Unegawahya

Members-

Posts

184 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Unegawahya

-

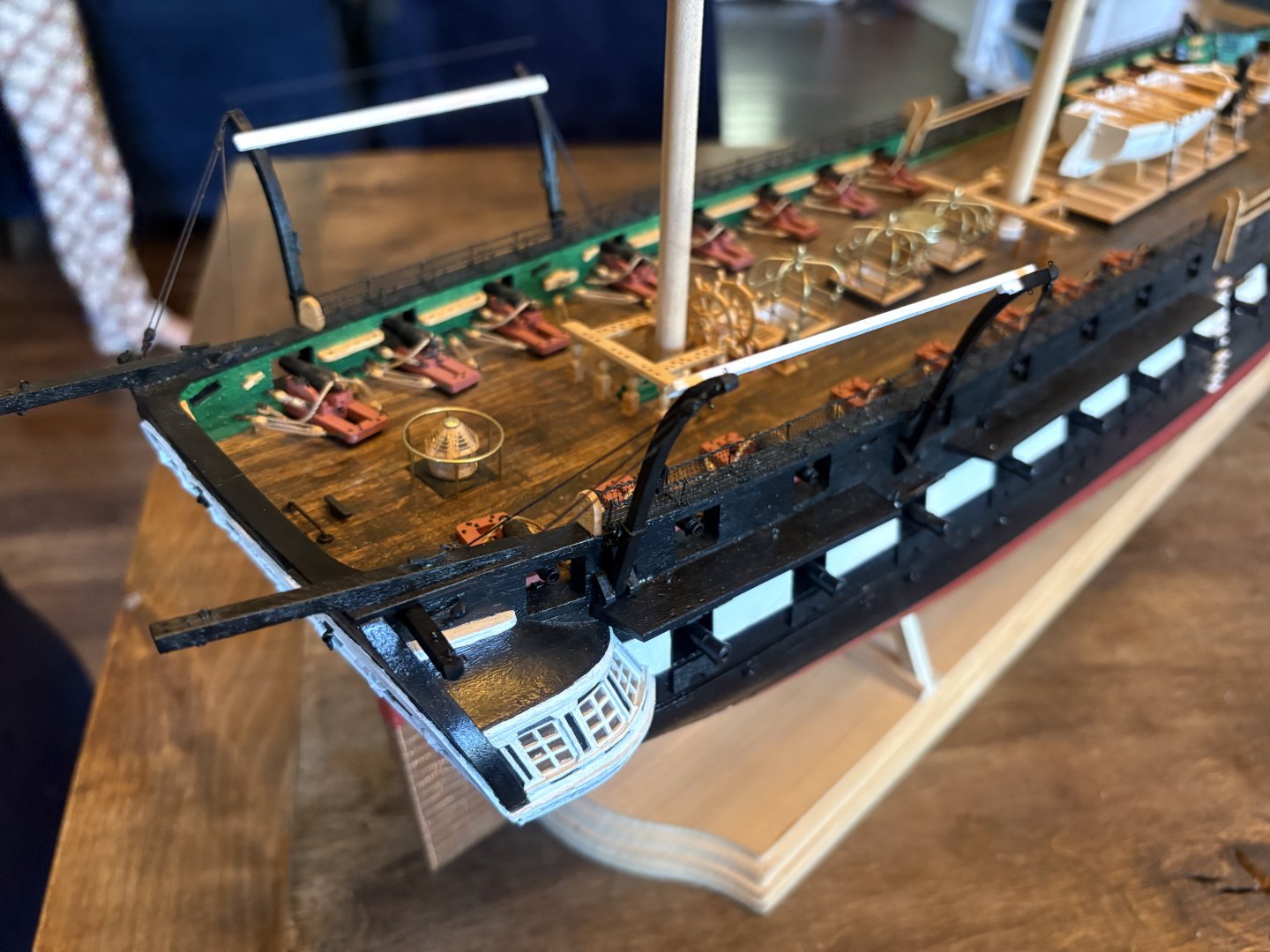

I finally got my whale boat davits completed. I also decided to get the block and tackles for the for and aft installed so the standing rigging won’t be in my way later. Next up is going to be the permanent display base. The main part is reclaimed oak. I’m going to have keel blocks made from reclaimed teak from the USS Iowa. I’m also going to have similar hull supports as my work base and they will either be made from teak or iron wood.

-

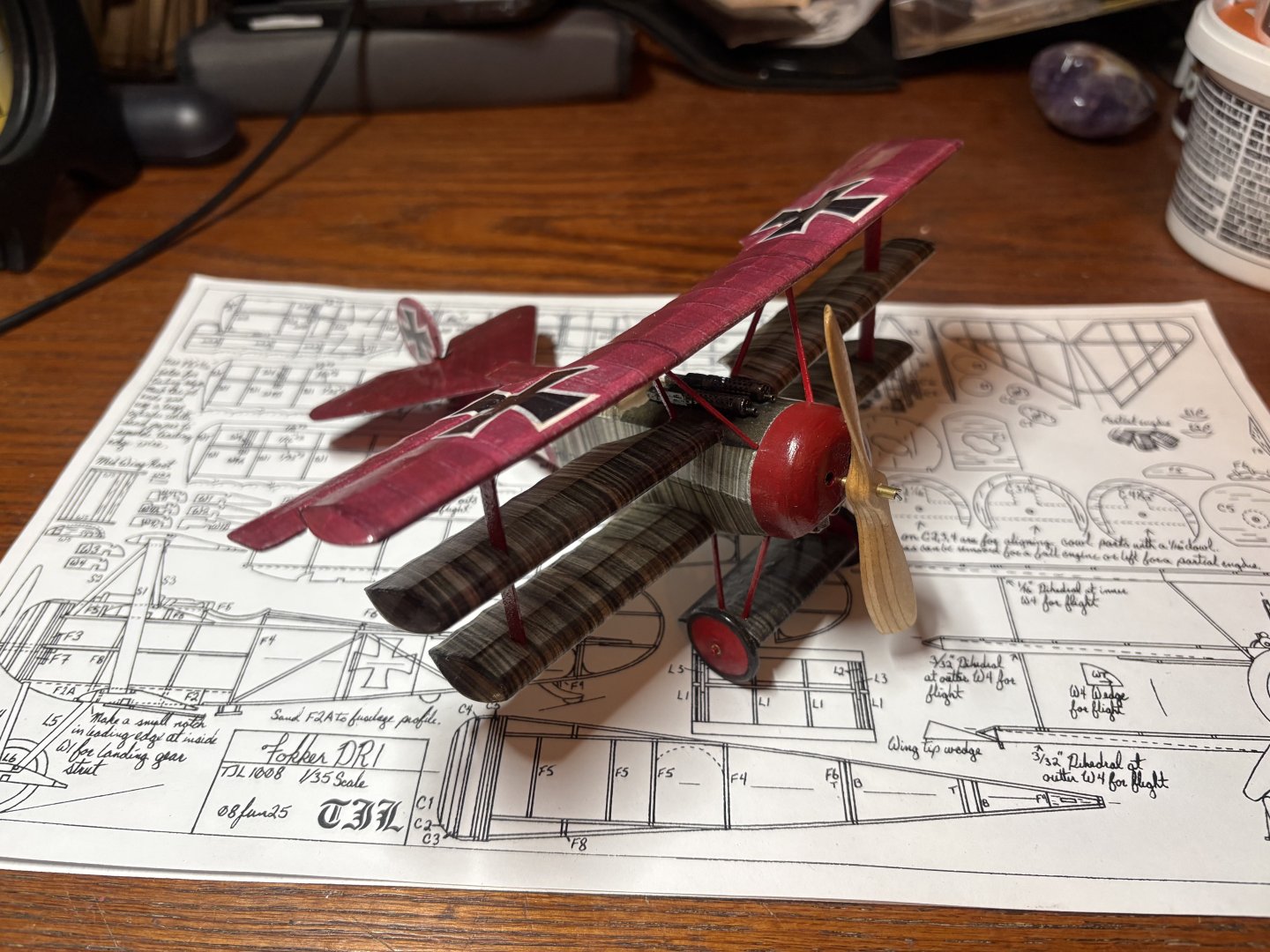

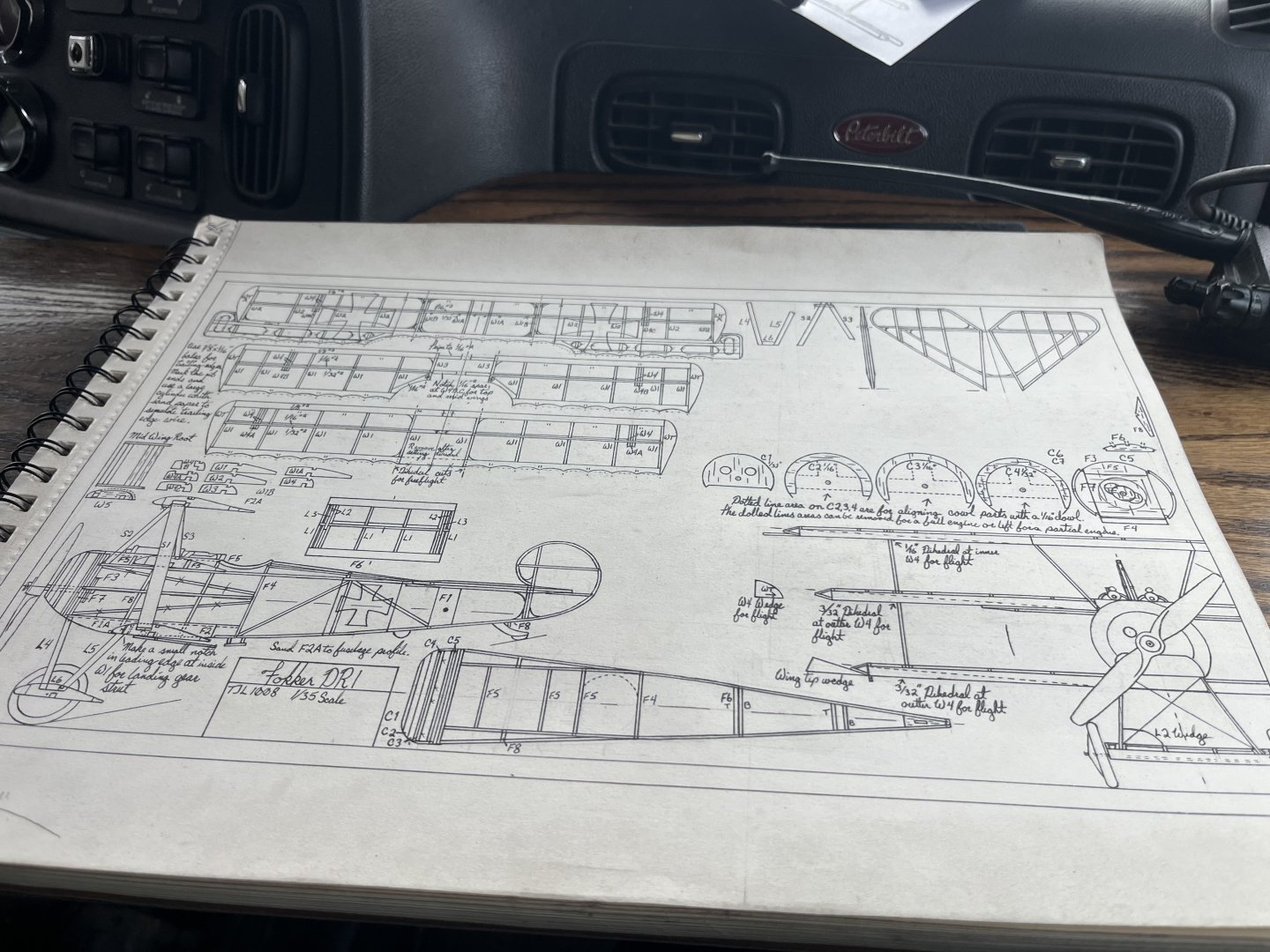

Your fighting top looks great! I was getting caught up! You got me thinking of the problem of bending the tight forward corners of the edging and I was wondering if using a similar method to what I recently used on the rudder for my DR1 would work? I made a jig for the rudder that was set up with a zip tie to hold the wood with just enough compression till it dried. I was extremely happy with that result.This is my jig.

-

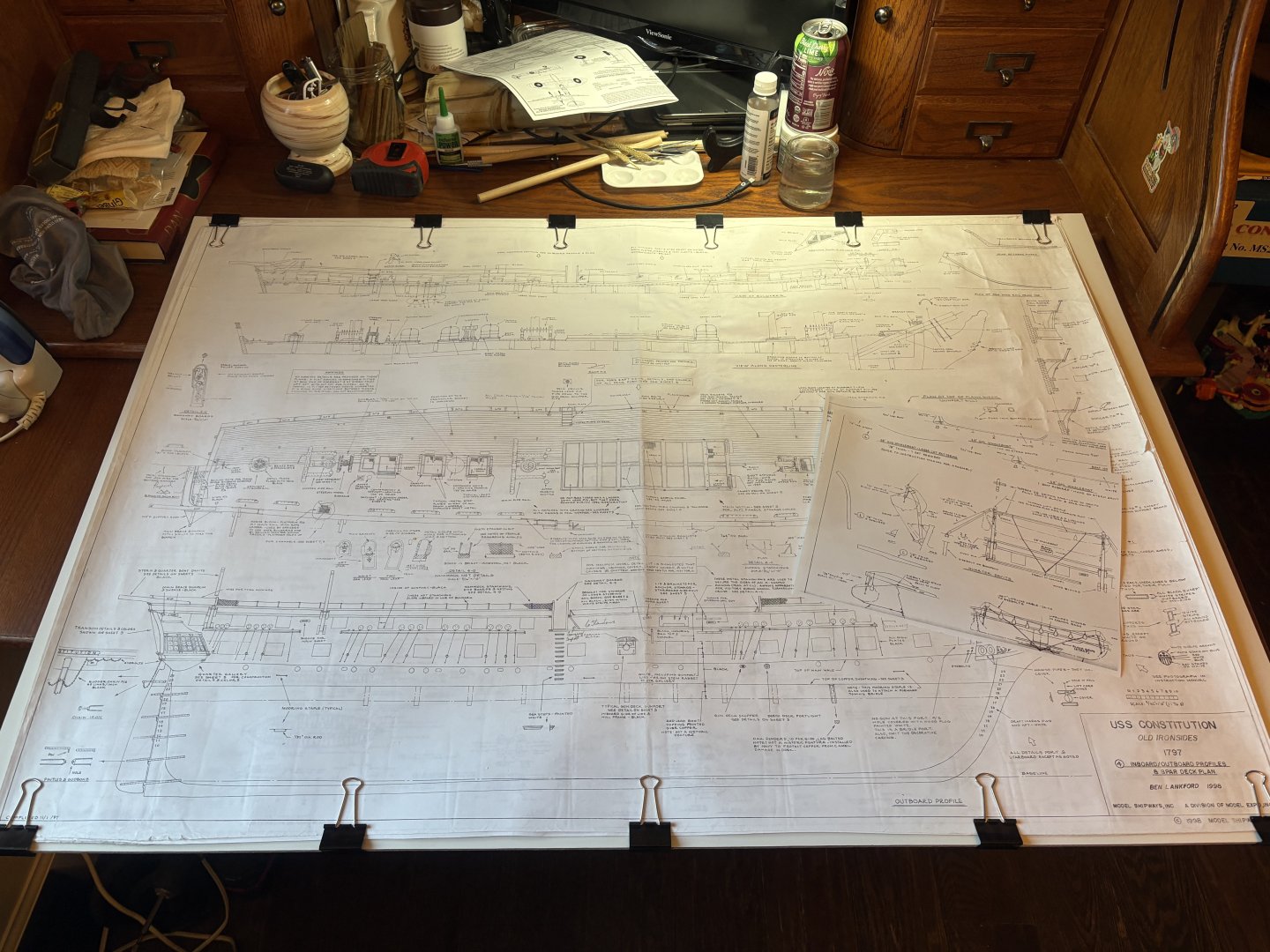

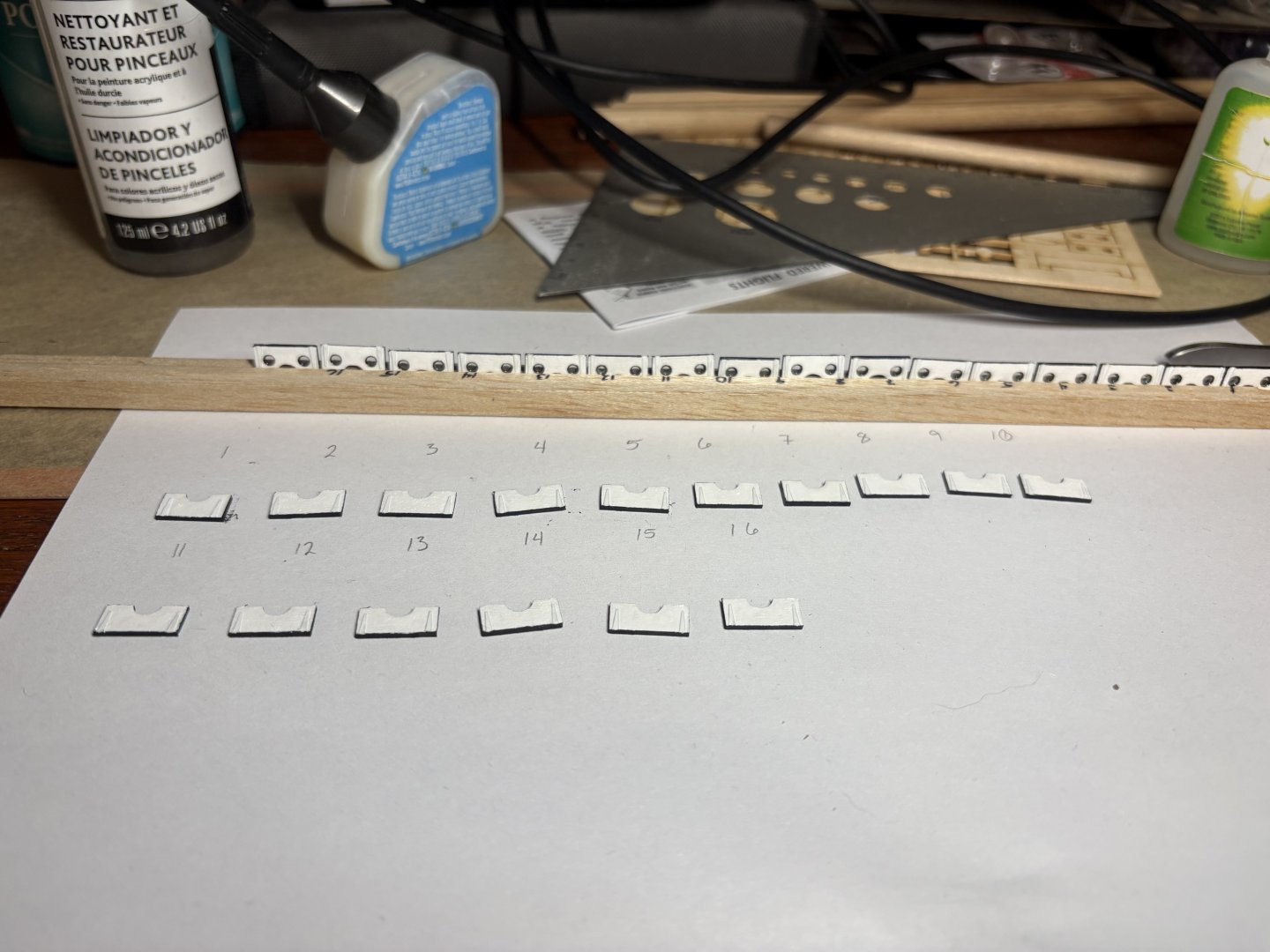

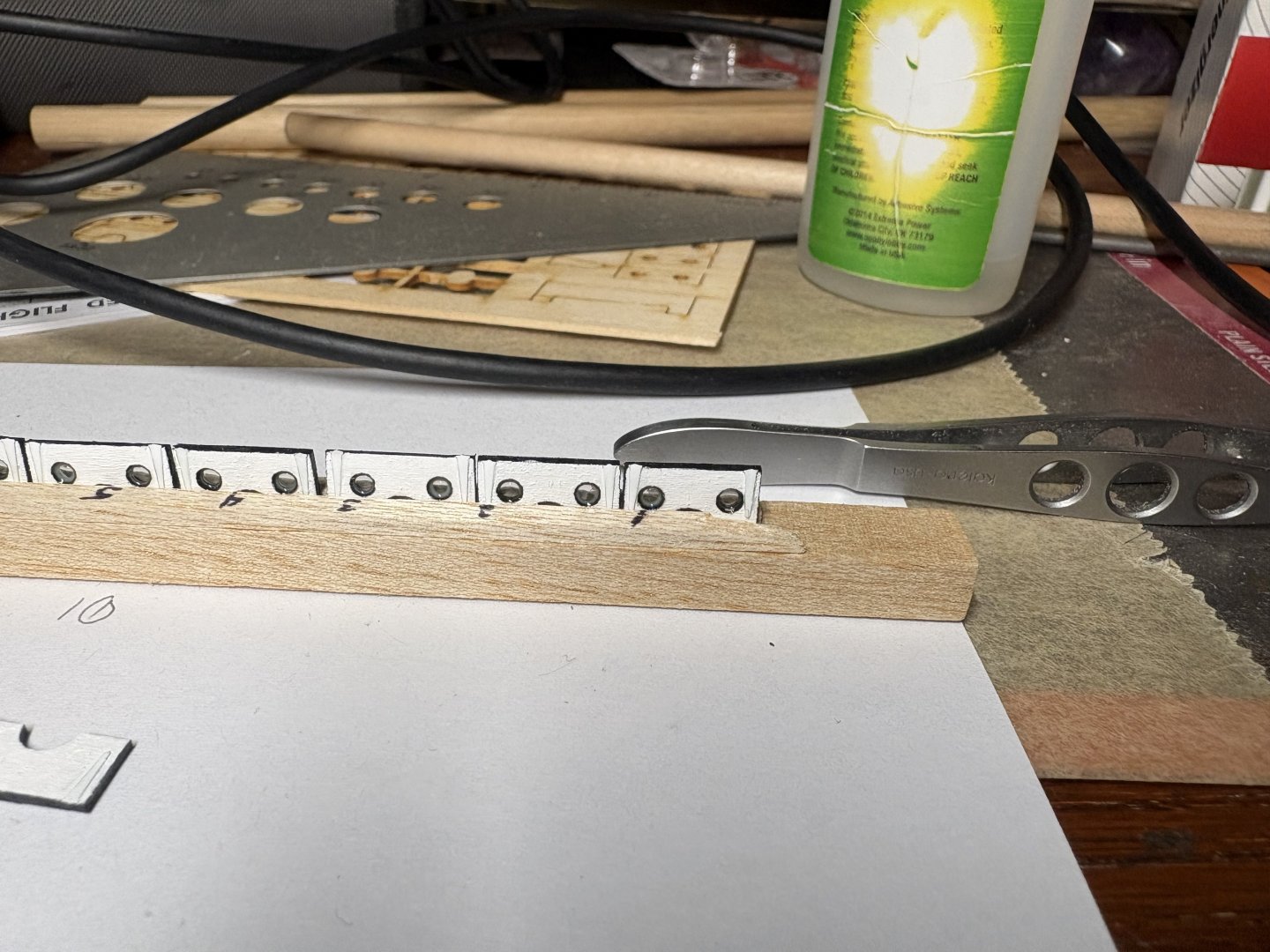

All of my port and starboard lids are now finally done and installed.Next up will by my stanchions for the 28’ whale boats followed by my new permanent base. I also had to take the time to fix all of my old land and get them to where they weren’t rolled up. I was finding that with my plans rolled up, I was avoiding pulling them out unless I had to. I now have them ironed out and clipped to a backing board to keep them flat and clean

-

My starboard gun port lids are done and as soon as they’re dry I should be able to start installing them.To simulate glass being in the portholes on the upper lids I used Testors Clear Parts Cement. I’ve gotten to the point that I love this cement because it dries completely clear and you can even use it to make small windows. It also can be easily removed from some plastic with a toothpick if you get a little messy!

-

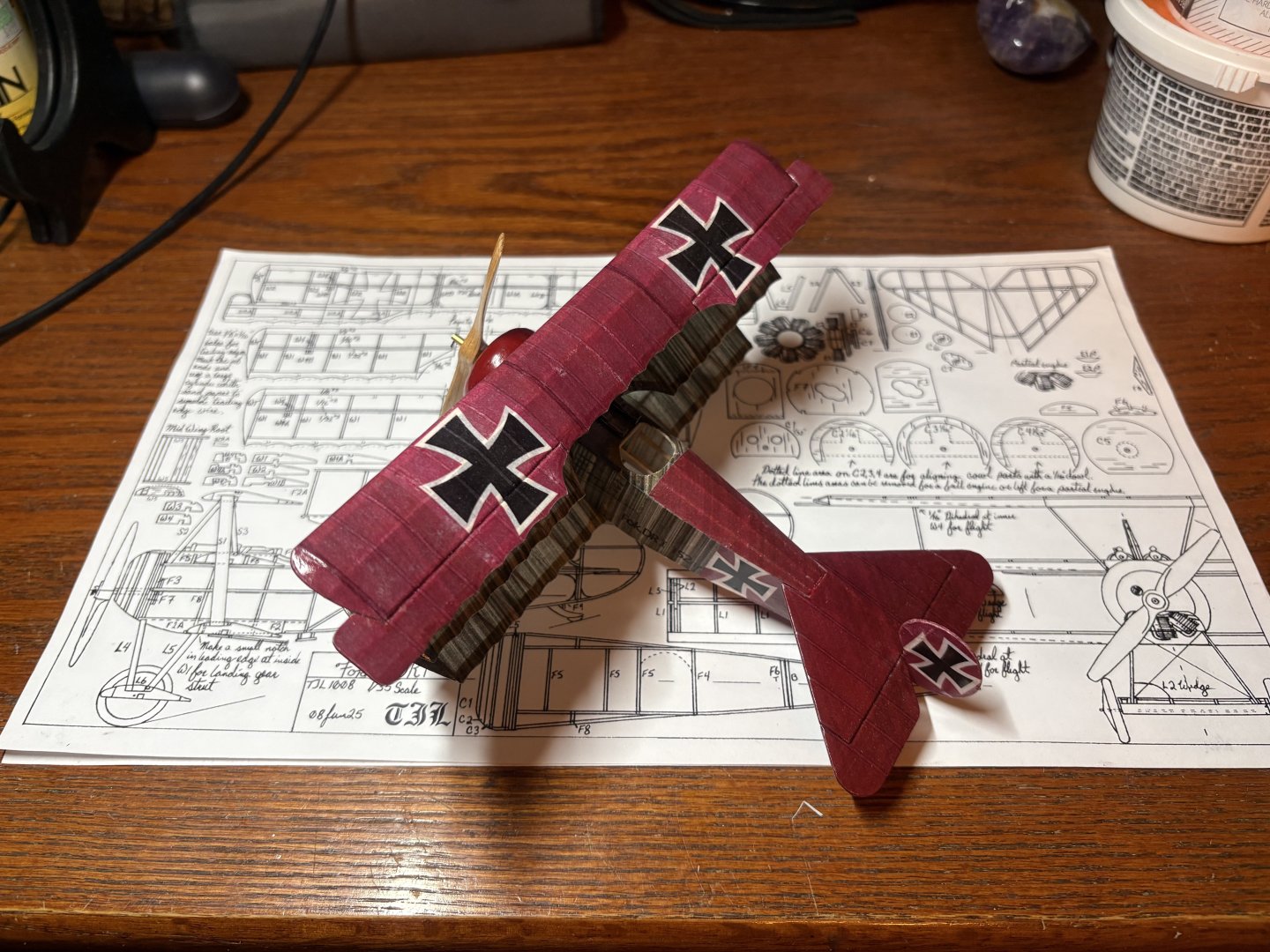

After a long absence, it’s finally time to convert my desk back into a shipyard! I got my Avro 504 completed. I want this one to like one of the original airframes, so I based it on the beautiful example that’s displayed at the London Museum. I got the remodel on the dining room complete!I got my scratch build of the Comet SuperStar P-51D complete. I modified this one to be my take on the pylon racer Voodoo. I call it Ghost Cat!Last, I just finished my scratch built 1/35 scale Fokker DR1. I designed this one after the early paint scheme of Manfred von Richthofen’s DR1 152/17. IMG_1931.mov I’m really hoping to get a chance tonight to figure out where I left off!

-

USS Constitution by mtbediz - 1:76

Unegawahya replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Great looking hammock stanchions! That exactly why I made mine the way I’d did! They wouldn’t have looked half as nice as yours. Did you use a jug to make your stanchions? -

USS Constitution by mtbediz - 1:76

Unegawahya replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you! Scoring the brass before hand must be what I was missing. -

USS Constitution by mtbediz - 1:76

Unegawahya replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

If you don’t mind me asking, how are you cutting your brass into strips. I’m going to need more and I can’t seem to find anyone that sells them. Your build is looking wonderful! -

I’m waiting on some supplies to photo etch my midship hammock stanchions. So in the meanwhile I’ve been working on my anchors. For a change, I’ve used the kit supplied parts for the anchor and the stock. The bands on the stock are .010 x .040 Polystyrene strips. The ring is a brass rod that I formed into shape.Looking at a lot of pictures, it looks like they would wrap the ring on two sides to keep the chain and shaft separate.Using my forceps and soldering holder to hold everything I got all three wrapped and painted.I ultimately decided to have the starboard stowed with the chain attached and the port anchor will be hanging from the cathead.Another thing I found that is extremely useful, is using 50/50 Easy Dope with water to help give a look of weight. When I first had the rope from the top of the anchor to the cathead, the rope wanted to stay in more of a loop. After I had everything tied off I used a brush to put some Easy Dope to the rope. Then I placed a pair of pliers on top to hold the top of the anchor down. Once the dope was dry, the rope stayed exactly where I wanted it!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.