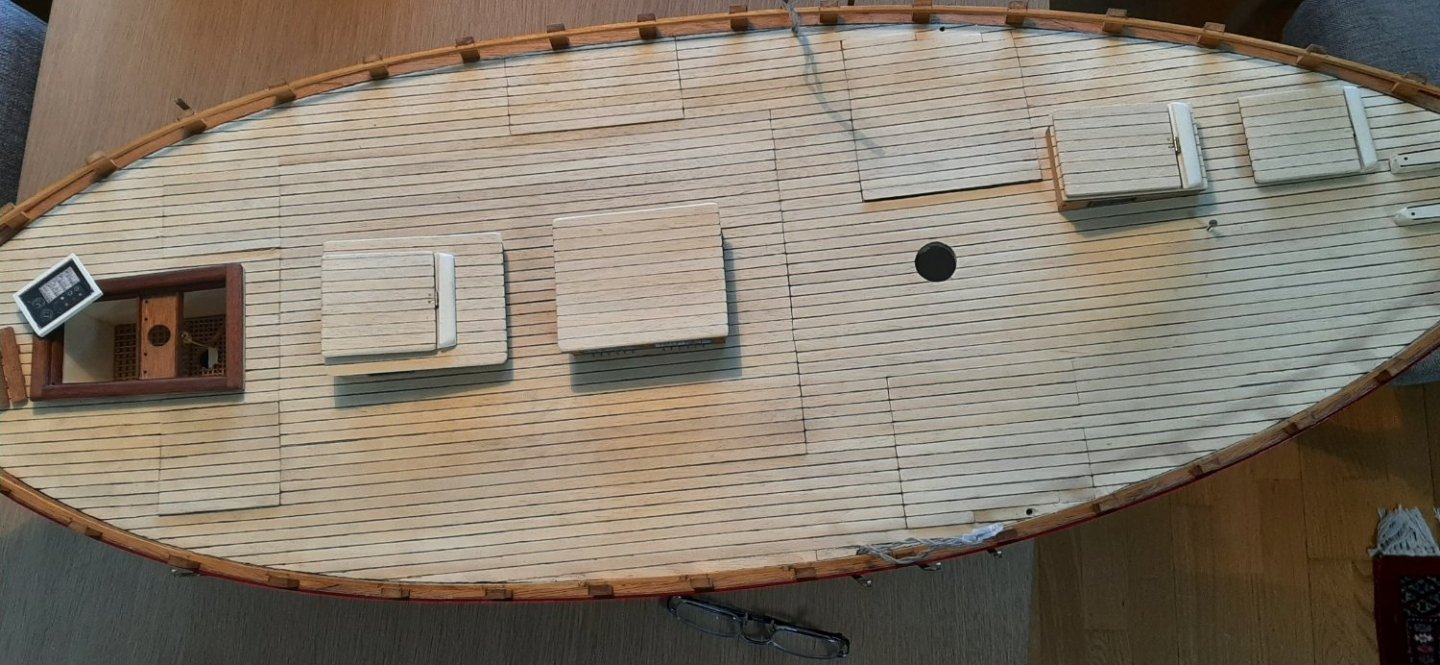

Deck planks have now been 'caulked'. Not a very good job, but with all the other parts to be fitted on deck a few mistakes in plank-marking will not be very noticeable. Some of the hatches have warped a bit while the glue has dried, so this will be fixed later. Hatch fasteners to be applied later, will also help to de-warp them!

A panel for the engine instruments has been prepared as well as teak gratings and a bench seat for the helmsman.

Started to prepare the catheads yesterday. They should have small pulleys in each 'head' but these do not seem to be included in the kit.

George

-

Last deck plank squeezed into place today. Deck structures placed on deck for self-inspiration. Made one or two small mistakes during the work....started planking over a deck hatch and glued it down to the surrounding deck. Luckily, noticed the blunder before the glue had set!

Will have to sharpen a few HB pencils to get ready for look-alike deck caulking.

George

-

Having made the semi-scale interior cabin details, I decided that the hatches on the 2 companionways as well as the foreward deck hatch should be functional. ie. the hatch can be opened to reveal the steps and a narrow view into the hull below.

To achieve this, I have installed a small brass hinge on each hatch. Each hinge will locate into a hinge 'beam' -as used on the present full size CA RS1. The small (non-operating) plastic hinges supplied in the kit will be used, but cut in two so that they will not prevent the hatch from being lifted up.

It's this kind of sidetracking that results in my rather long build times. I get some crazy detail idea then take ages to work out the logistics of it, and ages again to produce it! After all that thinking, my brain cell needs a rest before getting on with the build!'

George

-

Plodding along slowly with the Colin Archer RS1. The hope to launch at Easter has been abandoned. The skylight and other deck structures are under construction. Not sure if the planking on top of skylight and companionways should be stained teak or kept natural. I intend to keep the deck planking 'natural' with no stain -just oil and varnish. Some of the wood in my particular kit is quite dark and I stained it teak thinking that all the rest would be stained teak anyway. Post a few progress photos.

George